Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve chemical efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

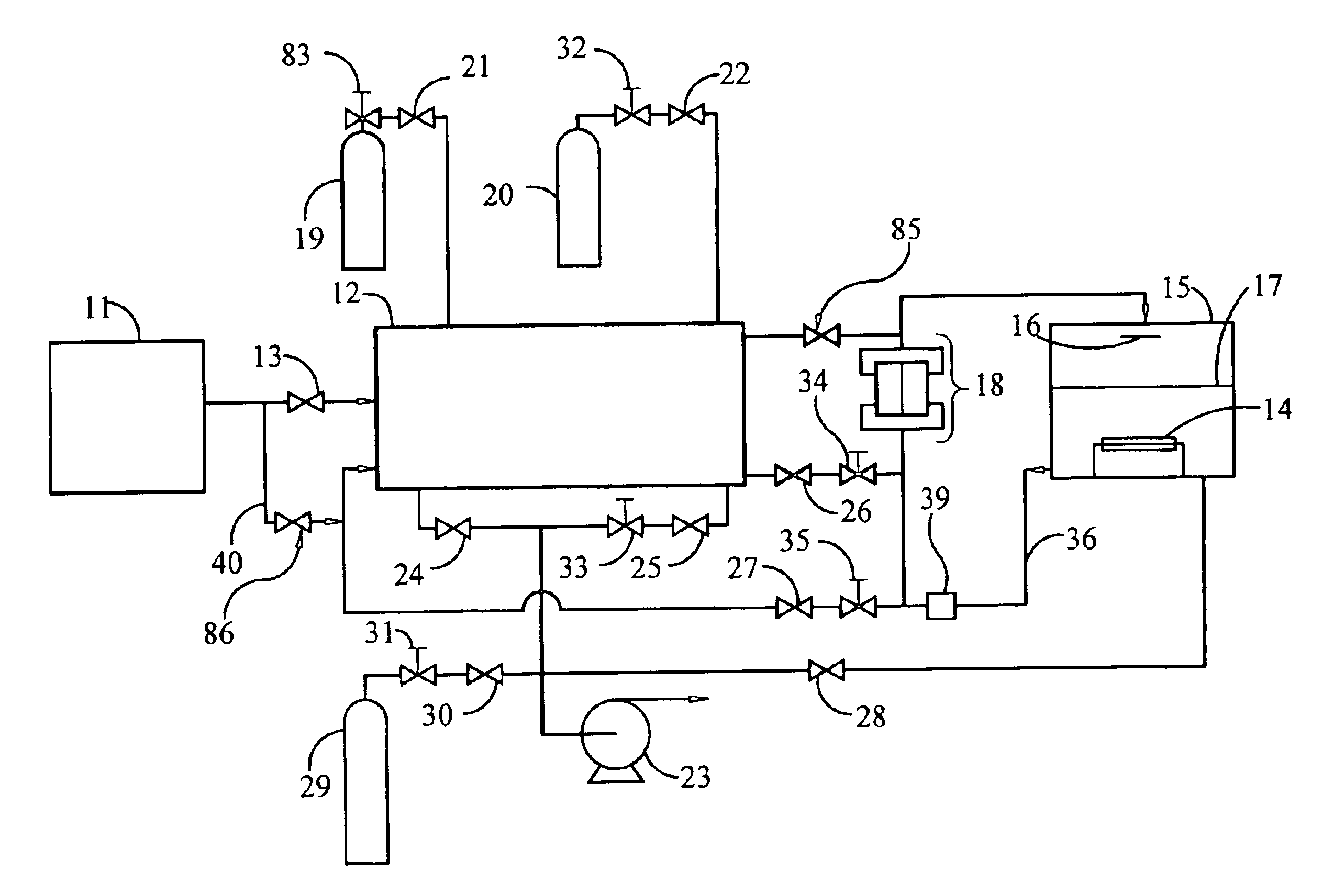

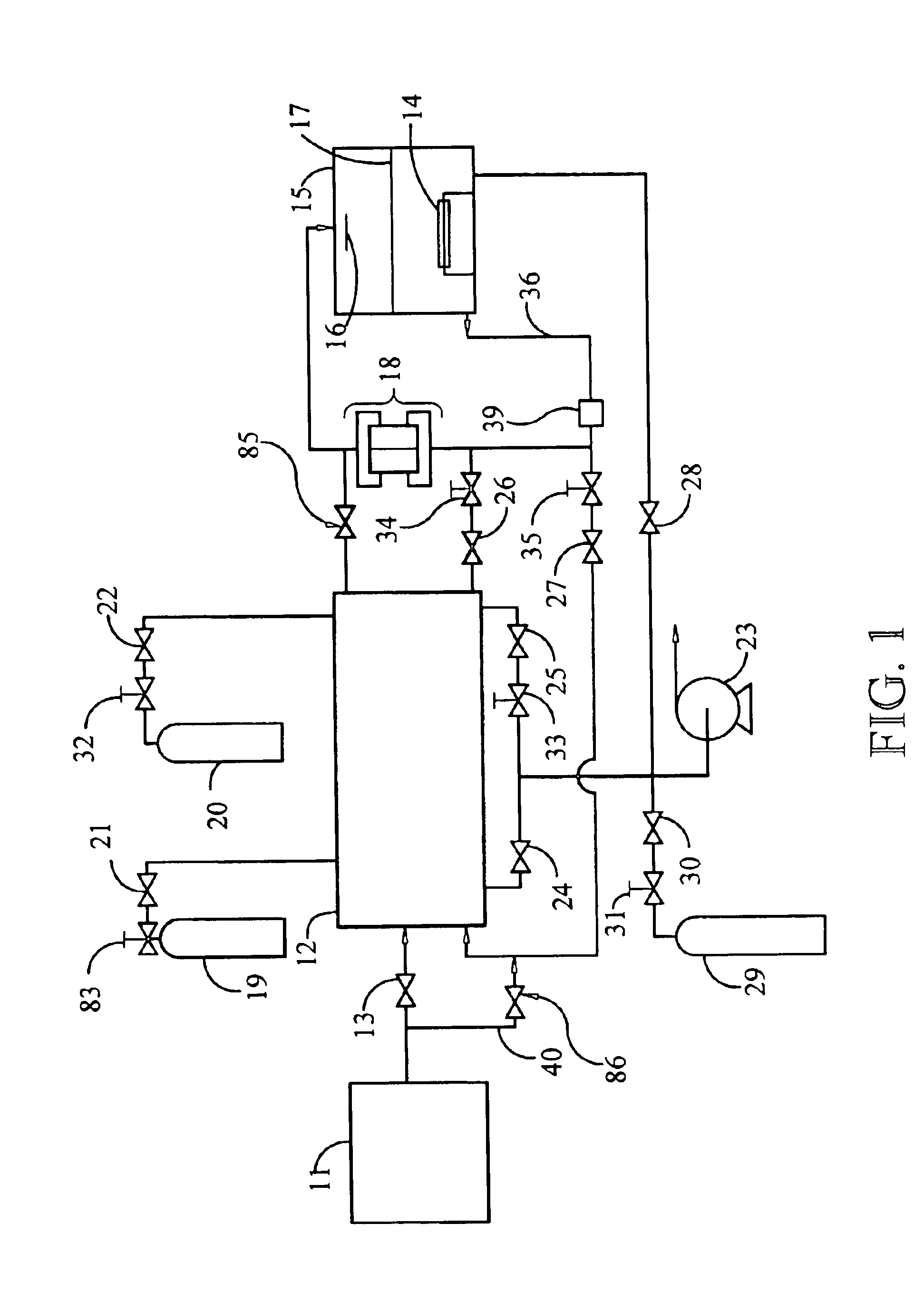

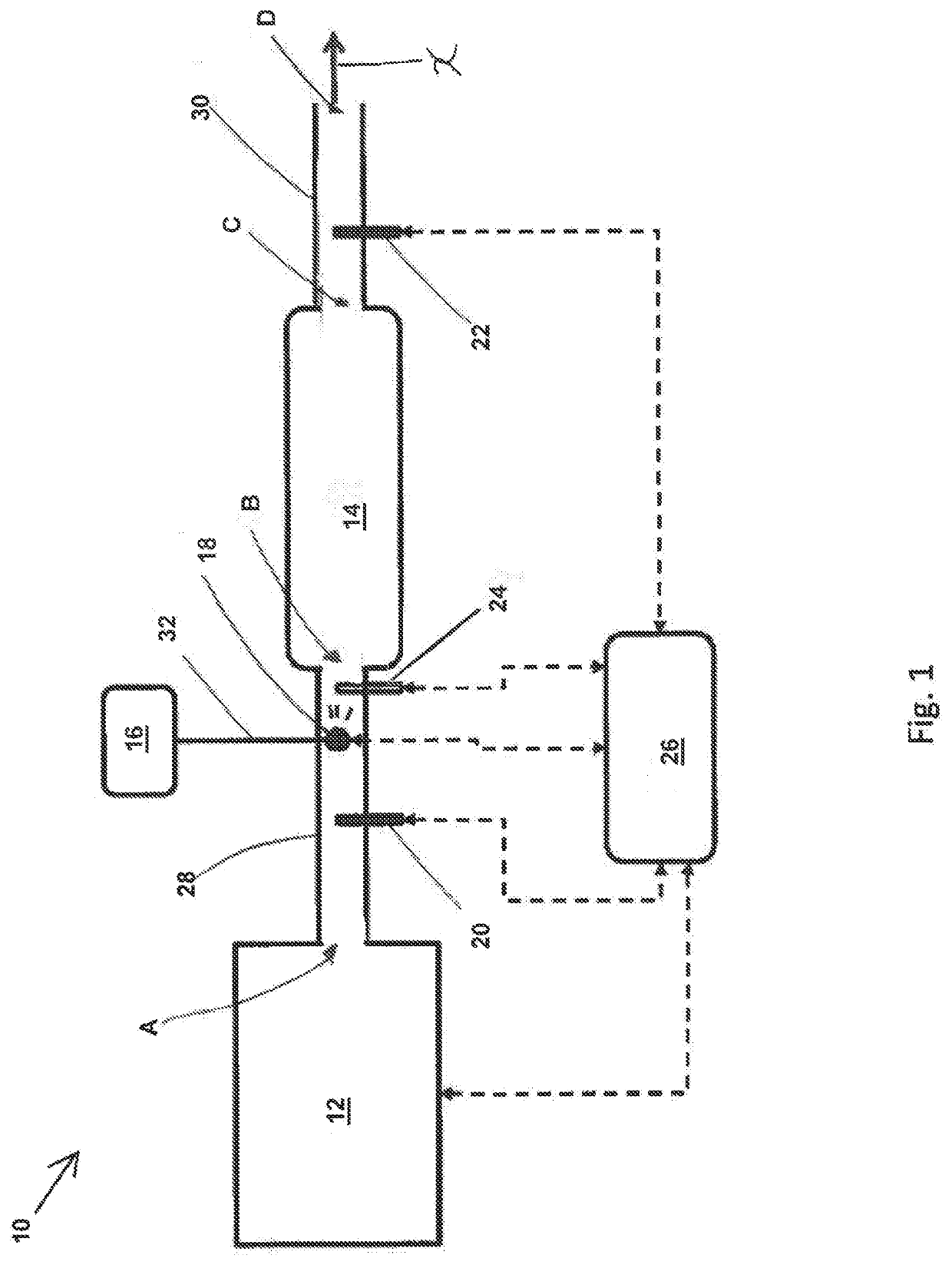

Apparatus and method for flow of process gas in an ultra-clean environment

InactiveUS6949202B1Improve effectivenessImprove processing efficiencyMaterial nanotechnologyDecorative surface effectsProduct gasProcess engineering

Processes for the addition or removal of a layer or region from a workpiece material by contact with a process gas in the manufacture of a microstructure are enhanced by the use of recirculation of the process gas. Recirculation is effected by a pump that has no sliding or abrading parts that contact the process gas, nor any wet (such as oil) seals or purge gas in the pump. Improved processing can be achieved by a process chamber that contains a baffle, a perforated plate, or both, appropriately situated in the chamber to deflect the incoming process gas and distribute it over the workpiece surface. In certain embodiments, a diluent gas is added to the recirculation loop and continuously circulated therein, followed by the bleeding of the process gas (such as an etchant gas) into the recirculation loop. Also, cooling of the process gas, etching chamber and / or sample platen can aid the etching process. The method is particularly useful for adding to or removing material from a sample of microscopic dimensions.

