Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Full stress release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick steel plate and manufacturing method thereof

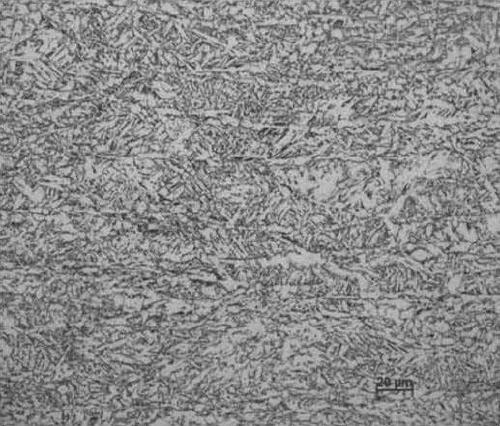

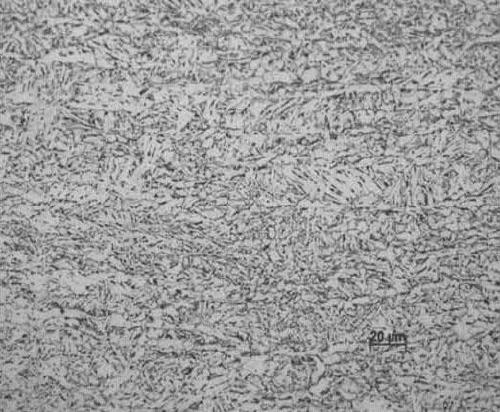

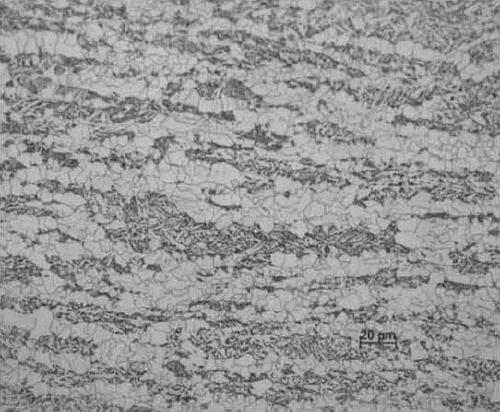

The invention discloses a thick steel plate and a manufacturing method thereof, and belongs to the field of ferrous metallurgy. The method comprises the following steps of molten iron KR pre-desulfuration, converter smelting, LF refining, RH vacuum treatment, wire feeding, flexible stirring, plate blank continuous casting, plate blank reheating, rough rolling, intermediate blank temperature holding cooling, precision rolling, ACC quick cooling, steel plate straightening and stacking slow cooling, wherein in the plate blank reheating stage, the temperature is 1120-1220 DEG C, and the in-furnacetime is longer than or equal to 1.0 min / mm; in the rough rolling stage, the temperature is 1000-1080 DEG C, and the thickness of an intermediate blank after rolling is larger than 2.5 times that of asteel plate; in the precision rolling stage, the temperature is lower than or equal to 900 DEG C, the finish rolling temperature is 780-820 DEG C, and the total compression ratio in the stage is larger than or equal to 60%; in the cooling stage, the finish cooling temperature is 300-400 DEG C, and the cooling rate is 10+ / -5 DEG C / s. The steel plate manufactured through the method comprises the following chemical components of, by mass percent, 0.06-0.09% of C, 0.10-0.30% of Si, 1.40-1.70% of Mn, 0.020-0.060% of Al, 0.03-0.05% of Nb, 0-0.020% of Ti, 0-0.30% of Cr, 0-0.016% of P, 0-0.005% of S,0-0.080% of N and the balance Fe and inevitable impurity elements, the carbon equivalent Ceq is equal to [C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15] and smaller than or equal to 0.42%, the welding crack sensitivity index CEpcm is equal to [C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B] and smaller than or equal to 0.20%, and the applicable thickness of the steel plate is 40-70 mm.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

