Aluminium nitride substrate for microwave power tube and manufacturing method therefor

A technology of aluminum nitride substrate and microwave power, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of device volume reduction, achieve volume reduction, solve the problem of packaging and interconnection heat dissipation, and avoid pressing wire plating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

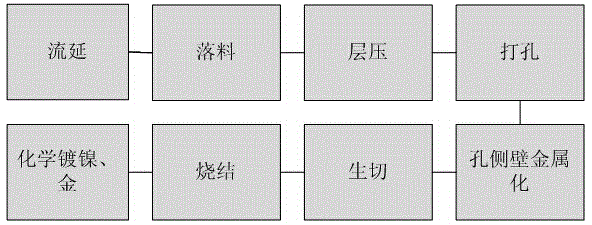

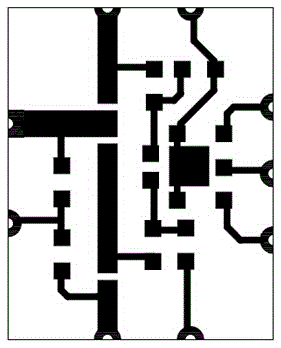

[0036] Using tape casting equipment, at a drying temperature of 120°C, a single sheet of green porcelain tape with a thickness of 0.27mm and a length and width of 210mm was obtained. Three layers of 0.27-thick aluminum nitride green ceramic strips were pressed into blocks using a dry press under a pressure of 2.0 kpsi. And use mechanical punching equipment to punch through holes with a diameter of 0.6mm. The tungsten paste is coated on the side wall of the through hole by using a screen and a printing machine, and after drying, the surface circuit and the bottom circuit are printed with the tungsten paste by using a screen and a printing machine. After drying, use a raw cutting machine to cut the whole plate of raw porcelain blocks according to the marked line to obtain units. Sintering is carried out at a temperature of 1700-1900° C. to obtain a cooked porcelain substrate. The substrate is subjected to chemical nickel plating, and after the nickel plating is completed, chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com