Owner:TEXAS INSTR INC +1

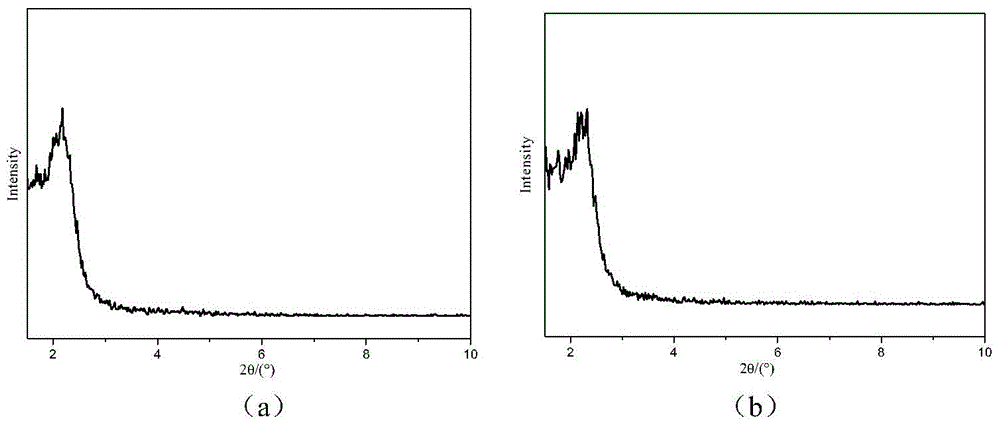

Preparation method of silanization-modified molecular sieve

ActiveCN104477933AReduce static and dynamic water adsorptionImprove hydrophobicityPentasil aluminosilicate zeoliteMolecular sieveNitrogen

The invention belongs to the field of synthesis and application of molecular sieves, and discloses a preparation method of a silanization-modified molecular sieve. The method comprises the following steps: transferring a molecular sieve subjected to acid-alkali alternate treatment, an accelerator and a silanization reagent dissolved in an organic solvent into a reactor, carrying out silanization modification on the molecular sieve in a nitrogen protective sealed environment under the conditions of certain temperature and high pressure, filtering, washing, and drying to obtain the silanization-modified molecular sieve. The preparation method disclosed by the invention can effectively enhance the silanization efficiency, does not have great influence on the pore structure of the molecular sieve, and has the advantages of low cost, simple technique and high silanization degree.

Owner:杭州富阳奥玛德科技有限公司

Polyimide fiber and preparation method thereof

InactiveCN101525783AAvoid decompositionAccelerate the rate of cyclizationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberMicrowave method

The invention discloses a polyimide fiber and a preparation method thereof. Synthesizing polyamide acid with a ternary polymerization method destroys the regularity and the symmetry property of molecular chains, so that the crystallization tendency of the molecular chains is reduced and the spinning property of PAA solution is improved; and partial cyclization treatment limits the degradation of polyamide acid, and spinning serum is easy to solidify and form when entering into coagulation bath. The microwave method is adopted to treat polyamide acid fiber, the cyclization rate is accelerated, and the reaction time is shortened; and simultaneously, no any side reaction is aroused under the microwave radiation. The prepared polyimide nascent fiber has high strength and good thermal resistance.

Owner:SUZHOU UNIV

Multi-stage AP mechanical pulping with refiner blow line treatment

InactiveUS20100263815A1More efficient processEffective bleachingDigestersPulp bleachingPulp and paper industryEngineering

The invention combines the step of adding chemicals such as alkaline peroxide to an intermediate line after refining, with the step of applying chemicals such as alkaline peroxide as a pre-treatment before primary refining and / or applying chemicals such as alkaline peroxide at the primary refiner. This is implemented in the preferred embodiment, by pre-treating feed material, refining the materials into a pulp in a superatmospheric refiner, and adding chemicals in the post refining blowline.