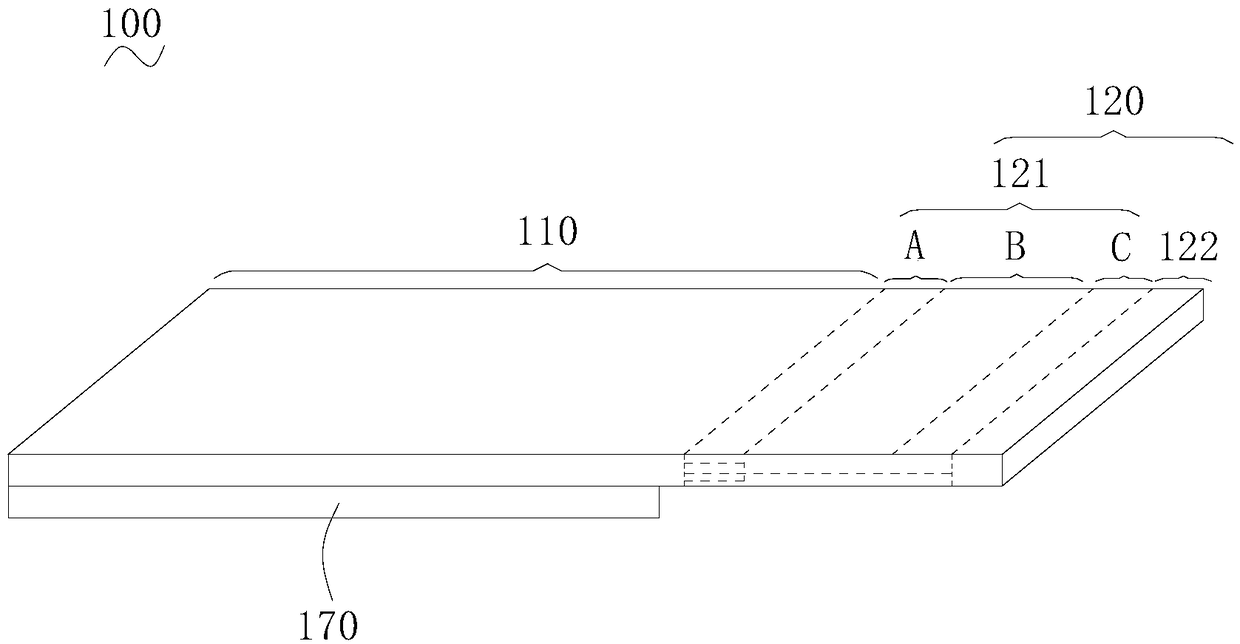

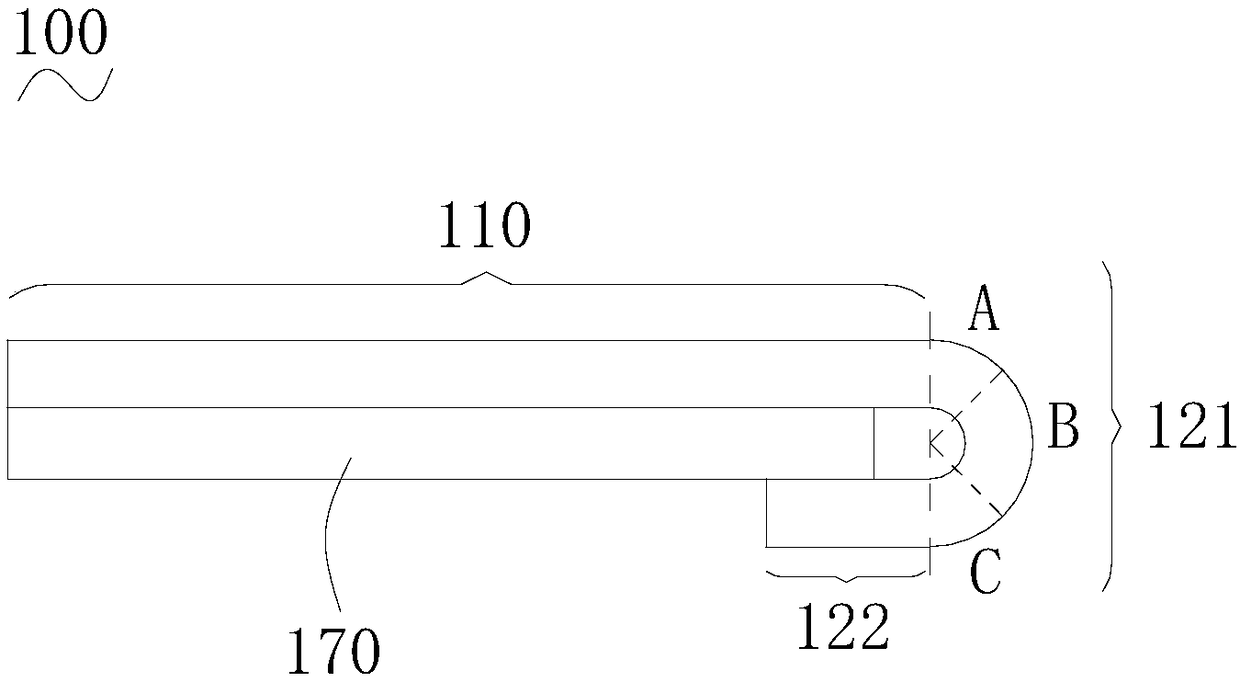

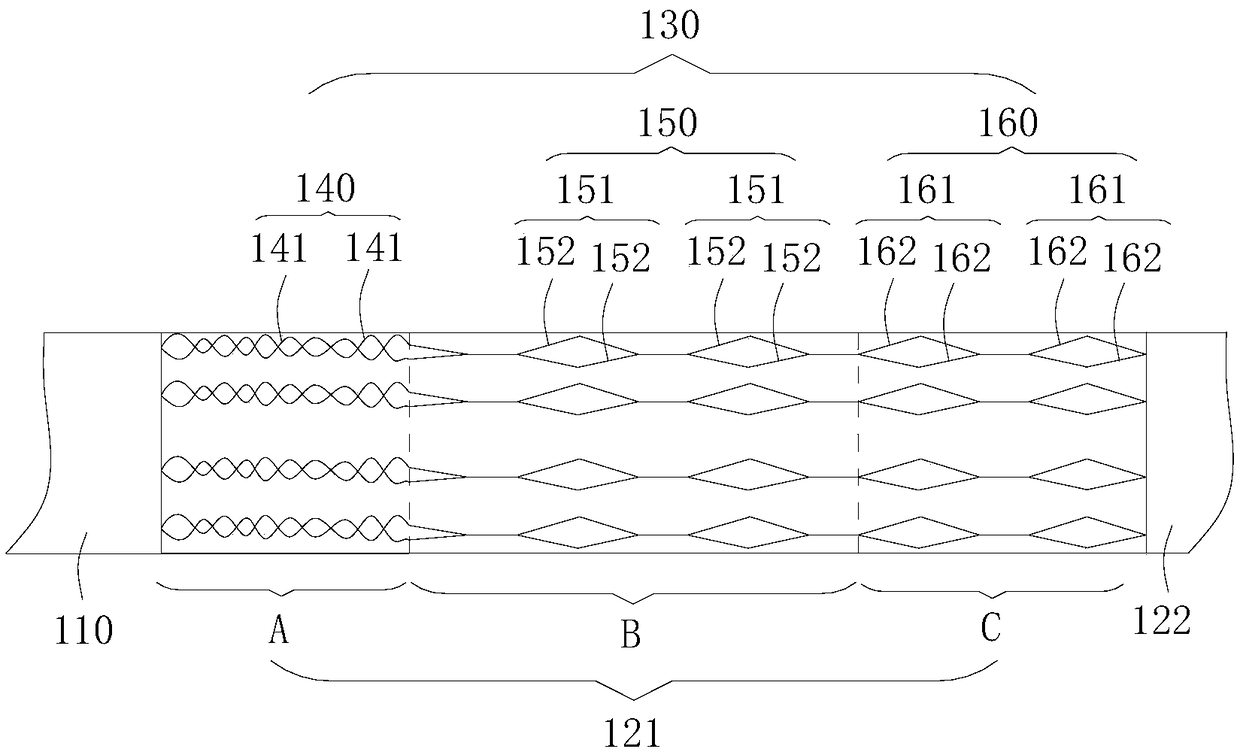

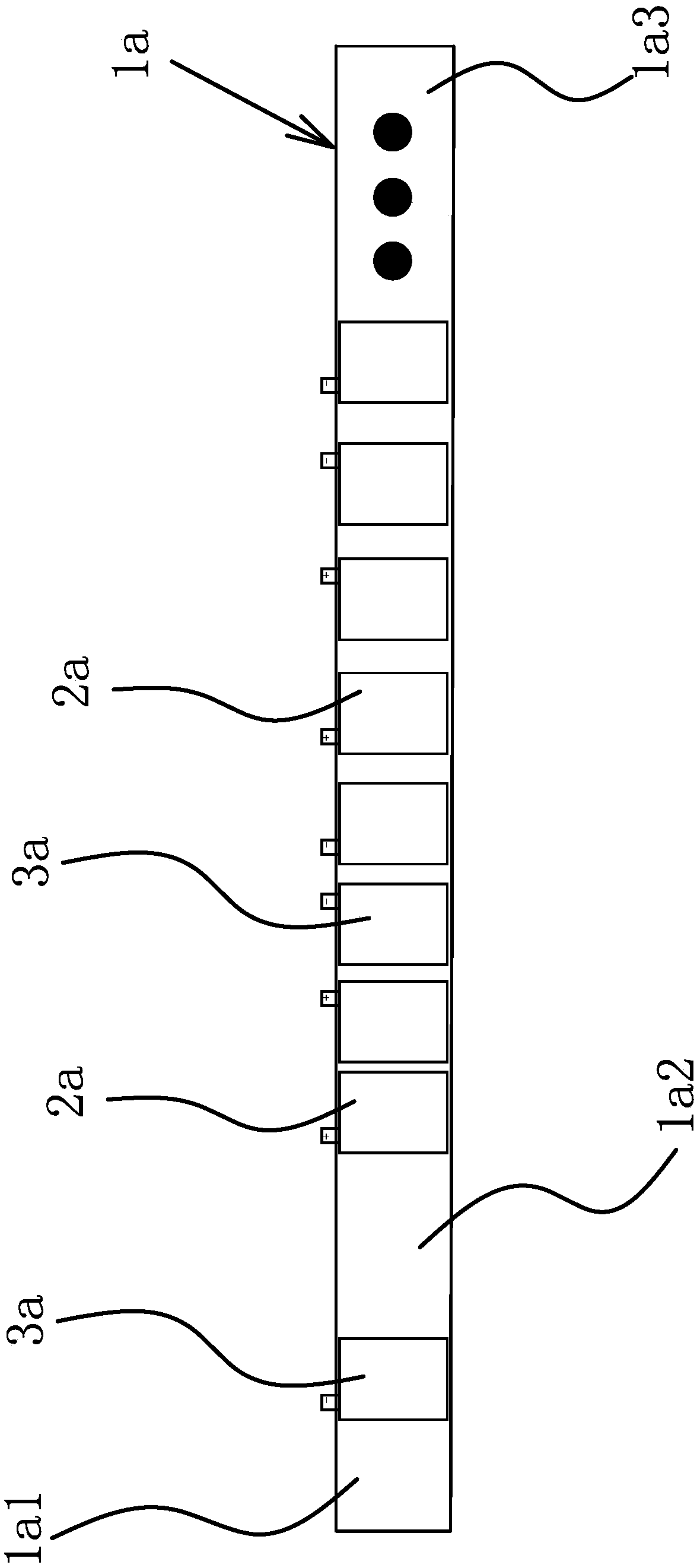

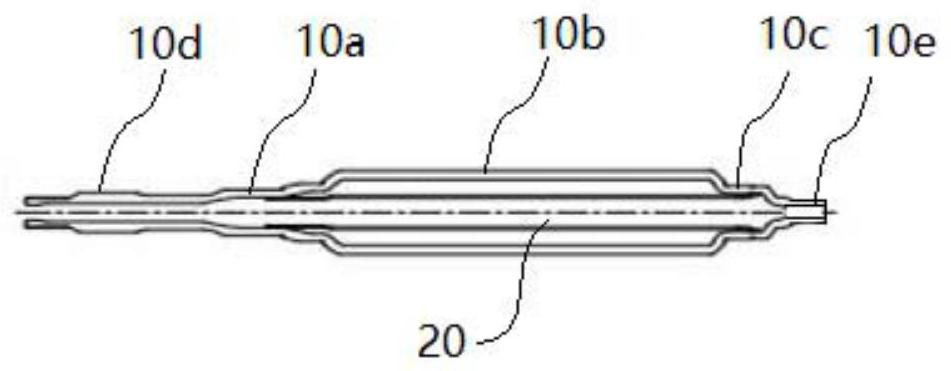

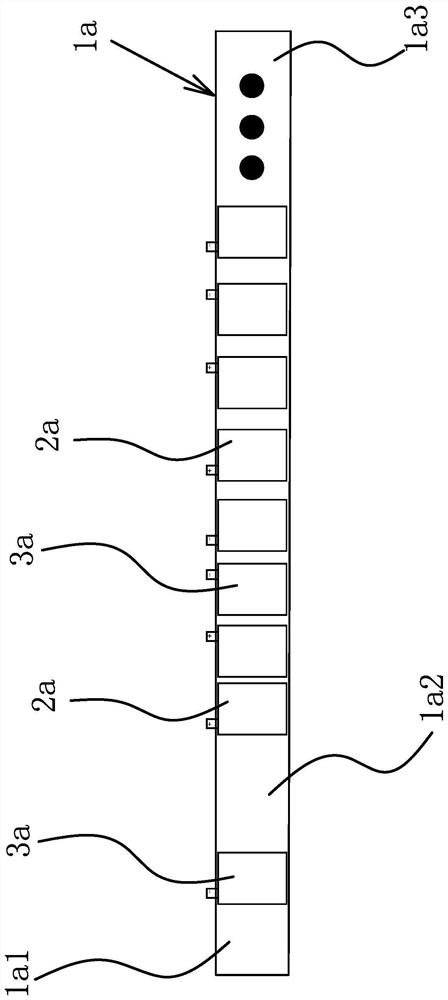

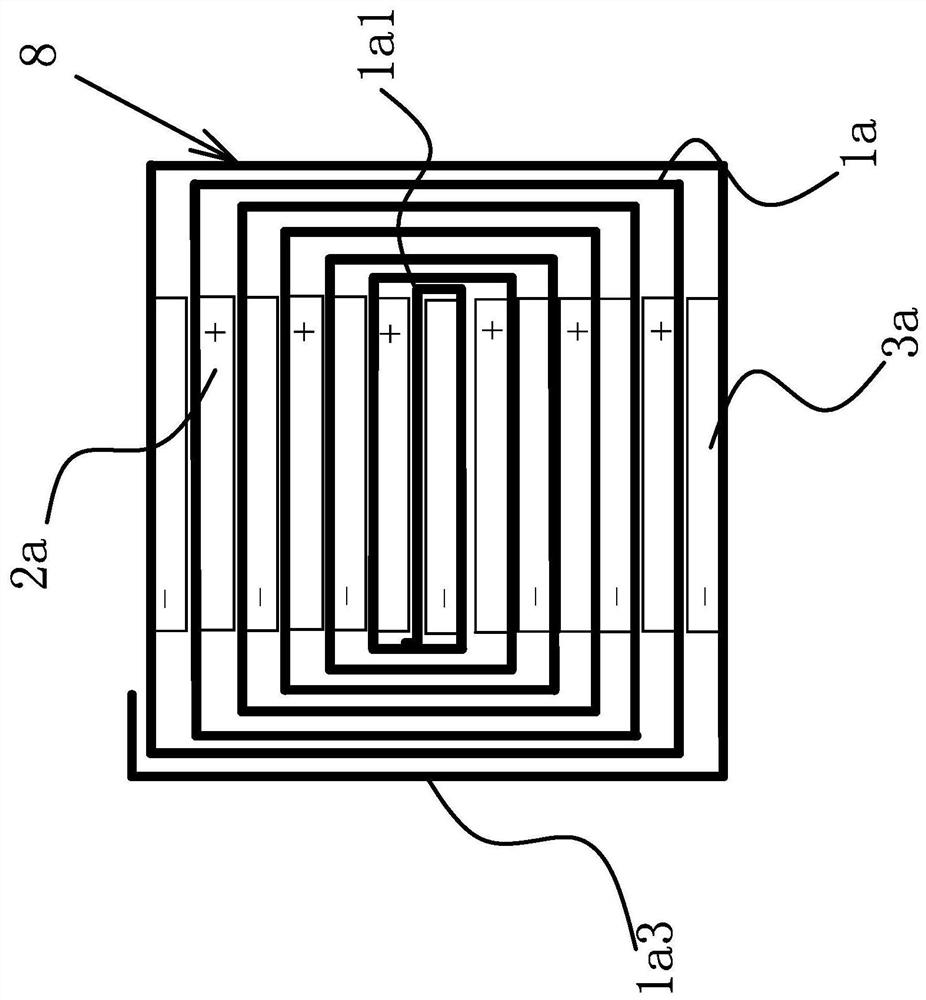

Flexible display screen and display device

PendingCN108766245AGuaranteed connectivityAvoid layeringIdentification meansPhotovoltaic energy generationDisplay deviceFlexible display

