Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "High product consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

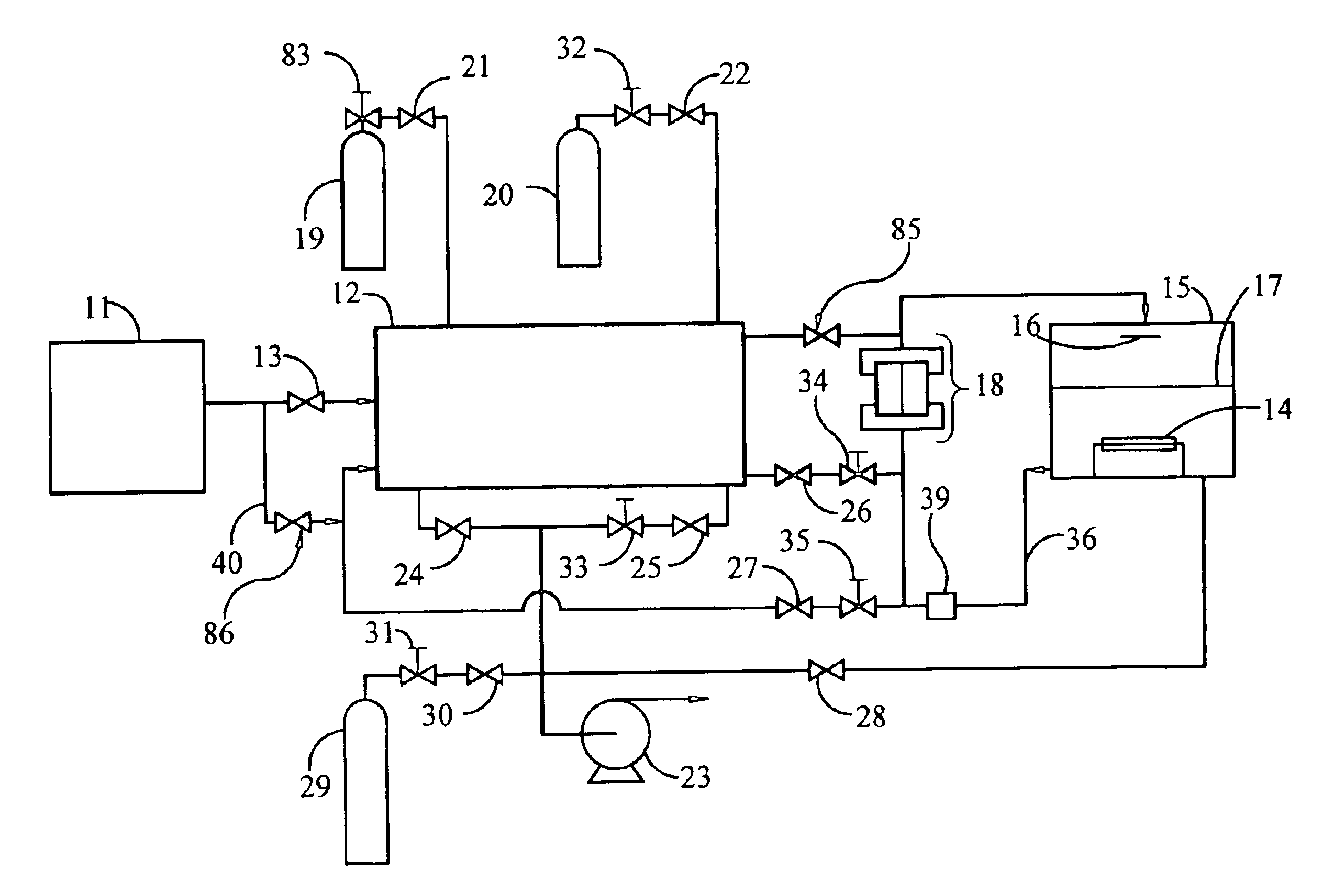

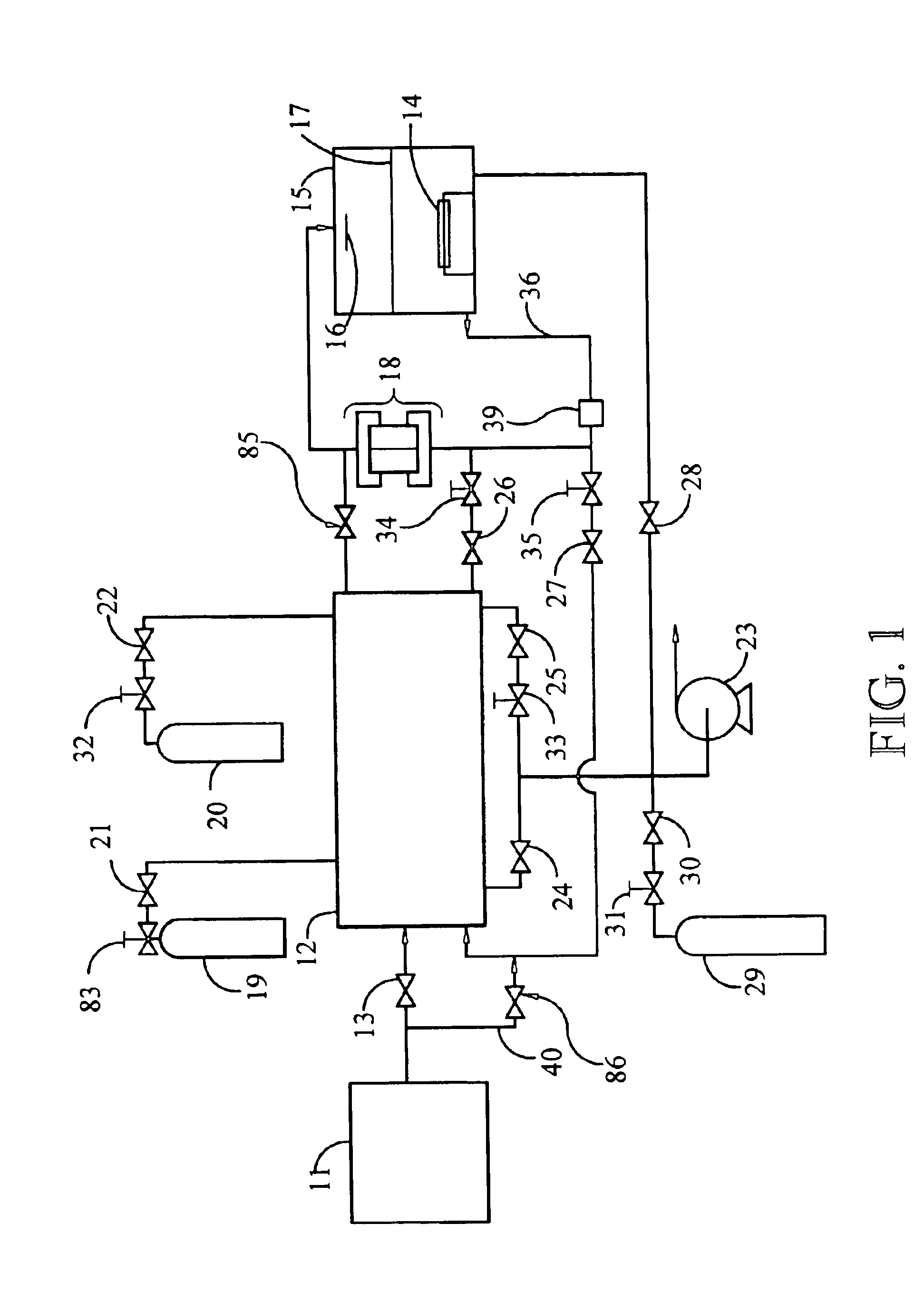

Apparatus and method for flow of process gas in an ultra-clean environment

InactiveUS6949202B1Improve effectivenessImprove processing efficiencyMaterial nanotechnologyDecorative surface effectsProduct gasProcess engineering

Processes for the addition or removal of a layer or region from a workpiece material by contact with a process gas in the manufacture of a microstructure are enhanced by the use of recirculation of the process gas. Recirculation is effected by a pump that has no sliding or abrading parts that contact the process gas, nor any wet (such as oil) seals or purge gas in the pump. Improved processing can be achieved by a process chamber that contains a baffle, a perforated plate, or both, appropriately situated in the chamber to deflect the incoming process gas and distribute it over the workpiece surface. In certain embodiments, a diluent gas is added to the recirculation loop and continuously circulated therein, followed by the bleeding of the process gas (such as an etchant gas) into the recirculation loop. Also, cooling of the process gas, etching chamber and / or sample platen can aid the etching process. The method is particularly useful for adding to or removing material from a sample of microscopic dimensions.

Owner:TEXAS INSTR INC +1

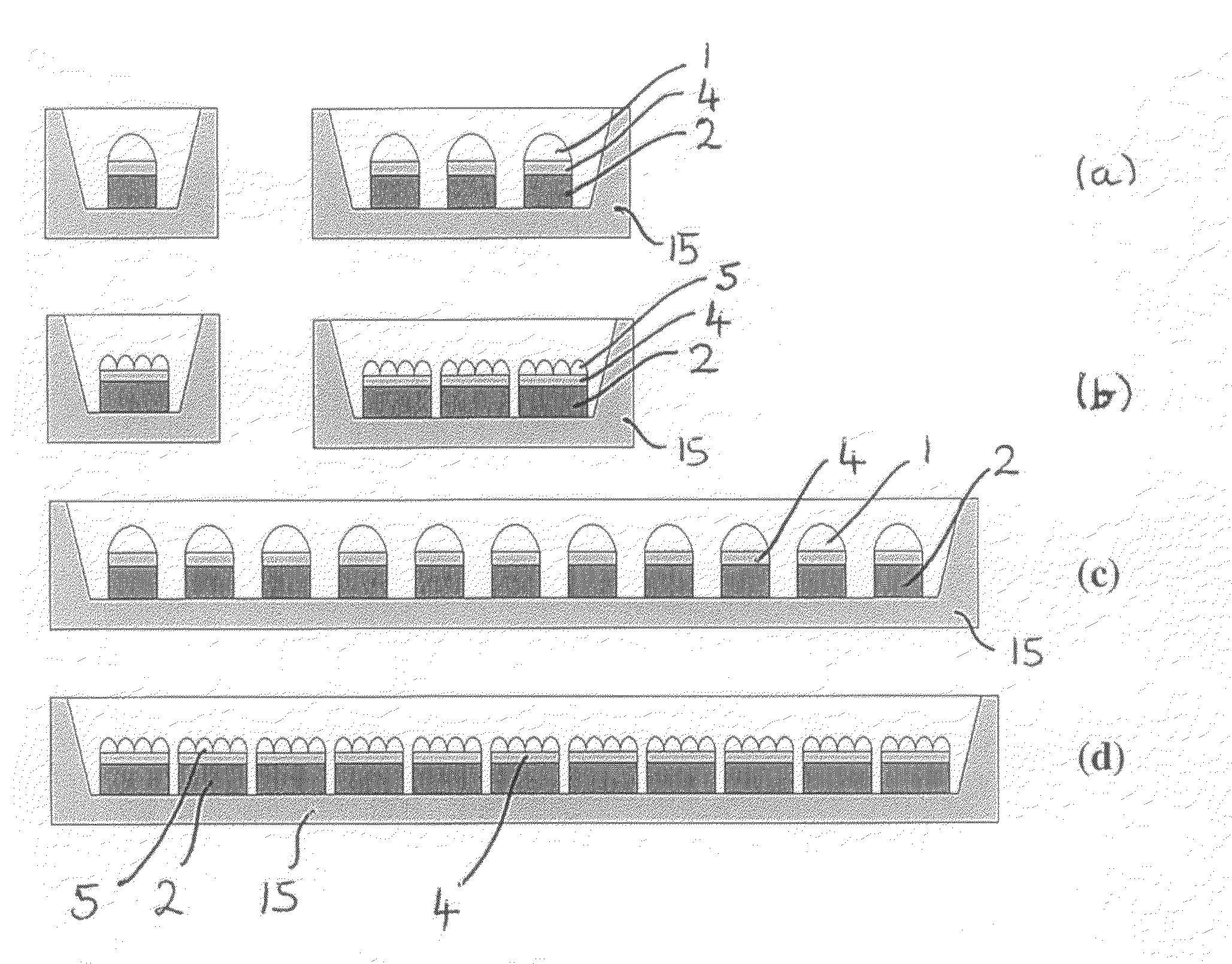

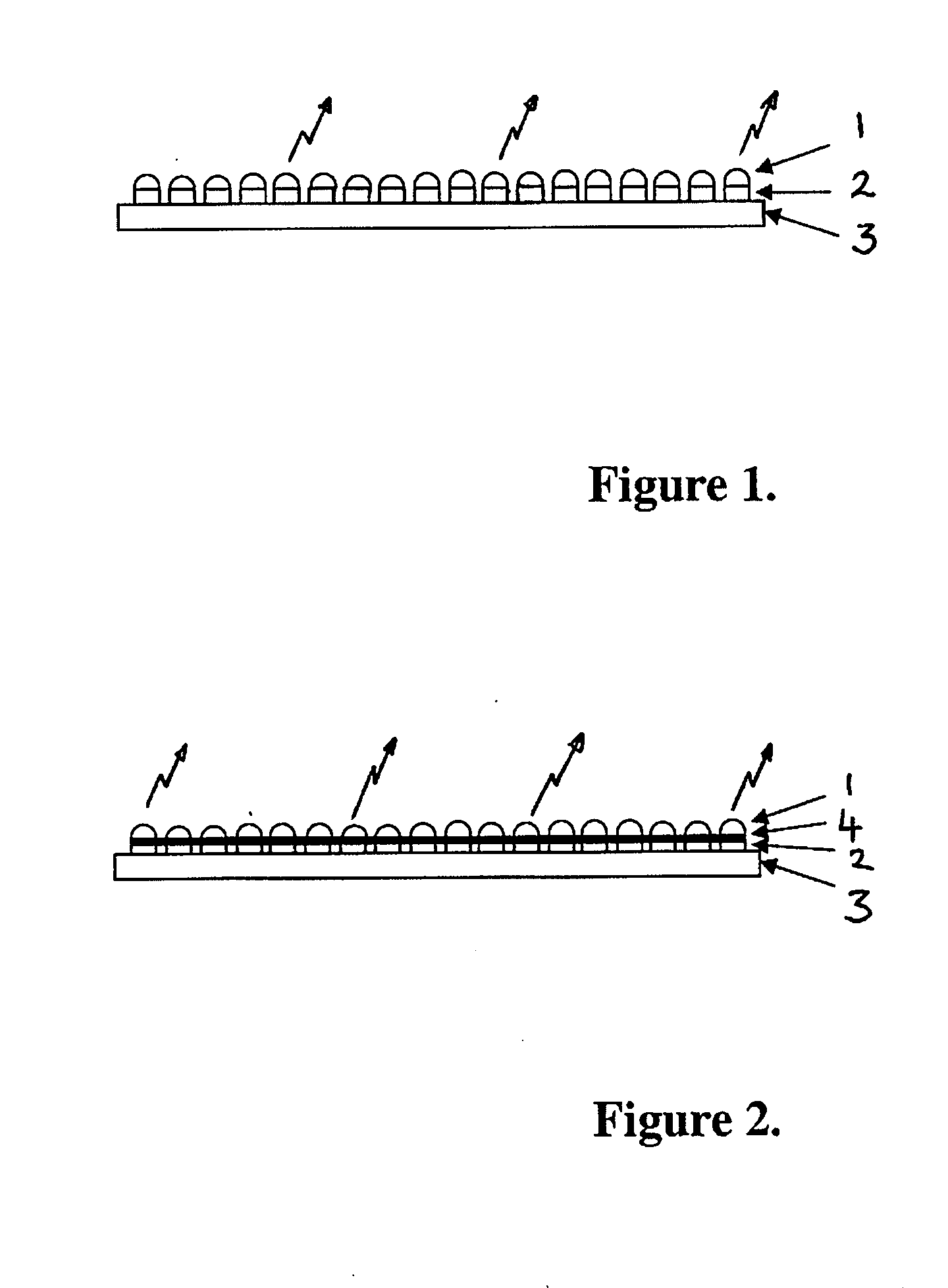

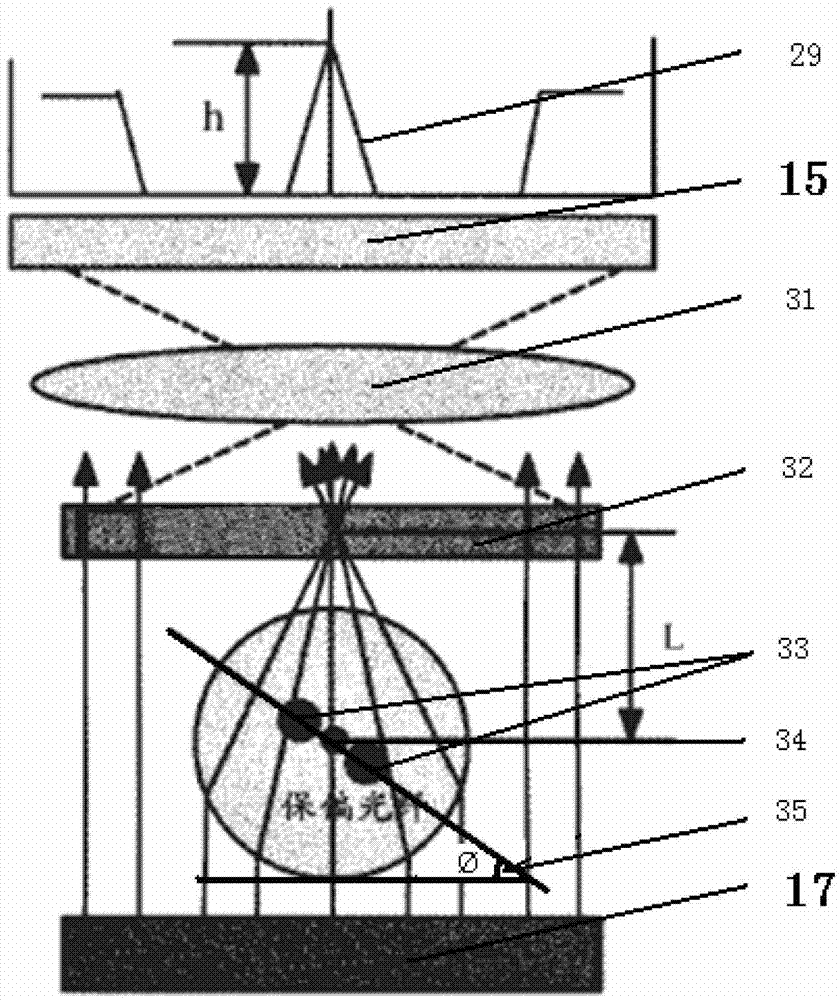

Light emitting diode assembly and method of fabrication

InactiveUS20080111141A1Light extraction efficiencyExcellent luminescence conversionDischarge tube luminescnet screensLamp detailsLed arrayLight emitting device

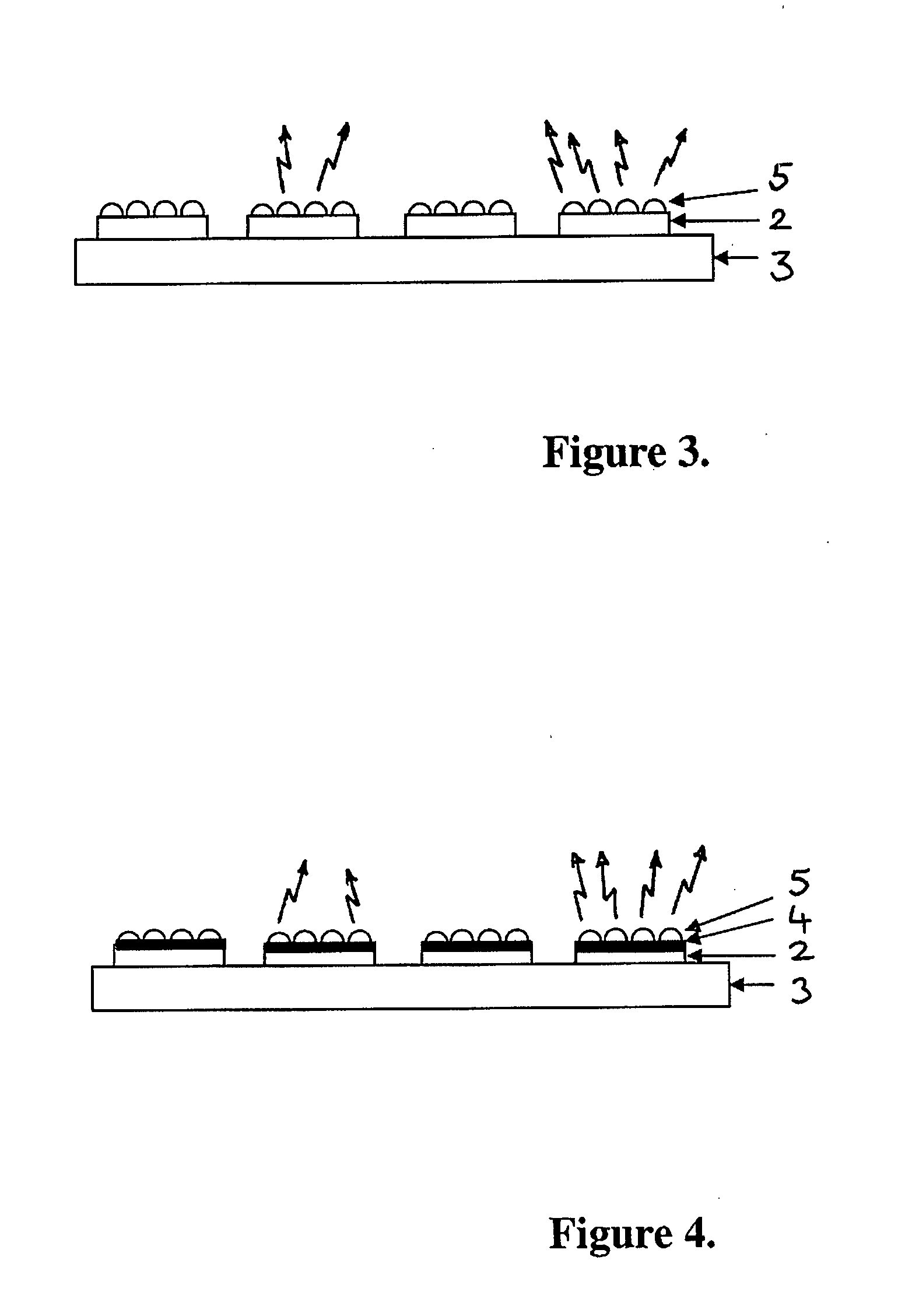

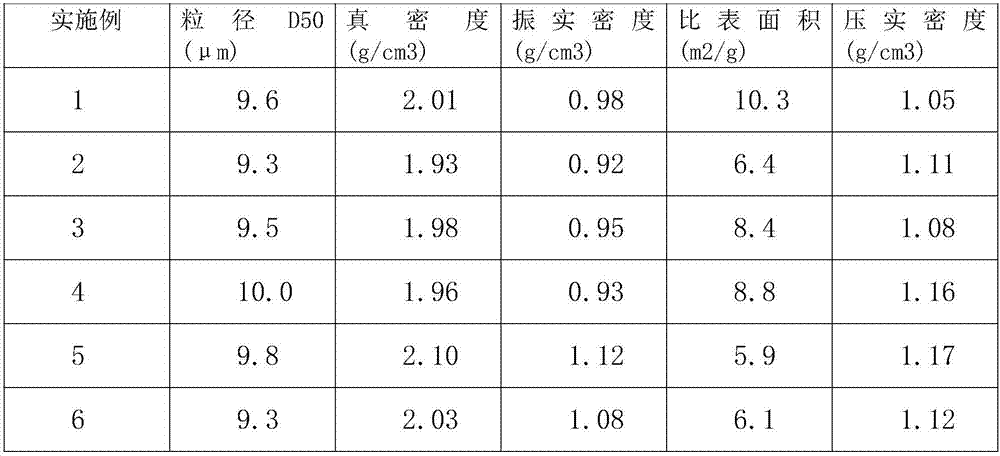

An LED assembly comprises an LED and a lens disposed adjacent to a light emitting surface of the LED. The area of cross-section of the lens projected onto the light emitting surface of the LED is substantially equal to or less than the area of the LED's light emitting surface. The light emitting device can comprise an array of LEDs and an array of lenses, in which at least one lens is associated with each member of the LED array and wherein the area of a cross-section of each lens projected onto the light emitting surface of its associated LED is substantially equal to or less than the area of the LED's light emitting surface.

Owner:INTEMATIX

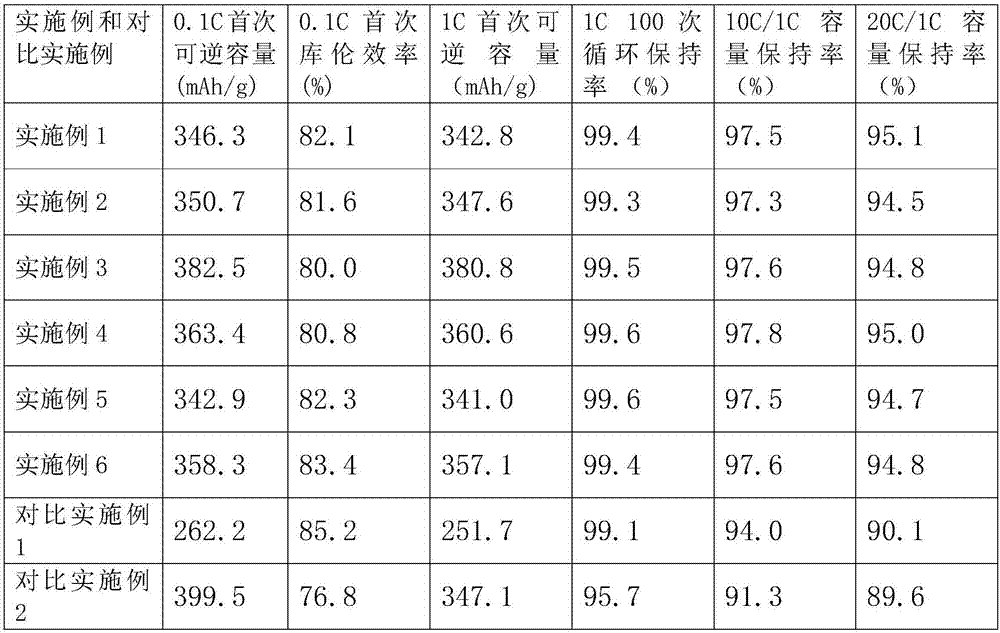

Preparation method of spherical hard carbon negative electrode material of high-capacity lithium ion battery

PendingCN106995210AOvercoming complexityOvercome costsCell electrodesSecondary cellsHigh rateCarbonization

The invention relates to the technical field of a lithium ion battery, in particular to a preparation method of a spherical hard carbon negative electrode material of a high-capacity lithium ion battery. The preparation method is characterized by comprising the following steps of (1) material mixing; (2) precrosslinked polymerization reaction; (3) crushing and grading; (4) polymer powder pelletizing treatment; (5) oxidation stability treatment; (6) pre-carbonization treatment; (7) carbonization treatment. Compared with the prior art, the preparation method has the advantages that the raw material sources are wide; the preparation process is simple; the structure and the processing performance of a precursor organic carbon source can be effectively improved through the precrosslinked polymerization reaction; the prepared spherical hard carbon has unique appearance and good pore diameter distribution, and also has the advantages of particle granularity distribution uniformity, high stacking density and the like; high capacity, high first coulombic efficiency, excellent high-rate performance and excellent circulation performance are also realized.