Owner:ANDRITZ INC

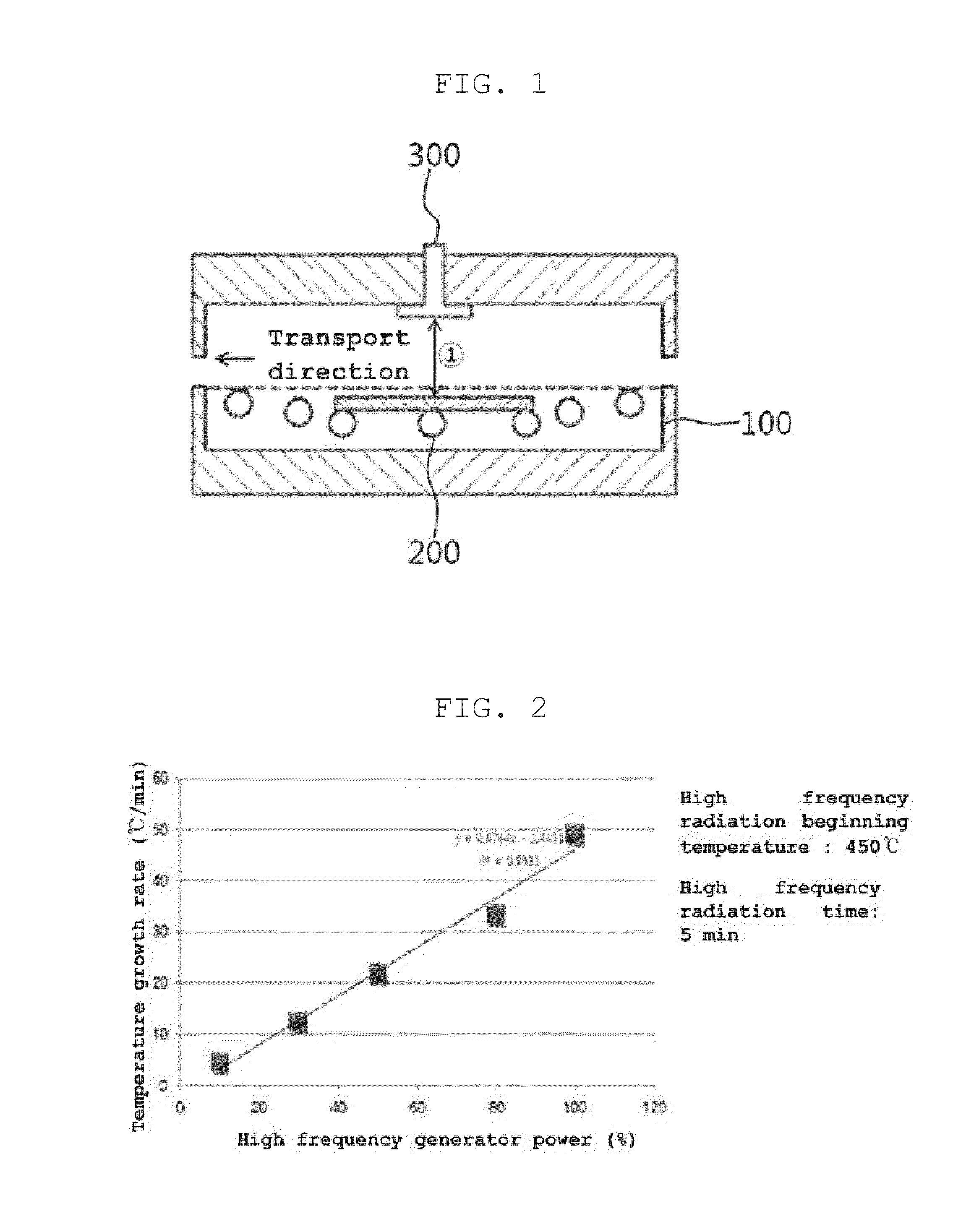

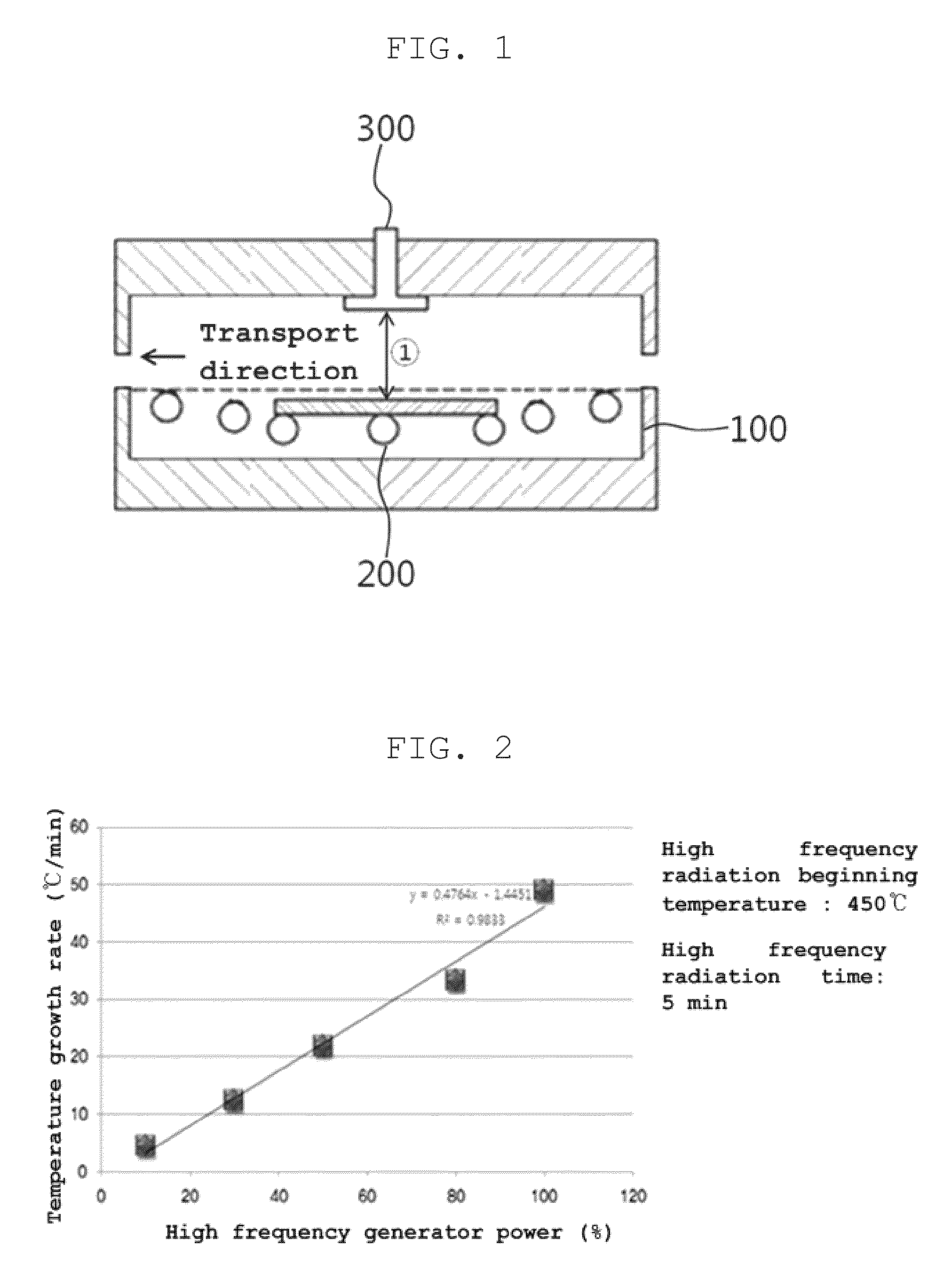

Apparatus for chemically toughening glass and method of chemically toughening glass using the same

ActiveUS20140116090A1Improve chemical toughening efficiencyIncreases ion exchangeOhmic-resistance heatingMicrowave heatingIon exchangeToughening

An apparatus for chemically toughening glass which can toughen the surface of the glass by inducing compressive stress on the glass surface through ion exchange and a method of chemically toughening glass using the same. The apparatus includes a chemical toughening bath which chemically toughens the glass; a transportation part which transports the glass from upstream of the chemical toughening bath through the chemical toughening bath to downstream of the chemical toughening bath; and a microwave generator disposed above the chemical toughening bath, the microwave generator radiating microwaves to the glass.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