The invention relates to a flexible display screen and a display device. The flexible display screen comprises a display area and a non-display area, wherein the non-display area is adjacent to the display area; the non-display area comprises a bending area adjacent to the display area; the flexible display screen comprises a plurality of leads; the leads comprise first lead sections in the display area, second lead sections in a position close to the display area in the bending area, and third lead sections in a middle position of the bending area; the second lead sections comprise at least two second sub-lead sections parallel to each other; the first lead sections, the second lead sections and the third lead sections are sequentially connected in series; a plurality of third lead sections are positioned on a same layer. By adopting the flexible display screen of the technical scheme of the invention, in a bending process of the non-display area, if one of the second sub-lead sections is broken, the rest second sub-lead section can still ensure circuit communication; in addition, stress can be sufficiently released, and organic membrane layers can be prevented from layering. Dueto adoption of the whole components, display failure in the bending process can be prevented.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

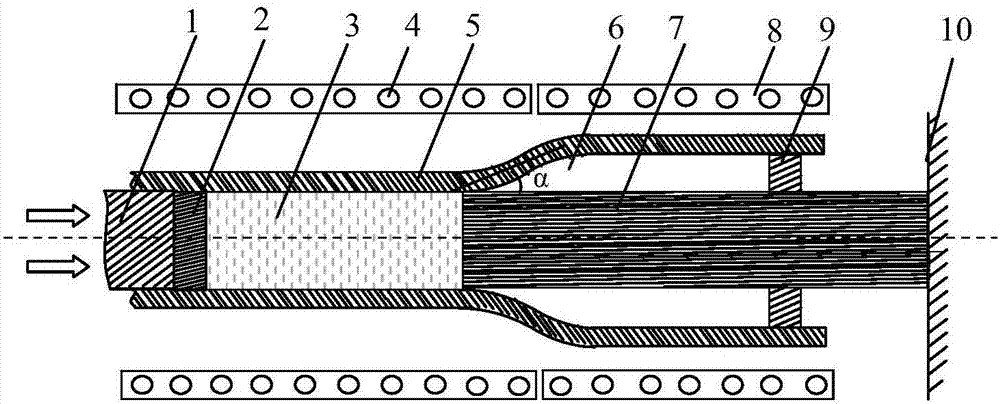

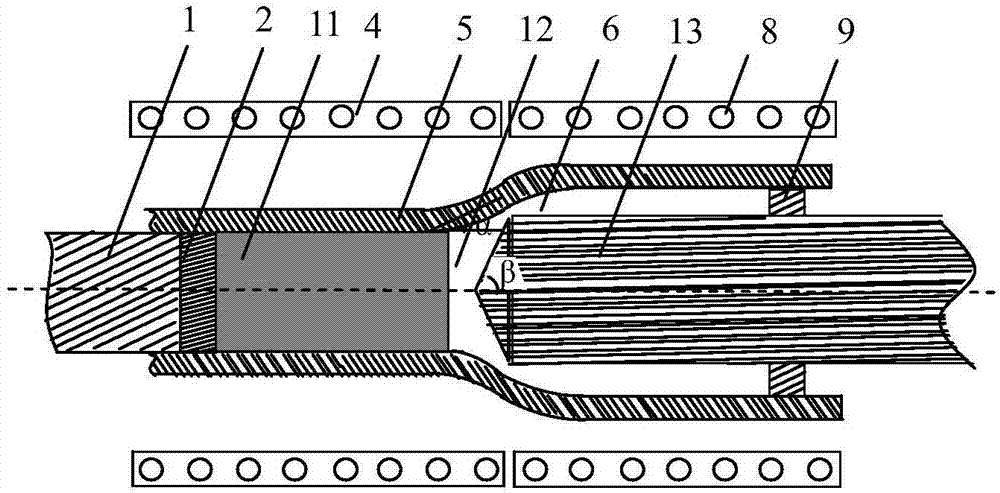

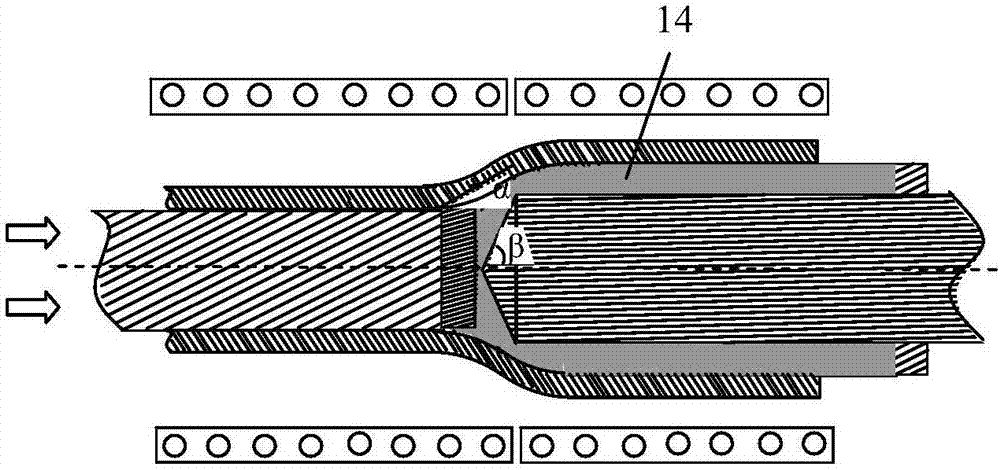

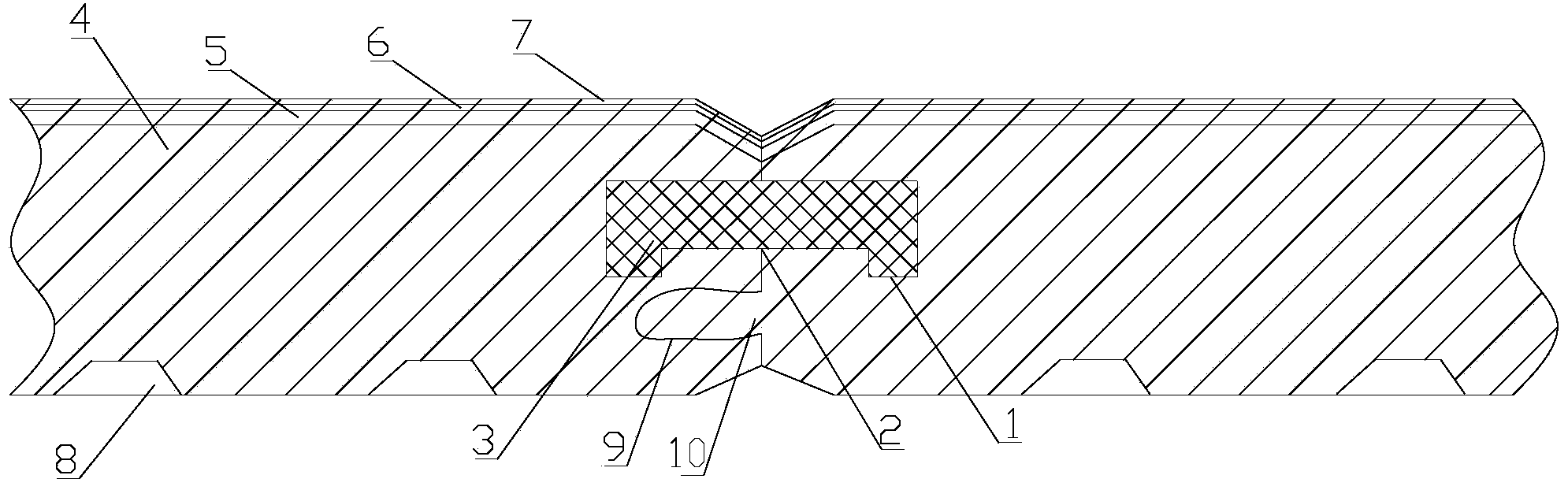

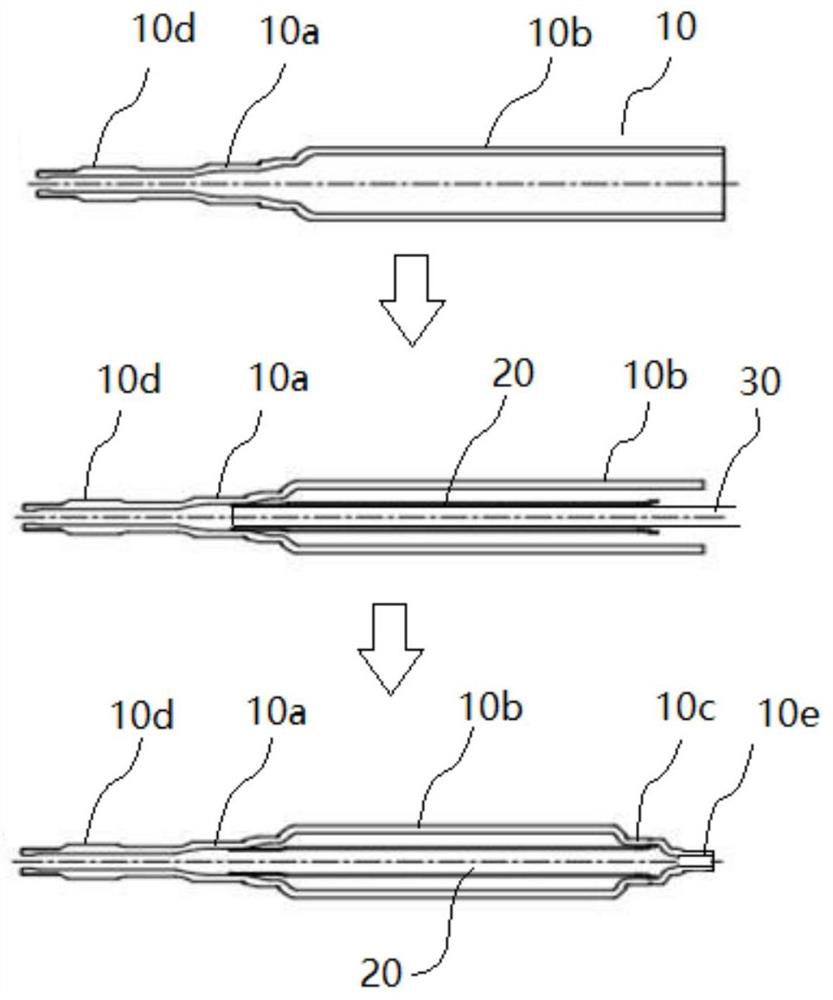

High-performanceradialorientation rare-earth permanent magnetic tube and thermal-deformationforming method thereof