Owner:SHANGHAI SHANSHAN TECH CO LTD

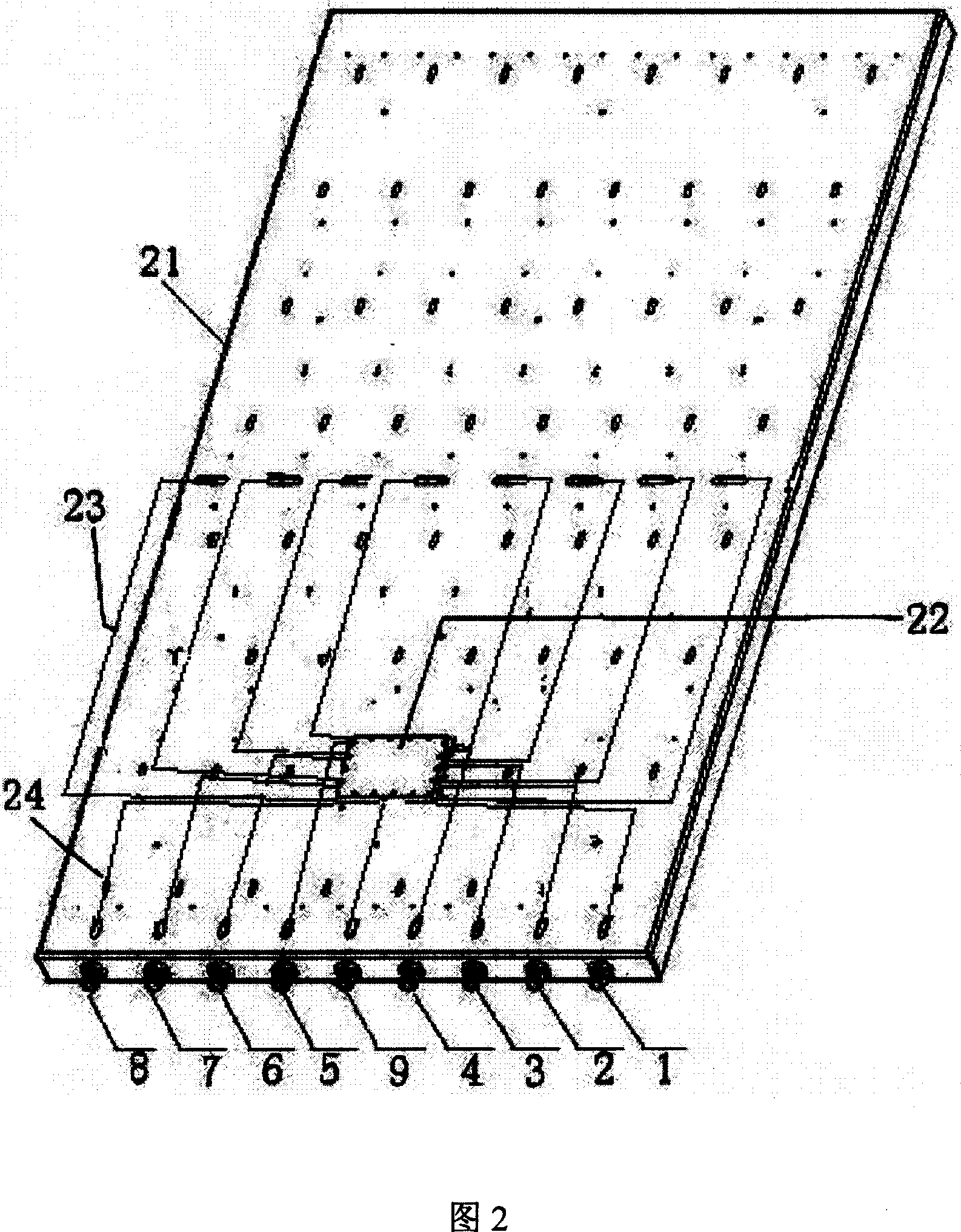

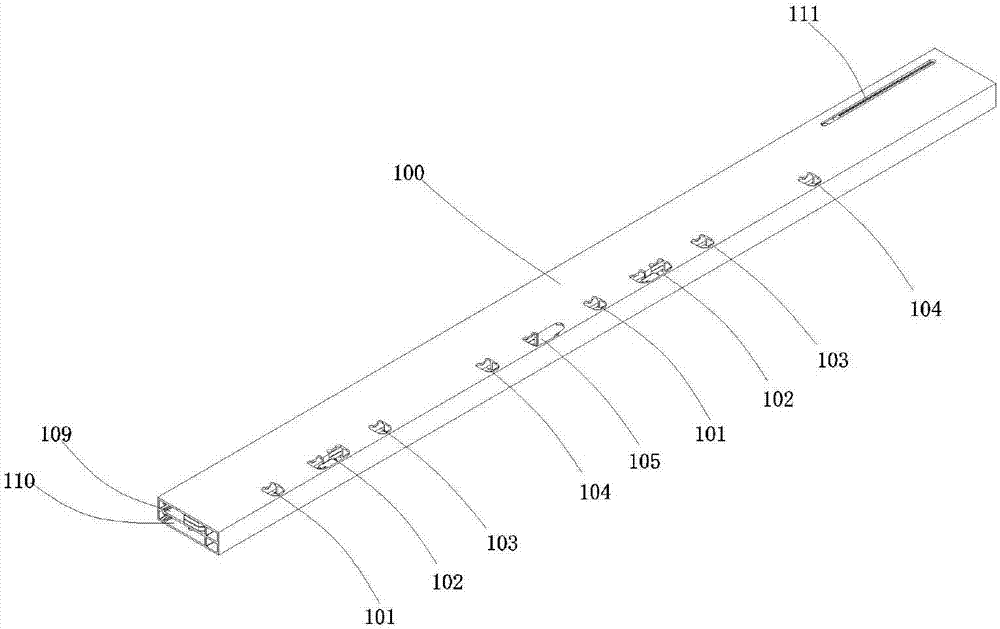

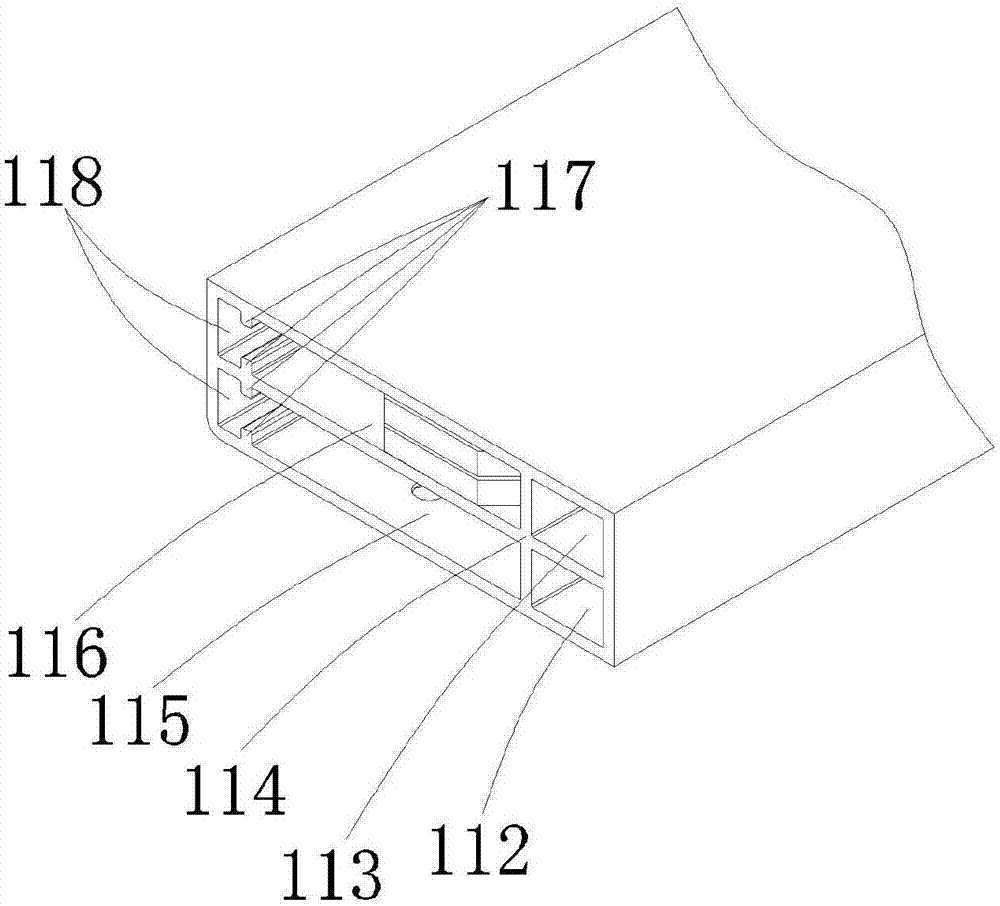

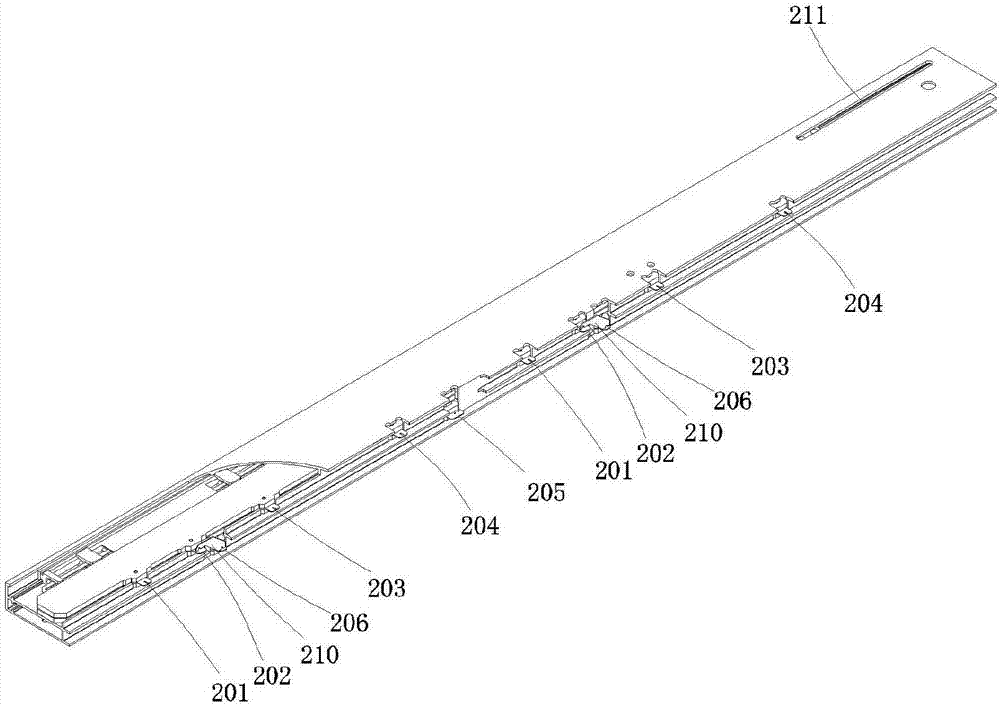

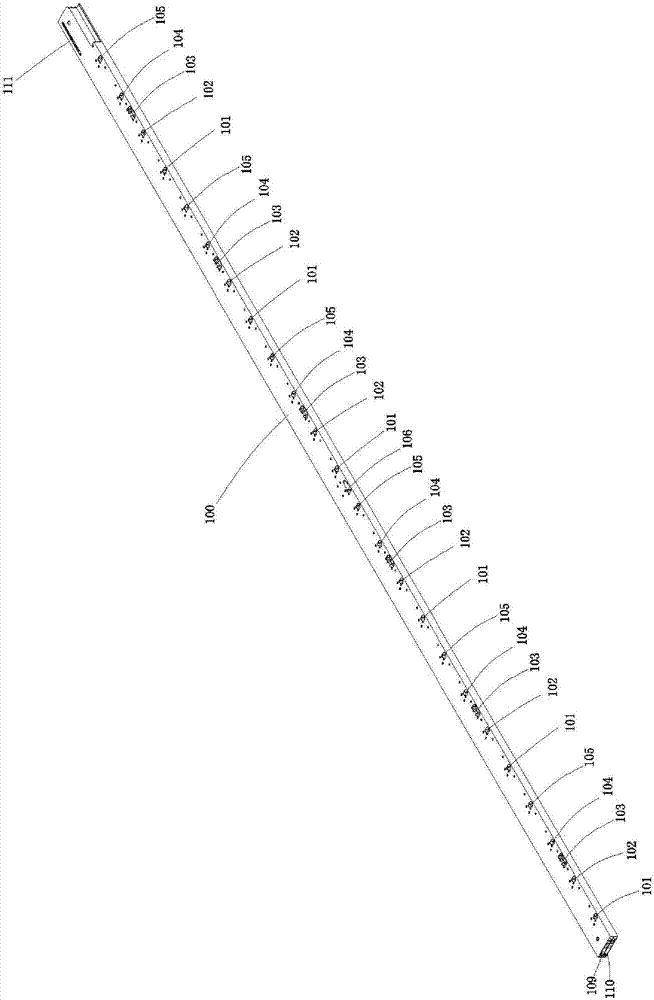

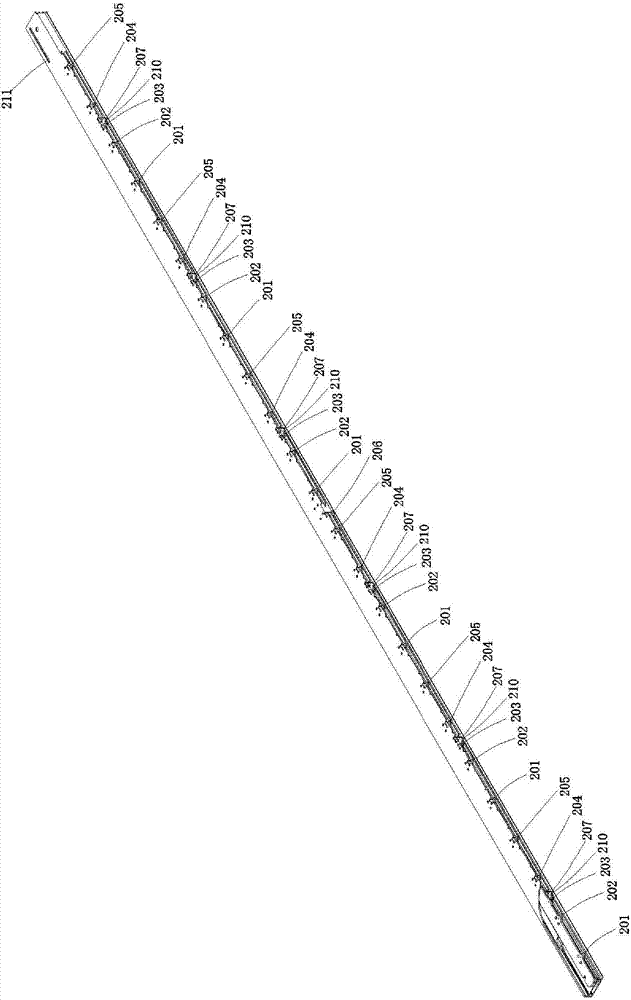

Super thin intelligent antenna for time division system

ActiveCN101005161AFix unstable performanceReduce thicknessAntenna arraysCode division multiplexCoaxial cableSmart antenna

Ultrathin intelligent antenna in use for time-division system includes feeding net, printed vibrator, calibration net, reflecting plate, and antenna outer cover. Characters are that the printed vibrators welded to the feeding net composed of microstrip circuit vertically constitute antenna array fixed on the reflecting plate. Through cable, antenna array connected to the calibration net constitutes main body of antenna. Connection cable for antenna array and calibration net is coaxial cable with SMA adaptor at two ends. There is certain proportional relation between distance from array to array and wavelength. The invention solves issue of unstable antenna performance existed for long time. Features are: lowering thickness of antenna, raising consistency and mechanical properties of antenna produced.