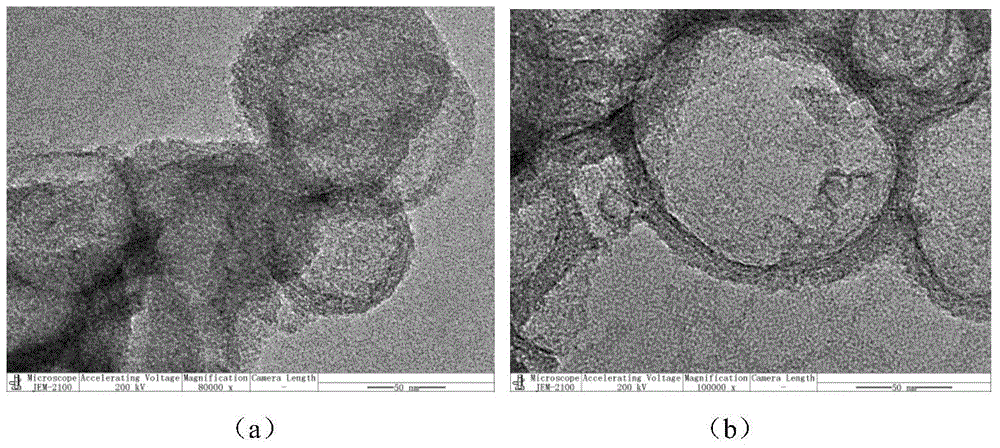

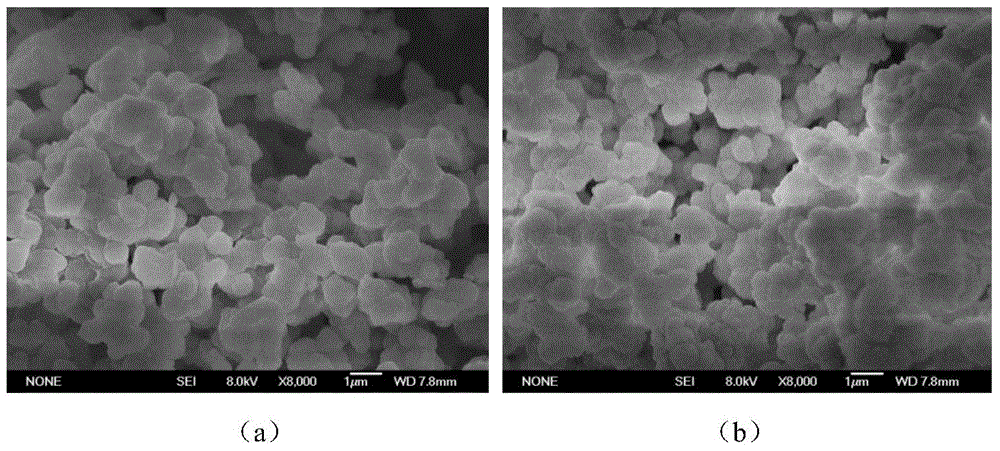

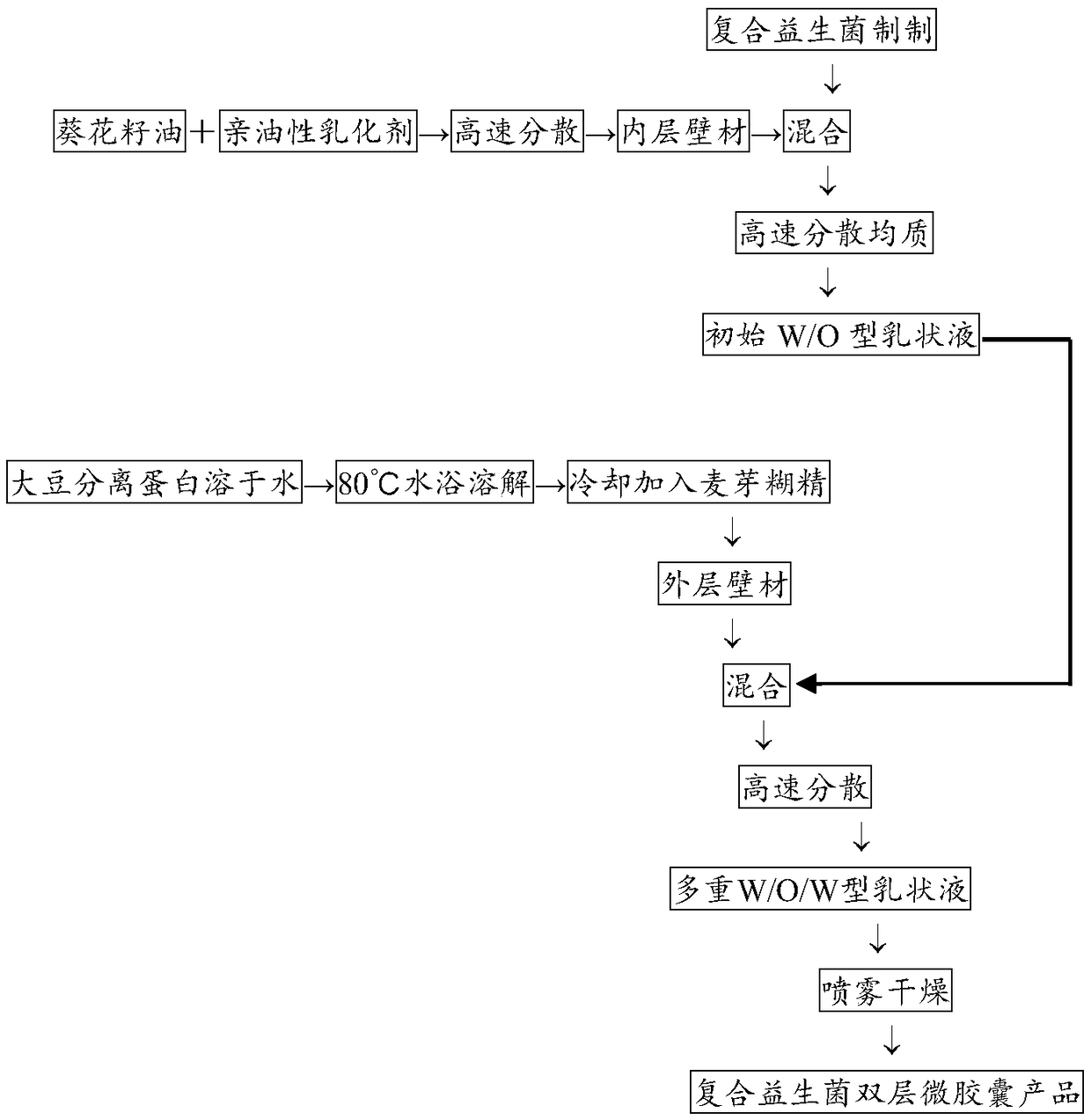

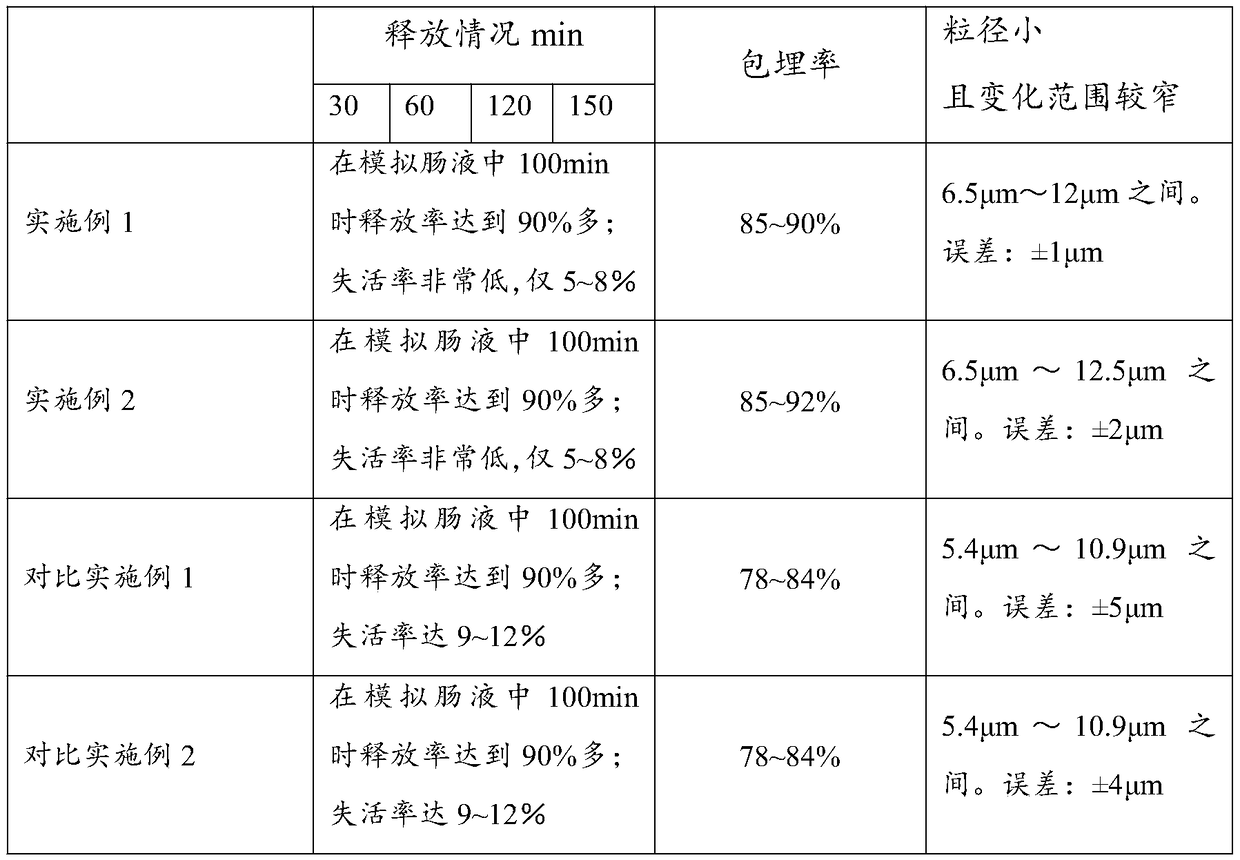

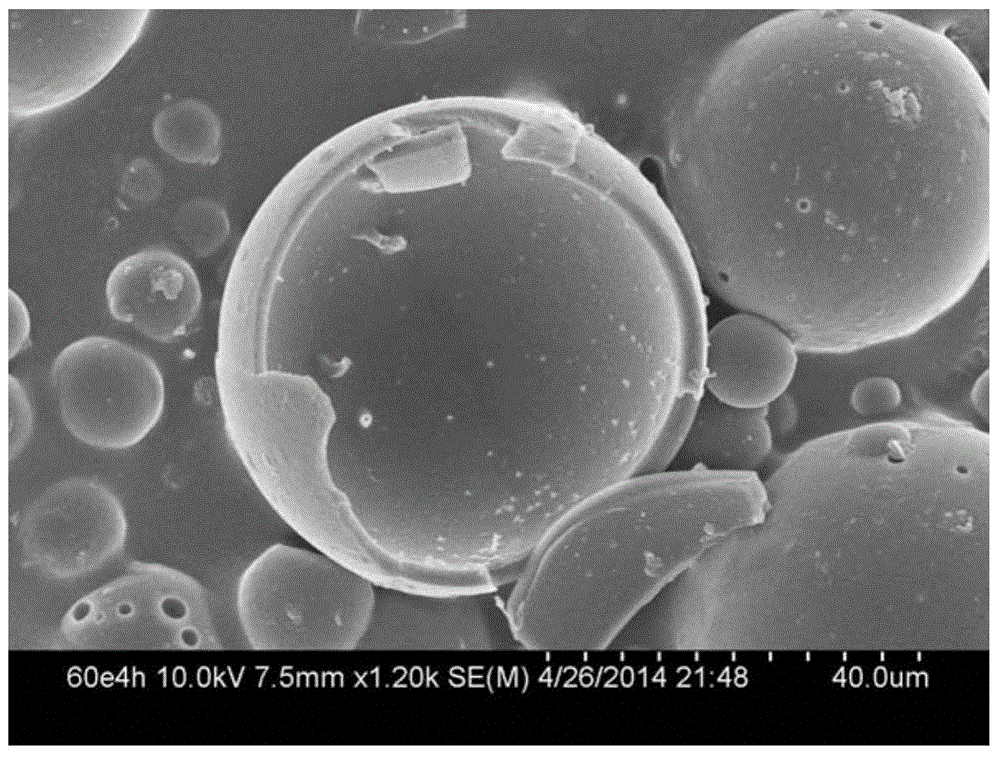

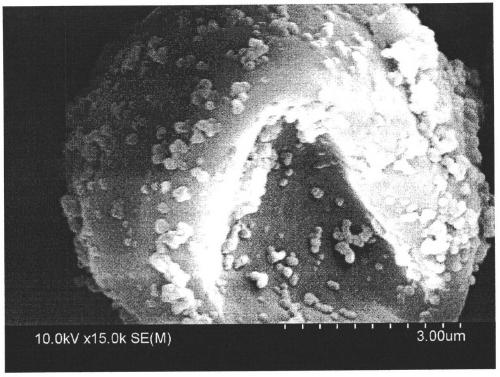

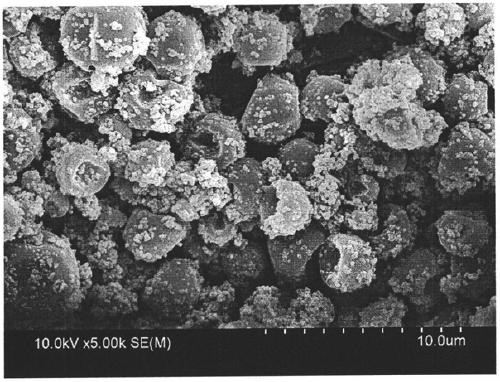

Technological method for producing composite probiotic two-layer microcapsule by virtue of double-emulsification method-spray drying

PendingCN108902983AOptimizing the composition mass to volume ratioFlat surfaceFood shapingProduction rateControl release

The invention relates to a technological method for producing a composite probiotic two-layer microcapsule by virtue of a double-emulsification method-spray drying which is suitable for various activeprobiotic composite micro-ecological preparations, which belongs to the technical field of food microorganisms. The two-layer microcapsule prepared by adopting the double-emulsificaiton-spray dryingmethod is high in probiotic embedding efficiency, good variable bacteria stability, complete in surface and is in an approximate spherical shape; and moreover, the embedded component is released afterpassing by two interfaces, so that the burst release phenomenon can be overcome, the release time can be prolonged, and the controlled-release performance is good. The production device is simple, the operation is convenient, the labor protection is facilitated, the process period is short, the productivity is high, the finished product has good acid tolerance and cholate resisting capability, the source of raw materials is wide, the price is low, the industrialized continuous mass production can be realized, and a foundation can be laid for the industrialized production of the probiotic products.

