Novel method for producing industrial phosphoric acid by purification with wet process phosphoric acid

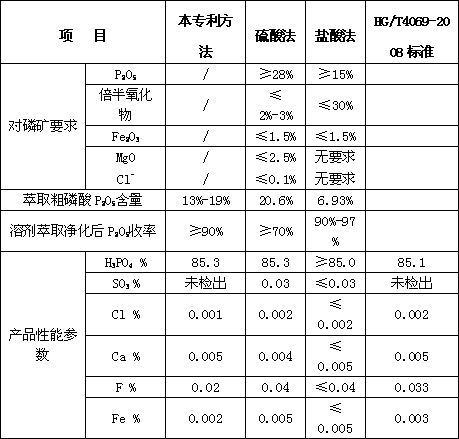

A wet-process phosphoric acid, industrial-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of high cost and achieve the effect of low cost, high quality and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

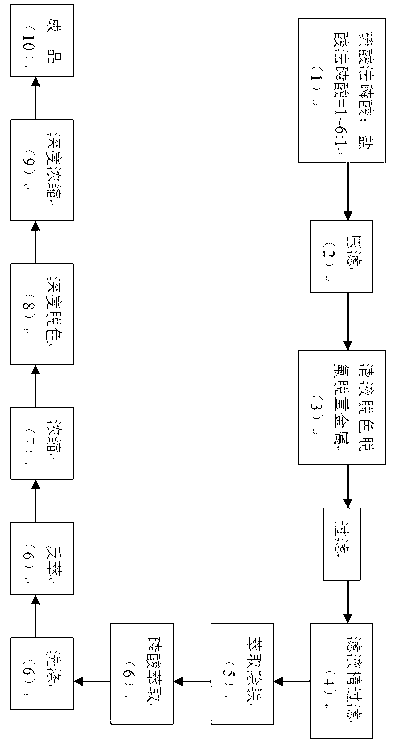

Method used

Image

Examples

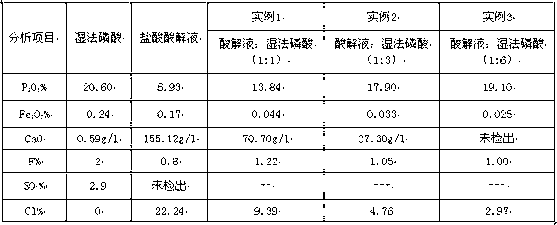

Embodiment 1

[0034]Mix 20.6% wet-process phosphoric acid and 6.93% hydrochloric acid acid solution at a volume ratio of 1:1, take 100ml of hydrochloric acid acid solution and slowly pour it into a mixed acid tank containing 100ml of wet-process phosphoric acid. , fully stirred and mixed, the stirring speed was 200rpm, and the reaction time was 60min; 1.5% volume of 0.1wt% flocculant was added to the mixed acid to coagulate and precipitate; filter with a filter press to obtain clear filtrate 190ml, ω(P 2 o 5 ) 13.84%; the filter residue was washed and dried to obtain 8.27g of alabaster.

Embodiment 2

[0036] Mix 20.6% wet-process phosphoric acid and 6.93% hydrochloric acid acid solution at a volume ratio of 3:1, slowly pour 50ml of hydrochloric acid acid solution into a mixed acid tank containing 150ml of wet-process phosphoric acid, and store it at 50-55°C , fully stirred and mixed, the stirring speed was 200rpm, and the reaction time was 60min; pressure filtration got clear filtrate 186ml, ω(P 2 o 5 ) 17.90%; the filter residue was washed and dried to obtain 10.16g of alabaster.

Embodiment 3

[0038] 20.6% wet-process phosphoric acid and 6.93% hydrochloric acid acid solution are mixed according to the volume ratio of 6:1, 180ml of wet-process phosphoric acid is placed in a 500ml beaker, and under the condition of full stirring at 50-55°C, slowly add 30ml of hydrochloric acid for acidification The liquid is slow, and the reaction time is 60 minutes. Press filtration, get clear filtrate 190ml, ω (P 2 o 5 ) 19.10%; the filter residue was washed and dried to obtain 11.3g of alabaster.

[0039] Embodiment effect situation is shown in Table 2:

[0040] Analysis results of crude phosphoric acid after mixing:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com