Owner:GUANGDONG SHENGLU TELECOMM TECH +1

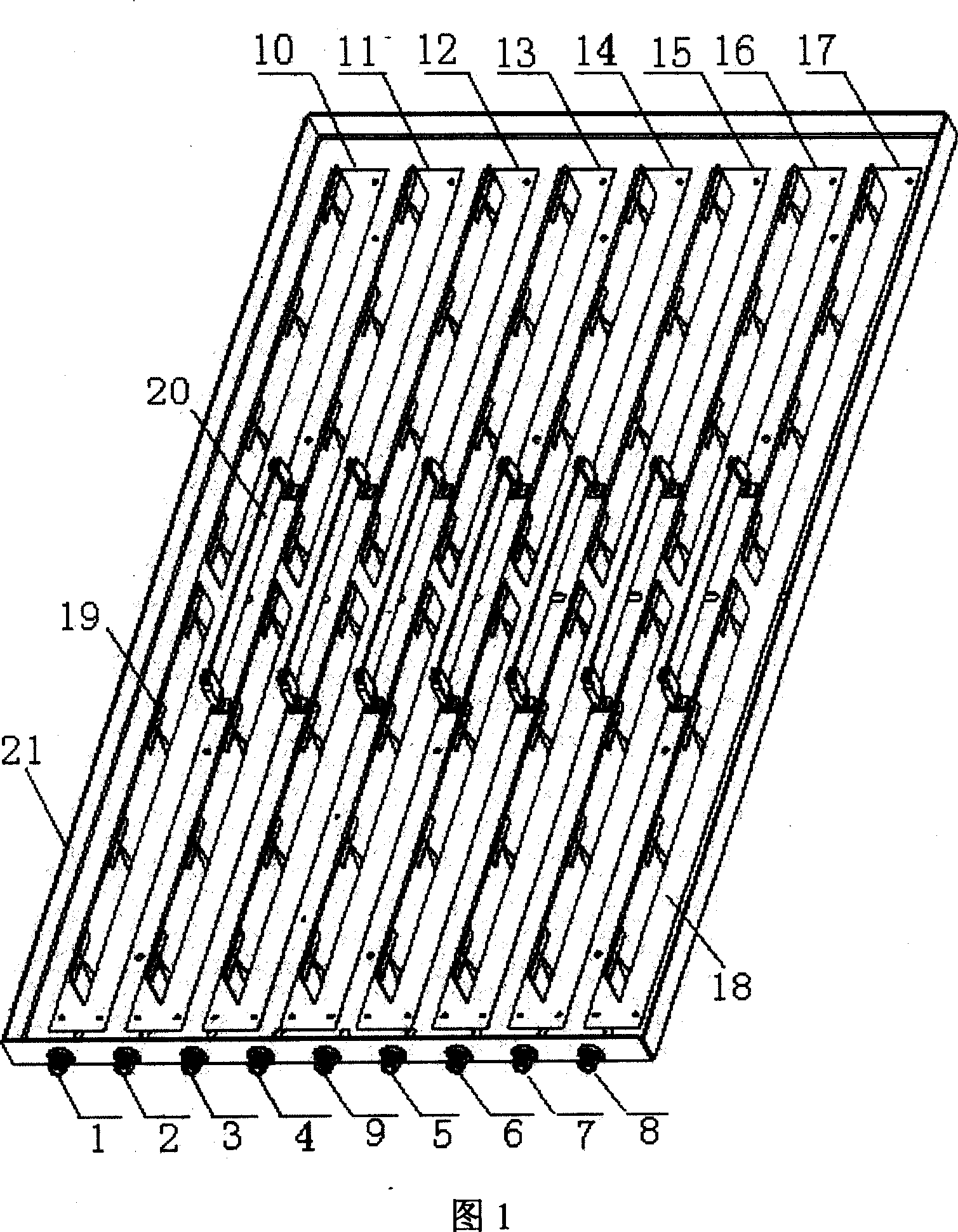

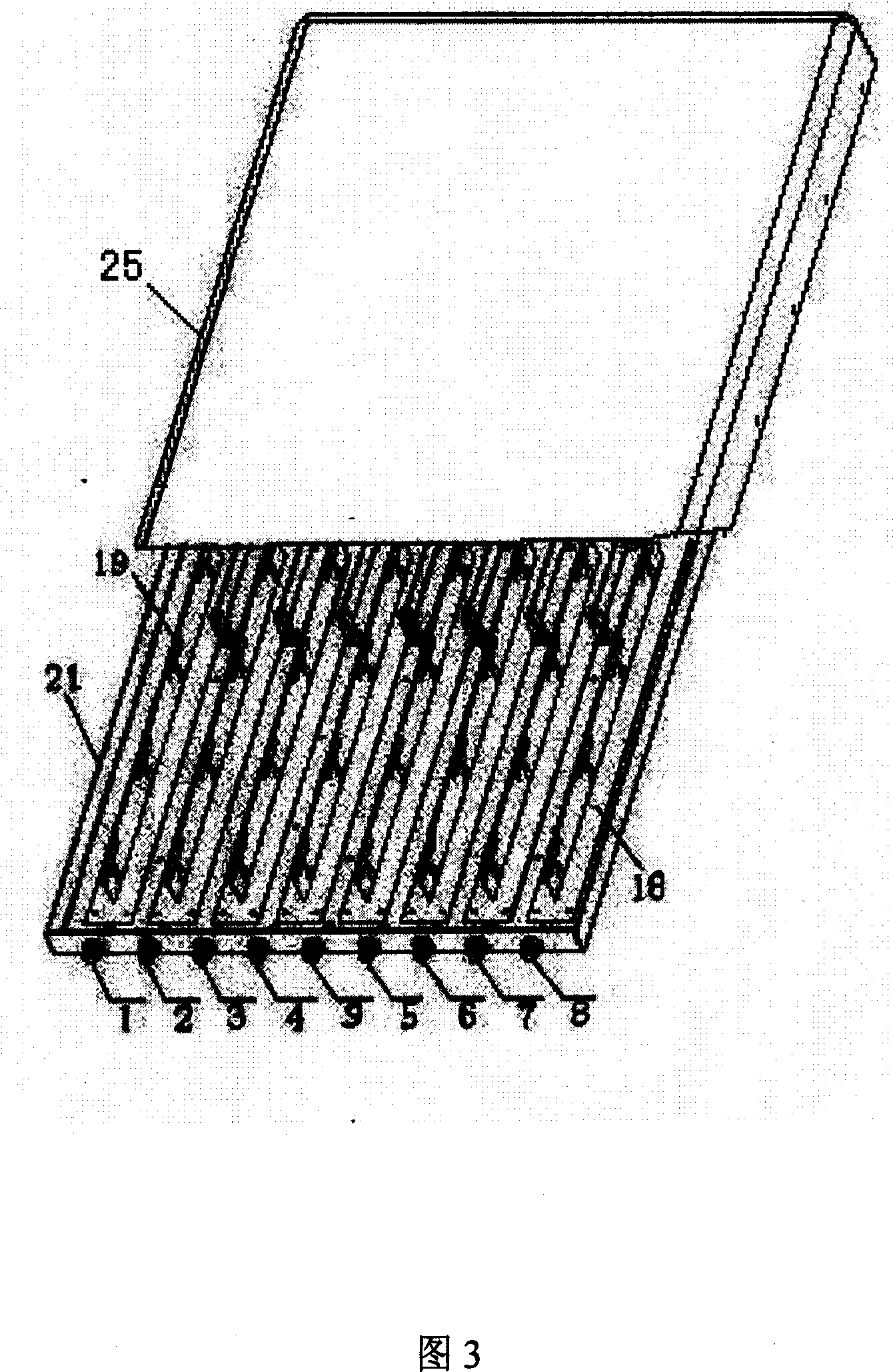

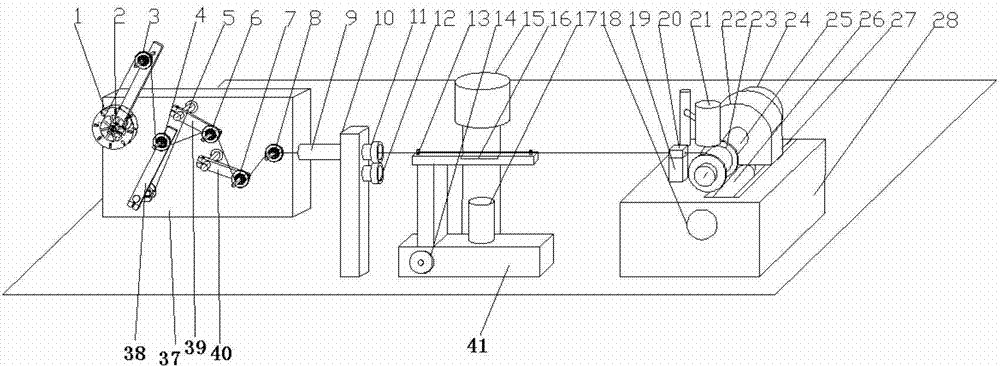

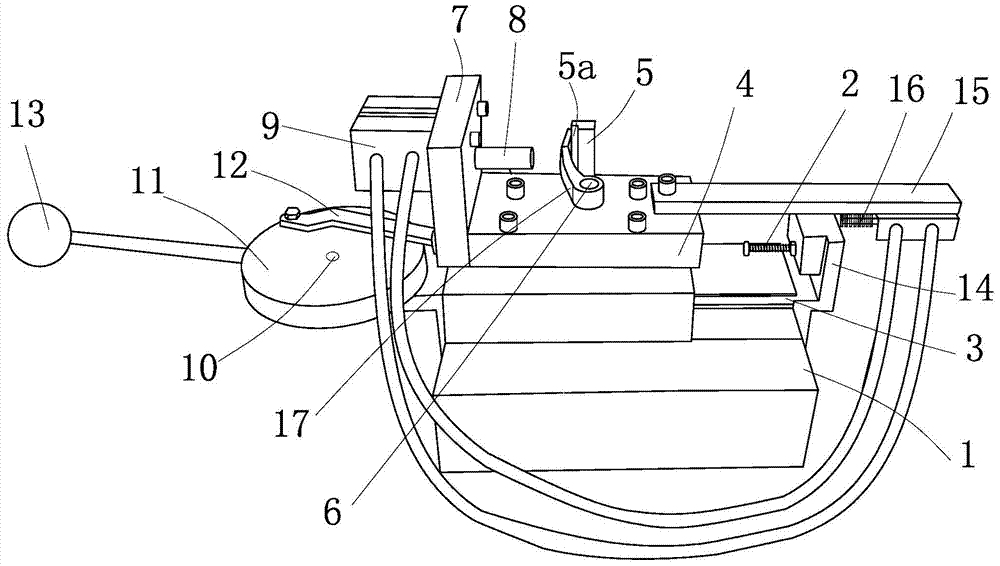

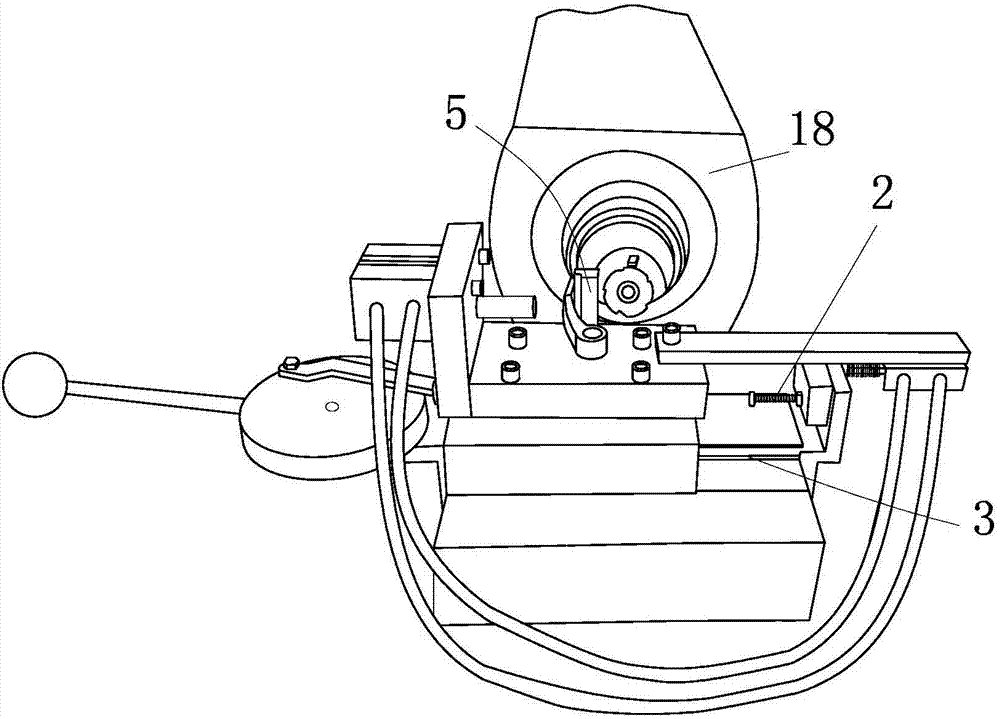

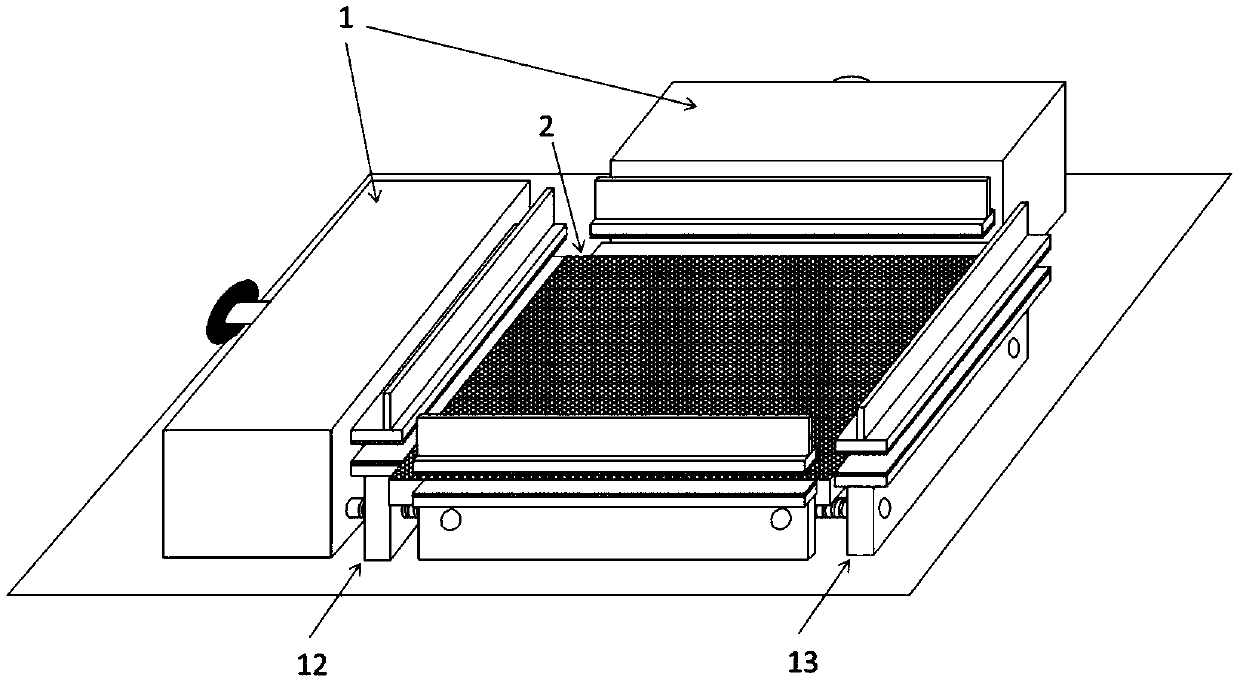

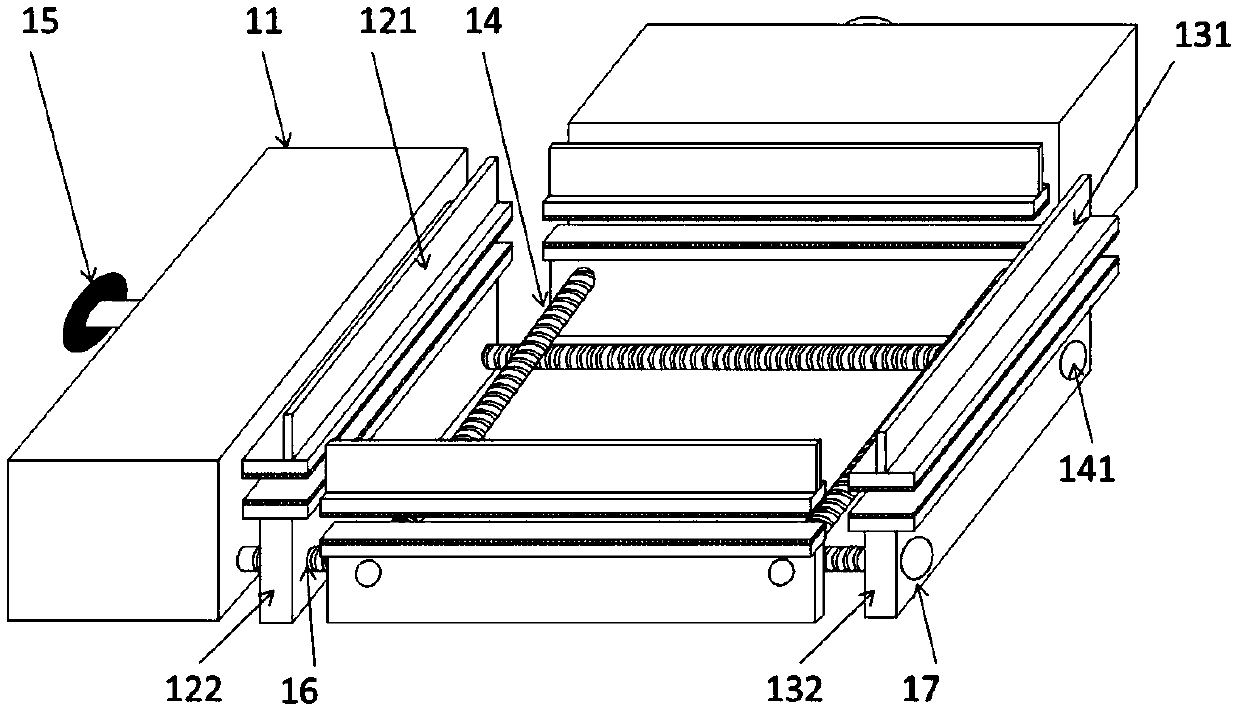

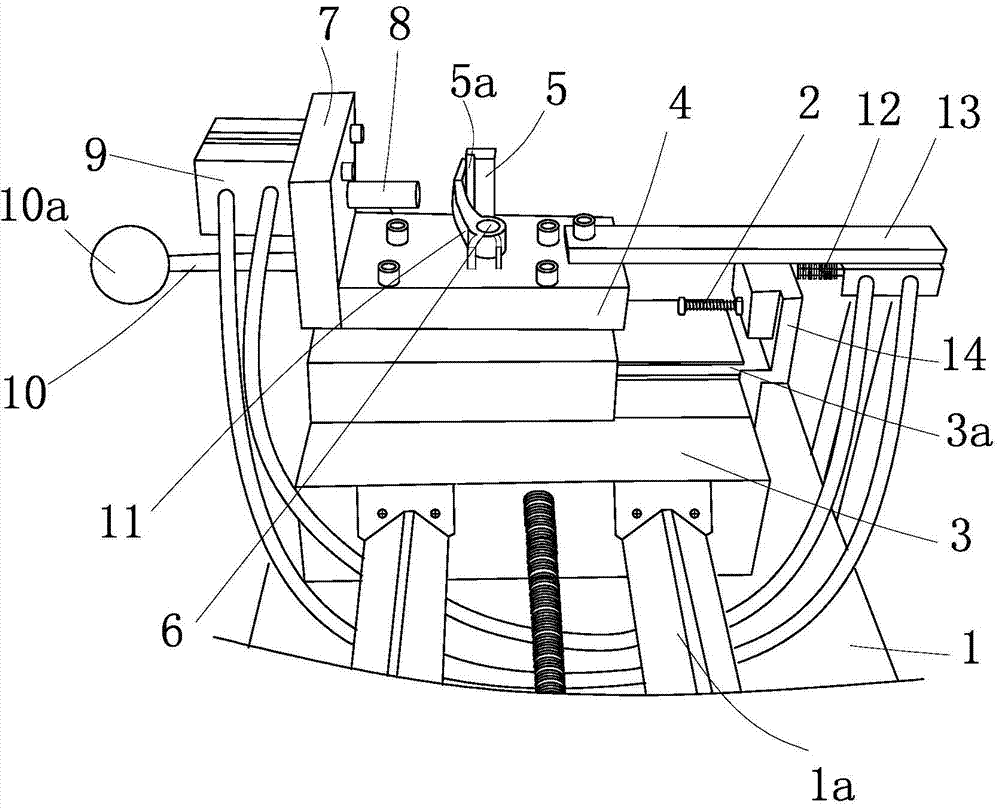

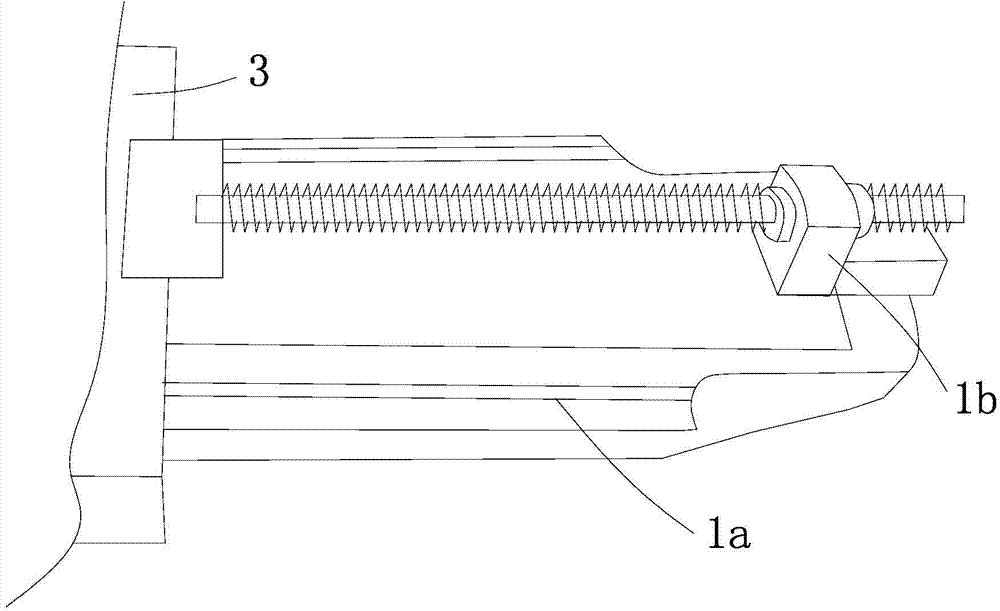

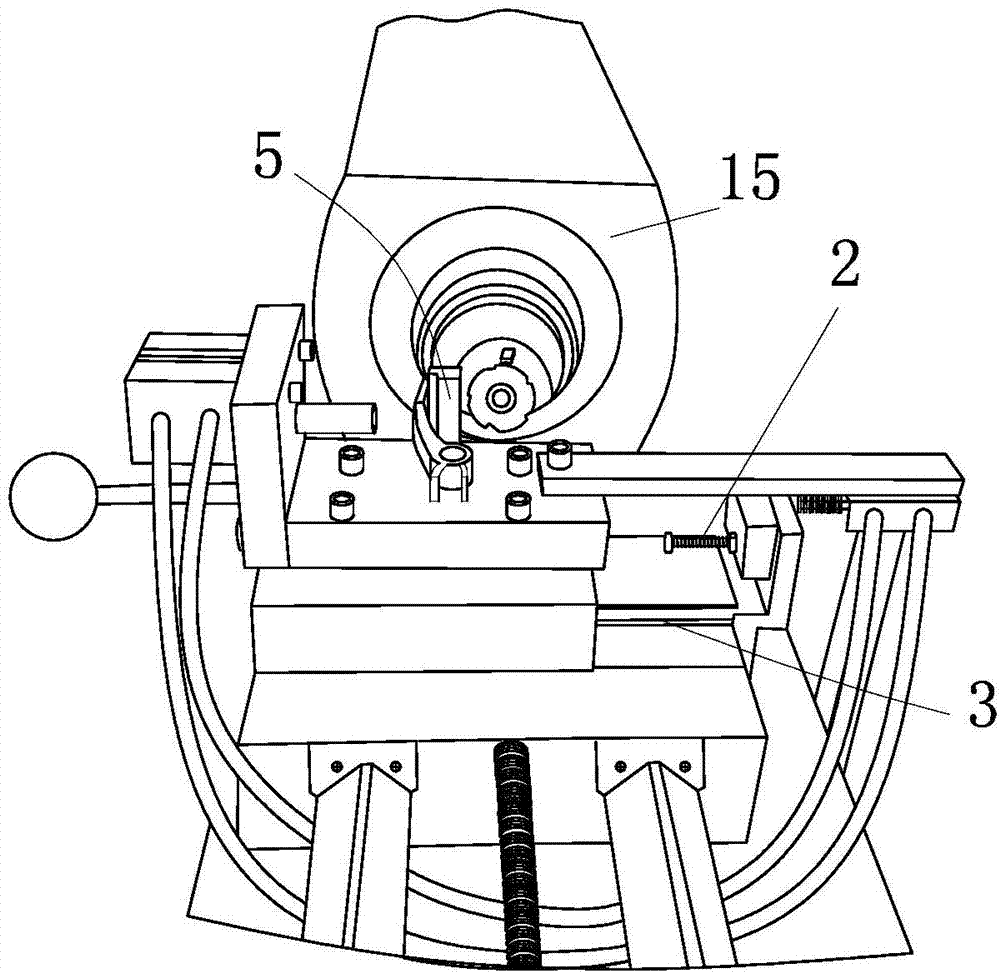

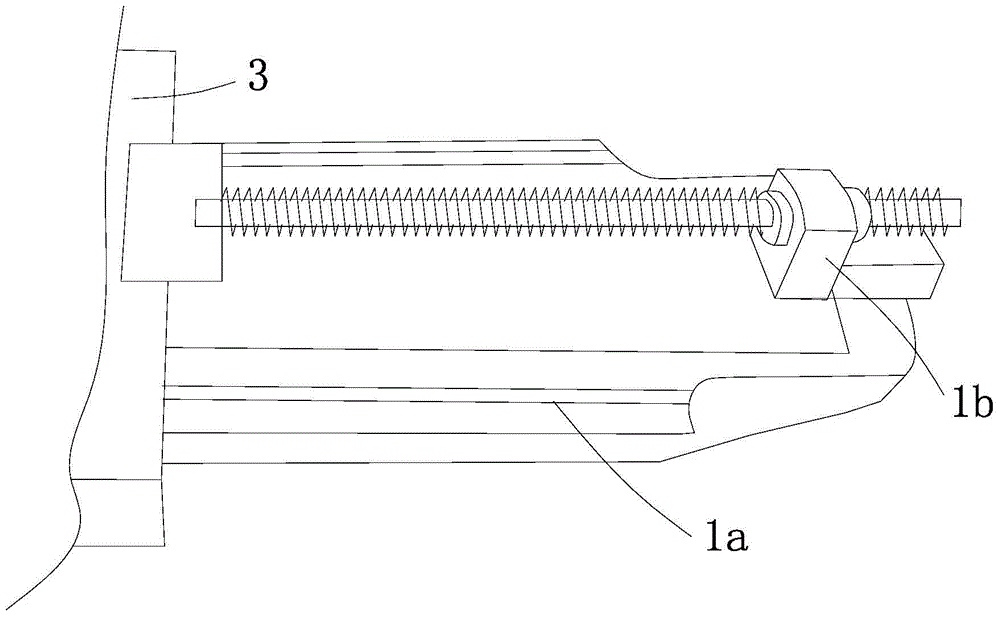

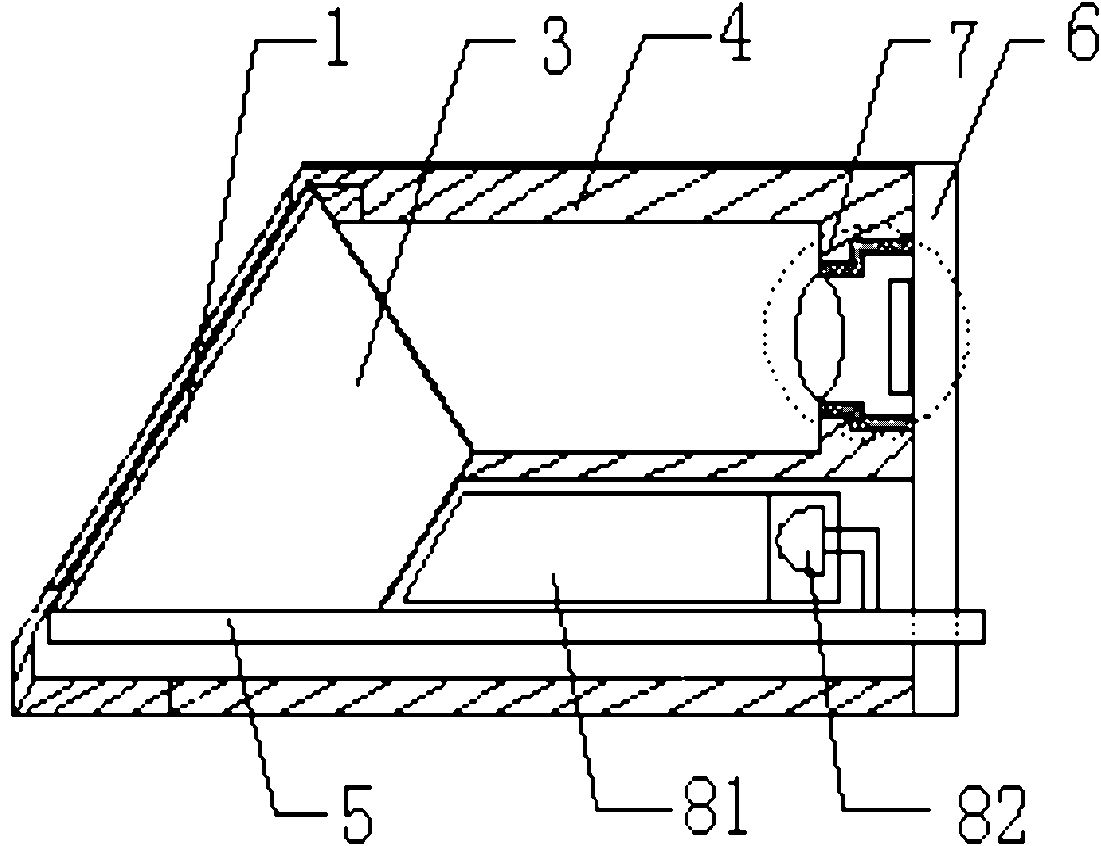

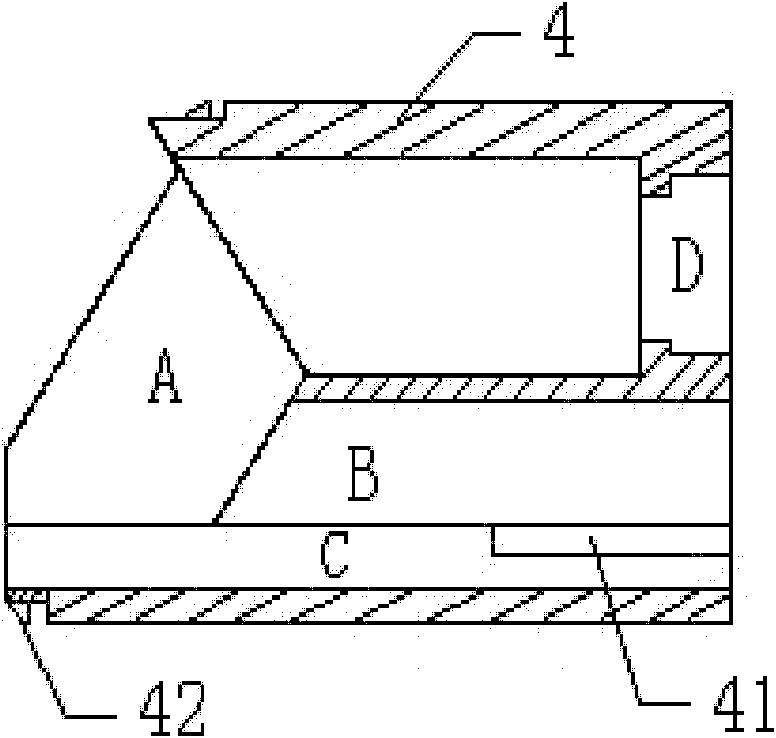

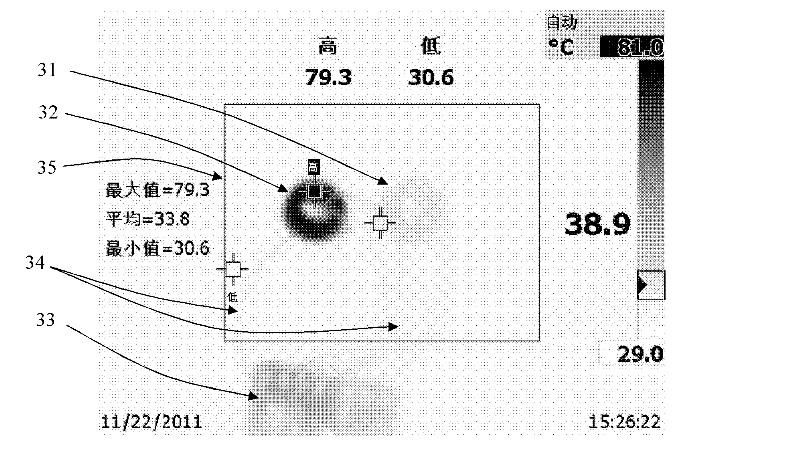

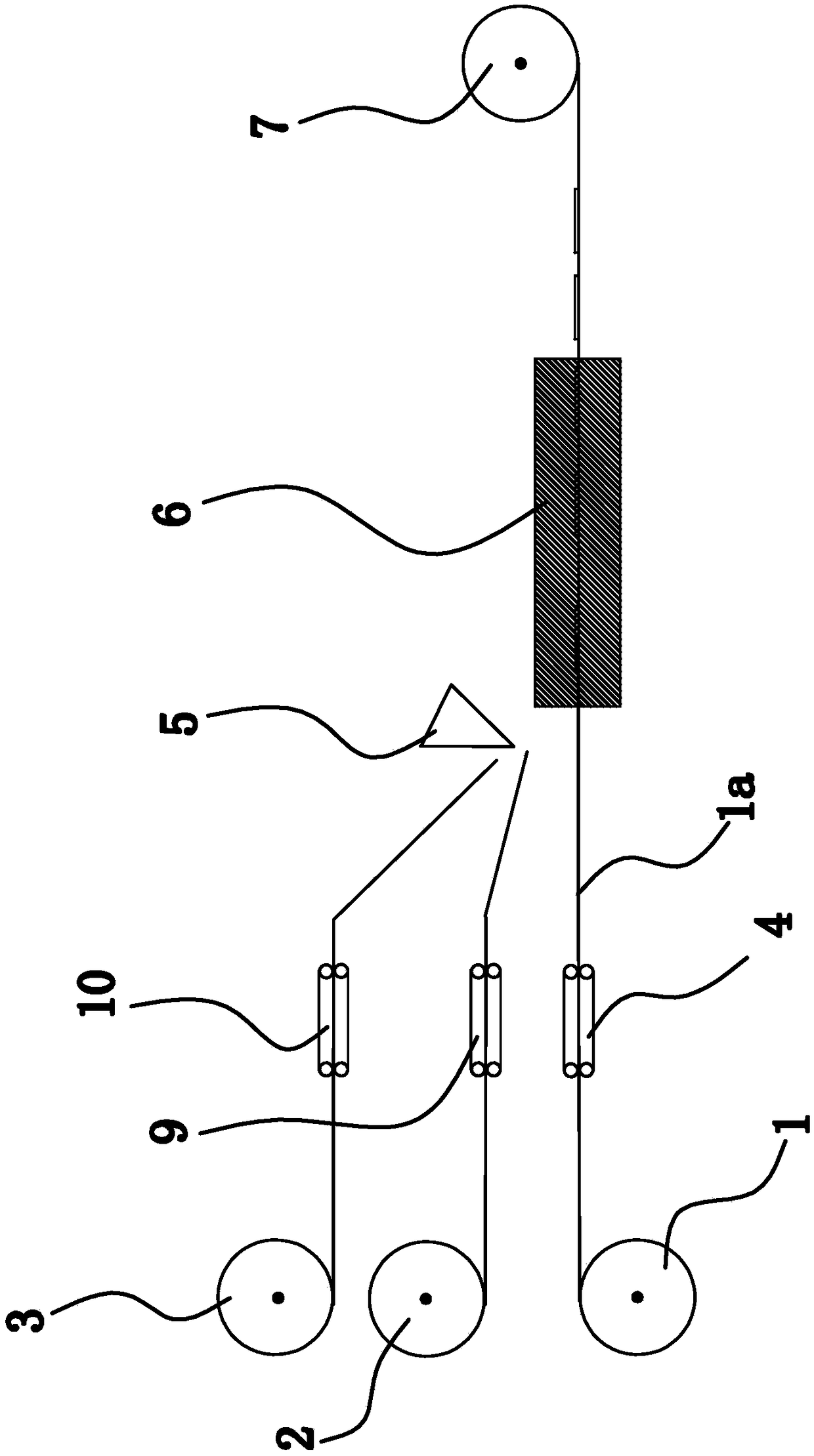

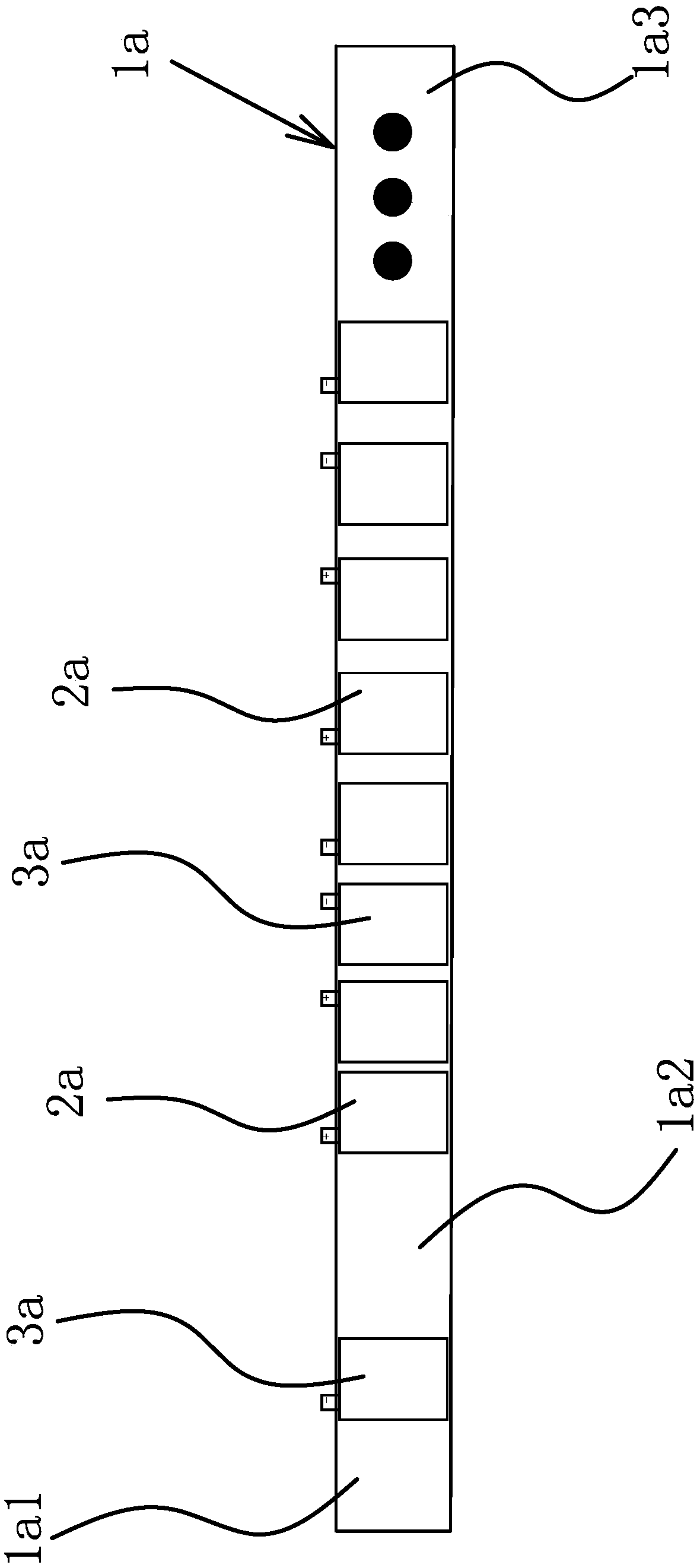

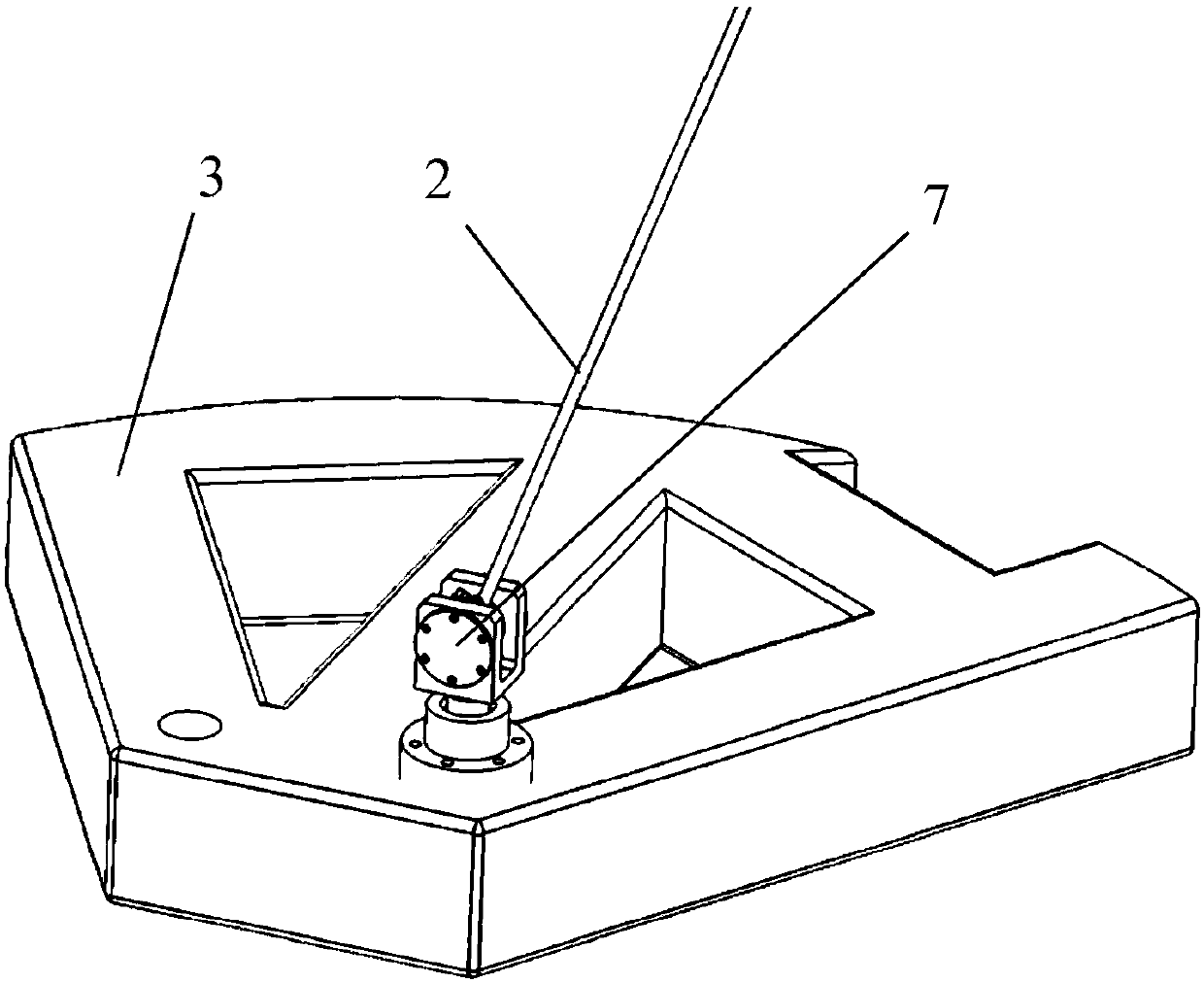

Full-fiber sensing probe winding device and winding method

ActiveCN103076758AEvenly distributedEasy to operateNumerical controlMechanical pressure/force controlFiberControl system

The invention discloses a full-fiber sensing probe winding device and a winding method. The full-fiber sensing probe winding device comprises a tension control system, a glue coating control system, a fiber state adjusting system and a wire arranging and winding system; and the tension control system comprises a preparing ring bracket (1), a tension control motor (2), a fiber guiding wheel (3), a dance wheel (4), a tension sensor (5), a first adjusting wheel (6), a second adjusting wheel (7) and a guiding pulley (8) which are arranged on a support block (37). When the full-fiber sensing probe winding device is adopted for winding fiber, the winding device and the method have the advantages that the winding tension is constant and the wire arranging is precise, and further, the operation is simple, the production consistency is high, the reliability is high, and the like.