Owner:SHENZHEN POLYTECHNIC

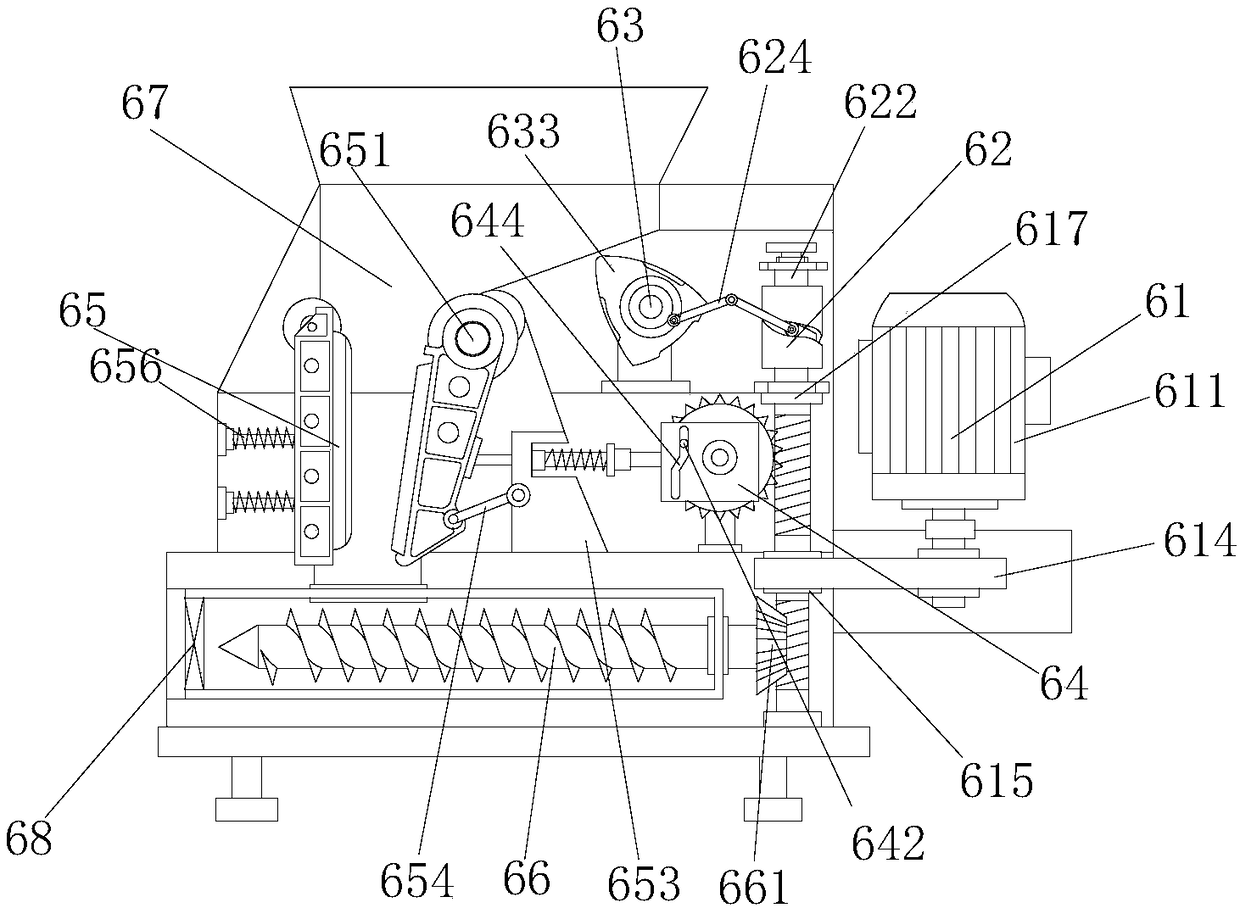

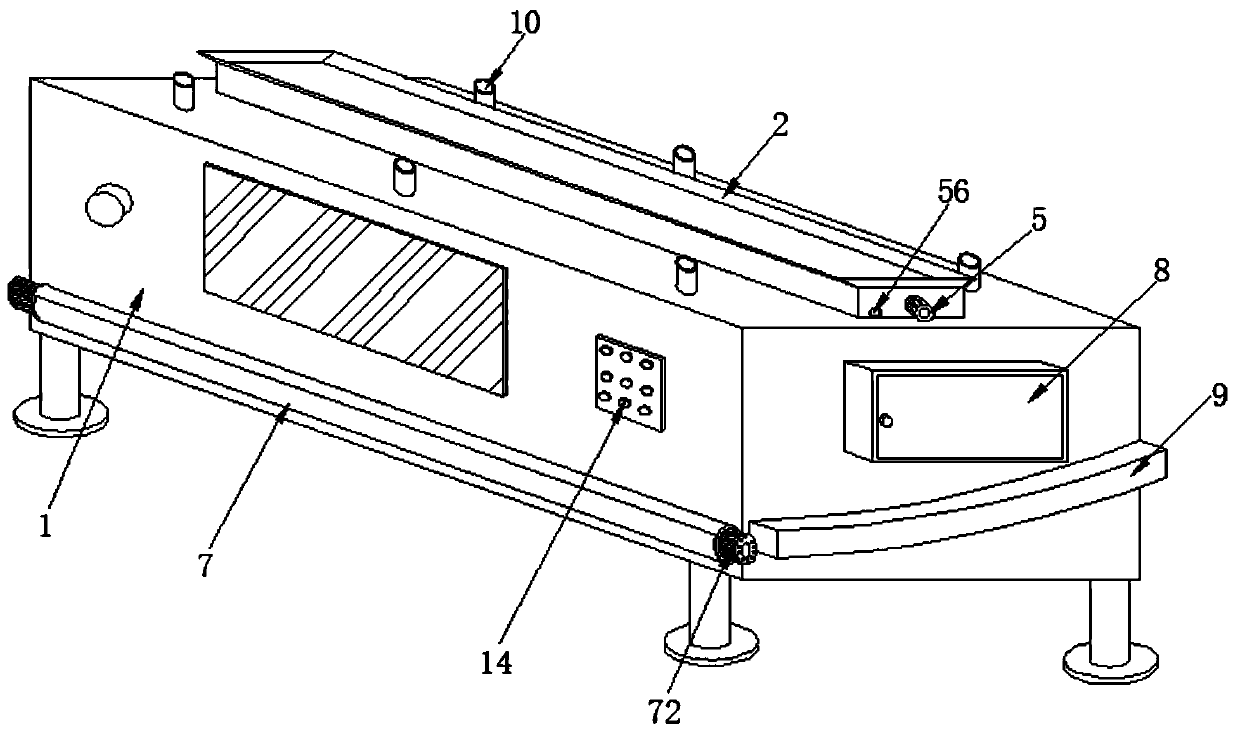

Novel automatic material dissolving machine

InactiveCN108499379AAchieve pre-shreddingAvoid cloggingRotary stirring mixersTransportation and packagingMotor driveRaw material

The invention discloses a novel automatic material dissolving machine. The machine structurally comprises a feeding hopper, an operation panel, a display screen, operation buttons, a motor fixing base, a main body device, supporting legs, a machine shell and a discharging hopper; the main body device comprises a motor driving mechanism, a grooved wheel transmission mechanism, a shaking feeding mechanism, a material crushing transmission mechanism, a material crushing mechanism, a stirring and material dissolving mechanism, a blanking cavity and an electronic discharging valve. The novel automatic material dissolving machine solves the problems that traditional automatic material dissolving machines lack material crushing structures, large-sized raw materials need to be stirred for a long time to be dissolved, and the material dissolving efficiency is low; the large-sized raw materials can be crushed in advance, and therefore the material dissolving efficiency is improved.

Owner:湖州致远互联软件有限公司

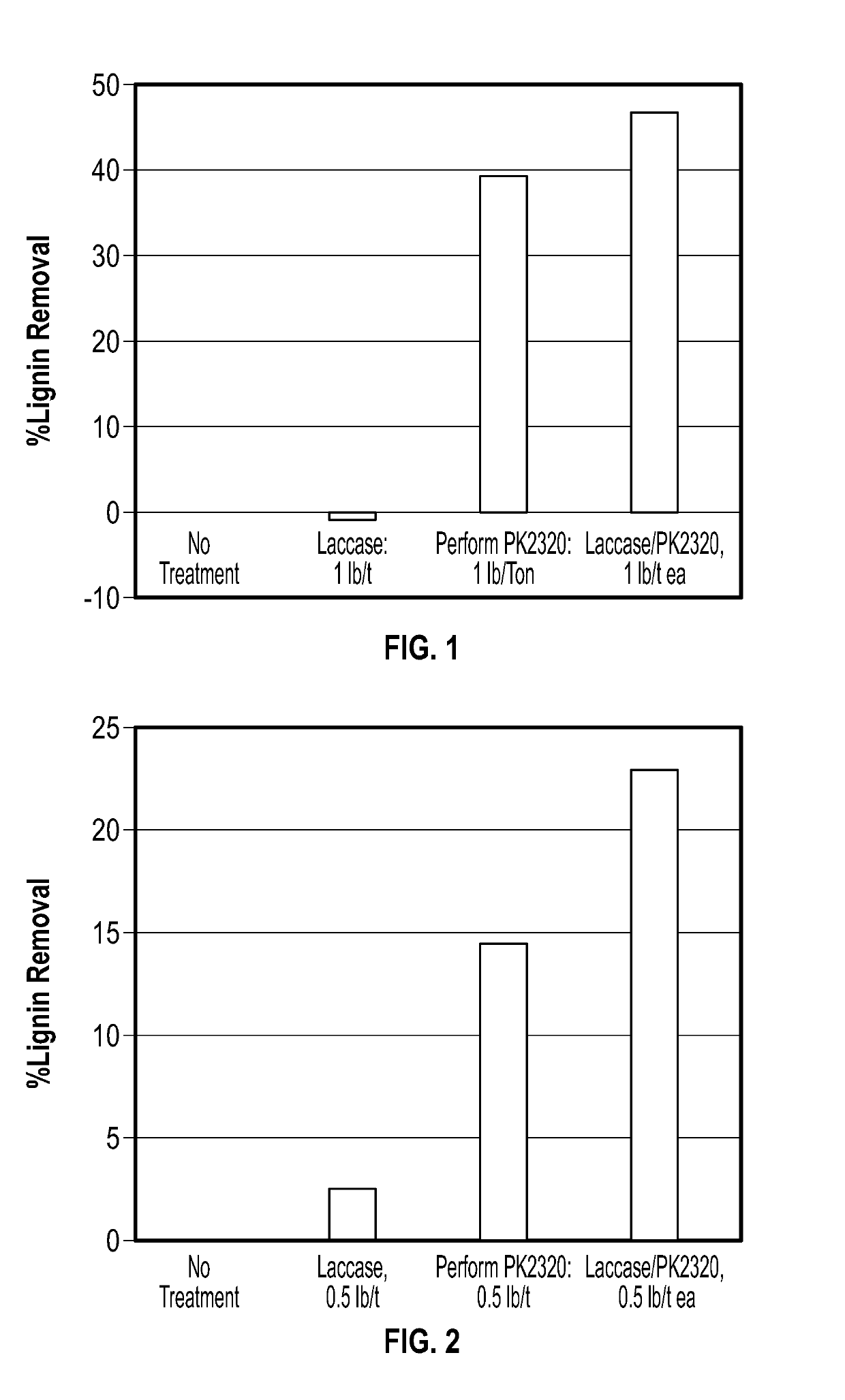

Chemical efficiency increase in papermaking process

ActiveUS20190100875A1Improve chemical efficiencyReduce the amount requiredPulp properties modificationMicroorganism/enzyme additionChemical additionChemistry

A method of increasing chemical efficiency of chemical additives in a papermaking system includes the steps of providing thick stock pulp comprising soluble lignin, process water, and at least about 2% by weight of cellulosic fiber based on total weight of thick stock pulp, and adding at least one laccase enzyme and at least one organic polymer to the thick stock pulp to reduce the amount of soluble lignin therein. The organic polymer is chosen from cationic polymers, non-ionic polymers and combinations thereof.

Owner:SOLENIS TECH CAYMAN

Finite element grid automatic division method and device and storage medium

ActiveCN114491824AMeet the requirements of the generatedImprove chemical efficiencyGeometric CADDesign optimisation/simulationComputational scienceAlgorithm

The embodiment of the invention discloses a finite element grid automatic division method and device and a storage medium. The method comprises the following steps: acquiring three-dimensional geometrical characteristics of a target part from CAE software; according to the characteristics of the three-dimensional geometric features, determining features needing to be cleaned and cleaning the features; performing grid generation on the cleaned three-dimensional geometric features by using CAE software to obtain three-dimensional grid features; according to the classification of the three-dimensional geometric features, adjusting the three-dimensional grid features corresponding to each classification; and according to the grid quality requirement, correcting the adjusted three-dimensional grid characteristics. According to the embodiment of the invention, an automatic finite element grid division process is realized, and the grid division efficiency is improved.