ActiveCN106887293AIncrease productivityEasy to producePermanent magnetsInductances/transformers/magnets manufactureRare earthLanthanide

The invention discloses a high-performanceradialorientation rare-earth permanent magnetic tube and a thermal-deformationforming method thereof, and belongs to the technical field of rare-earth permanent magnetic seamless tube manufacture. A raw-material component of the permanent magnetic tube is RE-(Fe,Co)-B, wherein RE is or one or more ofyttrium or lanthanide elements which are represented by Nd, and one or more other transition metal elements can be added at the same time; a horizontal loading horizontal-type rotation double-motion extrusion device of which a connecting angle alpha is greater than or equal to zero degree and smaller than or equal to 90 degrees is adopted, firstly, hot pressing is conducted on rapid-quenching magnetic powder to form a full-densityisotropousmagnet, then, horizontal positive shuntextrusion is conducted on the full-densityisotropousmagnet to form the radialorientation permanent magnetic tube, the tube length is greater than 50 mm, and the tube diameter is adjustable in a range of 0-150 mm.The horizontal extrusion technology overcomes the spatial height limit of a vertical device, the long-range rheological property improves the magnetism and microstructure uniformity of the permanent magnetic tube, the permanent magnetic tube of which the length, diameter and wall thickness can be freely adjusted in a large size range can be prepared, which is beneficial for the batch production of the radialorientation rare-earth permanent magnetic tube. Through conducting saw cutting on the permanent magnetic tube, nanometer rare-earth permanent rings, magnetic tiles and ceramic chips can be obtained.

Owner:CENT IRON & STEEL RES INST

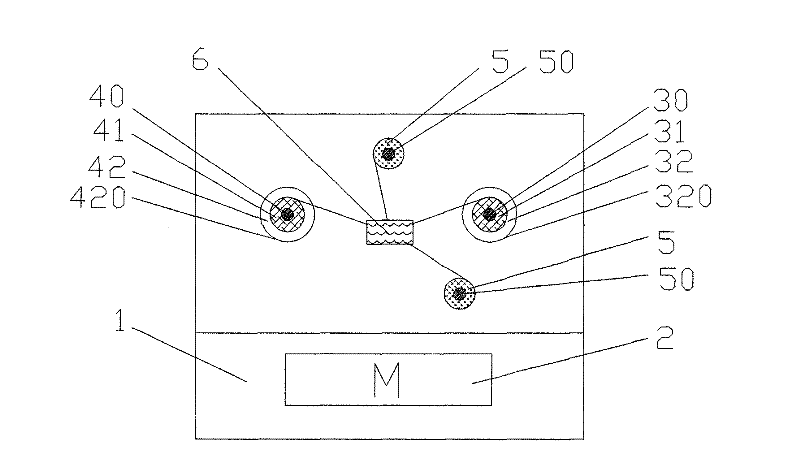

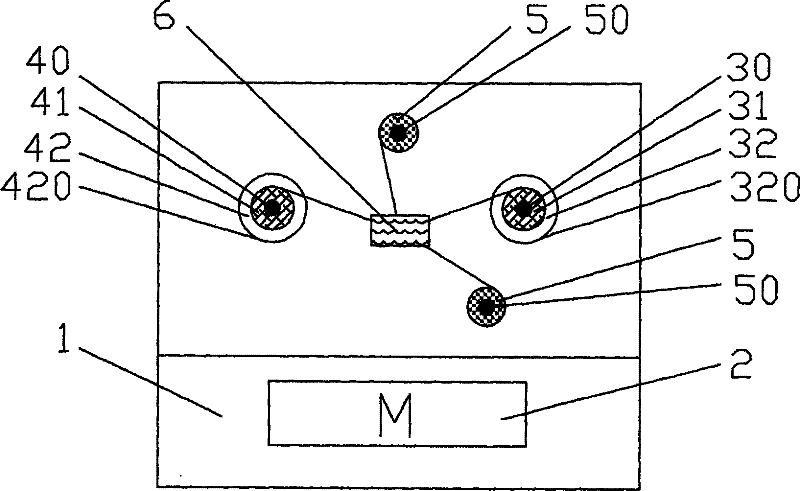

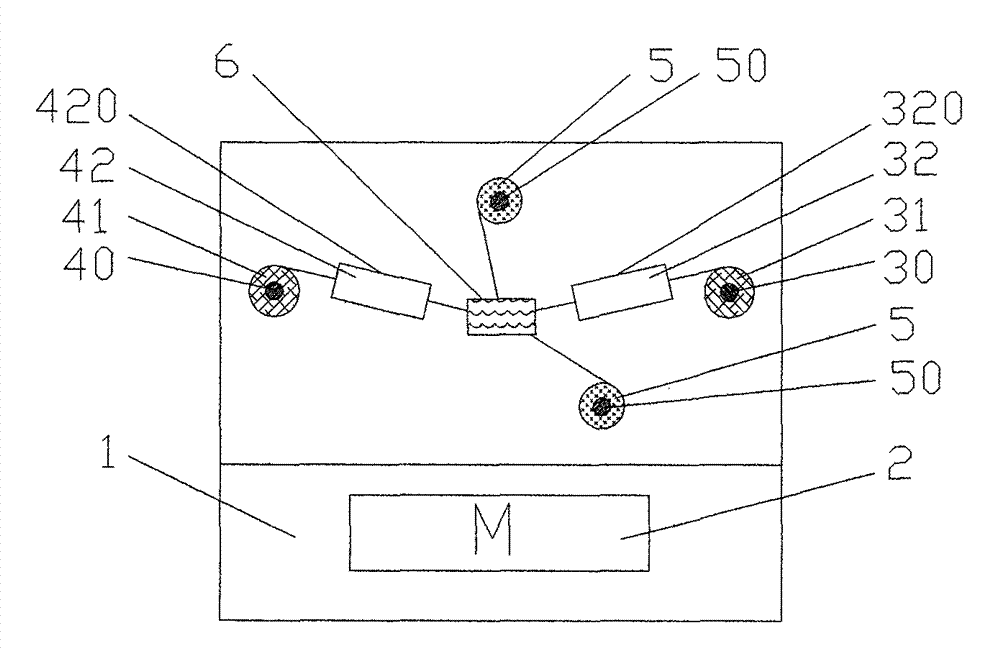

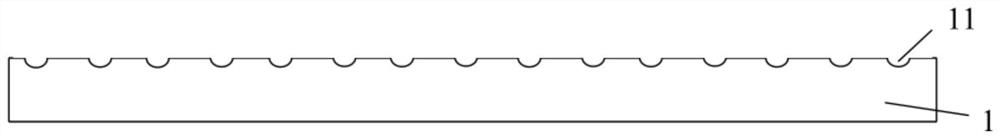

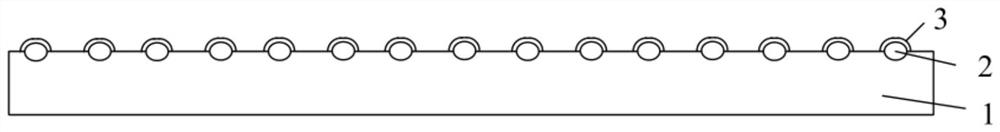

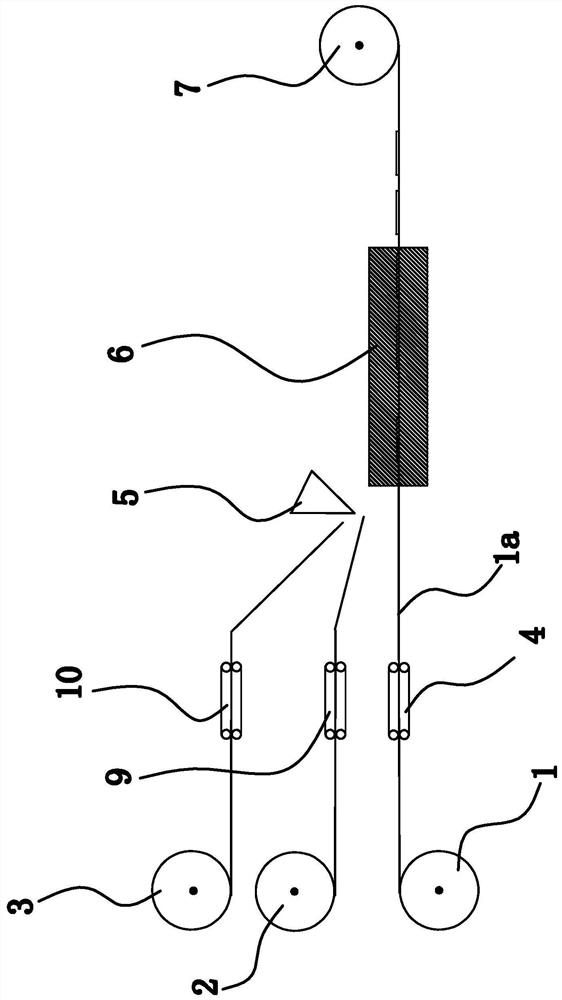

Battery cell winding method and equipment

ActiveCN102683736AEvenly heatedImprove deformationFinal product manufactureSecondary cells manufacturePole pieceBattery cell

The invention discloses a battery cell winding method and equipment. According to the method, a positive pole piece and a negative pole piece are heated before winding, so the stress of the pole pieces is sufficiently released, the pole pieces are lengthened to a certain degree under the tensile action during winding, after the winding is finished, the pole pieces contract along with an isolation film in the cooling process, and the deformation of the battery cell is accordingly improved. The equipment comprises a machine frame, a motor arranged in the machine frame, a positive pole piece feeding mechanism, a negative pole piece feeding mechanism, an isolation film feeding mechanism and a winding mechanism which are fixedly connected with the machine frame respectively, wherein the machine frame is also connected with a positive pole piece heating mechanism and a negative pole piece heating mechanism. The beneficial effects of the technical scheme are as follows: the method is simple and practical, and can be applicable to automation continuous production; and the equipment is simple to operate, the heating mechanisms are easy, and the large-scale manufacturing is facilitated.

