Composite collector, low-iron spodumene concentrate and preparation method for low-iron spodumene concentrate

A composite collector and concentrate technology, used in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of resource waste, excessive lithium, and inability to effectively capture lithium, and achieve a reduction in the content of lithium. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

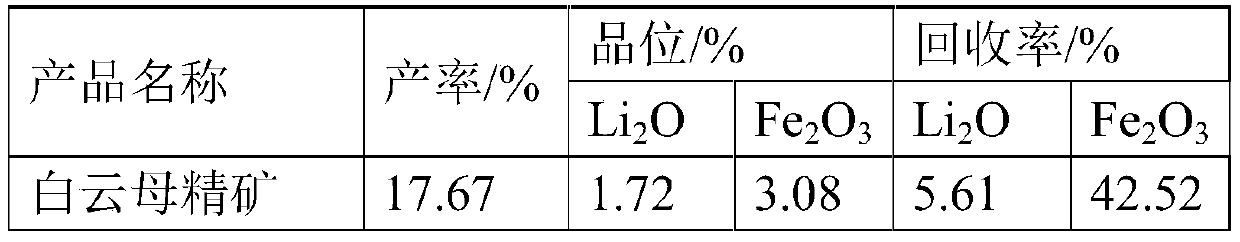

Examples

Embodiment 1

[0031] A composite collector is formed by mixing aspartic acid, oleic acid and diesel, and the weight ratio of aspartic acid, oleic acid and diesel is 80:10:10.

