Method and device for deironing continuously in slurry in bi-twisting mode

A double-rotation, slurry technology, applied in the field of magnetic separation, can solve problems such as complex structure, low iron removal efficiency, difficult maintenance and overhaul, etc., and achieve the goal of improving slurry quality, good iron absorption effect, and good iron removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

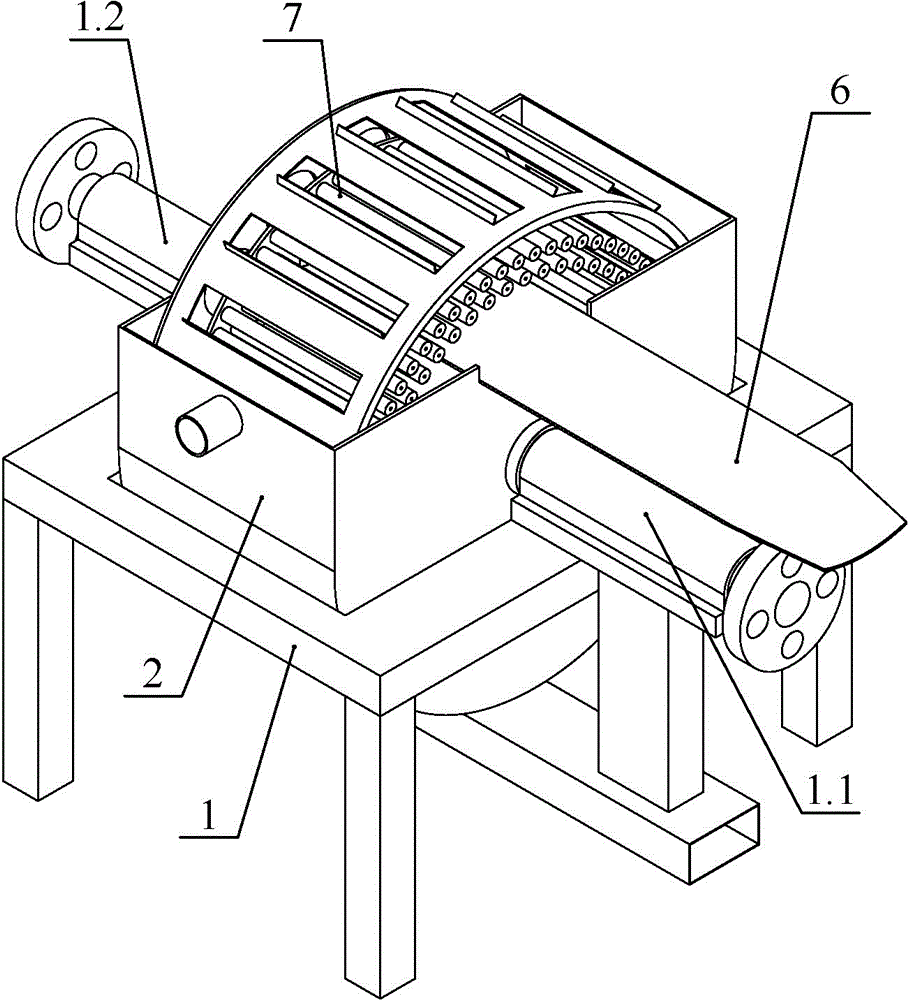

[0050] Such as figure 1 , 2 As shown, the device includes a frame 1, a slurry bucket 2, an inner container 3, a group of magnetic rods 4, an agitator 7 and a rotary water spray device 5. A first fixed frame 1.1 and a second fixed frame 1.2 are respectively installed at positions corresponding to the front and rear of the frame 1 .