Owner:NINGDE AMPEREX TECH +1

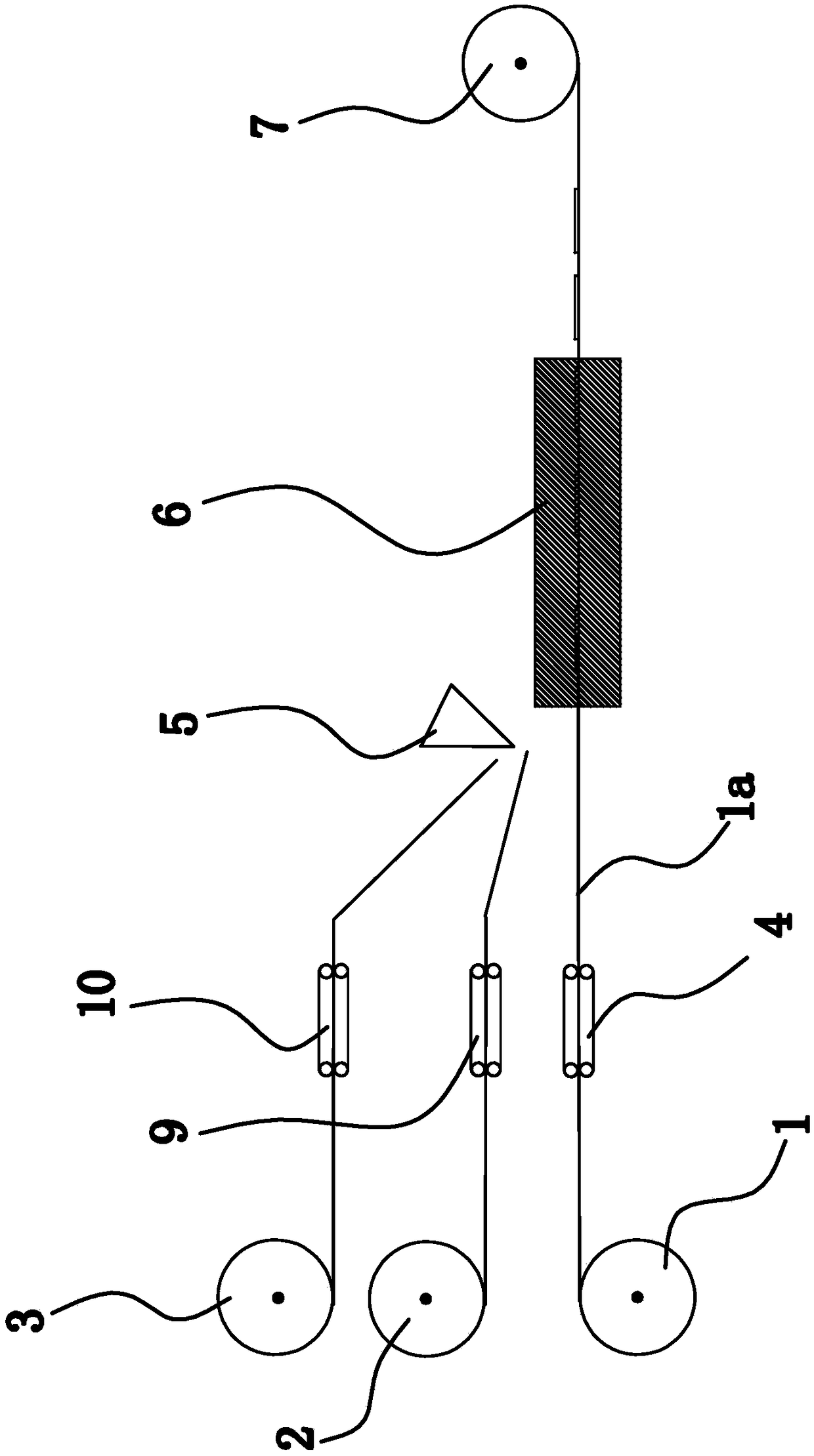

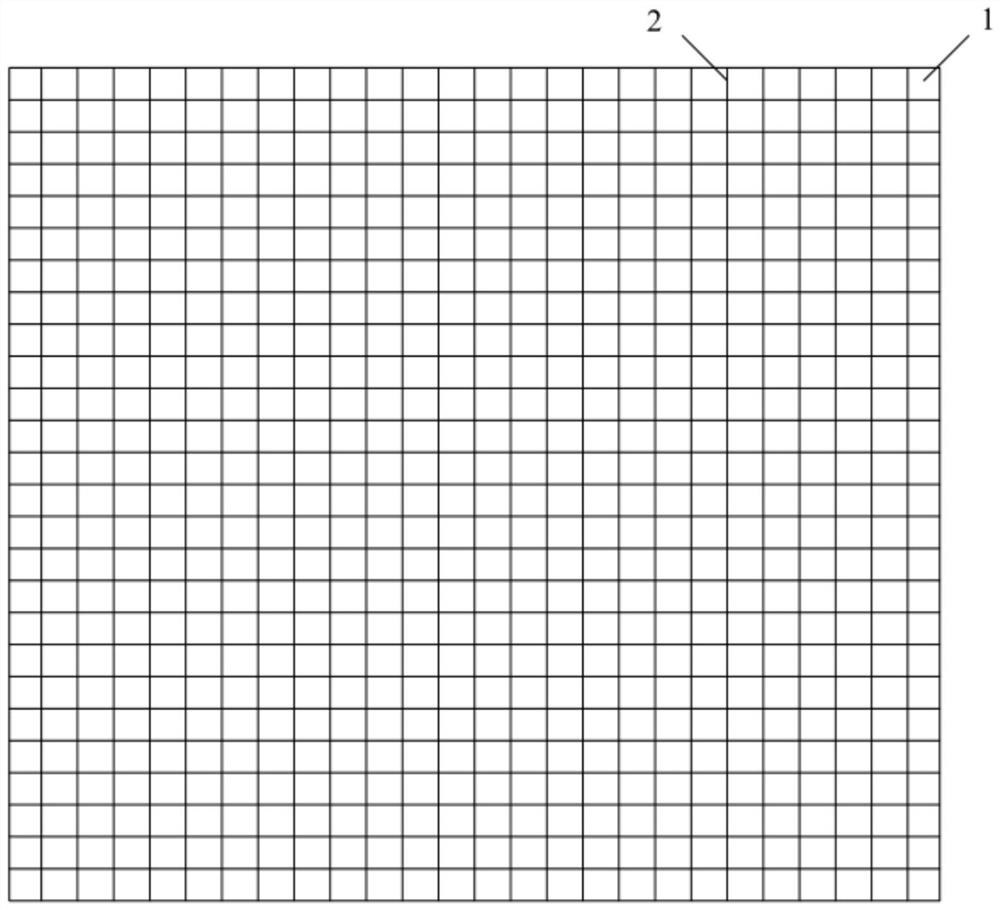

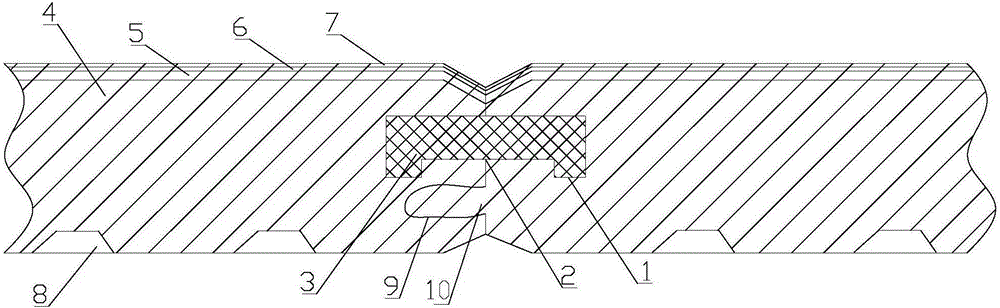

Winding type lithium ion cell and preparation method thereof

InactiveCN109361011AAvoid Position CorrectionFull stress releaseFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention provides a winding type lithium ion cell and a preparation method thereof, and belongs to the technical field of lithium ion battery. The problem of poor yield rate of existing technicalproducts is solved. The method comprises the steps that diaphragm belt unreeling is conducted on a diaphragm reel, a positive electrode reel and a positive electrode reel are unreeled in the conveying direction of the diaphragm belt and cut by a cutting mechanism to form a positive electrode single piece and a negative electrode single piece, the surface on the same side of the diaphragm is alternately provided with a positive electrode region and a negative electrode region, a corresponding electrode single piece is placed on the first region of the diaphragm belt, two corresponding electrode single pieces are placed in every subsequent positive electrode region and every subsequent negative electrode region after the first region, and the diaphragm belt on which the positive electrode single pieces and the negative electrode single pieces are placed are directly conveyed to a combining mechanism and a winding mechanism to be wound to prepare the winding type lithium ion cell. The winding type lithium ion cell is provided. The method can improve the production efficiency and the product qualification rate.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

Deformation-resistant composite solid wood floor board

ActiveCN103835475ALower technical standardsReduce technical standards and production costsFlooringSolid woodEngineering