Owner:HUNAN HAIDUN OPTICAL FIBER SENSING TECH ENG LAB

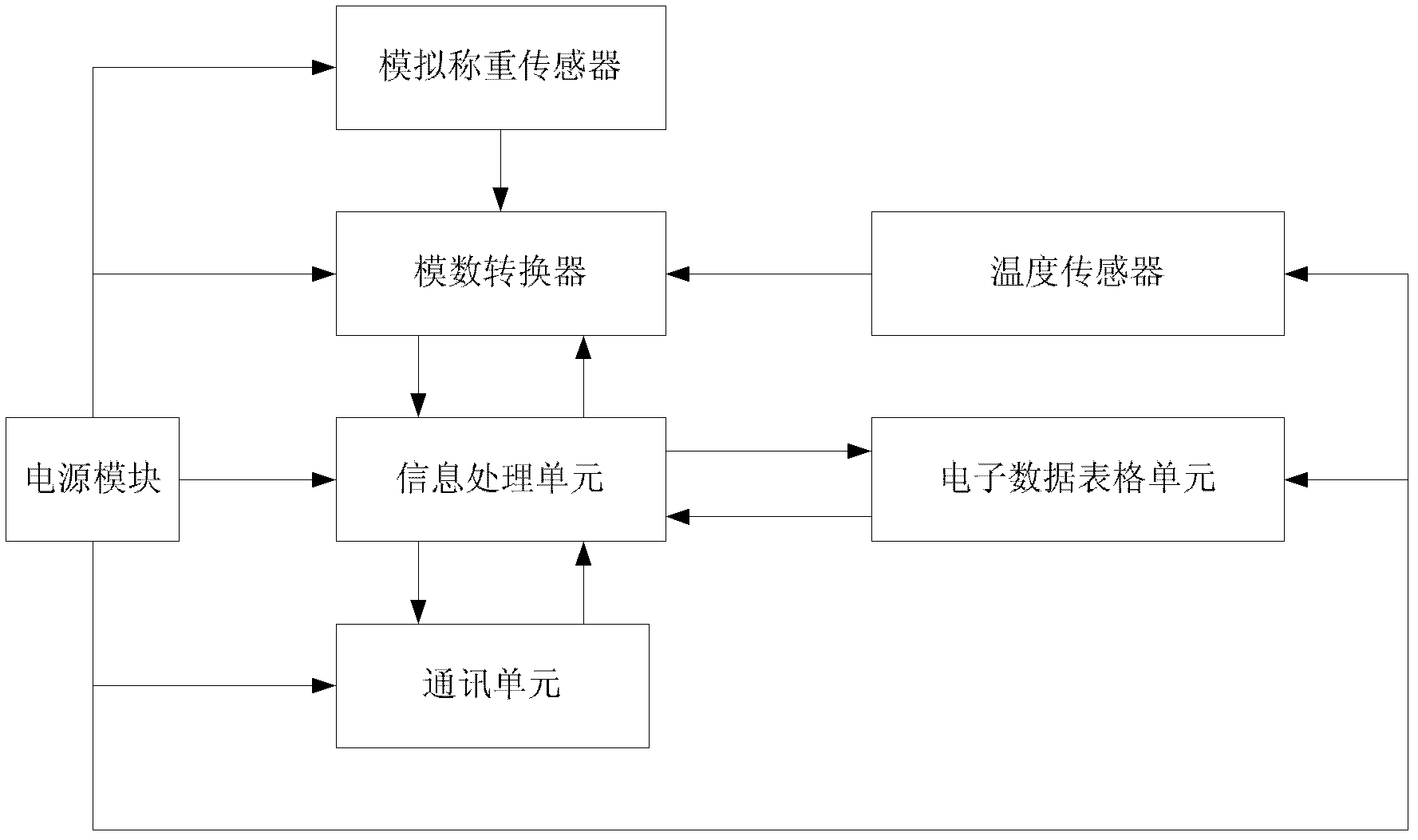

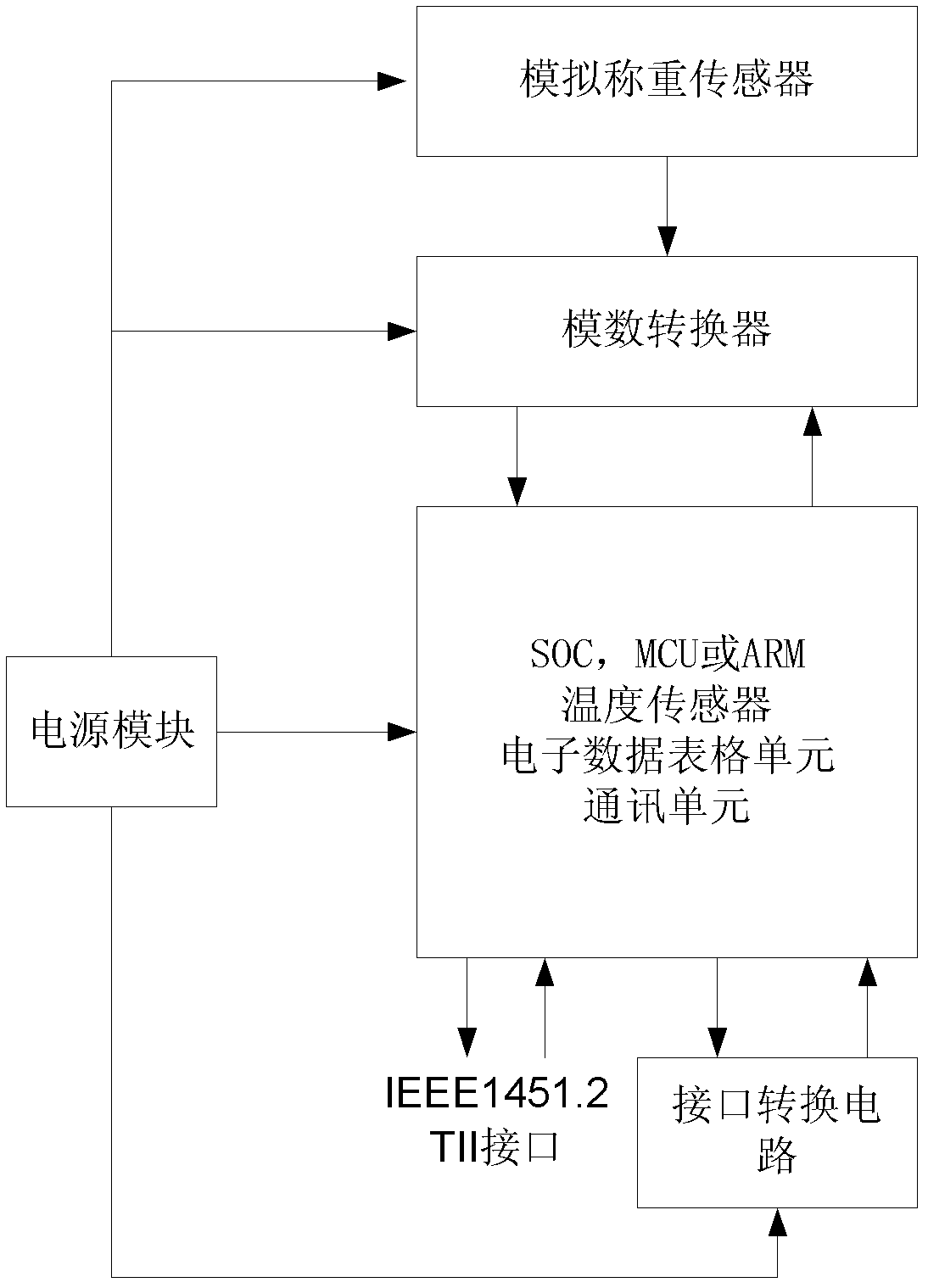

Networking intelligent digital weighing sensor

InactiveCN102538918AMeets the requirements of the Independent Interface (TII)Easy to addWeighing apparatus using elastically-deformable membersWeighing auxillary devicesSmart transducerImage resolution

The invention discloses a networking intelligent digital weighing sensor, which comprises a simulation weighing sensor, a temperature sensor, an analog-to-digital converter, an electronic data table unit, an information processing unit, a communication unit and a power supply module, wherein the electronic data table unit conforms to IEEE1415.2 standards, the simulation weighing sensor is used for collecting weight data, the temperature sensor is used for collecting real-time temperature data, the analog-to-digital converter is used for converting the weight data and the real-time temperature data into corresponding digital signals, the information processing unit is used for outputting weight data after compensation calibration, and the communication unit is provided with a universal serial interface and a communication interface compatible with IEEE1415.2. The technical scheme conforms to requirements of the IEEE1415.2 standards on an independent interface of the intelligent sensor and simultaneously solves the problems that in the sensor manufacture process, the precision is difficult to improve, the production efficiency is low, the finished product rate is low and the like, and in addition, the digital weighing sensors with the same resolution ratio can be produced in batches.

