Gold extraction process method for refractory gold ore

A process method, gold mine technology, applied in the field of gold mine extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

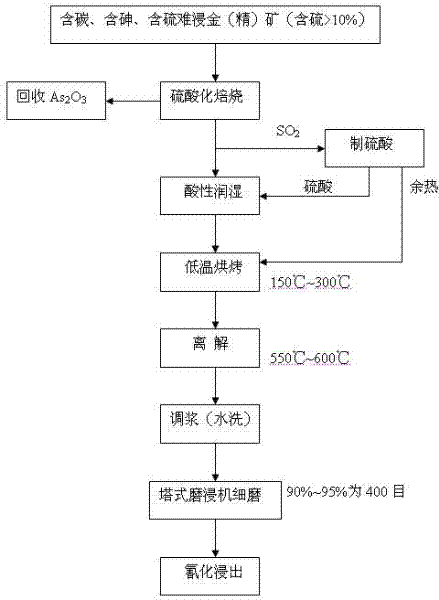

Method used

Image

Examples

Embodiment 1

[0031] Gold concentrate (dry) 1000g, when the temperature of the horse boiling furnace is 400 ° C, start the temperature to 650 ° C after 30 minutes, open the door of the furnace (three times in the middle of the mines), and control the warm roasting for 60 minutes.After cooling to room temperature, the weight was 867g, and the scum rate was 86.7%.

[0032] Called 433.5g of slag, 250GH 2 So 4 (About 136ml) and 150ml of water mix, and then bake them at low temperature.When the horses boil furnace temperature is 150 ° C, the furnace is baked for 30 minutes. When the grown is baked into a block, the shovel is touched into small pieces, and then baked for 30min for 30 minutes each heated to 200 ° C and 250 ° C.

[0033] After baking at low temperature, the temperature will be heated to 550 ℃ ~ 600 ℃, and continue to bake for 60 minutes.Then cooled to room temperature, the slag weight was 422g, and the scum rate was 84.4%at the raw material.After the water was added, at the 50%grinding...

Embodiment 2

[0036] Gold concentrate (dry) 1000g, when the temperature of the horse boiling furnace is 400 ° C, start the temperature to 650 ° C after 30 minutes, open the door of the furnace (three times in the middle of the mines), and control the warm roasting for 60 minutes.After cooling to normal temperature, the weight was 920g, and the scum yield was 92.0%.

[0037] Called 460g scum, 250GH 2 So 4 (About 136ml) and 150ml of water mix, and then bake them at low temperature.When the horses boil furnace temperature is 150 ° C, the furnace is baked for 30 minutes. When the grown is baked into a block, the shovel is touched into small pieces, and then baked for 30min for 30 minutes each heated to 200 ° C and 250 ° C.

[0038] After baking at low temperature, the temperature will be heated to 550 ℃ ~ 600 ℃, and continue to bake for 60 minutes.Then cool to room temperature, the slag weighs 449g, and the scum rate is 89.8%at the raw material.After the water was added, at the 50%grinding concentr...

Embodiment 3

[0041] Gold concentrate (dry) 1000g, when the temperature of the horse boiling furnace is 400 ° C, start the temperature to 650 ° C after 30 minutes, open the door of the furnace (three times in the middle of the mines), and control the warm roasting for 60 minutes.After cooling to room temperature, the weight was 858g, and the scum rate was 85.8%.

[0042] Called 429g scum, 250GH 2 So 4 (About 136ml) and 150ml of water mix, and then bake them at low temperature.When the horses boil furnace temperature is 150 ° C, the furnace is baked for 30 minutes. When the grown is baked into a block, the shovel is touched into small pieces, and then baked for 30min for 30 minutes each heated to 200 ° C and 250 ° C.

[0043] After baking at low temperature, the temperature will be heated to 550 ℃ ~ 600 ℃, and continue to bake for 60 minutes.Then cooled to room temperature, the slag weight was 413g, and the scum rate was 82.6%at the raw material.After the water was added, at the 50%grinding conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com