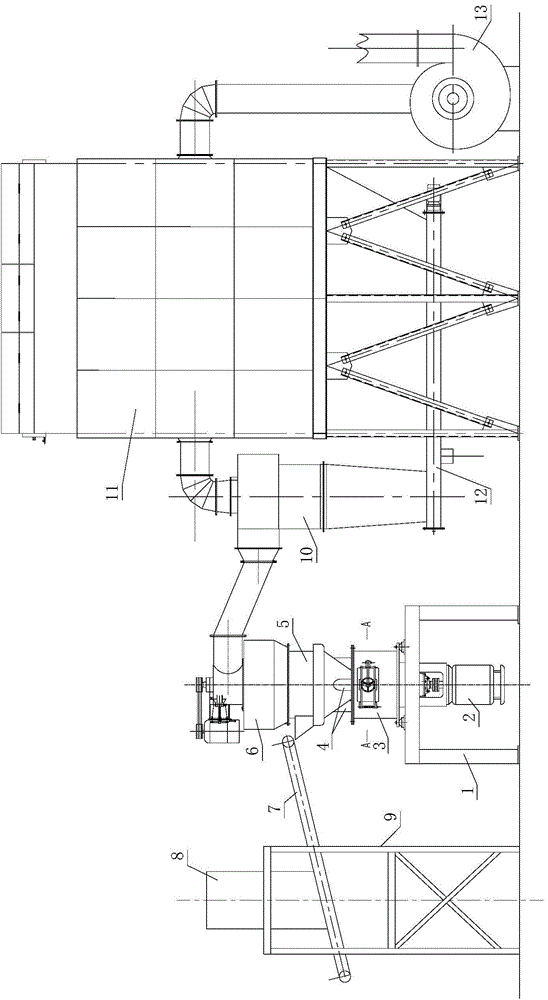

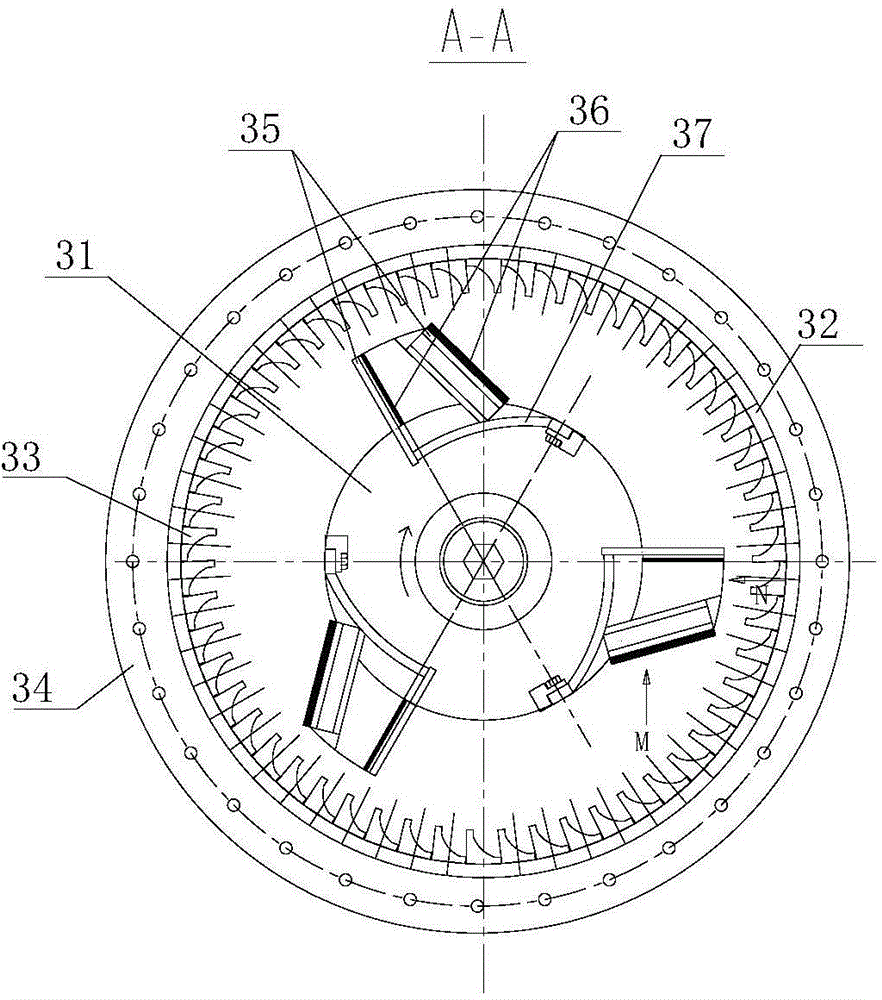

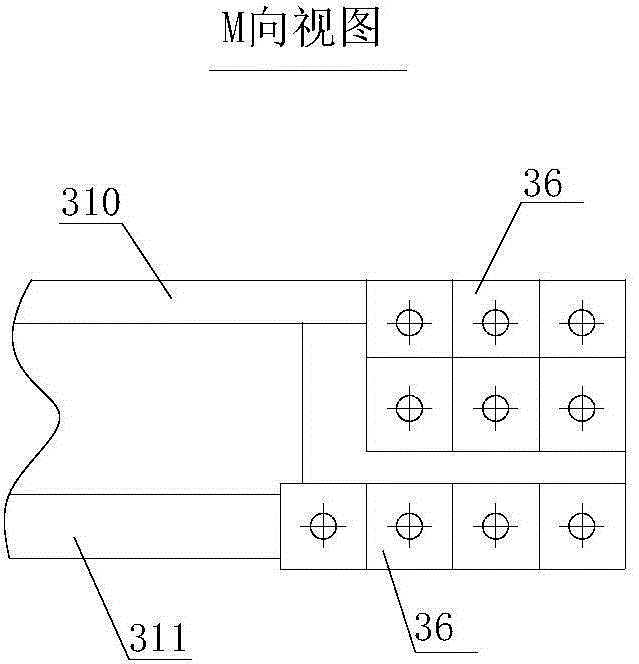

Solid material grinding method and solid material grinding machine

A technology of solid material and grinding method, applied in the direction of grain processing, etc., can solve the problems of ineffective collection power of fine powder, short service life of wearing parts and wear parts, and unsatisfactory separation effect of collection system. The fine powder collection effect is good, the overhaul and maintenance are simple, and the grinding particle size is fine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The ground material is talc slag, and the specific process parameters are shown in Table 1;

[0059] Table 1

[0060] Analyzer speed

Embodiment 2

[0062] The grinding material is fused magnesium, and the specific process parameters are shown in Table 2;

[0063] Table 2

[0064] Analyzer speed

Embodiment 3

[0066] The ground material is sintered magnesia, and the specific process parameters are shown in Table 3;

[0067] table 3

[0068] Analyzer speed

[0069] In the above three embodiments, the pass rates of all finished products all reach more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com