Owner:CHIPSEA TECH SHENZHEN CO LTD

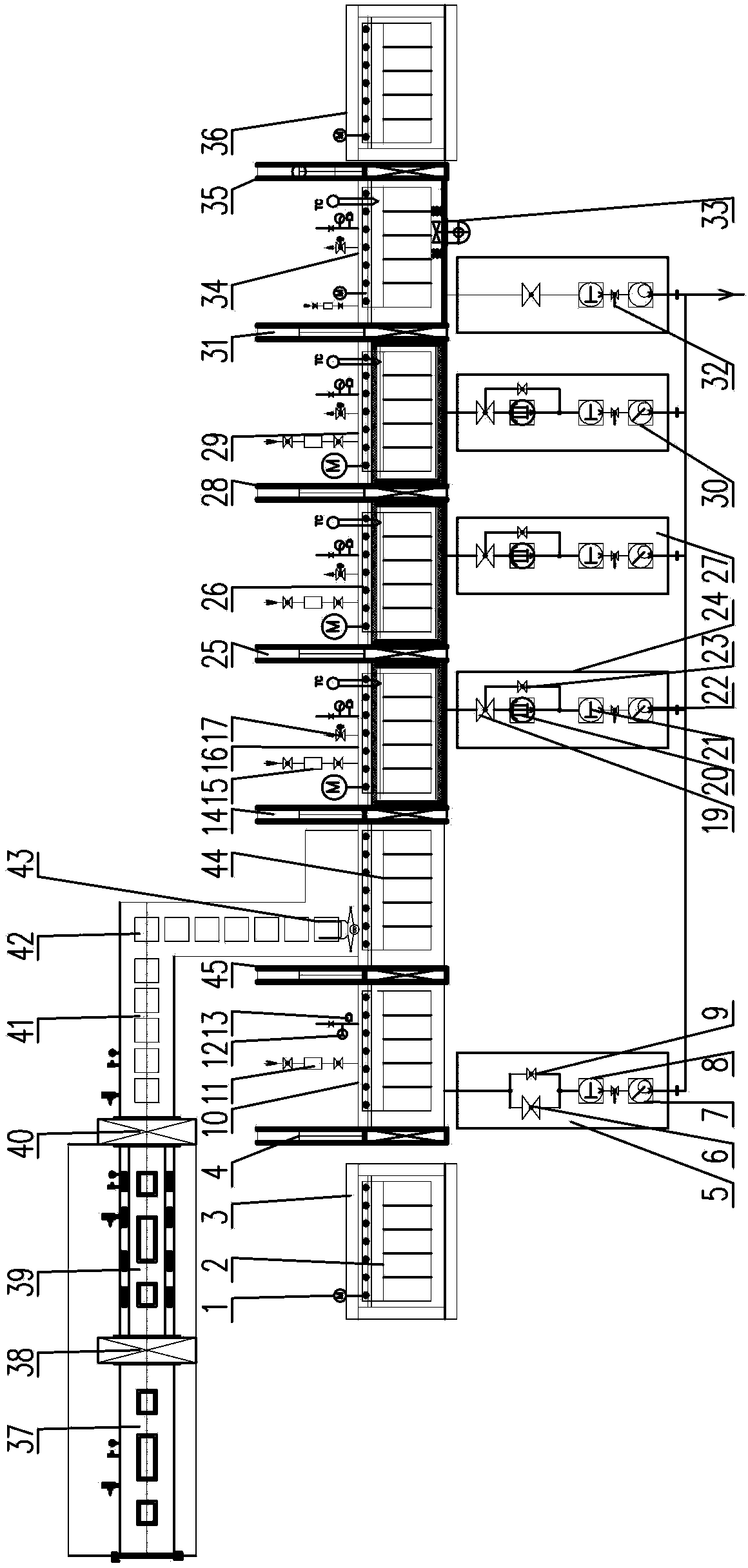

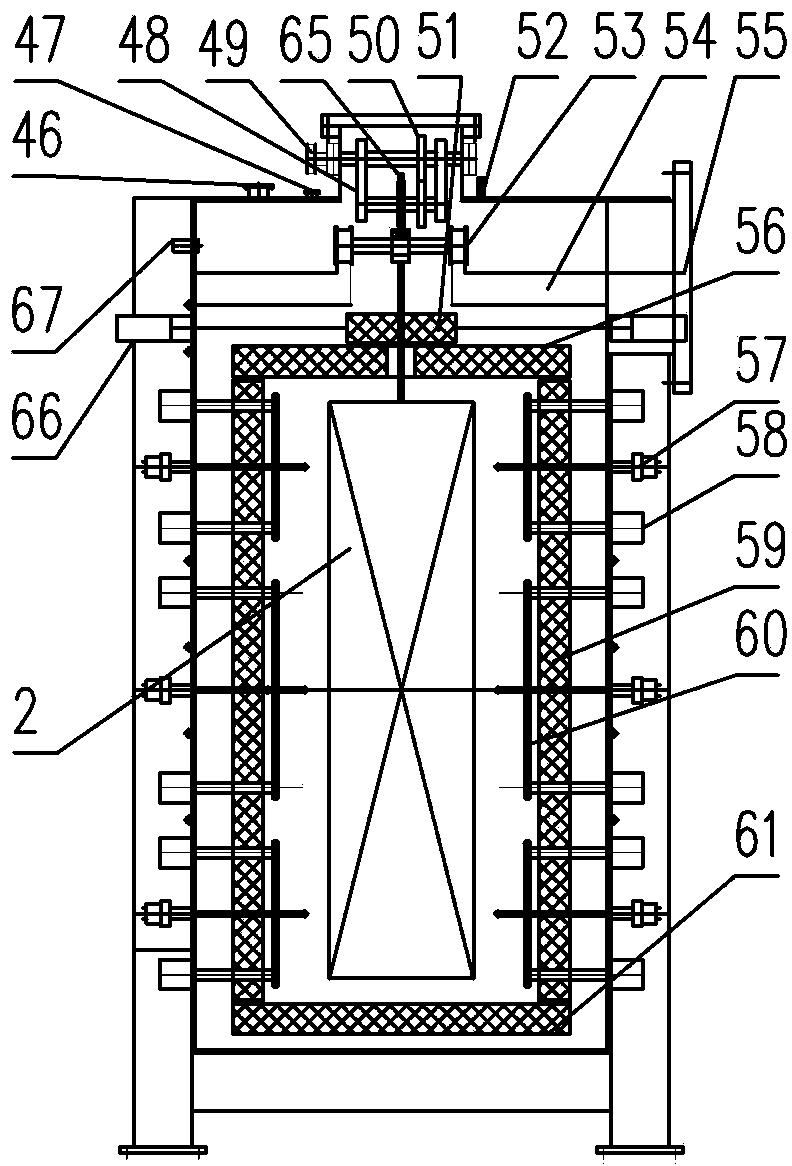

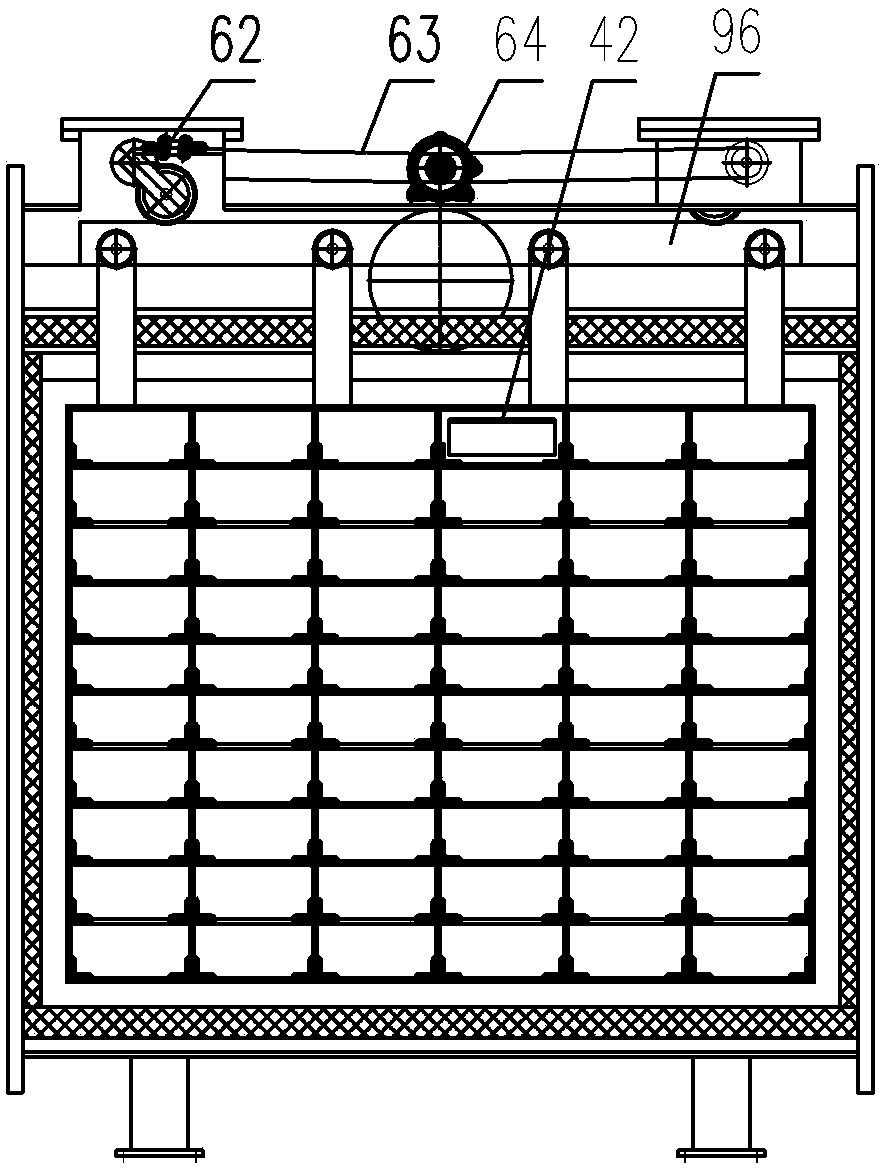

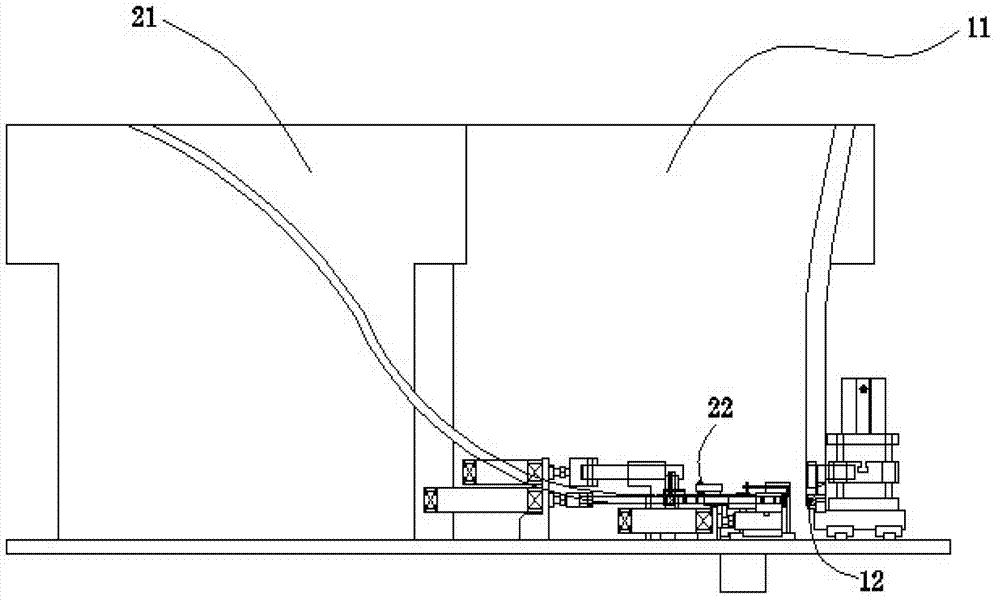

Rare earth permanent magnetic alloy continuous sintering equipment

The invention provides rare earth permanent magnetic alloy continuous sintering equipment. a preparation box, a glove box, a tunnel type transferring sealing box, a lock chamber, a material loading chamber, a preheating chamber, a heating degassing chamber, a sintering chamber and a cooling chamber are serially connected by valves among the boxes and valves among the chambers, compressed molded rare earth permanent magnetic alloy powder is transferred in an oxygen-free atmosphere, and is subjected to heating degassing treatment, sintering treatment and cooling treatment in different chambers. The preparation box, the glove box and the tunnel type transferring sealing box are transmitted on bottom rolls, transmission devices of other chambers are arranged on the upper part of each chamber, conveying is performed by idle wheels and tracks, the idle wheels of a material frame are suspended on the tracks of the transmission devices, and multiple material boxes can be loaded on the drawer-type material frame. An upright rectangular heating furnace has a heating area with narrow width and is uniform in heating, fast in cooling and efficient. Under the premise of greatly saving energy, oxygen-free transferring is realized, the product performances are improved by continuous sintering, and the consistency demand on the magnetism performance of the sintered rare earth permanent magnetic alloy body is ensured.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

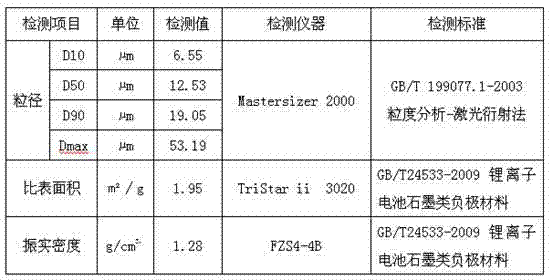

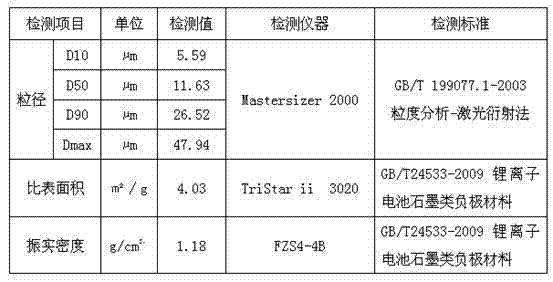

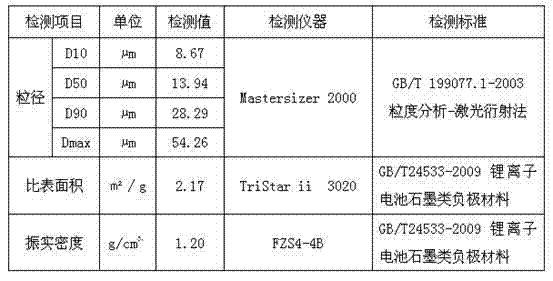

Method for recycling natural graphite fine powder as negative pole material

InactiveCN104766955AImprove cycle stabilityHigh product consistencyCell electrodesCarbonizationCharge and discharge

The invention provides a method for recycling natural graphite fine powder as a negative pole material. The method comprises the following steps: step A) taking 'tail material' produced in the production process of the natural graphite negative pole material of a lithium battery as raw material, adding a bonding agent and a pore-forming agent, performing kneading and granulation at a certain temperature, further performing roller pressing or pressing and performing carbonization at high temperature; step B) crushing, shaping and nodulizing the material after carbonization to obtain spherical or oval graphite powder which is in line with the requirement on particle size range, further performing high-temperature graphitizing and meanwhile, adding the 'tail material' which is re-collected in the crushing / nodulizing process into the step A) for recycling as the raw material; and step C) performing particle size allocation on the powder after nodulizing treatment and filling the powder into gaps between particles. The preparation method provided by the invention is safe and controllable in process; and by adopting the preparation method, the recycling of the low-value graphite 'tail material' is realized, and the prepared negative pole material has the advantages of good performances, and good recycling, rate charge and discharge and low-temperature performances.

Owner:田东

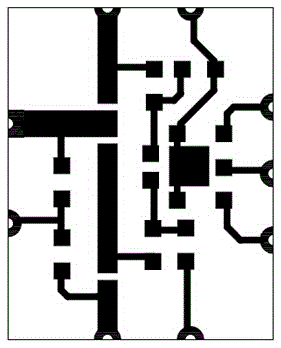

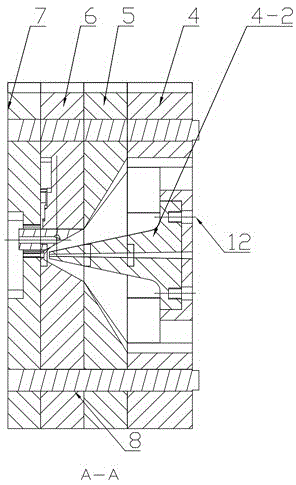

Spatial three-dimensional phase shifter for base station antenna

ActiveCN106972267AReduce widthReduce volumeAntennas earthing switches associationWaveguide type devicesElectrical conductorEngineering

The invention relates to a spatial three-dimensional phase shifter for a base station antenna, and the phase shifter is provided with a conductor housing and a feed network module, wherein the interior of the conductor housing is provided with a multilayer conductor, and the feed network modules are disposed in the conductor cavity. The phase shifter also comprises an insulating module which is insulated with the conductor housing. The phase shifter also comprises a transmission line which is connected with the adjacent two feed network module, and is insulated with the conductor housing. The lower feed network comprises one first input port and two second output ports, and the upper feed network comprises two four-port networks. Each four-port network comprises three second output ports and one second input port connected with one first output port through a transmission line. The four-port networks are metal conductor strips with a slow wave line or a microstrip printed circuit board with a slow wave line. When the phase shifter is used for the base station antenna, the phase shifter has a larger electric downward inclination angle, and the angle is from 0 to 20 degrees. The phase shifter is provided with six radiators, and the length of the antenna is 0.7m, and the largest gain is 16.5dBi.

Owner:GUANGZHOU SINAN ANTENNA DESIGN RES INSTCO

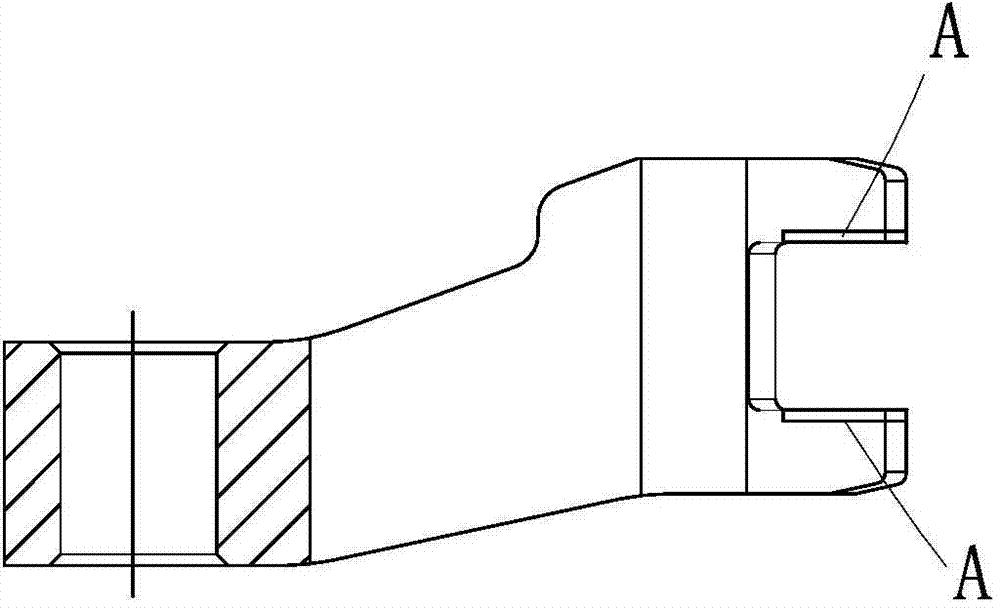

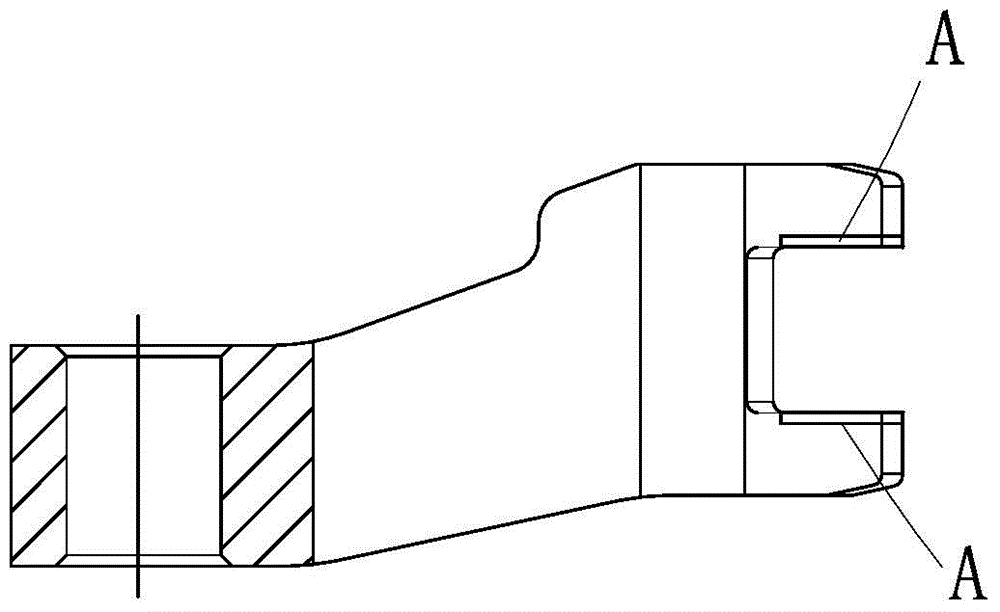

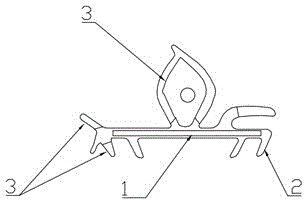

Deburring positioning tool for end face of automobile gear-shifting shifting fork

ActiveCN104325328ANovel ideaIngenious designPositioning apparatusMetal-working holdersCircular discEngineering

The invention discloses a deburring positioning tool for an end face of an automobile gear-shifting shifting fork. A guide rail and a slide seat are mounted above a worktable, wherein the slide seat is fixedly provided with an end face positioning column, a workpiece sleeve cylinder and a first vertical plate; the first vertical plate is provided with a pneumatic ejection rod and an air cylinder; the pneumatic ejection rod is extended or retracted towards the direction of the end face positioning column under the driving of the air cylinder; one end of a connection rod is hinged on a left side wall of the slide seat and the other end of the connection rod is hinged to a circular disc and is deviated from the center of the circular disc; the circular disc is driven by a handle to rotate around a shaft, so that the slide seat is driven to move on the guide rail from left to right; a second vertical plate is fixedly arranged on the right side of the guide rail and a horizontal limiting screw rod is arranged on the left side of the second vertical plate; a horizontal connection plate is fixedly arranged above the slide seat; a horizontal connection plate crosses over the second vertical plate and stretches to the right side of the second vertical plate; a pneumatic switch for controlling the air cylinder is mounted below the horizontal connection plate. The deburring positioning tool is ingenious in design, convenient to operate and high in automation degree, and the production efficiency and the product consistency are remarkably improved.

Owner:聊城市翔达钢管有限公司

Permanent-magnet motor stator by taking iron core as slotless partitioned type structure and production method thereof

InactiveCN102332759AIncrease productivityImprove product qualityMagnetic circuit stationary partsManufacturing stator/rotor bodiesProduction linePunching

The invention relates to a permanent-magnet motor stator by taking an iron core as a slotless partitioned type structure and a production method thereof. An annular cylindrical stator iron core of the stator is composed of a plurality of arc-shaped laminated members which are mutually spliced and all the arc-shaped laminated members are piled by arc-shaped punching sheets. The invention provides the permanent-magnet motor stator by taking the iron core as the slotless partitioned type structure which has the advantages of simple structure, scientific design, safety and reliability and strong practical applicability and the production method thereof; and with the adoption of the motor stator and the production method of the motor stator, the material cost can be greatly saved, the production efficiency and the product consistency are improved, a large batch of mechanically automatic production lines are established, and the popularization and the development of the stator permanent-magnet motor with the stator which takes the iron core as the slotless type structure are convenient.

Owner:TIANJIN NAVIGATION INSTR RES INST

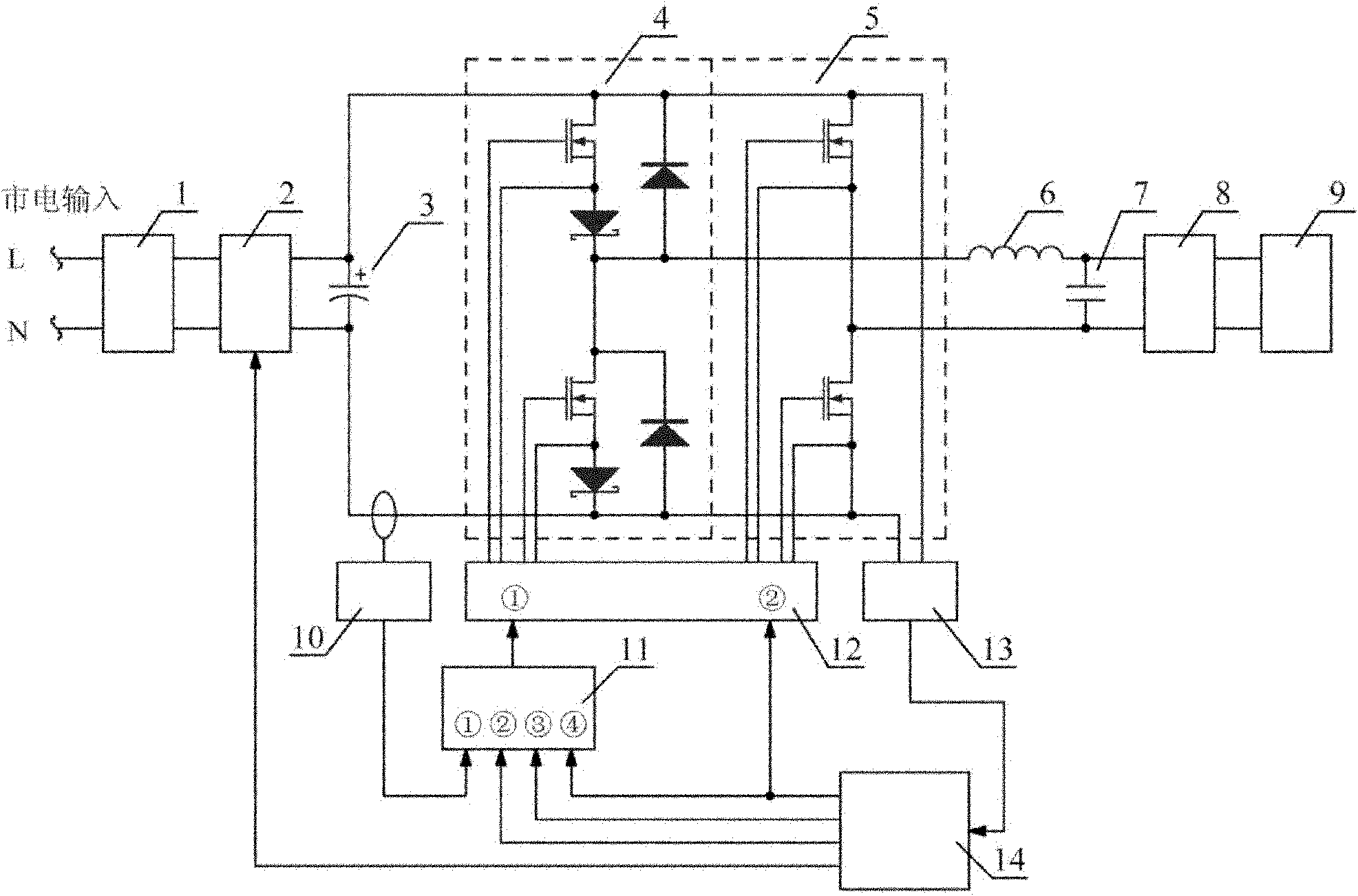

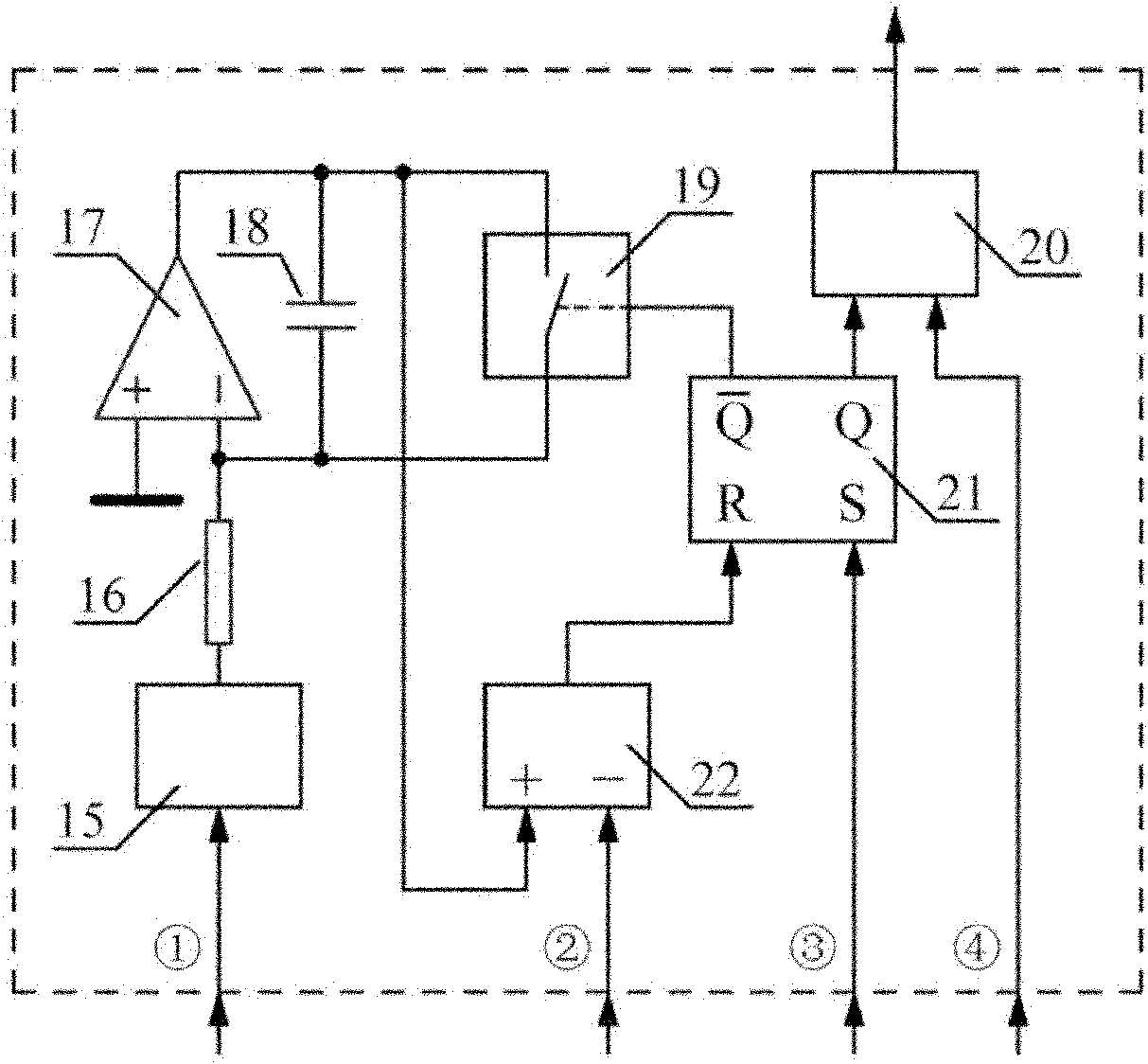

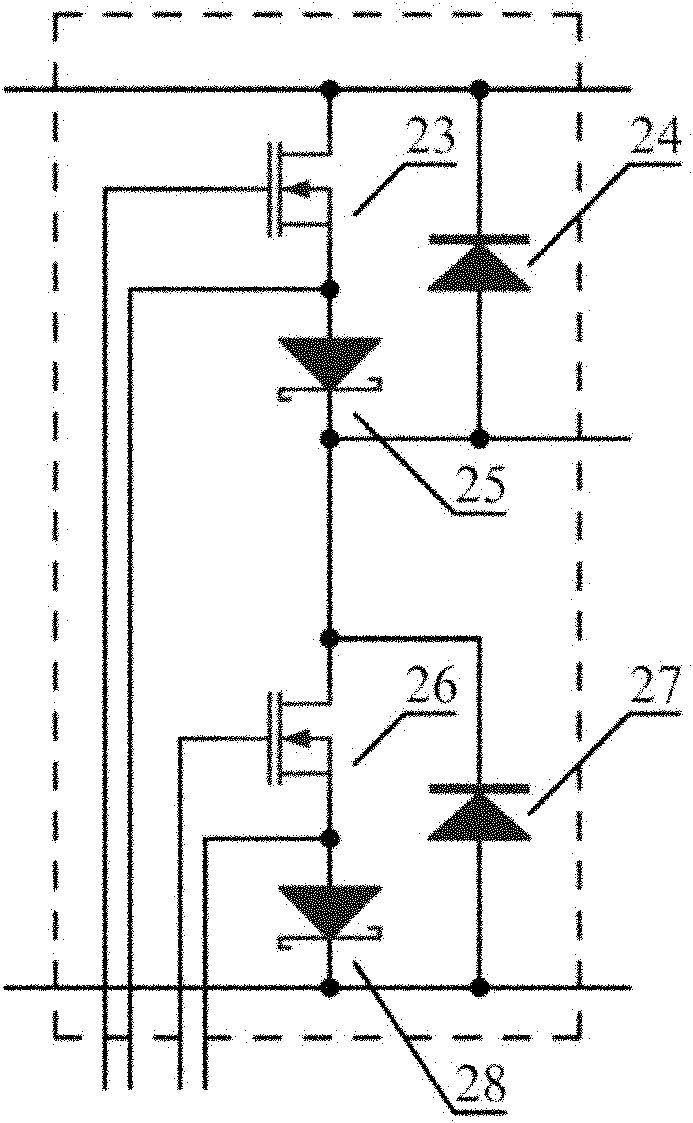

One-cycle controlled constant-power electronic ballast for high intensity discharge (HID) lamp and control method of electronic ballast

ActiveCN102065621APrevent high frequency electromagnetic interferenceImprove electromagnetic compatibilityElectrical apparatusElectric lighting sourcesCycle controlConstant power

The invention relates to a one-cycle controlled constant-power electronic ballast for a high intensity discharge (HID) lamp and a control method of the electronic ballast. The electronic ballast has the advantages of high overall efficiency, good electromagnetic compatibility, stable and reliable system, simple structure and the like, and is easy in implementation. The electronic ballast comprises an electromagnetic compatible filtering unit, a high power factor rectifying unit, an energy storage capacitor, a high frequency inverted half bridge, a low frequency inverted half bridge, a filter inductor, a filter capacitor and an ignition unit which are connected in sequence, wherein the input end of the electromagnetic compatible filtering unit is connected with commercial power; the outputend of the ignition unit is connected with the HID lamp; the high frequency inverted half bridge and the low frequency inverted half bridge are respectively connected with a drive unit; the drive unit is connected with a one-cycle controller and a main control unit; the one-cycle controller is connected with a current detection unit and the main control unit; the current detection unit is connected in the input loop of a direct current (DC) bus in series; the main control unit is connected with a voltage detection unit; and the voltage detection unit is connected with the DC bus.