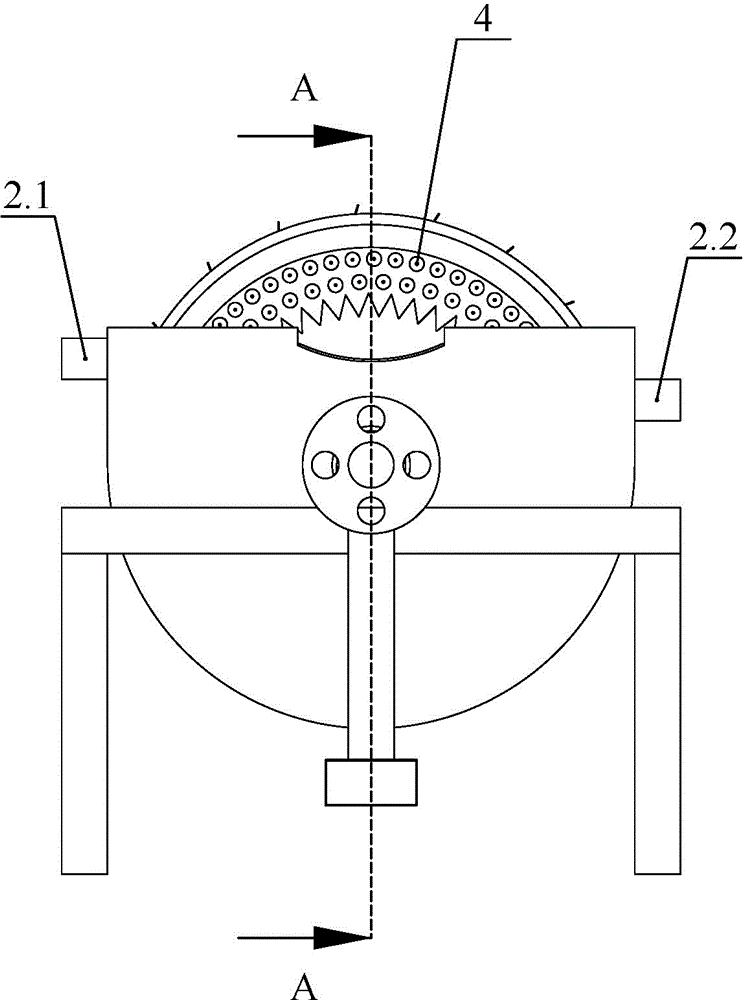

[0051] The slurry bucket 2 is installed on the frame 1, and the bottom of the slurry bucket 2 is an arc structure and the radius of curvature is half of the distance between the left and right side walls. A slurry discharge port 2.2 is opened near the position where the magnetic bar just enters the slurry, and a slurry inlet 2.1 is opened near the position where the magnetic bar just leaves the slurry. And the height of the stock inlet port 2.1 is greater than the height of the stock discharge port 2.2. This ensures that the slurry can be discharged normally.

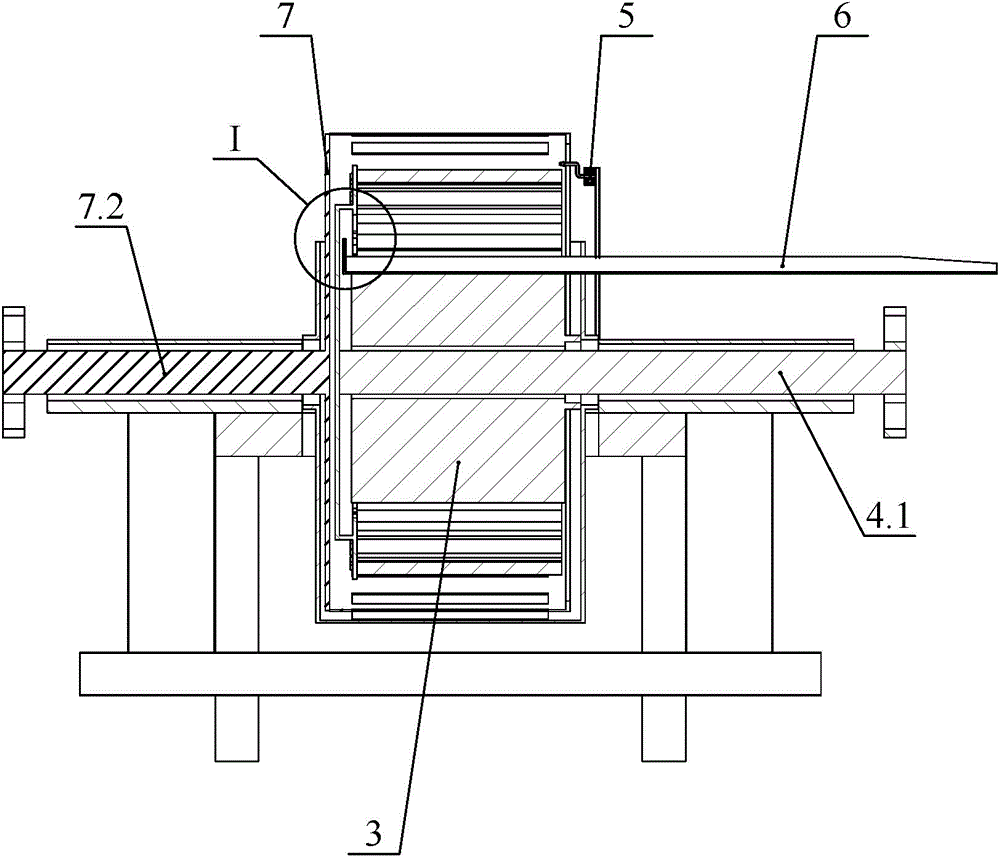

[0052] Such as image 3 , 4 As shown, an inner container 3 is set in the slurry ba...

Embodiment 2

[0063] Compared with Embodiment 1, this embodiment has made changes in the way of removing iron. Such as Figure 7 As shown, in order to remove the iron filings adsorbed on the magnetic rod 4.2 more quickly without scratching the magnetic rod 4.2, high-pressure water flow can also be used for flushing. The rotary water spray device 5 is installed on the frame 1, and the rotary water spray device 5 comprises a shower head 5.1, which can rotate, and the rotary water spray device is positioned at one side of the finger. Therefore, when the magnetic bar group rotates so that the scraper 8 on it just enters the gap between the left finger 9.1 and the right finger 9.2, the arm 9 drives the scraper 8 to move to the front end of the magnetic bar while the nozzle rotates and sprays water. The sprayed water forms a spiral water circle to flush the magnetic bar, and the iron filings absorbed by the magnetic bar and the iron filings on the scraper 8 are washed away. Aiming at the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com