The invention discloses a deformation-resistant composite solid wood floor board. Two first grooves in uniform distribution are formed at the bottom of the composite solid wood floor board, a second groove is formed on one end face of the composite solid wood floor board, a protrusion is arranged on the other opposite end face of the composite solid wood floor board and can be contained in the second groove when two composite solid wood floor boards are spliced, and the first grooves, the second groove and the outer edge of the protrusion jointly form a four-point balance stress groove of the composite solid wood floor board. By the four-point balance stress groove, deformation-resistant standard is enhanced, stress is fully released, and the objective of deformation preventing is achieved.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

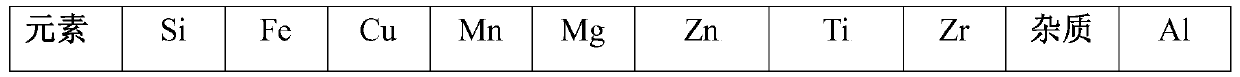

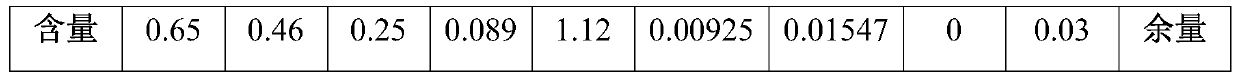

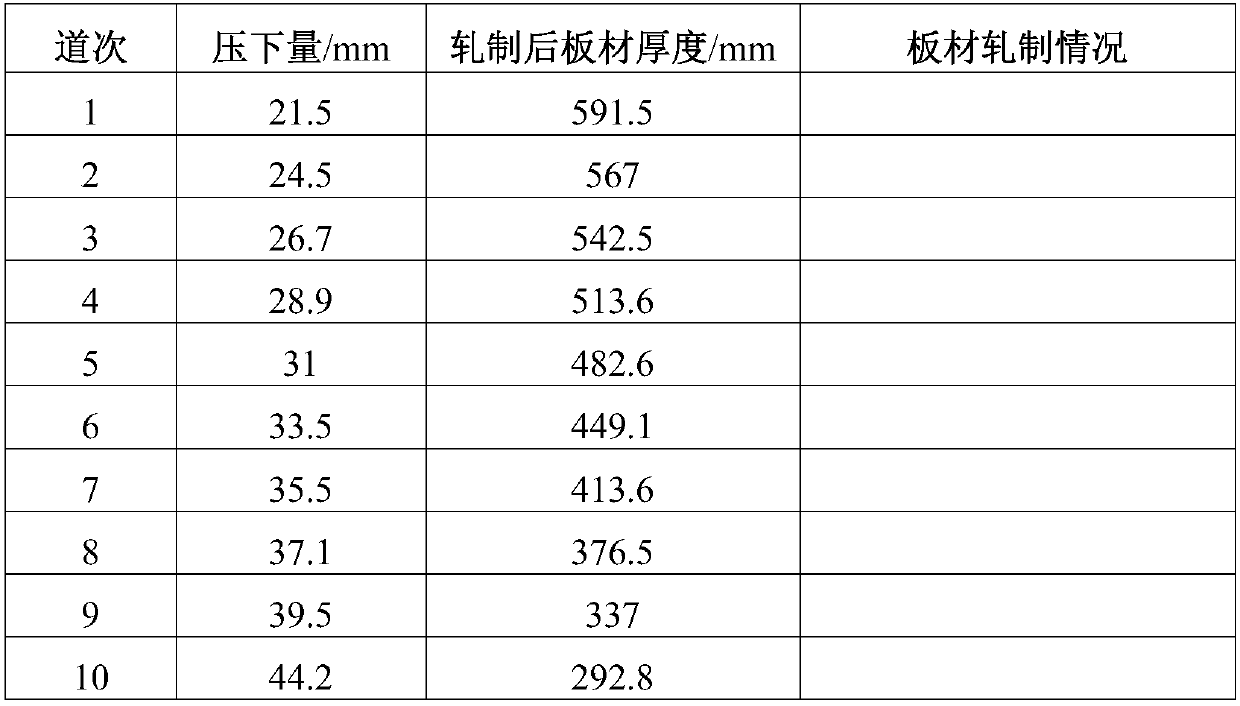

Machining technology of ultrawide 6061 aluminum alloy panel for military test detection platform

The invention belongs to the technical field of aluminum alloy, and relates to a machining technology of an ultrawide 6061 aluminum alloy panel for a military test detection platform. Aluminum alloy is prepared from, by weight percentage, 0.63-0.69% of Si, 0.45-0.55% of Fe, 0.2-0.3% of Cu, 0.08-0.12% of Mn, 1.05-1.15% of Mg, 0-0.1% of Zn, 0.013-0.02% of Ti, 0-0.05% of Zr, 0-0.05% of single impurities, and the balance Al, wherein the total weight percentage of the above raw materials except Al is smaller than or equal to 0.15%. The lost pass is added in the hot rolling process, during shallow pass, by cooling the panel with rolling mill air-blowing equipment, the purpose of uniformly and slowly lowering the finish rolling temperature is achieved, arching of the back of the panel due to theexcessive width is avoided, and the problems that for the ultrawide 6061 aluminum alloy panel prepared through an existing machining technology, the contradiction between the width and flatness of thepanel and the machining deformation is prominent, and it is hard to meet customer needs are solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

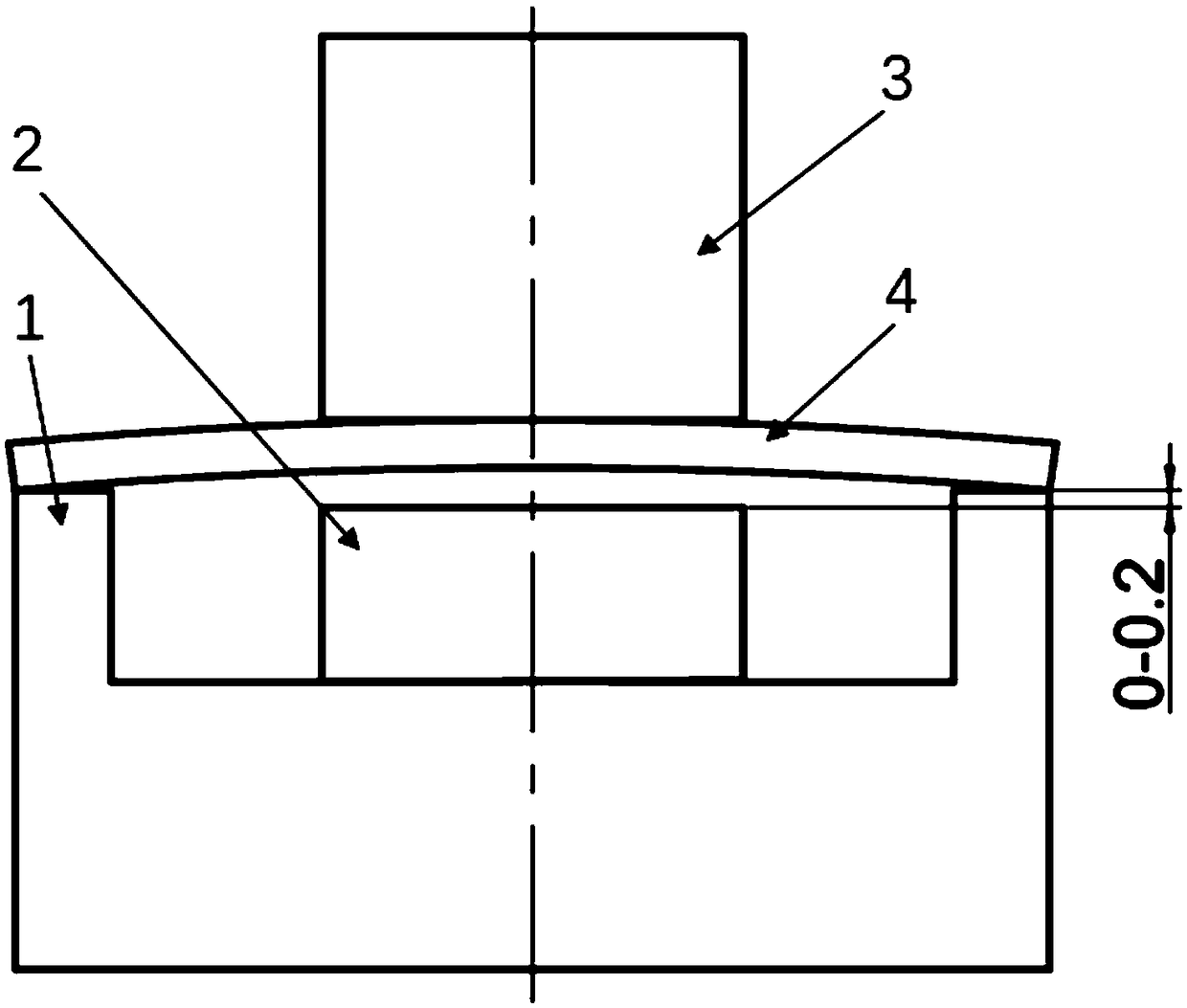

Heat treatment method for correcting plane warping deformation of injection molded product

The invention provides a heat treatment method for correcting the plane warping deformation of an injection molded product and belongs to the technical field of injection molding. A correcting tool isdivided into three parts including a U-shaped correcting support frame, a regulating block and a pressure application block. The heat treatment method comprises the steps: placing the regulating block in the middle of the U-shaped correcting support frame, placing a corrected injection molded product above the regulating block and the U-shaped correcting support frame, and mounting the pressure application block above the corrected injection molded product; then, placing a combined body into a drying oven or completing the combination in the drying oven, carrying out heat insulation, meanwhile, keeping a drying environment, setting the temperature of the drying oven to be 10-20 DEG C lower than the glass transition temperature of the material of the injection molded product, keeping the temperature for 1-2 h, and then, taking out and separating each part; and cooling a to-be-corrected injection molded product to the room temperature, and repeating the process once or twice. Accordingto the heat treatment method, a plastic product is subjected to heat treatment, and the internal stress of the plastic product is firstly released under the assistance of correcting measures, so thatthe problem of injection molding plane warping deformation is effectively solved.