Owner:山东智慧照明科技有限公司

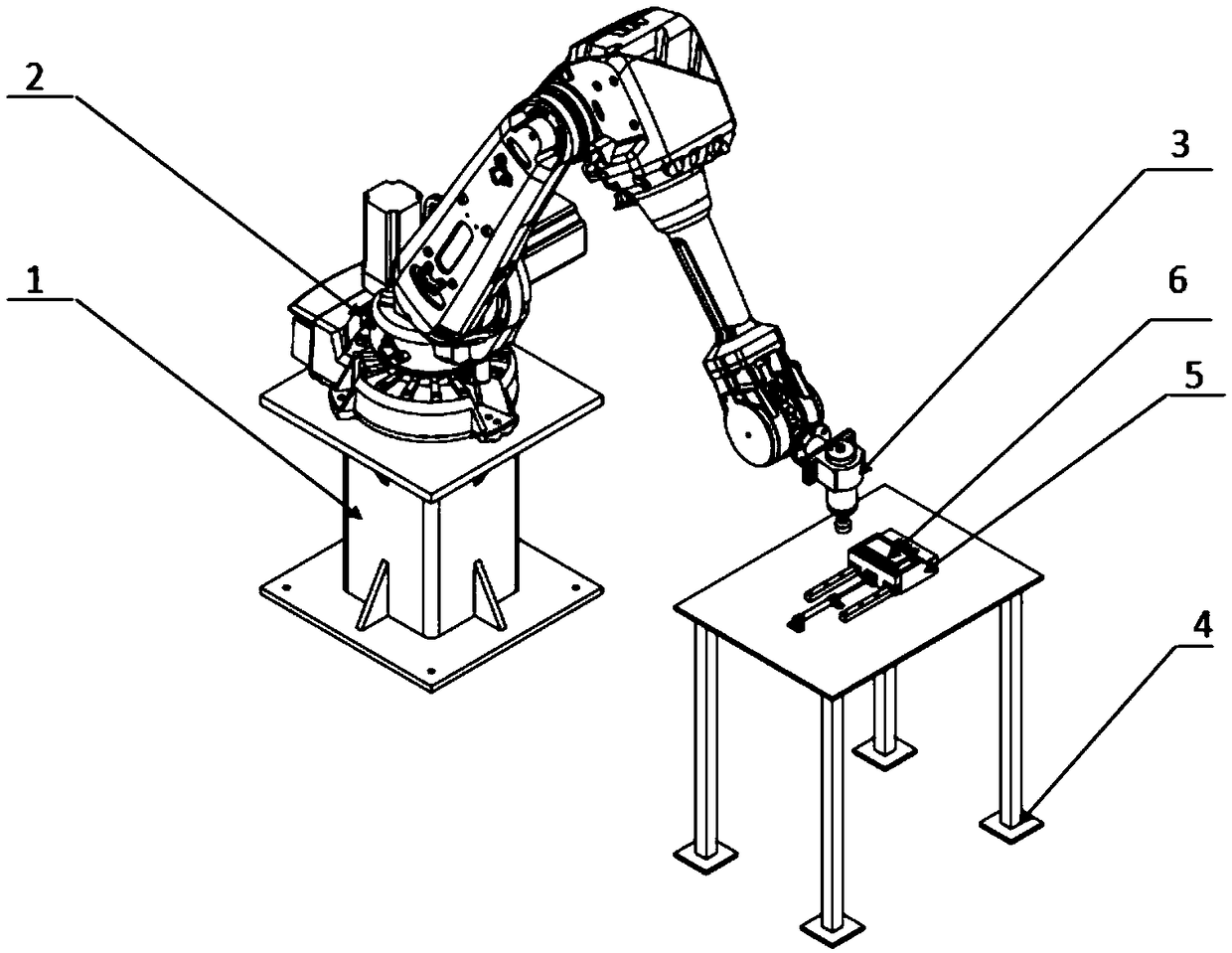

Hand-imitating silicon carbide dissociating abrasive polishing equipment and method

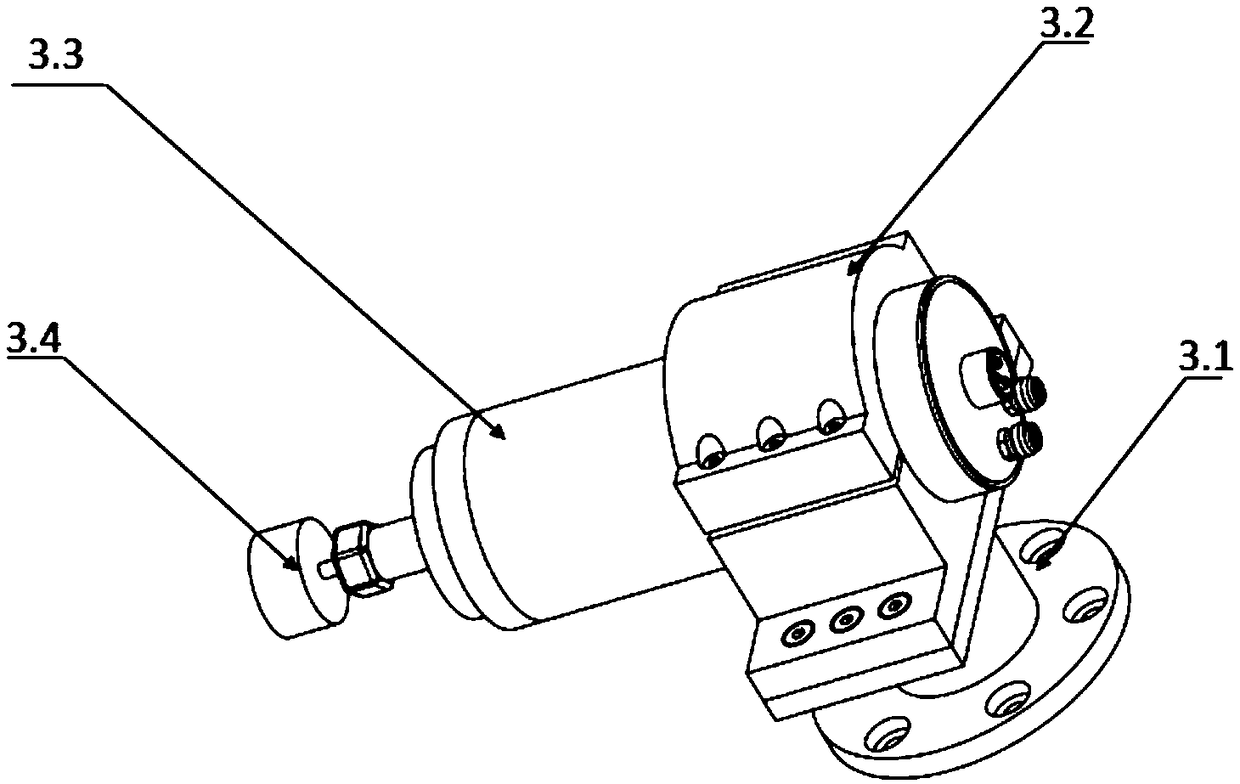

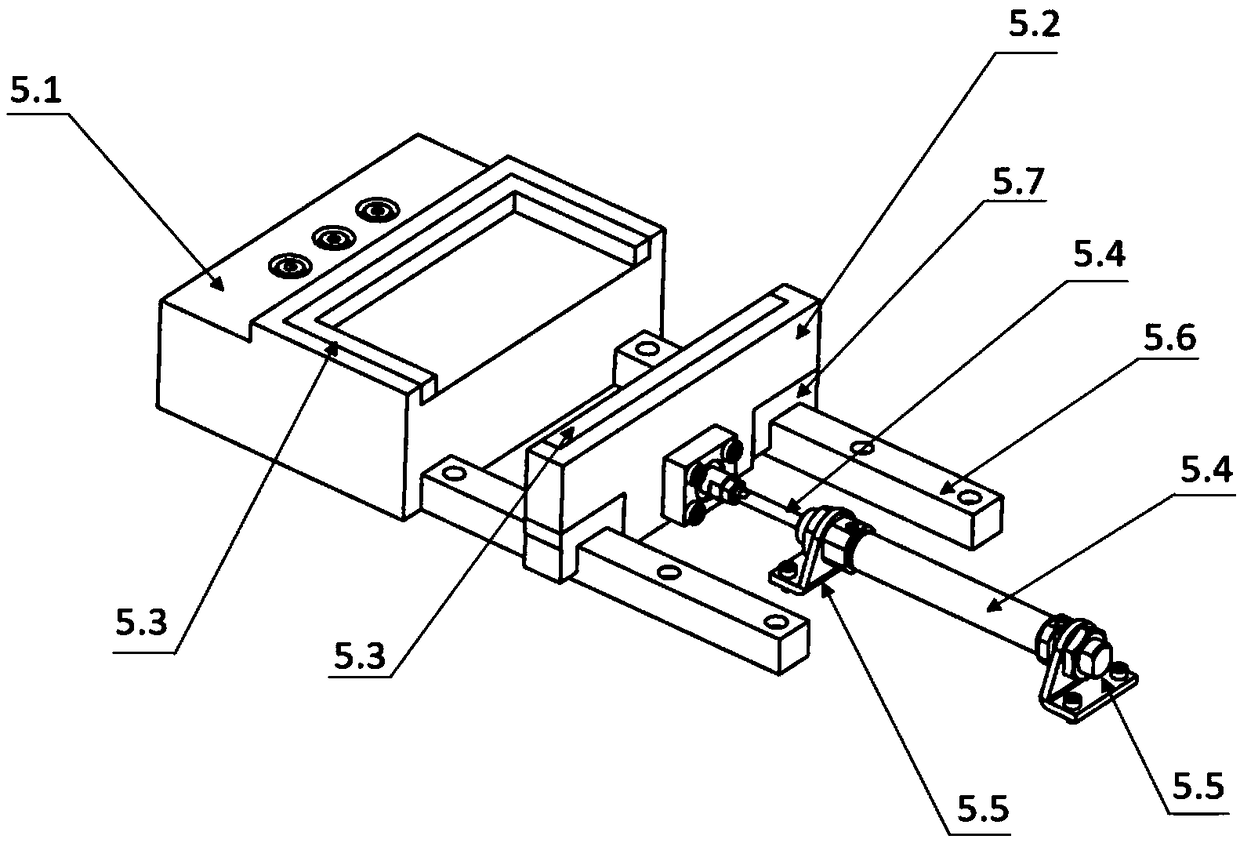

InactiveCN109397041AFast clamping and positioningImprove polishing efficiency and precisionGrinding carriagesPolishing machinesTelescopic cylinderFlange

The invention provides hand-imitating silicon carbide dissociating abrasive polishing equipment and method. The equipment comprises a robot base, a robot, an end-of-arm tool, a workpiece placing tableand a clamping mechanism, wherein the end-of-arm tool is composed of a connecting flange, a spindle holding seat, a high-speed spindle and a wool wheel and is used for polishing a silicon carbide part, the required optimal speed can be obtained by changing the rotating speed of the high-speed spindle, and the wool wheel can be replaced with a diamond grinding wheel so as to grind the part. The clamping mechanism is fixed on the workpiece placing table and used for positioning and clamping the silicon carbide part, and the clamping mechanism comprises a fixed part, a movable part, a telescopiccylinder used for enabling the movable part to act, a guide rail and a sliding block, wherein the telescopic cylinder is fixed to the workpiece placing table through a mounting support, the part canbe quickly clamped and positioned, the fixed part and the movable part are provided with rubber, and thus the silicon carbide part can be prevented from being damaged during clamping.

Owner:WUHAN UNIV OF TECH

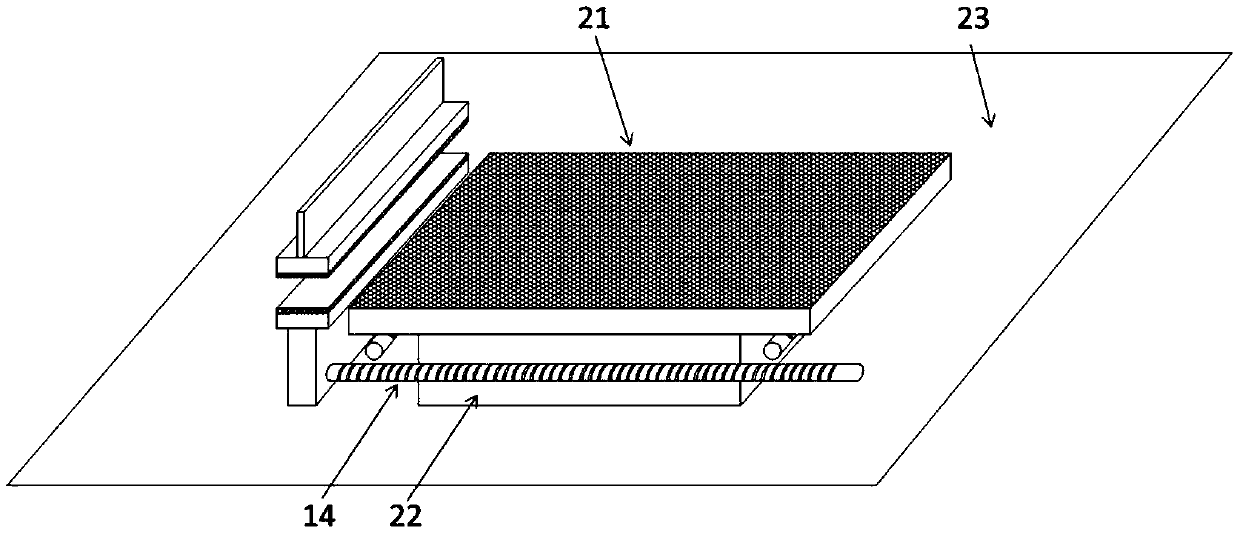

Proton exchange membrane and fuel cell membrane electrode spraying fixture and preparation method thereof

ActiveCN109847974AEasy to disassembleReduce installationCell electrodesSpraying apparatusMembrane surfaceProton

The invention relates to a proton exchange membrane and fuel cell membrane electrode spraying fixture and a preparation method thereof. The fixture is composed of two sets of two-way clamping devicesand a vacuum adsorption heating platform. The two-way clamping devices provided with magnets and rubber pads are utilized to replace a fixing mode of replacing combination of bolts, clamps and variousframes, the structure is simple, assembling is quick, damage to a proton exchange membrane is reduced in the processing process, the work efficiency and quality are improved, and the fixture is suitable for bulk preparation of proton exchange membrane and fuel cell membrane electrodes; the edges of the to-be-sprayed proton exchange membrane are fixed in the four directions of the plane, by adjusting the tension degree of the membrane surface, the situation that the membrane is folded due to external force and the environment when flat laid on a vacuum adsorption heating plate is avoided, meanwhile, the fixture is easy to demount, an install-and-play effect is achieved, the mounting and adjusting time of front side spraying and reverse side spraying is shortened, and the spraying efficiency, spraying quality and product consistency of the membrane electrodes are improved significantly.

Owner:FAW JIEFANG AUTOMOTIVE CO

Deburring clamping mechanism of five-reverse gear shifting fork

ActiveCN104325329ANovel ideaIngenious designWork clamping meansPositioning apparatusEngineeringAutomation

The invention discloses a deburring clamping mechanism of a five-reverse gear shifting fork. A sliding seat which is matched with a first guide rail is arranged above a workbench, a second guide rail and a tooling seat which is matched with the second guide rail are arranged on the sliding seat, the back end of the sliding seat is fixedly connected with the front end of a screw rod, the back end of the screw rod passes through a mounting hole in the workbench and is locked on the workbench by a nut, an end surface positioning column, a workpiece sleeving column and a first vertical plate are fixedly arranged on the tooling seat, a pneumatic ejector rod and an air cylinder are installed on the first vertical plate, the pneumatic ejector rod is driven by the air cylinder to extend towards the direction of the end surface positioning column or retract , a horizontal push-pull rod is fixedly arranged on the left end of the tooling seat, a second vertical plate is fixedly arranged on the right side of the sliding seat, a horizontal limiting screw rod is arranged on the left side of the second vertical plate, a horizontal connecting plate is fixedly arranged above the tooling seat, the horizontal connecting plate crosses the second vertical plate and then extends to the right side of the second vertical plate, and a pneumatic switch is installed below the horizontal connecting plate. The deburring clamping mechanism has the advantages of skilled design, convenience in operation and high degree of automation, and the production efficiency is improved.

Owner:临沂金盛机械配套有限公司

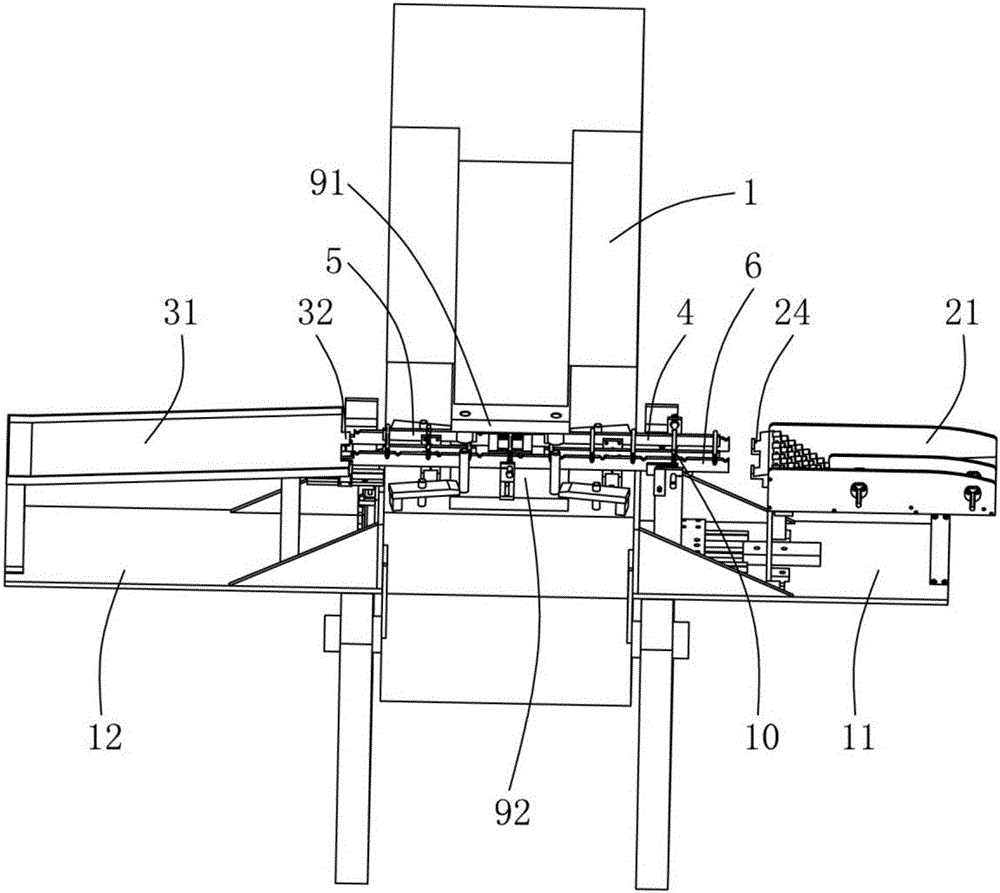

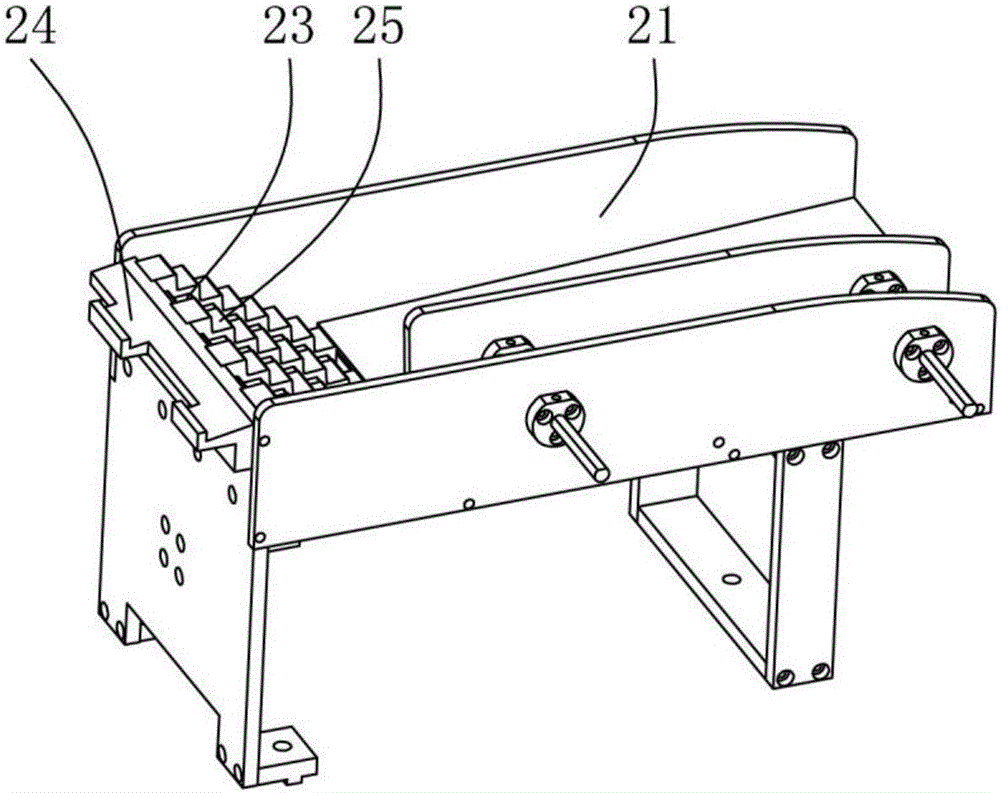

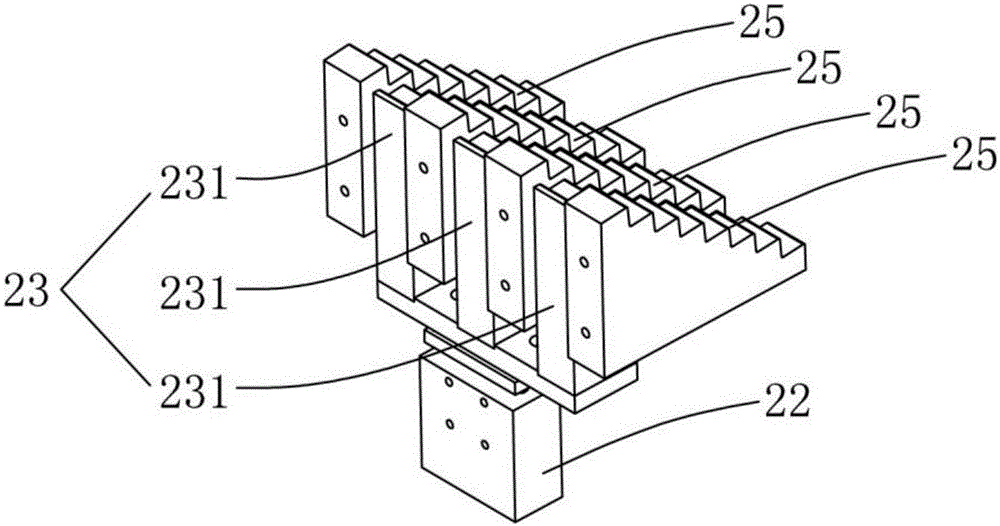

Full-automatic rib press

ActiveCN106040810AAchieve outputAvoid simultaneous entryMetal-working feeding devicesEngine componentsPunch pressReciprocating motion

The invention discloses a full-automatic rib press. The full-automatic rib press comprises a punching machine, a loading mechanism, an unloading mechanism, a first fixed beam module, a second fixed beam module and a movable beam module; a first holding module is arranged on a loading box of the loading mechanism; a second holding module is arranged on a receiving box of the unloading mechanism; the first fixed beam module and the second fixed beam module are both fixed on the punching machine; multiple first positioning grooves for placing workpieces are formed in the first fixed beam module at equal intervals; multiple second positioning grooves for placing the workpieces are formed in the second fixed beam module at equal intervals; the movable beam module is movably mounted on the punching machine; multiple shifting grooves for shifting the workpieces are formed in the movable beam module at equal intervals; and a driving mechanism for driving the movable beam module to perform a periodic reciprocating motion is arranged on the punching machine. The full-automatic rib press is simple and reasonable in structure, convenient for use and higher in automation degree, facilitates improvement of the machining efficiency and the product consistency, and reduces the labor intensity of workers and the production danger coefficient.

