Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

A technology of refractory gold ore and low grade, which is applied in the gold extraction process of carbon-containing low-grade refractory gold ore and the field of arsenic, which can solve the problems of high cost, low gold leaching rate and complicated process, and achieve the goal of improving the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

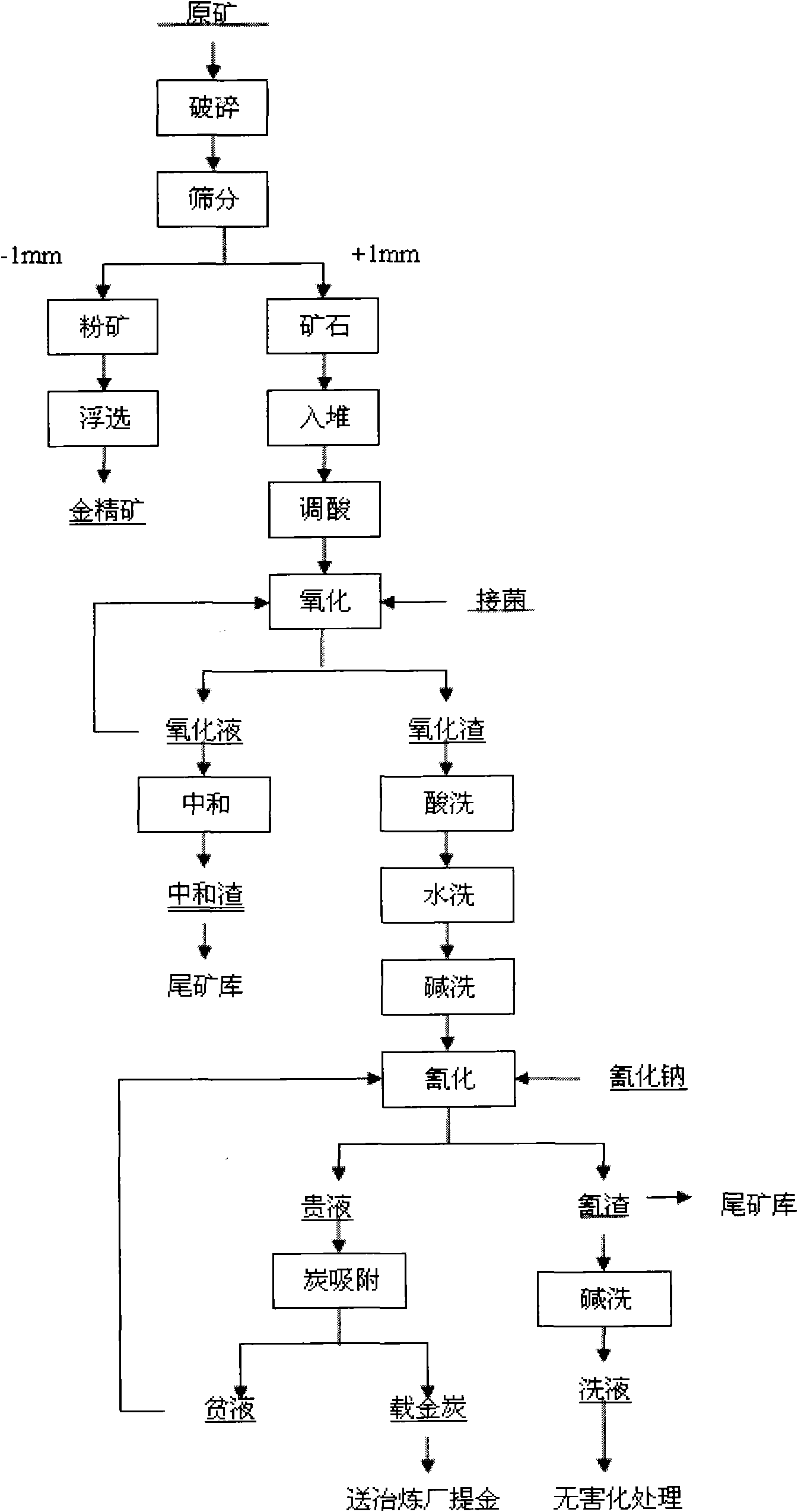

Method used

Image

Examples

example 1

[0032] Crush the ore to -10mm, and directly heap leaching cyanide, the concentration of sodium cyanide is 0.1%, and the cyanide time is 8 months. The permeation rate is basically 0.