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD +1

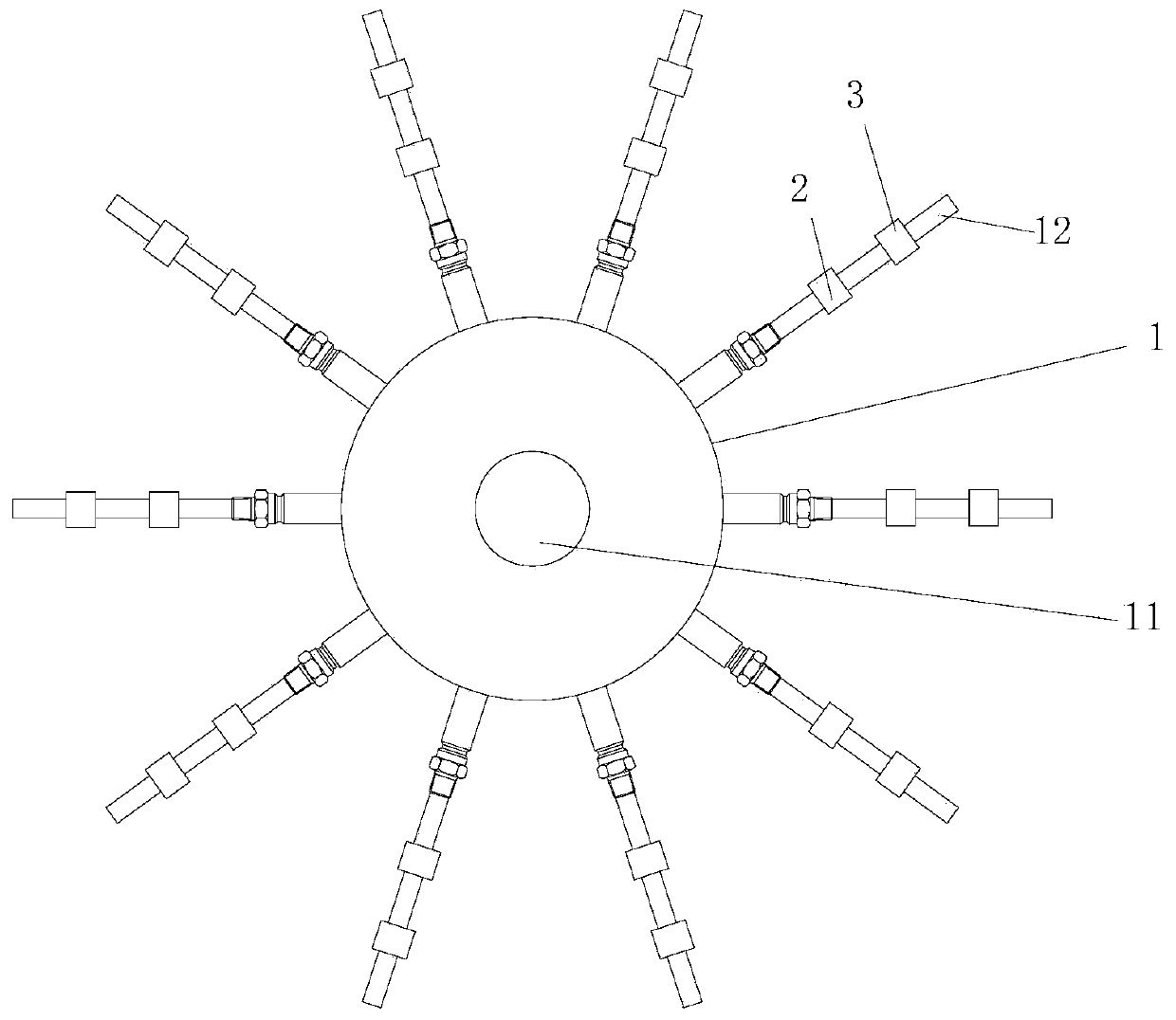

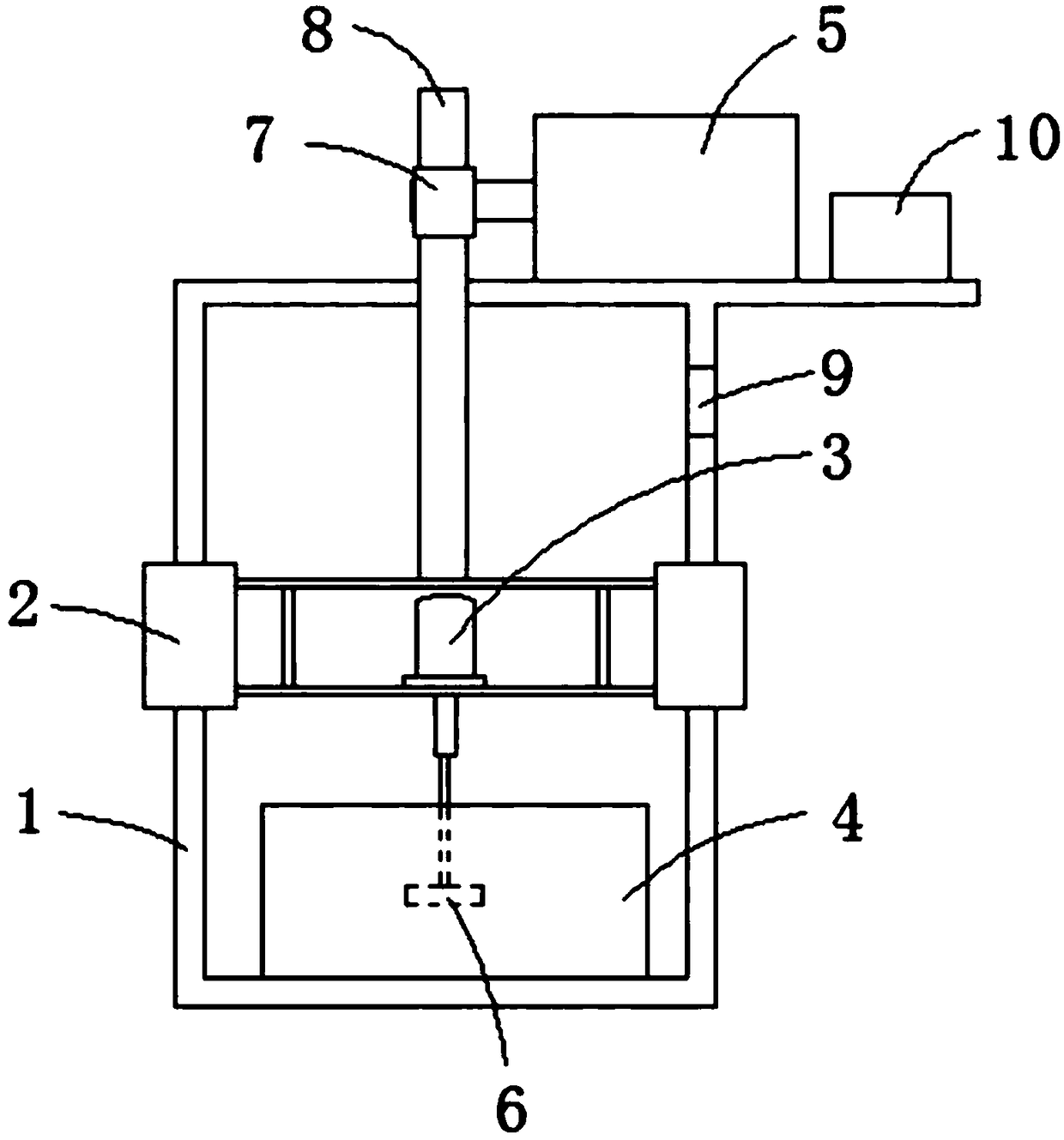

Control device for crystal growth furnace cooling water flow adjustment

InactiveCN103741218AImprove control abilityImprove yieldAfter-treatment apparatusPolycrystalline material growthWater storageWater flow

A control device for crystal growth furnace cooling water flow adjustment is characterized by comprising a water storage body, flow monitoring devices and flow adjustment devices; a water storage cavity is arranged in the water storage body, the water storage body is provided with a total water inlet for communicating with the water storage cavity, and multiple water outlets all communicating with the water storage cavity, wherein each water outlet is provided with a flow monitoring device and a flow adjustment device; and by observing of the surface velocity of an alumina melt in a crystal growth furnace, the flow monitoring device and the flow adjustment device are controlled to achieve precise adjustment of the cooling water flow of each water outlet.

Owner:福建鑫晶精密刚玉科技有限公司

Process to Improve the Yield of Chemical Polyurethane Foam Recycling

InactiveUS20160347927A1Improve efficiencyGeneration of dust can be suppressedPlastic recyclingChemical/physical/physico-chemical stationary reactorsMaterials scienceWetting

A process to enhance the chemical recycling of polyurethane foam comprises improving the process of grinding (which is a necessary precursor to chemolysis reactions), by employing a wetting process, concurrent with grinding, which reduces the loss of foam during grinding process.

Owner:POLYMER RES TECH

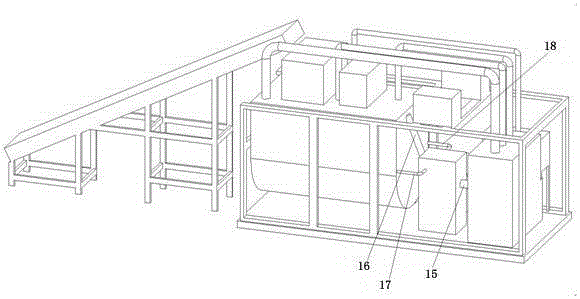

Livestock and poultry harmless intelligent processor

ActiveCN103817135BQuick breakdownImprove the efficiency of the chemical systemSolid waste disposalOil and greaseCombustion chamber

The invention provides a livestock and poultry waste harmless completely-intelligent processor, which comprises a waste decomposition apparatus, wherein the waste decomposition apparatus is connected to a waste lifting and conveying apparatus, a rendering case apparatus is provided at right below the waste decomposition apparatus, a grease refining and separating apparatus is arranged at the lower part of the rendering case apparatus, and a hot-blast stove apparatus and a medium oil heating device are connected to the side surface of the rendering case apparatus. The used decomposition apparatus is a design with original creation, and is capable of rapidly decomposing a raw material, wherein the decomposition efficiency is several times than that in this industry, and the original creation is capable of finely decomposing the raw material and greatly increasing the rendering efficiency. A medium oil heating device, a hot-blast stove apparatus are used, medium oil is introduced for heating, and then rendered by hot air, rendering efficiency is increased, the exhaust gas is simultaneously introduced in a combustion chamber of the hot-blast stove for pyrolysis processing, and thereby the exhaust gas can reach a discharge standard.

Owner:ZHEJIANG DUOBAOTIAN AUTOMATION EQUIP CO LTD

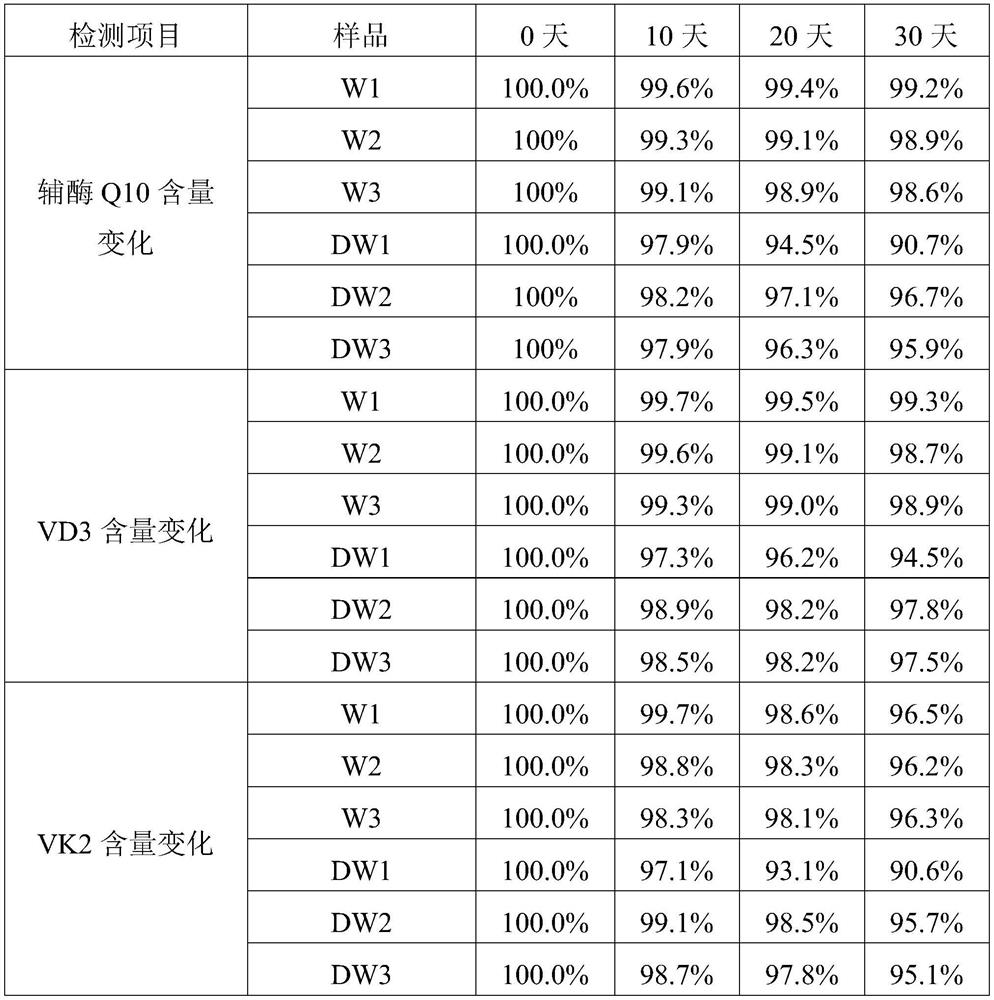

Coenzyme Q10, VD3 and VK2 sugar vitrified microcapsules and preparation method thereof