Owner:NINGBO NEWSTAR PRECISION MACHINERY

Flying Apparatus

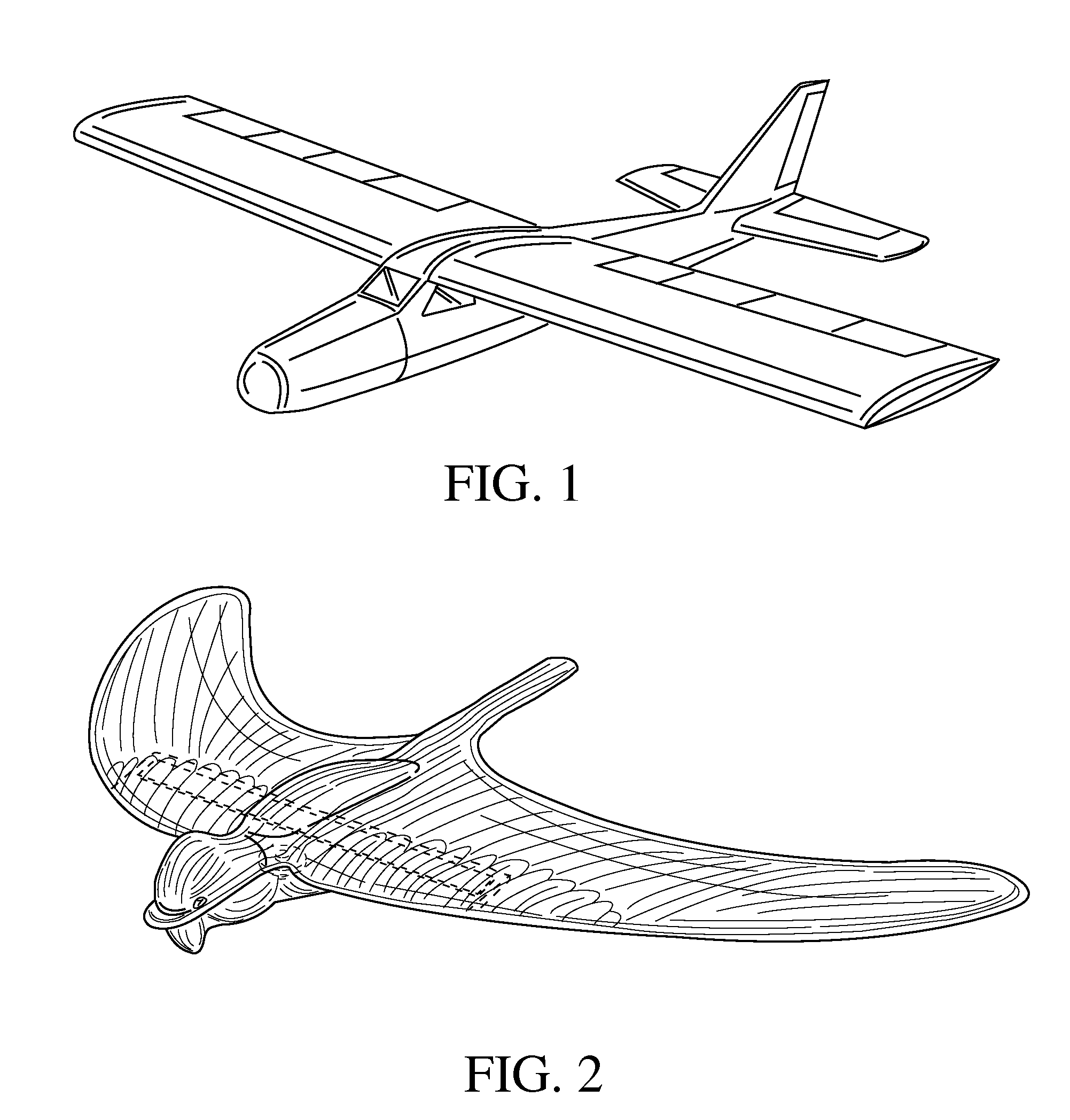

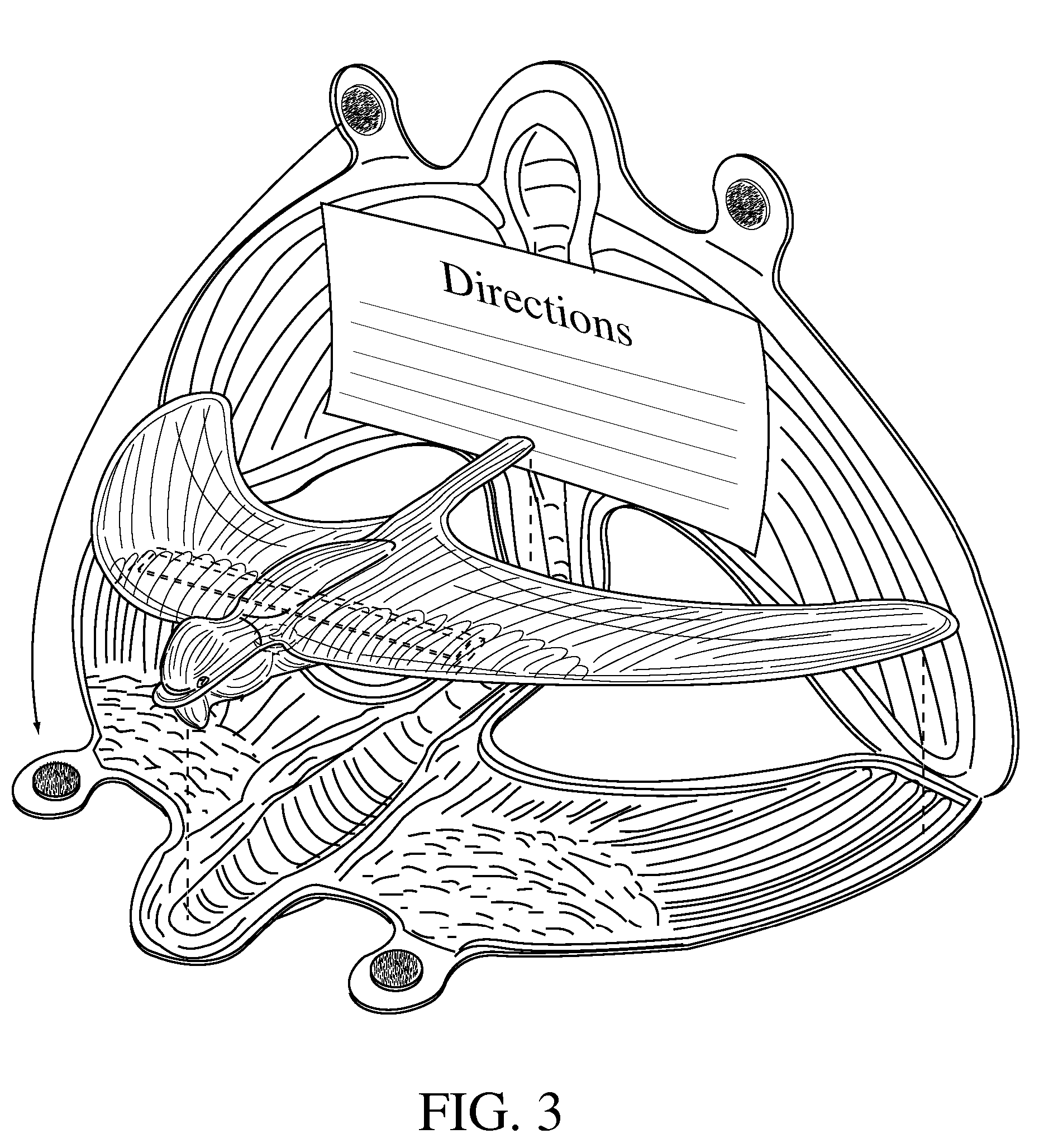

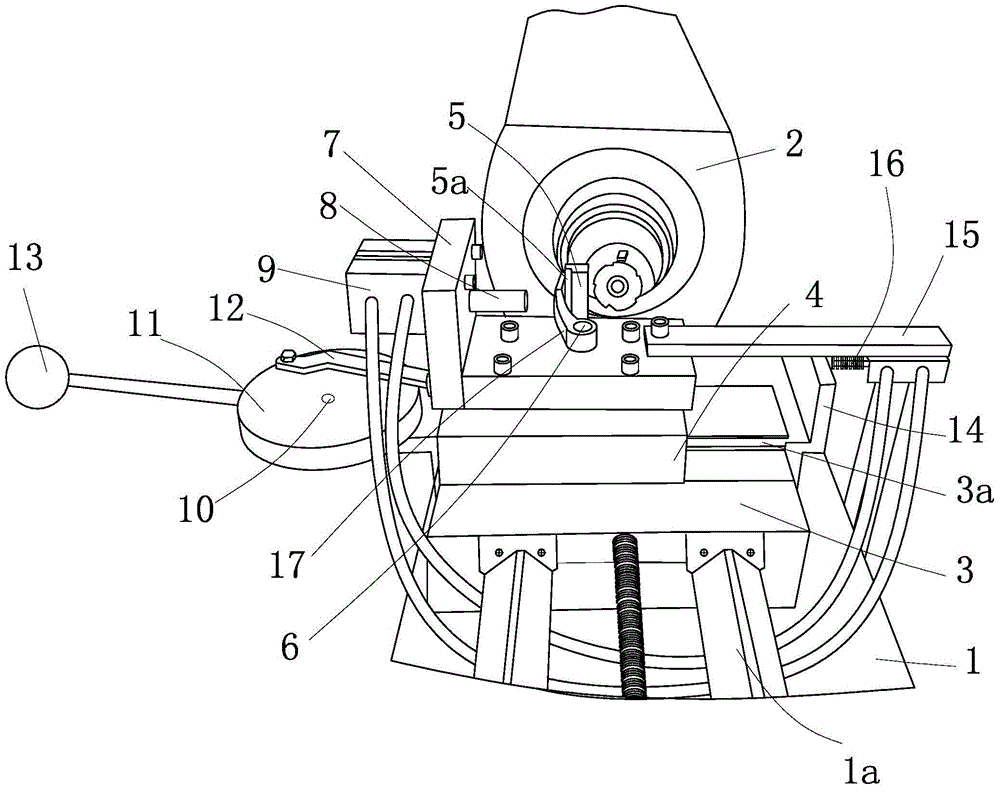

ActiveUS20060292957A1Increase the amount of preparationReduce material wasteToy aircraftsRight flankHollow core

This invention provides a small lightweight glider that is hollow and made from a molded thin film material. Typically the glider is formed in the shape of a bird or a plane. The body of the glider comprises top half and a lower half, which form a hollow fuselage, a left wing and a right wing extending laterally from the fuselage. The glider also comprises a ballast weight, a stiffener, and optionally an interior skeleton. The interior of the glider is open to the outside atmosphere and requires no inflation.

Owner:HOWARD DAVID

Finishing machine for fork opening end face of automobile shifting fork

The invention discloses a finishing machine for a fork opening end face of an automobile shifting fork. A workbench is provided with a facing cutter, a sliding seat, a second guide rail and a tool seat, wherein the sliding seat is matched with the first guide rail, the second guide rail extends left and right, the tool seat is matched with the second guide rail, the rear end of the sliding seat is fixedly connected with the front end of a screw rod, the rear end of the screw rod passes through a mounting hole in the workbench and is locked on the workbench through a nut, the tool seat is fixedly provided with an end face location column, a tool bushing cylinder and a first vertical plate, and the first vertical plate is provided with a pneumatic ejector rod and an air cylinder and drives a circular plate to rotate around a shaft by utilizing a handle, so that the tool seat moves on the second guide rail left and right; a second vertical plate is fixedly arranged on the right side of the second guide rail, a horizontal connection plate is fixedly arranged on the tool seat and extends to the right side of the second vertical plate over the second vertical plate, and a pneumatic switch for controlling an air cylinder is arranged on the lower part of the horizontal connection plate. The finishing machine for the fork opening end face of the automobile shifting fork has the advantages that the concept is novel, the design is smart, the automation degree is high, and the production efficiency and the product consistency are remarkably improved.

Owner:武汉投知家信息科技有限公司

Optical fingerprint identification module assembly

InactiveCN102194112AEasy to installEasy to disassembleCharacter and pattern recognitionFlexible circuitsComputer module

The invention provides an optical fingerprint identification module assembly, which comprises a cover, a sensing sheet, an acquisition prism, a base, a first circuit board, a second circuit board, a light source and an imaging device, wherein the first circuit board is arranged in the circuit board installation cavity of the base, and the length of the first circuit board is greater than the bottom length of the base; the first circuit board is vertically connected with the second circuit board; the sensing sheet is positioned on the surface of the acquisition face of the acquisition prism, the sensing sheet is connected with a proximity sensing circuit on the first circuit board through a flexible circuit board, and the sensing sheet comprises a sensing electrode area and a shielding area; and the acquisition prism is arranged in the prism installation cavity of the base, and the cover and the base are buckled together to fix the acquisition prism. The parts are installed in a buckling mode and installed and detached conveniently; and the parts are buckled together in production, so that the complexity of production and maintenance is reduced, and the production consistency is increased.

Owner:CHENGDU FINCHOS ELECTRONICS

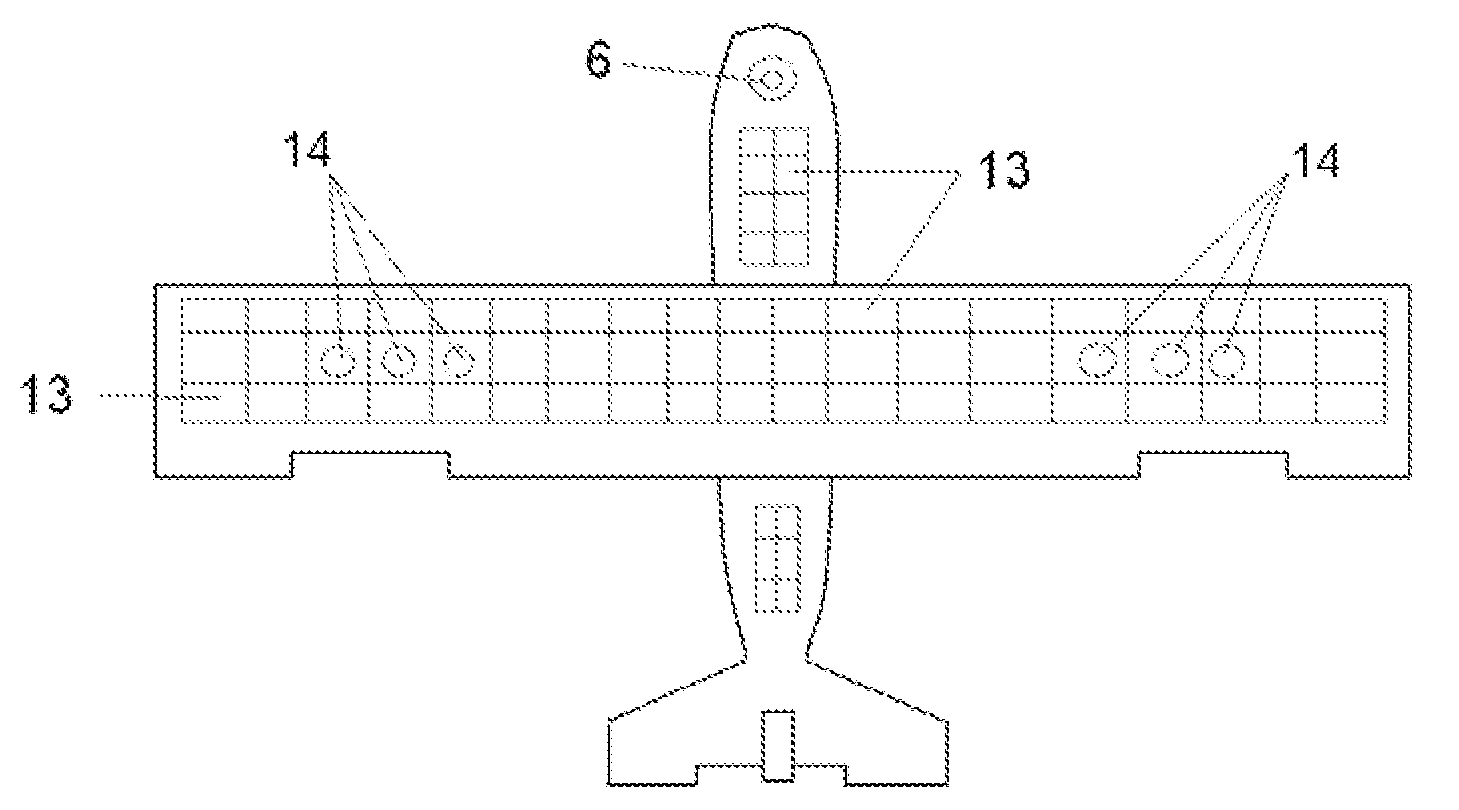

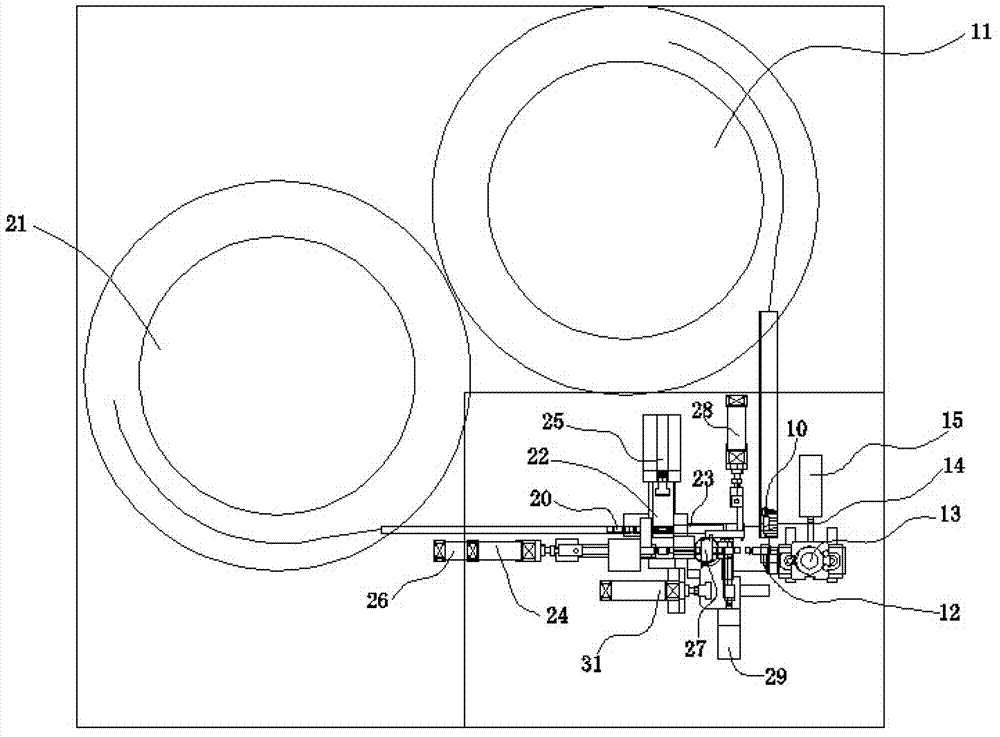

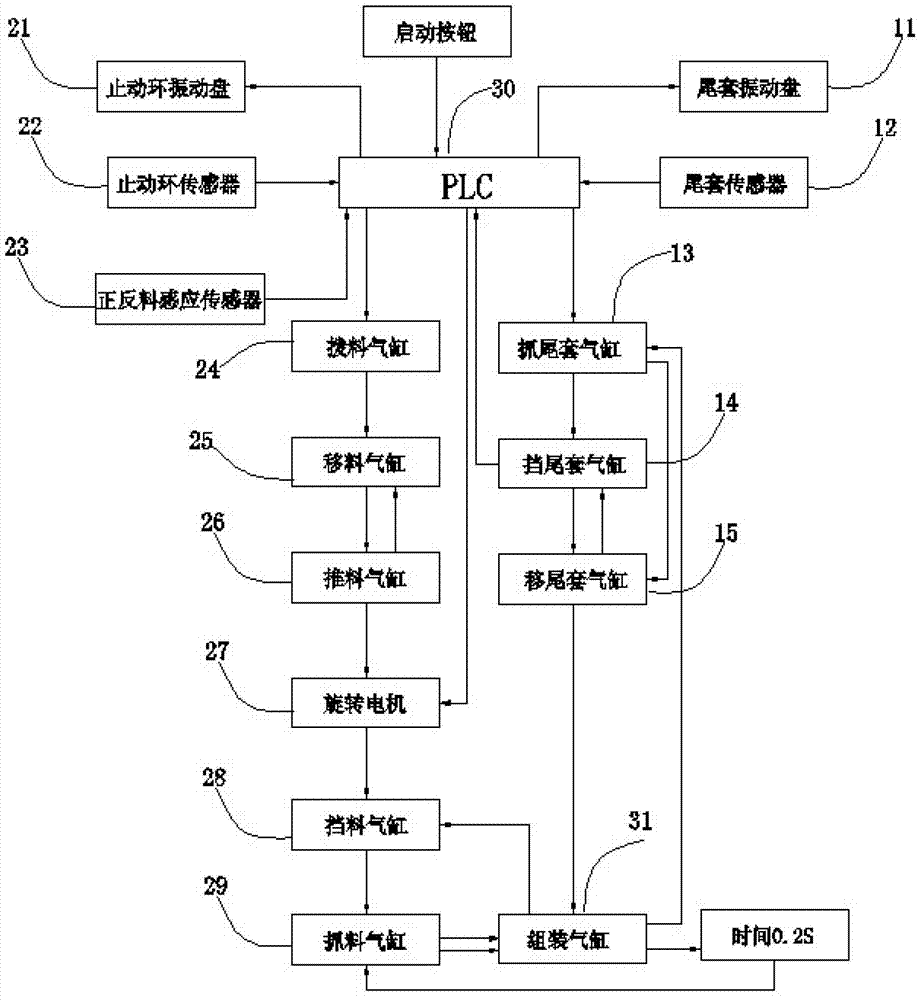

Automatic assembly machine for tail sleeve and check ring

ActiveCN102962662AHigh product consistencyReduce labor costsMetal working apparatusProgrammable logic controllerEngineering

The invention discloses an automatic assembly machine for a tail sleeve and a check ring. The automatic assembly machine comprises a workbench, and a tail sleeve feeding device, a check ring feeding device, a check ring correction device, a PLC (Programmable Logic Controller) and an assembly air cylinder that are mounted on the workbench, wherein the tail sleeve feeding device, the check ring feeding device and the check ring correction device are connected with the PLC; and the tail sleeve and the check ring are controlled by a PLC program to automatically complete assembly in the assembly air cylinder. The automatic assembly machine is provided with a forward-reverse material inductive sensor, when the forward-reverse material inductive sensor detects that the direction of the check ring is reverse, a rotating motor rotates for 180 DEG to allow the direction of the check ring to be forward. The automatic assembly machine adopts the PLC for automation operation, the product consistency is improved, the automatic feeding is adopted for the automatic assembly, the labor cost is lowered, the labor intensity is reduced, and the yield is increased.