example 2

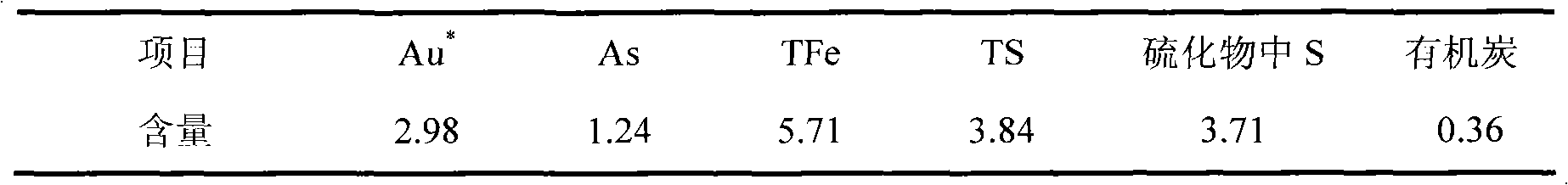

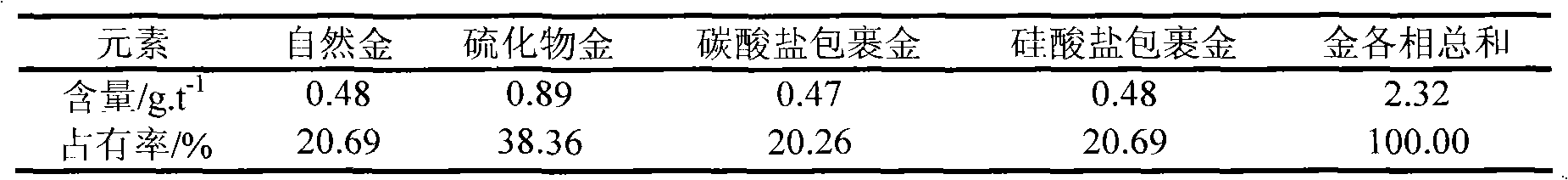

[0034] The ore is crushed to -10mm, and then the crushed ore is screened through a -1mm sieve, the amount of fine ore under the sieve accounts for 23.23% of the total ore, and the gold content of the +1mm ore is 2.32g / t, and the + The 1mm ore is piled up for biological heap leaching oxidation, the gold content in the -1mm fine ore is 4.30g / t, and the -1mm fine ore is sent to the flotation plant for flotation of gold concentrate. Use dilute sulfuric acid with pH=1.3 to 1.6 to wash the ore heap until the pH of the washing solution is stable at 1.3 to 1.6, then transfer the acclimatized and cultivated bacterial solution. After 4 months of bacterial oxidation, the oxidation rate of sulfide is 65.98%. Wash the ore heap with dilute sulfuric acid of 1.3 to 1.6, wash out the soluble Fe and As plasma in the ore heap, then wash the ore heap with clean water, and finally wash the ore heap with sodium hydroxide or calcium hydroxide solution until the pH of the washing solution is > 9.5 Th...

example 3

[0036] The ore is crushed to below -10mm, and then the crushed ore is sieved through a -1mm sieve. The amount of fine ore under the sieve accounts for 22.02% of the total ore, and the gold content of the +1mm ore is 2.22g / t. The ore of +1mm is piled up for biological heap leaching oxidation, the gold content of -1mm fine ore is 4.36g / t, and the -1mm fine ore is sent to the flotation plant for flotation of gold concentrate. Use dilute sulfuric acid with pH=1.3 to 1.6 to wash the ore heap until the pH of the washing solution is stable at 1.3 to 1.6, then transfer the acclimatized and cultivated bacterial solution. After 5 months of bacterial oxidation, the oxidation rate of sulfide is 65.68%. Wash the ore heap with dilute sulfuric acid of 1.3 to 1.6, wash out the soluble Fe and As plasma in the ore heap, then wash the ore heap with clean water, and finally wash the ore heap with sodium hydroxide or calcium hydroxide solution until the pH of the washing solution is > 9.5 Then sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com