PendingCN112515172AFast formingReduce lossesSugar food ingredientsFood shapingPolymer sciencePlasticizer

The invention belongs to the technical field of vitamins, and relates to a coenzyme Q10, VD3 and VK2 sugar vitrified microcapsule and a preparation method thereof. The sugar vitrified microcapsule comprises a core material and a wall material, the core material contains coenzyme Q10, VD3 and VK2, the wall material contains starch sodium octenylsuccinate, a saccharide compound, a pH value regulatorand a plasticizer, the viscosity of the starch sodium octenylsuccinate at 25 DEG C is 20-100mPa. s, and the DE value of the saccharide compound is larger than 16. According to the method provided bythe invention, cavities can be prevented from being formed in the microcapsules, cracks and recesses can be prevented from appearing on the surfaces of the microcapsules, and coenzyme Q10, VD3 and VK2microcapsules with excellent water solubility, stability and multiple emulsion properties can be efficiently produced.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

Microencapsulated flame retardant and preparation method thereof

PendingCN114044940AImprove chemical efficiencyLess side effectsMicroballoon preparationMicrocapsule preparationPolymer scienceOrganic solvent

The invention discloses a microencapsulated flame retardant and a preparation method thereof. The invention aims at the defects of poor compatibility and poor water resistance of a flame retardant and a high polymer material, the method adopts an interfacial polymerization method, the flame retardant, an amine compound and an emulsifier are dissolved in deionized water to form a water phase, then an organic solvent is added into the water phase and dispersed at a high speed to form a water-in-oil emulsion; after the emulsion is stable, a curing agent isocyanate is added; and polymerization reaction is carried out on the isocyanate and the amine compound aggregated on the surface of the flame retardant to form the polyurea microencapsulated flame retardant. Compared with a flame retardant which is not subjected to microencapsulation treatment, the flame retardant subjected to microencapsulation modification of the polyurea has the advantages that the water resistance and the compatibility with macromolecules are effectively improved, the flame retardant property of the material is greatly improved, and the damage of the flame retardant to the mechanical property of the material is reduced.

Owner:NANJING UNIV OF SCI & TECH

Garden leaf waste materialization equipment

InactiveCN111589541AImprove chemical efficiencyHigh degree of automationGrain treatmentsAgricultural engineeringWaste material

The invention relates to the technical field of waste disposal equipment and discloses garden leaf waste materialization equipment, which comprises a cabinet, a feed nozzle, a discharge inclined platform and a crushing mechanism. The feed nozzle is fixedly installed on the top of the cabinet. The discharge inclined platform fixedly installed at the bottom of the inner wall of the cabinet. The crushing mechanism is arranged inside the cabinet. The inside of the feed nozzle is provided with a filter turning component. The inside of the cabinet is provided with a scraping mechanism adapted to thedischarging inclined platform. The bottom of one side of the cabinet is fixedly installed with an anti-blocking discharging device. Through setting the automatic scraping mechanism in the materialization equipment, the garden leaf waste materialization equipment can realize auxiliary discharge, thus greatly improving the automation degree of discharging, speeding up the discharging speed, and making the discharge cleaner. The staff need not spend a lot of time on manual auxiliary discharging. Even if the leaf waste is relatively viscous, the leaf waste can be discharged quickly and cleanly, thus greatly improving the materialization efficiency of the leaf waste.

Owner:李成

Process flow and treatment system for harmless treatment of sick and dead poultry and livestock

ActiveCN104998893BAchieve the effect of reuseTo achieve the effect of recyclingSolid waste disposalClimate change adaptationCombustionWater vapor

The invention discloses a harmless treatment technological process for dead poultry and livestock. The harmless treatment technological process comprises steps as follows: 1), automatic loading and breaking; 2), heating treatment; 3), dry melting; 4), waste gas treatment; 5), solid-liquid separation after melting. According to the technological process, hot oil circularly flows on the periphery of a melting barrel, so that the heating requirement is met, and the condition required by the dry melting is met; waste gas produced in the melting process is concentrated and discharged to a water vapor inlet of a water vapor chamber through a pipeline and is pyrolyzed by heat produced in an oil path, thereby meeting the emission requirement; the heat energy demand of a melting machine and the water vapor chamber is met by a combustion furnace in a single heating process, the energy is saved, the occupied space is reduced, and energy conservation and environmental protection are realized; after hot air entering the combustion furnace from an inlet is discharged from an outlet after circulation, part of the hot air is discharged into a high-temperature melting barrel through a pipeline, the melting efficiency is improved, the other part is discharged into a drying barrel, the heat energy recycling effect is realized, more energy is saved, and resources are sufficiently recycled.

Owner:ZHEJIANG DUOBAOTIAN AUTOMATION EQUIP CO LTD

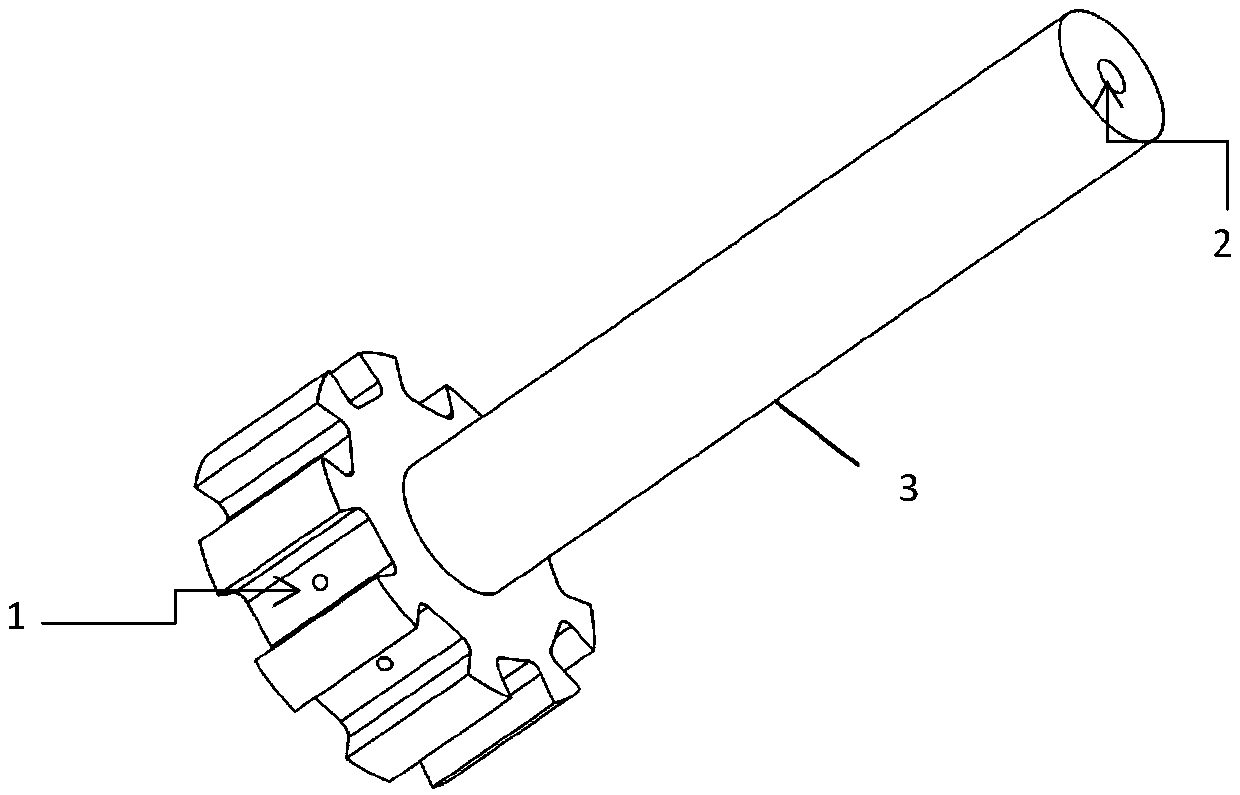

A method for swirling and blowing refining of low-pressure casting aluminum alloy melt with argon protection

ActiveCN109628773BSolve the problem of large melt contentImprove compactnessPressure castingHydrogen content

The invention discloses an argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt. The method comprises the following steps that an aluminum alloy materialis melted; a refining device is adopted for carrying out argon gas blowing refining on molten aluminum after melting is finished, and molten aluminum alloy metal is left to stand after refining is finished; and a mold shell model waits to be poured; and a casting is poured by adopting a low-pressure casting device connected with an air compressor through a low-pressure casting process. The problem that the content of the aluminum alloy melt casted by low-pressure casting is large is solved, the density and pressure bearing capacity of the aluminum alloy are improved, the situation that the metallurgical quality is unstable and even scrapping occurs due to the fact that the aluminum alloy melt is large in gas content is avoided, so that the production cost of castings is greatly reduced; and the hydrogen content of every 100 g of a sample after refining is less than 0.1 mL, and the production efficiency is improved while the gas content of the aluminum alloy melt is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

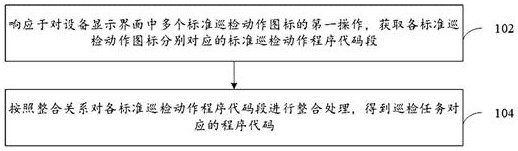

Inspection task coding method and device, electronic equipment and computer storage medium

InactiveCN113703637AImprove chemical efficiencyIntelligent editorsVisual/graphical programmingProgramming languageProcessing

The embodiment of the invention provides a routing inspection task coding method and device, electronic equipment and a computer storage medium, a routing inspection task is formed by integrating a plurality of standard routing inspection actions according to an integration relationship, and the method comprises the following steps: responding to a first operation on a plurality of standard routing inspection action icons in an equipment display interface; obtaining a standard inspection action program code segment corresponding to each standard inspection action icon, wherein each standard inspection action program code segment corresponds to one standard inspection action in the inspection task; and performing integration processing on each standard inspection action program code segment according to the integration relationship to obtain a program code corresponding to the inspection task. According to the embodiment of the invention, the coding efficiency of the inspection task can be improved.