Owner:SHENZHEN KEXIN COMM TECH

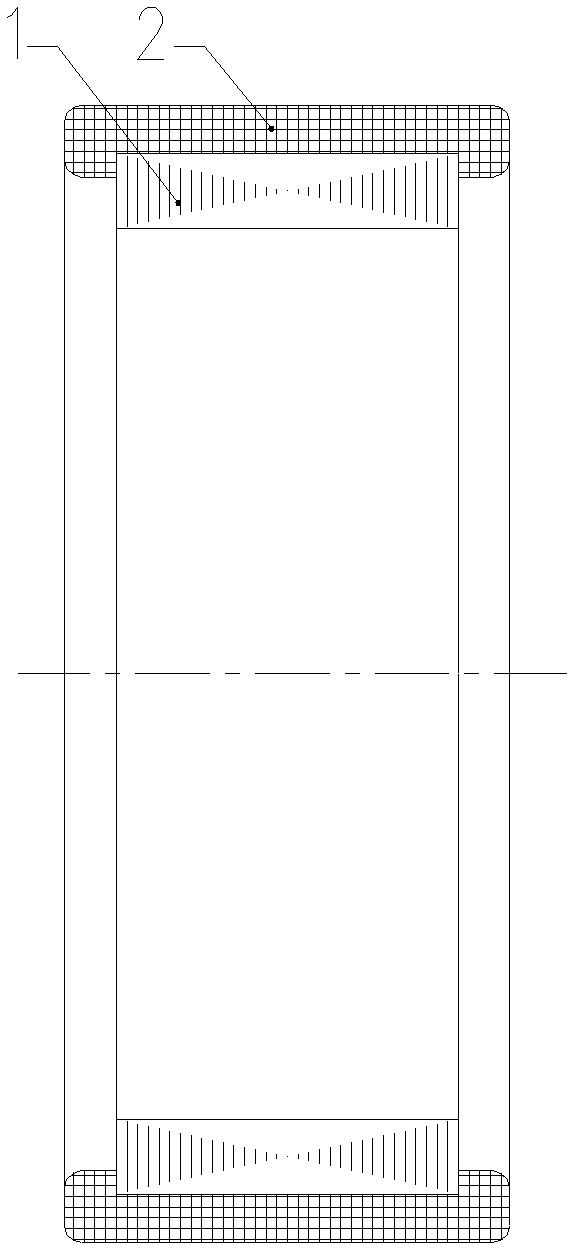

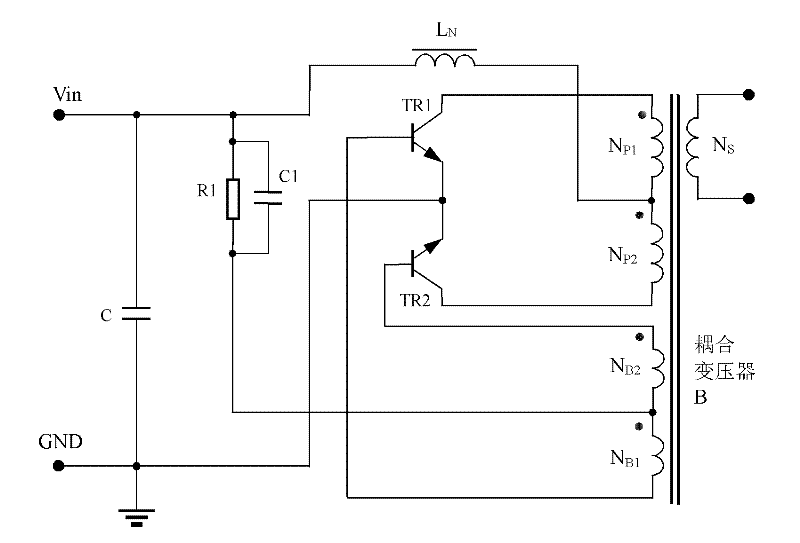

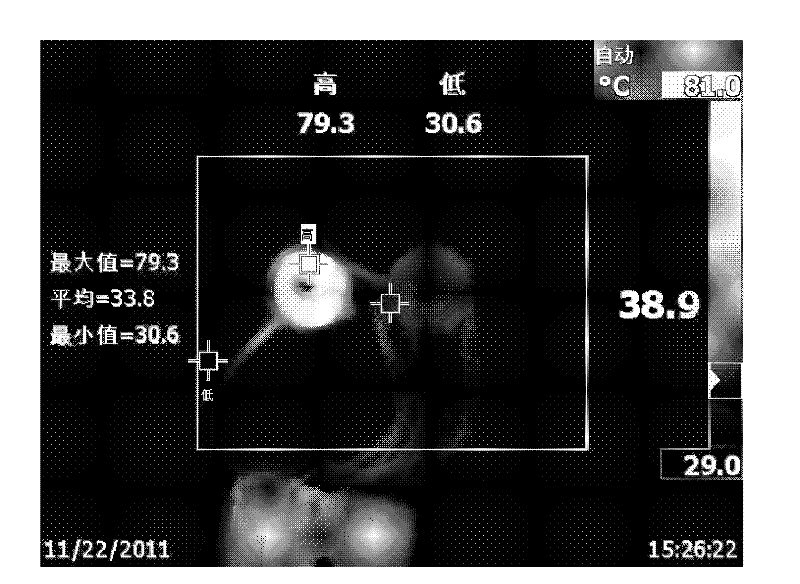

Magnetic core

ActiveCN102543371AEasy to processHigh product consistencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic coreShort circuit protection

The invention discloses a magnetic core which comprises an air-gap-free closed-magnetic-circuit magnetic core, wherein the external surface of the air-gap-free closed-magnetic-circuit magnetic core is provided with one or more than one same-material cylindrical magnetic column extending outwards; the air-gap-free closed-magnetic-circuit magnetic core is an annular magnetic core, and the cylindrical magnetic column extends outwards along the diameter direction of the annular magnetic core; alternatively, the air-gap-free closed-magnetic-circuit magnetic core is an annular magnetic core, and the cylindrical magnetic column extends outwards along the direction perpendicular to the diameter direction of the annular magnetic core. The magnetic core can be applicable to a self-excited push-pull type transformer with output short circuit protection function, so that magnetic lines of force between the transformer or a common-mode inductor and an inductor are independent and are not mutually influenced; magnets of the same material are magnetically integrated, and the magnetic core is formed through one set of moulds and is easy to machine during production, and the product has high conformance; and the magnetic core is integrally manufactured by using the same mould and has good heat transfer effect.

Owner:MORNSUN GUANGZHOU SCI & TECH

Method for vacuum smelting and casting for Mar-M246 alloy

InactiveCN105483446APrecise control of casting temperatureIncrease productivityFoundry mouldsFoundry coresWaxCrucible

The invention discloses a method for vacuum smelting and casting for a Mar-M246 alloy. The method comprises the following steps: (1) processing Mar-M246 alloy bars, and the Mar-M246 alloy comprising the following chemical ingredients in percentage by weight: 0.13-0.17% of C, 8-10% of Cr, 9-11% of Co, 9-11% of W, 2.25-2.75% of Mo, 1.25-1.75% of Ta, 5.25-5.75% of Al, 1.25-1.75% of Ti, 0.01-0.02% of B, 0.03-0.08% of Zr, not greater than 1.0% of Fe, not greater than 0.1% of Cu, not greater than 0.2% of Mn, not greater than 0.015% of S, and balance Ni and inevitable impurities; (2) pressing a wax pattern, and combining the wax pattern with a refractory crucible through bonding wax; (3) smearing the wax pattern combined with the refractory crucible, with a paste, and then dewaxing to produce a formwork; (4) roasting the formwork; and (5) filling the refractory crucible with the Mar-M246 alloy bars, and smelting and casting the Mar-M246 alloy bars.

Owner:DALIAN HUASHENG PRECISION CASTING CO LTD

Winding type lithium ion cell and preparation method thereof

InactiveCN109361011AAvoid Position CorrectionFull stress releaseFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention provides a winding type lithium ion cell and a preparation method thereof, and belongs to the technical field of lithium ion battery. The problem of poor yield rate of existing technicalproducts is solved. The method comprises the steps that diaphragm belt unreeling is conducted on a diaphragm reel, a positive electrode reel and a positive electrode reel are unreeled in the conveying direction of the diaphragm belt and cut by a cutting mechanism to form a positive electrode single piece and a negative electrode single piece, the surface on the same side of the diaphragm is alternately provided with a positive electrode region and a negative electrode region, a corresponding electrode single piece is placed on the first region of the diaphragm belt, two corresponding electrode single pieces are placed in every subsequent positive electrode region and every subsequent negative electrode region after the first region, and the diaphragm belt on which the positive electrode single pieces and the negative electrode single pieces are placed are directly conveyed to a combining mechanism and a winding mechanism to be wound to prepare the winding type lithium ion cell. The winding type lithium ion cell is provided. The method can improve the production efficiency and the product qualification rate.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

Burr removing tool for inner end of positioning pin hole of gear shifting swing rod of automobile transmission

The invention discloses a burr removing tool for an inner end of a positioning pin hole of a gear shifting swing rod of an automobile transmission. The burr removing tool comprises a working table and a sliding supporting plate; an automobile swing rod sleeve cylinder and automobile swing rod anti-rotating blocks are fixedly arranged above the sliding supporting plate; a manual swing rod is hinged to the middle position of the front side wall of the sliding supporting plate; the left side and the right side of the sliding supporting plate are each provided with a connecting rod which extends left and right; each connecting rod is sleeved with a return spring. The outer side of each connecting rod is provided with a supporting block for supporting the corresponding connecting rod; the front side and the rear side of the sliding supporting plate are each provided with two bearings; the bearings are arranged at intervals in a left and right manner to guide left and right moving of the sliding supporting plate; and the left side and the right side of the neck of the sliding supporting plate are each provided with a limiting plate for limiting left and right moving of the sliding supporting plate. The burr removing tool is novel in conception, ingenious in design, convenient to operate and high in automation degree; the production efficiency and product consistency are remarkably improved; and the burr removing tool has the wide popularization value.

Owner:重庆市广角机械制造有限公司

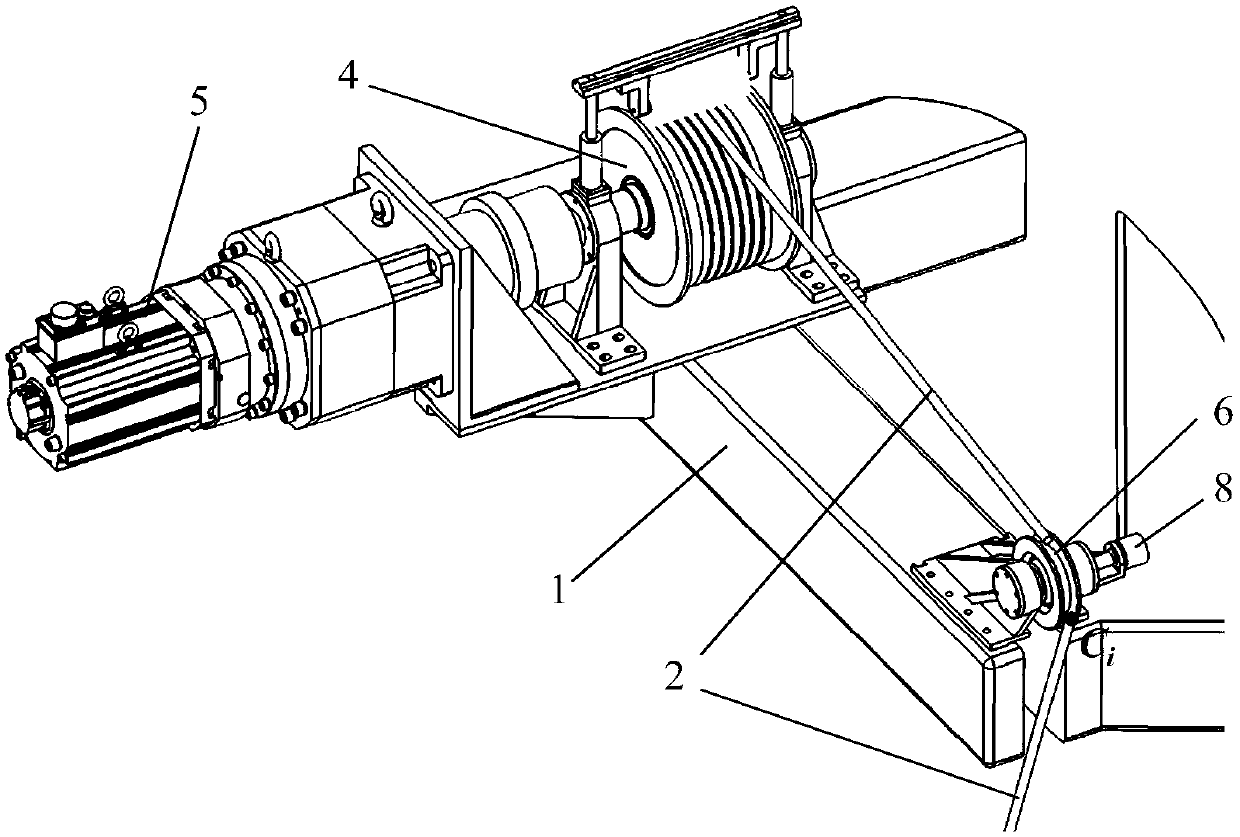

Heavy-duty lifting robot based on parallel wire driven mechanism

PendingCN110815170AStructural stress is smallReduce internal loadProgramme-controlled manipulatorElectric machineryAdvanced manufacturing

The invention belongs to the field of advanced manufacturing and automation, and particularly discloses a heavy-duty lifting robot based on a parallel wire driven mechanism. The heavy-duty lifting robot comprises an upper platform, a lower platform and six wires. The upper platform is a fixed platform, the lower platform is a movable platform, and the upper platform is connected with the lower platform through the six wires to form a Stewart type parallel mechanism. Each branch wire is connected with the upper platform through a fixed pulley and a motor roller and connected with the lower platform through a crossed hinge. An encoder is installed on a pulley shaft of each branch and can measure the length change of the corresponding wire. When the center of the upper platform and the centerof the lower platform are located on the same plumb line and the movable platform of the robot naturally droops in balance, the gravity surface conditions are met between the circumferential radius of the center points of the pulleys on the upper platform and the circumferential radius of the joints of the lower platform, and the pulley central plane, perpendicular to the rotating axis, of each branch pulley and the corresponding gravity surface are coplanar. The practical application conditions of the heavy-duty automatic operation are sufficiently considered, and the heavy-duty lifting robot has the advantages of being high in loading capacity, high in operation precision, reasonable in structural optimization and capable of realizing six-dimensional motions.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

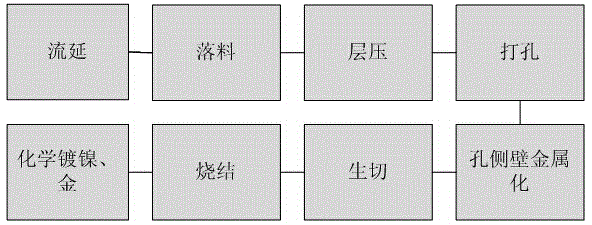

Aluminium nitride substrate for microwave power tube and manufacturing method therefor

ActiveCN105489559ASolve the heat dissipation problem of package interconnectionEasy to realize integrated designSemiconductor/solid-state device detailsSolid-state devicesAluminium nitrideElectroless nickel plating

The invention discloses an aluminium nitride substrate for a microwave power tube. Metal wiring is arranged on the structural surface of the aluminium nitride substrate; a hole side wall is metalized; the bottom surface is grounded and metalized fully; multiple pipe cores are welded and interconnected on the metalized surface layer; the grounding requirements are satisfied through the metallization of the hole side wall and the full metallization of the bottom surface; a multi-layer co-firing process is adopted; aluminium nitride ceramic is used as the ceramic base material, and tungsten is used as the metalizing material; interconnection between an upper layer and a lower layer is formed by adopting a hole side wall metalizing process; the surface tungsten metal wiring layer is plated by adopting a chemical nickel plating process and a chemical gold plating process. The aluminium nitride substrate for the microwave power tube has the advantages that compared with the thermal conductivity of less than 10W / mK of an organic substrate and about 30W / mK of an aluminium oxide substrate, the thermal conductivity of the aluminium nitride substrate is improved to 170W / Mk, so that the packaging requirement of a high-power density microwave device can be satisfied; and in addition, the hole side wall metallization process, the chemical nickel plating process and the chemical gold plating process are adopted, so that the aluminium nitride substrate is suitable for high efficiency mass production.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Composite sealing strip extrusion die and molding technology using same

ActiveCN104149301AReduce installationSave labor intensityDomestic articlesCoatingsEngineeringUltimate tensile strength

The invention relates to a composite sealing strip extrusion die and a molding technology using the composite sealing strip extrusion die. The extrusion die comprises a first flow channel piece, a second flow channel piece, a molding piece and a duckbilled piece, wherein the first flow channel piece, the second flow channel piece and the molding piece are connected into a whole; the duckbilled piece is formed by a connecting piece and a duckbill; the connecting piece is connected with the first flow channel piece; the duckbill penetrates through the first flow channel piece and the second flow channel piece; the centers of the connecting piece and the duckbill are respectively provided with a core material channel; the connecting piece is provided with a dense glue channel and a gelatin sponge channel around the duckbill; the first flow channel piece is provided with a first dense glue channel and a first gelatin sponge channel; the second flow channel piece is provided with a second dense glue channel and a second gelatin sponge channel; the molding piece is provided with a molding hole. When the extrusion die is used for molding, the core material is not needed to be pre-molded. The problems that the glue material covering the two sides of the core material is not uniform, the core material is missed and the like caused by the change of relative position of an opening die and the duckbill in the installation process can be effectively solved; the labor intensity of workers in the installation and disassembly processes of the opening die and the duckbill can be lightened, and the product switching time is shortened.

Owner:GREAT WALL MOTOR CO LTD

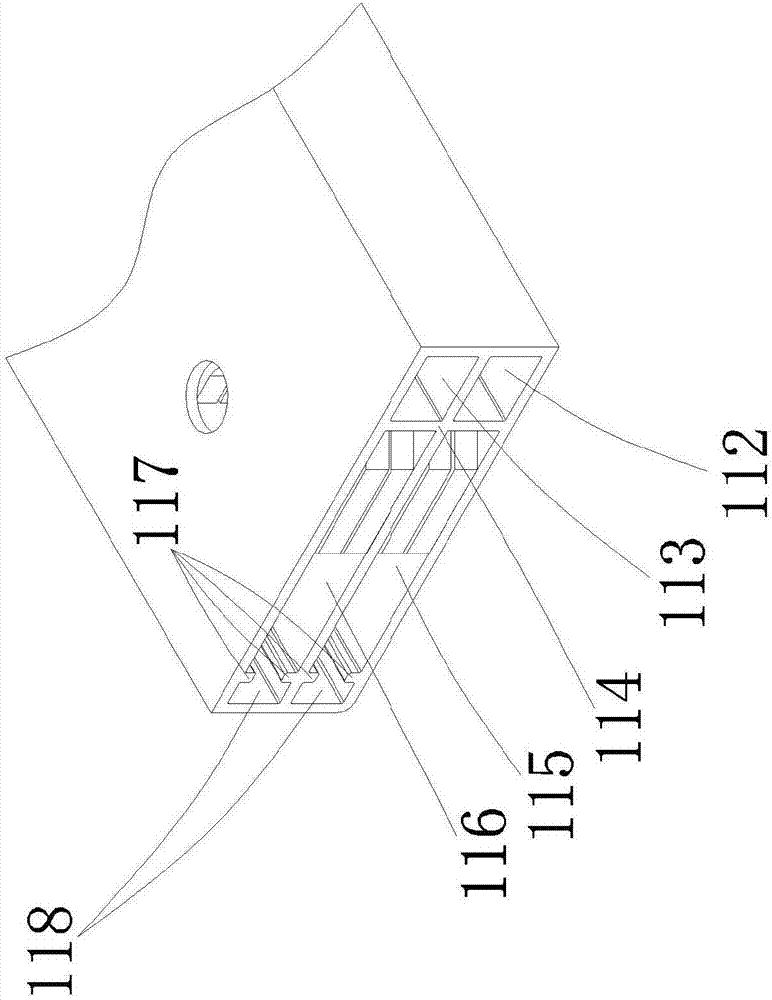

Spatial three-dimensional phase shifter for base station antenna

ActiveCN106972265AReduce widthReduce volumeAntennas earthing switches associationHigh level techniquesElectrical conductorNetwork connection

The invention relates to a spatial three-dimensional phase shifter for a base station antenna, and the phase shifter comprises a conductor housing and feed network modules, wherein the interior of the conductor housing comprises an upper conductor cavity and a lower conductor cavity, and the feed network modules are respectively disposed in the upper conductor cavity and the lower conductor cavity. A lower feed network disposed on the lower feed network module comprises a first input port and N first output ports. The upper feed network module disposed on the upper feed network module comprises N five-port networks, and each five-port network comprises four second output ports and one second input port connected with one first output port through a transmission line, wherein N is a positive integer. According to the invention, the upper and lower feed networks are connected together through the transmission line, thereby reducing the bandwidth of the feed network by 50%. The upper feed network employs the five-port networks, thereby reducing the number of transmission lines, saving the material, reducing the cost, and facilitating the transportation. The antenna length is 2.5m, and the maximum gain is 23dBi.

Owner:GUANGZHOU SINAN ANTENNA DESIGN RES INSTCO

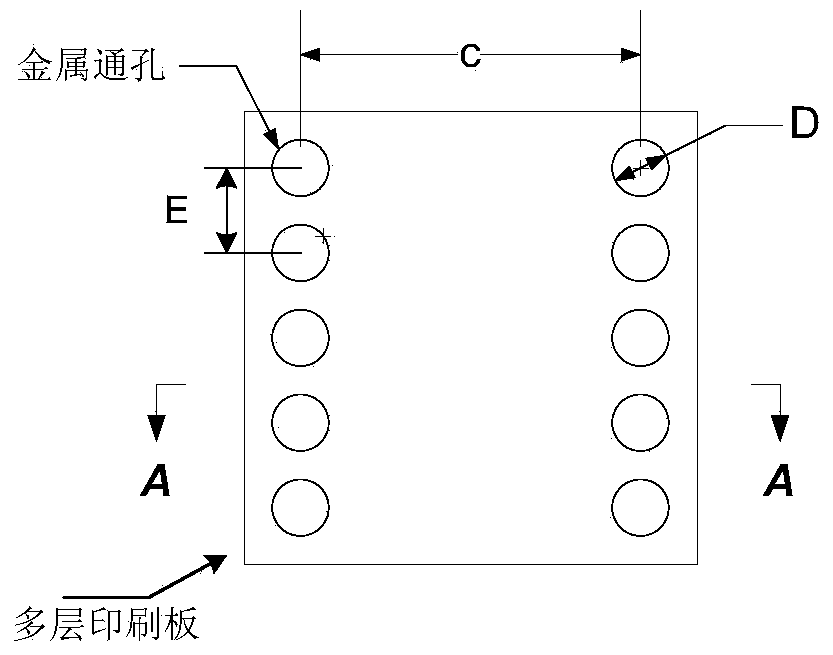

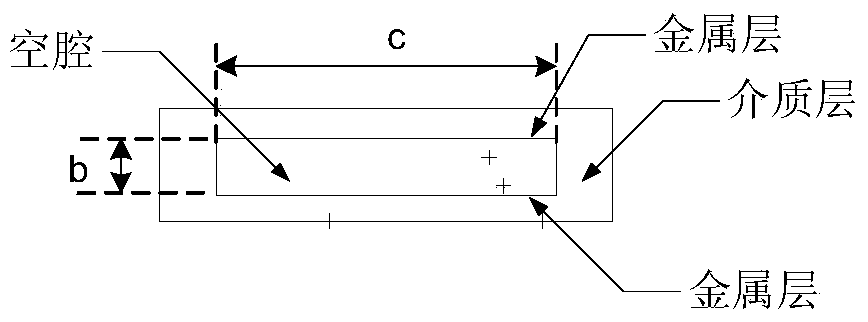

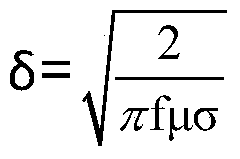

Multilayer printing technology based waveguide and preparation method thereof

ActiveCN104218296AImprove transmission efficiencyConducive to integrated designPrinted circuit detailsWaveguidesRadiation lossMetal coating

The invention relates to a multilayer printing technology based waveguide and a preparation method thereof. The multilayer printing technology based waveguide is characterized in that multiplayer surface plates serve as a dielectric substrate group, the top surface plate and the bottom surface plate are subjected to metal coating, and a cavity and metal holes are formed in the dielectric substrate group consisting of the multiplayer surface plates according to design, so that a substrate integrated metal waveguide is obtained. The multilayer printing technology based waveguide follows a method that SIW (substrate integrated waveguide) discrete grounding substitutes for continuous grounding, and a metalloid waveguide structure is achieved in a multilayer printing structure. The substrate integrated metal waveguide obtained by the preparation method according to the design is consistent with a metal waveguide in transmission characteristic when radiation loss is neglected, and a waveguide processing technique is simplified.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

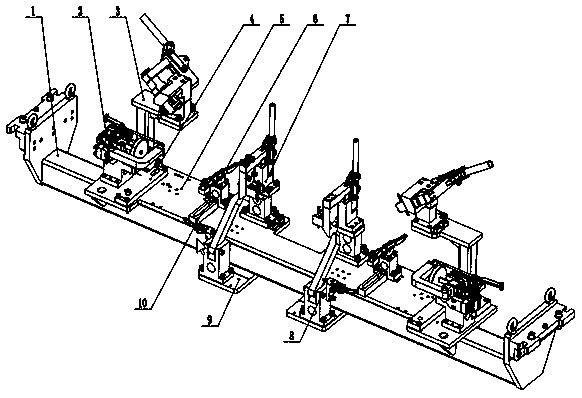

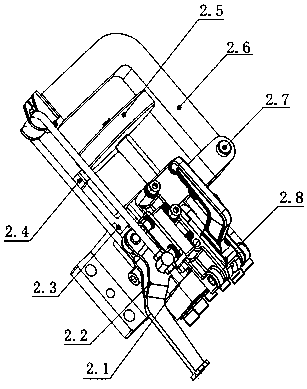

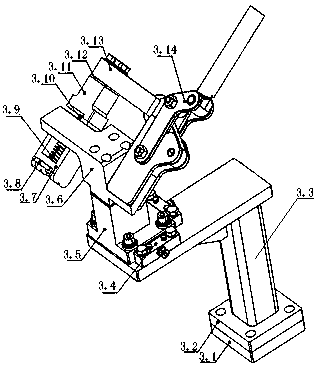

Welding fixture of carrier roller bracket robot

PendingCN108188639AReduce deformationStrong commonalityWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringRobot

The invention relates to the technical field of welding fixtures, in particular to a welding fixture of a carrier roller bracket robot. The welding fixture comprises a public bottom beam, a supportingpillar holding mechanism, a supporting pillar positioning mechanism, a base anchor positioning mechanism, a quick changing platform, a crossbeam clamping mechanism, a middle supporting pillar positioning mechanism, a medium supporting pillar clamping mechanism, a simple mounting plate and an L-shaped block. The quick changing platform is arranged on the upper surface of the public bottom beam. The supporting pillar holding mechanism and the supporting pillar positioning mechanism are symmetrically arranged on the left side and the right side of the end of the quick changing platform. The baseanchor positioning mechanism is fixed to the position, between the supporting pillar holding mechanism and the supporting pillar positioning mechanism, of the upper side of the quick changing platform. The middle supporting pillar positioning mechanism and the medium supporting pillar clamping mechanism are arranged in the middle of the quick changing platform. The middle of the quick changing platform is further provided with the L-shaped block and the crossbeam clamping mechanism. The L-shaped block is arranged under the crossbeam clamping mechanism. An installing hole is formed in the middle of the L-shaped block. The installing hole is a long and round countersunk head type groove. According to the welding fixture of the carrier roller bracket robot, the welding efficiency, the welding quality and the product consistency are improved significantly compared with a technology in the prior art.

Owner:TAIYUAN XIANGMING INTELLIGENT CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com