Owner:DALIAN UNIV OF TECH

Wide slab longitudinal crack control process

InactiveCN111761039ASuitable for production conditionsReduce cooling intensityCrazingManganese sulfide

The invention discloses a wide slab longitudinal crack control process, and relates to the technical field of continuous casting processes. The manganese-sulfur ratio is improved by reducing the massfraction of sulfur, manganese and the sulfur are combined to generate manganese sulfide, and the manganese sulfide is a plastic inclusion so that the sensitivity of cracks can be effectively reduced;high-alkalinity casting powder has lower heat-conducting property and higher crystallization rate so that the defect of surface cracks a cast slab caused by peritectic reaction can be effectively overcome; the cooling intensity of a crystallizer is properly reduced so that the cooling non-uniformity can be effectively relieved, and then a uniform slab shell is obtained; and the overall taper of the crystallizer is set in a proper interval, so that serious abrasion of a slab shell and a copper plate caused by the too large overall taper is avoided, the situation that the two side faces of the cast slab are bulged due to the fact that an initial slab shell cannot be effectively supported due to the fact that a gap between the initial slab shell and the copper plate becomes large due to the too small overall taper is also avoided, and through the arrangement, the occurrence rate of longitudinal cracks can be greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

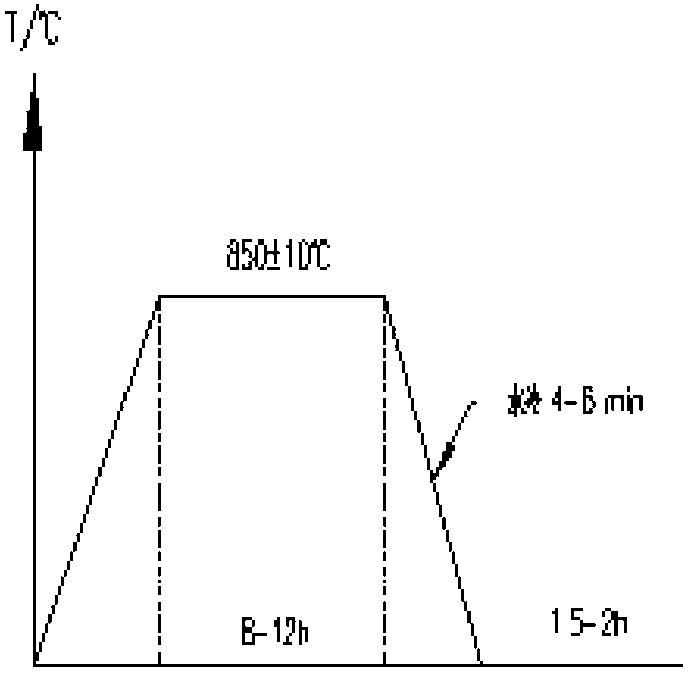

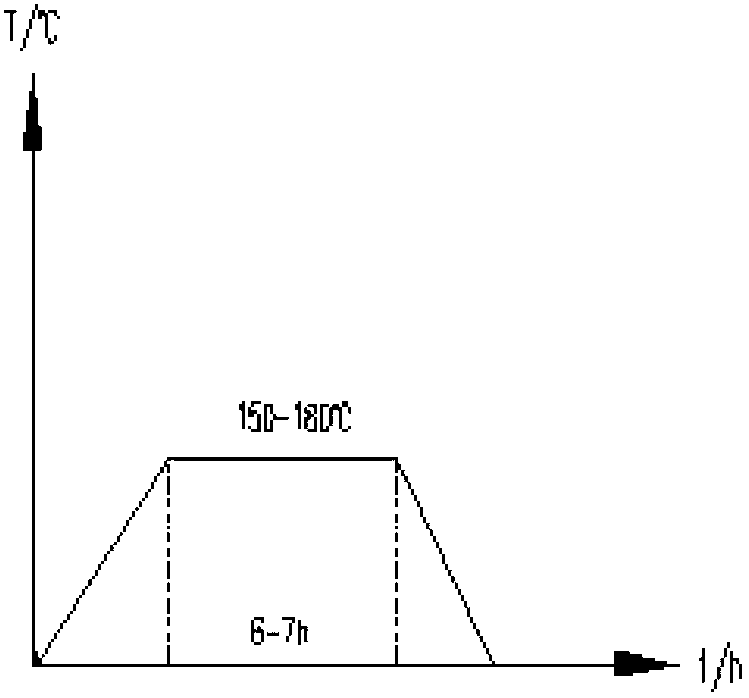

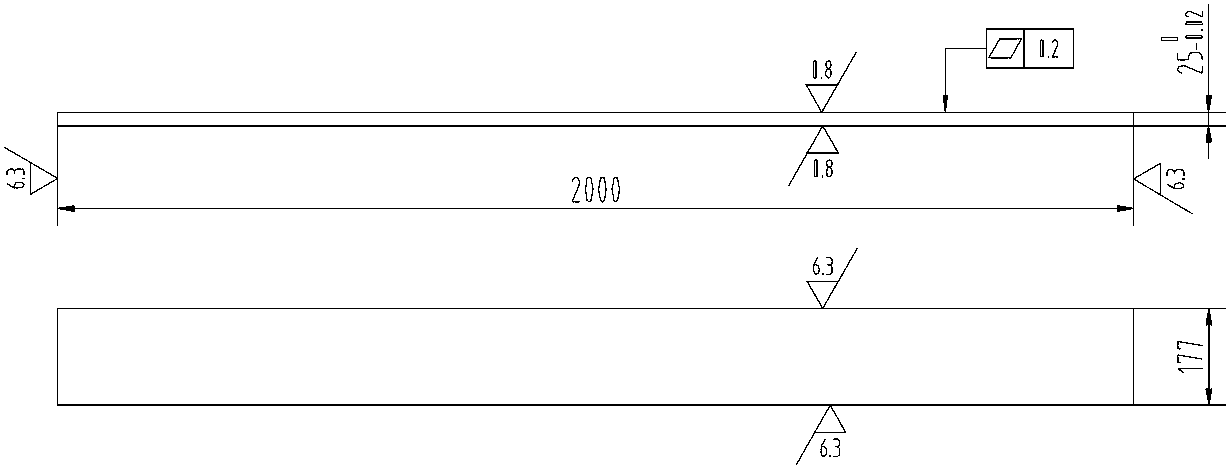

Production method of thin and long thin-plate type part

InactiveCN103014303AIncrease pressureAvoid deformationFurnace typesHeat treatment process controlSpring steelWater cooling

The invention relates to a production method of a thin and long thin-plate type part and belongs to the field of machine manufacturing. The temperature of heat treatment is 820-900 DEG C and the heat-preservation time is 8-12 hours; a pressing machine is used for pressing to quench and the pressure of the pressing machine is improved to 6-12 Mpa; water cooling is adopted, the water temperature is 20-40 DEG C and the time is 4-6 minutes; after the quenching, annealing is carried out immediately within two hours; the annealing temperature is 150-180 DEG C and the heat-preservation time is 6-8 hours; a milling manner is used for carrying out fine machining and the fine machining comprises rough milling, natural aging and fine milling; the rough milling is carried out, namely, front and back surfaces of the part are exposed, the front and back surfaces are repeatedly milled for 4-5 times and the machining amount is 1.8-2 mm; the natural ageing is that the part is placed on a flat plate or is vertically suspended and the natural ageing is carried out for 24 hours; and the fine milling is carried out, namely, the front and back surfaces are repeatedly milled for 2-3 times and the machining amount is 1-1.2 mm. According to the production method, water quenching and cooling are adopted and the pressing machine is used for pressing to quench; spring steel is arranged so that the pressure of the pressing machine is improved and the natural ageing procedure is increased; and the deformation of the thin and long thin-plate type part is solved and the hardening crack can be effectively prevented.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

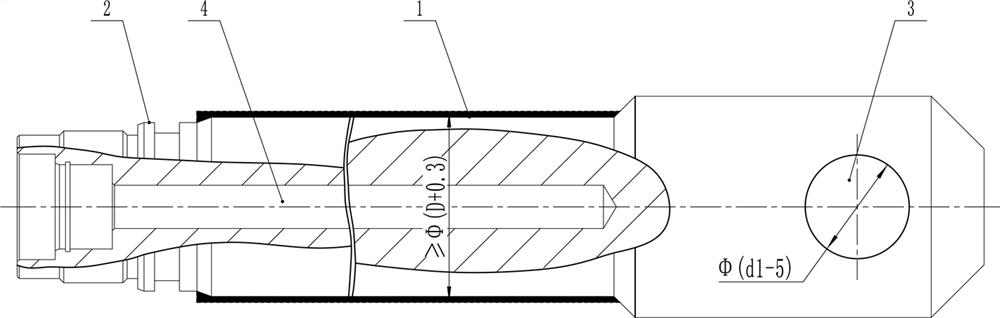

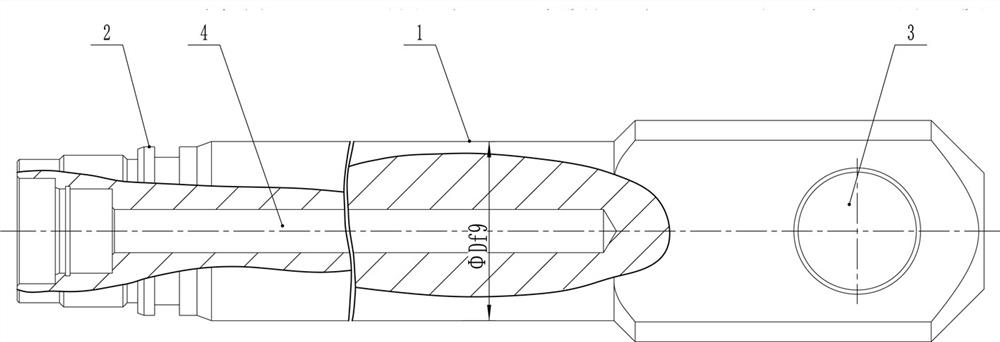

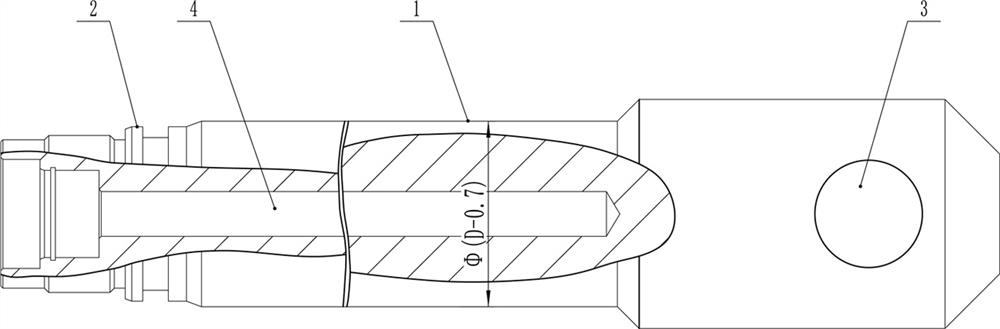

Laser cladding deformation control method for slender piston rod

InactiveCN112059545ANot easy to cause deformationHighlight substantive featuresMetallic material coating processesPolishingDeformation control