Owner:北京红山信息科技研究院有限公司

Cavitation apparatus, configured to perform multiple simultaneous cavitations

ActiveUS10864495B1Enhanced cavitationShorten the timeSludge treatmentFlow mixersCavitation (process)Engineering

A cavitation apparatus capable of performing multiple, different-type cavitation processes taking place simultaneously in the same geometric space, thereby obtaining an effective cavitation process that is significantly faster than those provided by conventional cavitation apparatus. The cavitation apparatus can include consecutive and / or simultaneous cavitation units which are configured to carry out consecutive and / or simultaneous cavitation processes on a material flowing through the apparatus, such that effects of one or more prior cavitation processes are present in the material while the material is subjected to one or more further cavitation processes within the apparatus, enhancing the cavitation effects in a reduced amount of time and increasing productivity of the apparatus. In some embodiments, the apparatus can perform seven cavitation processes, of four different types.

Owner:ZUCCA TULLIA +1

The preparation method of polyurethane capsule

Owner:天津优米优科技有限公司

Argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt

ActiveCN109628773AImprove density and pressure bearing capacityAvoid unstable or even scrapped metallurgical qualityHydrogen contentAluminium alloy

The invention discloses an argon gas protection rotary blowing refining method for low-pressure casting of aluminum alloy melt. The method comprises the following steps that an aluminum alloy materialis melted; a refining device is adopted for carrying out argon gas blowing refining on molten aluminum after melting is finished, and molten aluminum alloy metal is left to stand after refining is finished; and a mold shell model waits to be poured; and a casting is poured by adopting a low-pressure casting device connected with an air compressor through a low-pressure casting process. The problem that the content of the aluminum alloy melt casted by low-pressure casting is large is solved, the density and pressure bearing capacity of the aluminum alloy are improved, the situation that the metallurgical quality is unstable and even scrapping occurs due to the fact that the aluminum alloy melt is large in gas content is avoided, so that the production cost of castings is greatly reduced; and the hydrogen content of every 100 g of a sample after refining is less than 0.1 mL, and the production efficiency is improved while the gas content of the aluminum alloy melt is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

Automatic material dissolving machine

InactiveCN108057364ARealize automatic mixingImprove chemical efficiencyRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention relates to an automatic material dissolving machine. The automatic material dissolving machine comprises a machine frame, a lifting mechanism, a motor, a material dissolving cylinder anda servo motor; the lifting mechanism can be placed in the machine frame in a vertically movable manner; the two ends of the lifting mechanism are respectively arranged on side rods on the two sides of the machine frame in a sleeving manner; the motor is fixedly placed on the lifting mechanism; a stirring paddle is arranged on an output shaft of the motor in a sleeving manner; the material dissolving cylinder is detachably placed at the bottom of the machine frame; the stirring paddle is positioned in the material dissolving cylinder; the servo motor is placed at the upper end of the machine frame; a gear is mounted on an output shaft of the servo motor in a sleeving manner; a gear rack is arranged at the upper end of the lifting mechanism; the gear on the output shaft of the servo motor is engaged with the gear rack; the servo motor drives the lifting mechanism to move vertically along the machine frame through the gear and the gear rack. Compared with the prior art, the automatic material dissolving machine is high in automation degree and uniform in stirring; the material dissolving efficiency is improved.

Owner:PIONEDA INTELLIGENT AUTOMATION TECH NINGBO

Apparatus for chemically toughening glass and method of chemically toughening glass using the same

ActiveUS9221714B2Improve chemical efficiencyImprove chemical toughening efficiencyOhmic-resistance heatingMicrowave heatingMicrowaveIon exchange

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Chemical efficiency increase in papermaking process

ActiveUS10876254B2Improve chemical efficiencyReduce the amount requiredPulp properties modificationMicroorganism/enzyme additionCellulose fiberIonic polymerization

A method of increasing chemical efficiency of chemical additives in a papermaking system includes the steps of providing thick stock pulp comprising soluble lignin, process water, and at least about 2% by weight of cellulosic fiber based on total weight of thick stock pulp, and adding at least one laccase enzyme and at least one organic polymer to the thick stock pulp to reduce the amount of soluble lignin therein. The organic polymer is chosen from cationic polymers, non-ionic polymers and combinations thereof.

Owner:SOLENIS TECH CAYMAN

A method for preparing capsules from oil-soluble etherified amino resin

ActiveCN105797660BGood lookingImprove chemical efficiencyMicroballoon preparationMicrocapsule preparationOil phaseCarbon chain

The invention provides a method for preparing capsules with oil-soluble etherified amino resin in situ as wall-forming monomers. The method includes the following steps that firstly, alkanol etherified amino resin with different carbon chain lengths and oil-soluble matter are mixed and fully stirred and dissolved to obtain a homogeneous oil phase; secondly, the prepared homogeneous oil phase is added into an aqueous solution containing emulsifier for sufficient stirring, shearing and emulsifying, and emulsion drops with the grain size ranging from 10 nm to 5 mm are obtained; thirdly, the emulsion drops are heated according to programs, the pH value is adjusted so that the etherified amino resin can have a polymerization and solidification reaction on the surfaces of the emulsion drops to form capsule walls covering the oil phase, and the capsules with nuclear shell structure are obtained after filtering and washing. The synthesis technology is simple, energy consumption is low, requirements of equipment are low, reaction conditions are easy to control, and the prospect of large-scale production is achieved. The easy capsulation method has very huge application prospects in the fields of pesticide, cosmetics and intelligent heat-storage temperature-adjusting textile.

Owner:天津优米优科技有限公司

Sewage treatment method

InactiveCN106430734AHigh chemical efficiencyImprove recycling ratesTreatment involving filtrationMultistage water/sewage treatmentWaste pondSewage

The invention discloses a sewage treatment method. The method applies a first sedimentation pond, a second sedimentation pond, a third sedimentation pond, a sewage pond and the like. The method applies multi-stage circulation reciprocation filtration treatment. The last stage is the recycling treatment and the like. Compared with the prior art, the method uses the multi-stage circulation treatment manner, adds different purifying agents for the different treatment of different levels of sewage water, and recycles the sewage water at last. The method has the advantage of high purifying efficiency and high reusable rate.

Owner:ANHUI XINRUI HEAVY IND

Automatic material dissolving machine

InactiveCN109806786AReasonable designRealize automatic mixingRotary stirring mixersMixer accessoriesMotor driveElectric machinery

The invention relates to the technical field of automatic equipment, and particularly relates to an automatic material dissolving machine. The automatic material dissolving machine comprises a rack, alifting mechanism, an electric motor, a material dissolving cylinder and a servo motor; the lifting mechanism is arranged in the rack in a vertical movable mode; the two ends of the lifting mechanismrespectively sleeve the side bars on the two sides of the rack; the electric motor is fixedly arranged on the lifting mechanism; the output shaft of the electric motor is vertically downwards; the output shaft of the electric motor is sleeved with a stirring paddle; the material dissolving cylinder is detachably arranged at the bottom of the rack; and the stirring paddle is positioned in the material dissolving cylinder. The automatic material dissolving machine is reasonable in design; and the servo motor drives the lifting mechanism to go up and down, so that control is more convenient, vertical movement is more accurate, and material dissolving efficiency is improved.

Owner:山东天拓电子科技有限公司

Exhaust gas detection and treatment, and related systems

InactiveUS20200157994A1Chemical reaction be improvedImprove estimation accuracyInternal combustion piston enginesExhaust apparatusExhaust gas emissionsExhaust fumes

A method for calculating the relative ratios of NH3 and NOx in exhaust gases to detect NH3 slip using NOx sensors includes measuring a first NOx level at an upstream NOx sensor, administering a first predetermined dose of urea to the exhaust gases, measuring a second NOx level at a downstream NOx sensor, administering a second predetermined dose of urea to the exhaust gases, measuring a third NOx level at the downstream NOx sensor, calculating a difference between the second NOx level and the third NOx level, and comparing the difference between the second NOx level and the third NOx level to a lookup table to determine a ratio of a concentration of NH3 to a concentration of NOx in the exhaust gases. Related systems and methods are also disclosed.

Owner:AGCO INT GMBH

Discharging system for moisture absorption and sweat releasing finishing agent

PendingCN110711538AReduce labor intensityImprove chemical efficiencyChemical/physical/physico-chemical stationary reactorsGrain treatmentsGrindingChemistry

The invention discloses a discharging system for a moisture absorption and sweat releasing finishing agent in the technical field of textile production. The system comprises an industrial reaction kettle, a reactor and a brush rod, wherein the reactor comprises a shell, a grinding plate, an upper-layer frame and a lower-layer frame; the grinding plate is arranged in the middle of an inner cavity of the shell; the upper-layer frame is positioned at the top of the grinding plate; the lower-layer frame is positioned at the bottom of the grinding plate; the upper-layer frame and the lower-layer frame are both located in an inner cavity of the shell. Through use of the reactor, workers can directly pour the moisture absorption and sweat releasing finishing agent (solid) into a reactor of an industrial reaction kettle; the reactor is used for feeding and grinding the moisture absorption and sweat releasing finishing agent (solid), so that the hands of workers are liberated, the labor intensity of the workers is reduced, meanwhile, the hydrolysis reaction of the moisture absorption and sweat releasing finishing agent (solid) in water is facilitated, and the material dissolving efficiencyof the moisture absorption and sweat releasing finishing agent (solid) in the industrial reaction kettle is improved.

Owner:江苏文理新材料科技有限公司

Synthetic method of cefathiamidine

The invention belongs to the field of medicine synthesis, and particularly relates to a synthesis method of cefathiamidine. The preparation method comprises the following steps: enabling N,N-diisopropylthiourea to react with ethyl chloroacetate, performing an acylation reaction by using thionyl chloride, and further performing a reaction with silanized 7-ACA to generate cefathiamidine. According to the synthetic method of cefathiamidine provided by the invention, two silanization reagents are used, and the second silanization reagent plays a role in catalysis of silanization, so silanization efficiency is improved; and N,N-diisopropylthiourea and ethyl chloroacetate generate acyl chloride which then react with 7-ACA to synthesize thiamidine, s chloroacetyl 7-ACA impurities generated by reaction of acyl chloride and 7-ACA are avoided.

Owner:SHANDONG LUOXIN PHARMA GRP HENGXIN PHARMA CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com