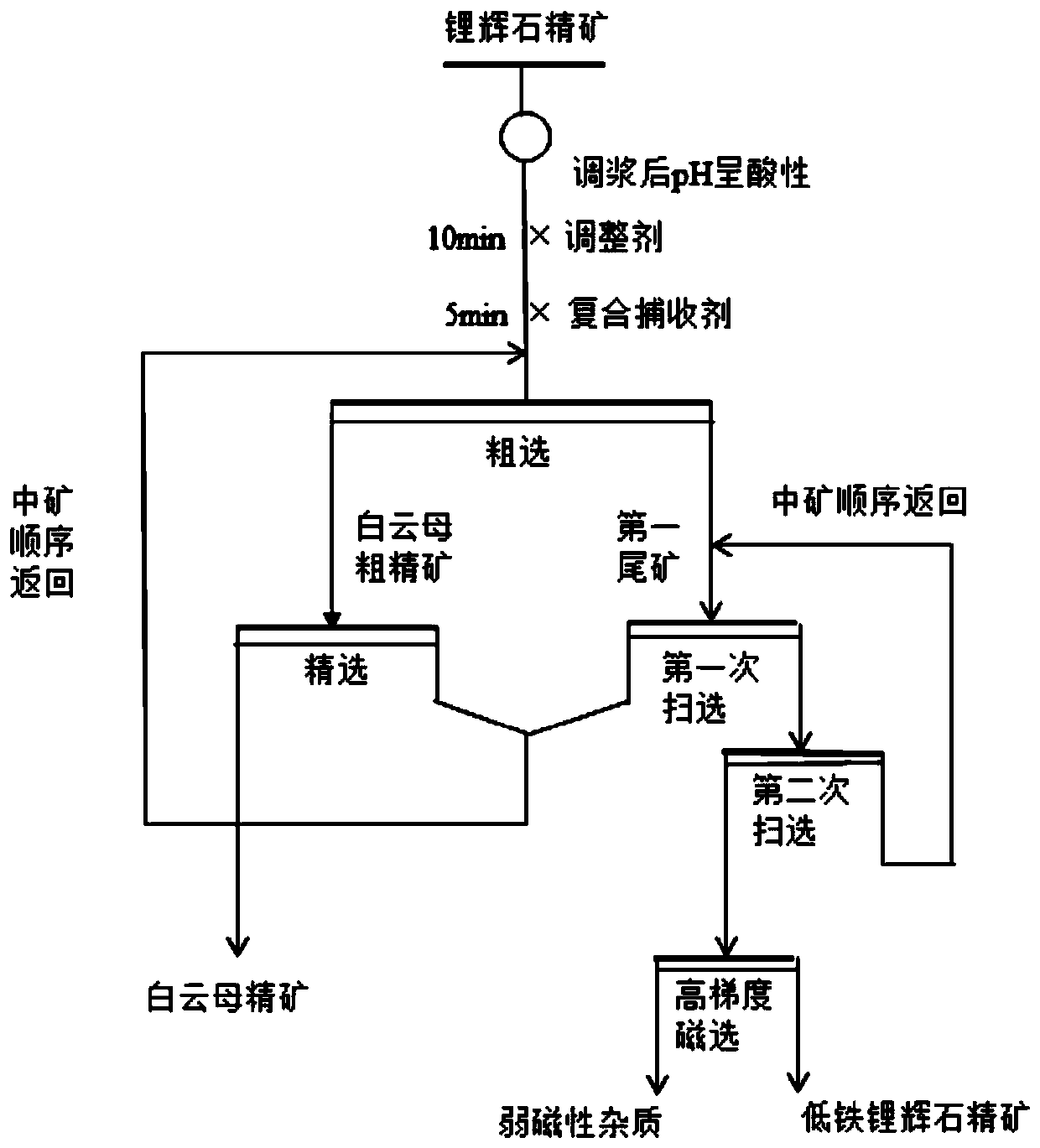

[0032] See figure 1 , A method for preparing low-iron spodumene concentrate, including the following steps:

[0033] 1) Add sulfuric acid with a mass concentration of 10% to the spodumene concentrate for slurry adjustment, and the pH of the slurry after slurry adjustment is 2.

[0034] 2) Adding the regulator and the composite collector of the above-mentioned component ratio to the ore slurry for flotation to obtain muscovite concentrate and flotation tailings. The specific method of flotation is:

[0035] According to the ratio of adding 500 grams of modifier per ton of slurry, add water glass to the above slurry, stir for 10 minutes, and then add 500 grams of composite collector per ton of slurry, add the composite collector of the above component ratio, Fully agitate, perform roughing, and roughing for 5 minutes to obta...

Embodiment 2

[0044] A composite collector is formed by mixing glutamic acid, dodecanoic acid and diesel oil, and the weight ratio of the glutamic acid, dodecanoic acid and diesel oil is 90:5:5.

[0045] A preparation method of low-iron spodumene concentrate includes the following steps:

[0046] 1) Add dilute hydrochloric acid to the spodumene concentrate for slurry adjustment. After slurry adjustment, the pH of the slurry is 3.

[0047] 2) Adding the regulator and the composite collector of the above-mentioned component ratio to the ore slurry for flotation to obtain muscovite concentrate and flotation tailings. The specific method of flotation is:

[0048] According to the ratio of 1000 grams of adjusting agent per ton of slurry, add sodium hexametaphosphate to the above slurry, stir for 5 minutes, and then add 1000 grams of composite collector per ton of slurry, and add the composite collection of the above component ratio Mix well and carry out the first roughing to obtain the first crude mus...

Embodiment 3

[0057] A composite collector is formed by mixing threonine, caproic acid and diesel, and the weight ratio of threonine, caproic acid and diesel is 80:5:10.

[0058] A preparation method of low-iron spodumene concentrate includes the following steps:

[0059] 1) Add sulfuric acid with a mass concentration of 20% to the spodumene concentrate for slurry adjustment, and the pH of the slurry after slurry adjustment is 6.

[0060] 2) Adding the regulator and the composite collector of the above-mentioned component ratio to the ore slurry for flotation to obtain muscovite concentrate and flotation tailings. The specific method of flotation is:

[0061] According to the ratio of adding 1500 grams of regulator per ton of pulp, add carboxymethyl cellulose to the above pulp, stir for 10 minutes, and then add 1200 grams of composite collector per ton of pulp, and add the composite trap of the above component ratio. Collect the agent, fully stir, and perform the first roughing to obtain the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com