The invention provides a laser cladding deformation control method for a slender piston rod. The laser cladding deformation control method comprises the following steps of rough turning, wherein the reserved size is larger than or equal to phi(D+n) mm; drilling a hinge hole; hardening and tempering; straightening, wherein the jerk value of the slender piston rod is less than or equal to 1mm; Semi-finish turning, wherein the reserved size is larger than or equal to phi(D+n1) mm; finish turning, specifically, carrying out further finish machining on the outer circle of the slender piston rod bytaking a semi-finish-turned outer circle as a benchmark; high-speed laser cladding, specifically, detecting the jerk value of a sealing surface; size detection, specifically, detecting the diameter ofeach part of the slender piston rod; and carrying out milling-flattening, excircle grinding and polishing in order to complete the laser cladding process of the slender piston rod. The laser claddingdeformation control method for the slender piston rod has the advantages that severe workpiece deformation caused by excessive heat generated in the laser cladding process is avoided, and the processflow and time are saved.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

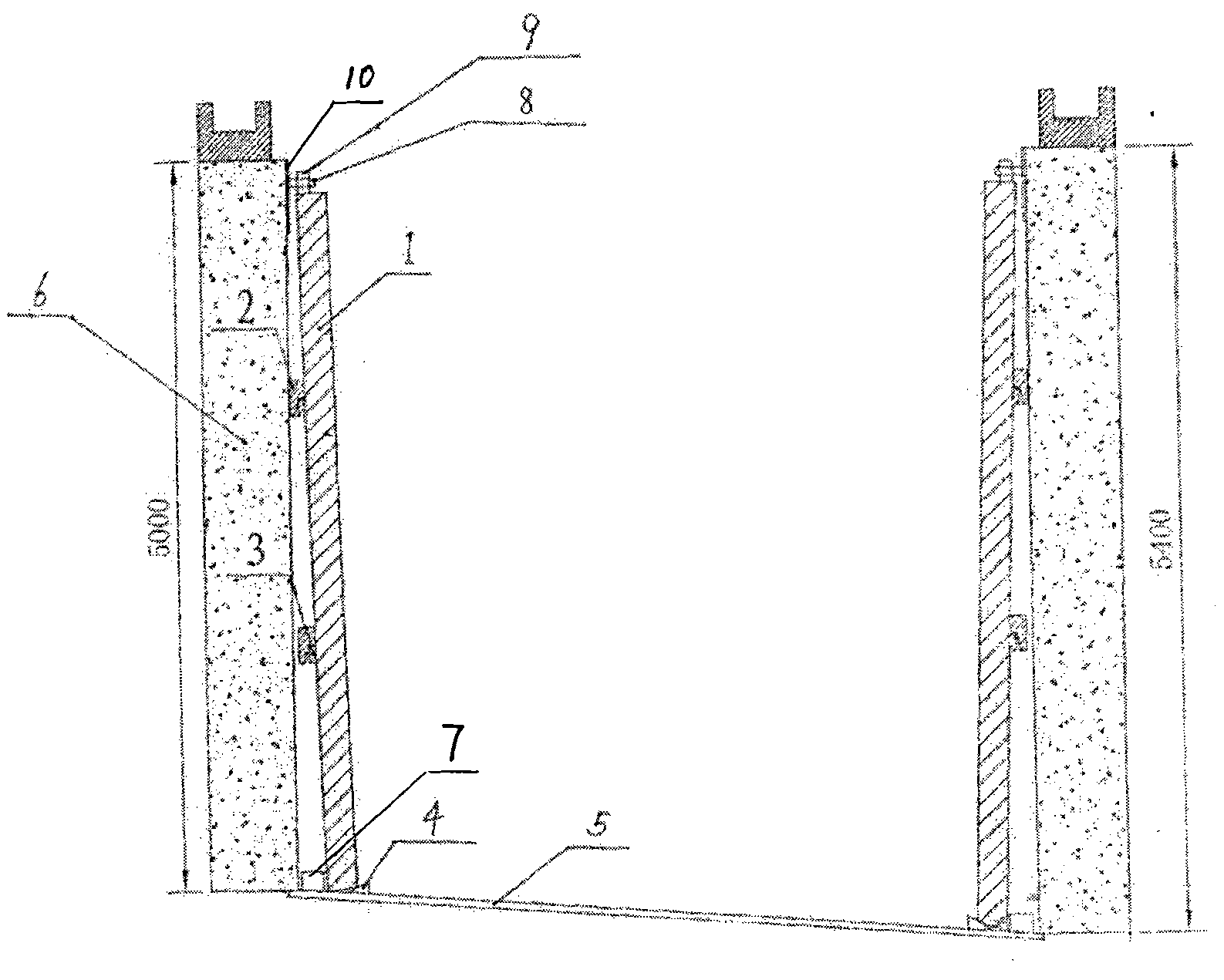

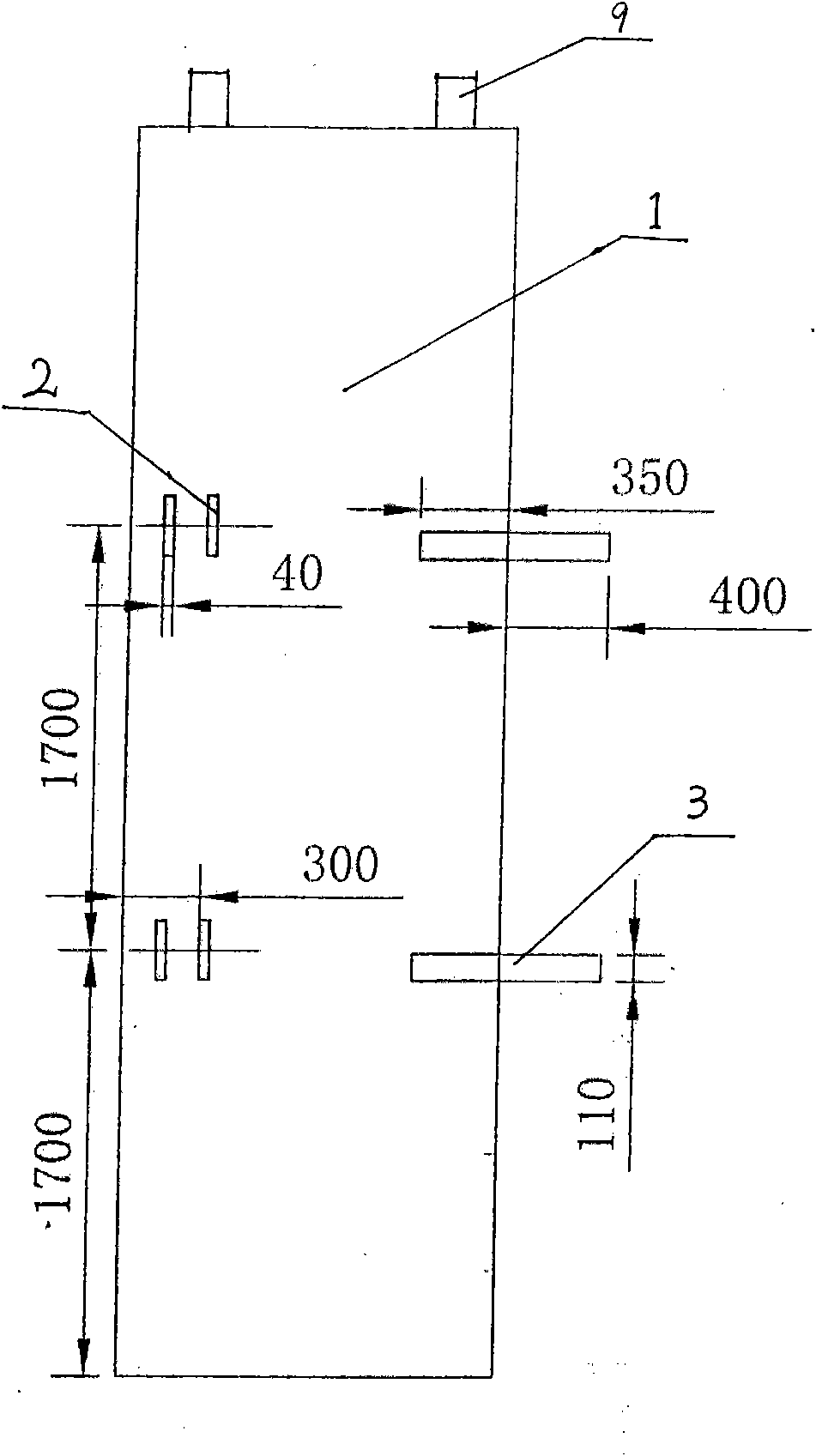

Method for installing and fixing large lining plate

InactiveCN102061344AStable structureSimple structureRecycling and recovery technologiesInsulation layerSlag

The invention relates to a method for installing and fixing a large lining plate for a metallurgical steel slag treatment hot stuffy tank. The method is characterized in that: plate blanks serving as lining plates lean against an embedded iron plate on the wall of the hot stuffy tank in certain angles and play a role in structure stabilization by using dead weight, and certain gaps are reserved on the plate blanks and the cement tank wall to form a heat insulation layer so as to play a role in protecting the tank wall. At the lower ends of the plate blanks, stop iron and wedge iron are welded close to two sides of the plate blanks by using tank bottom steel plates to form inner wedge and outer stop; and the degree of freedom of the plate blanks is controlled, and the extension of the plate blanks is not affected, so that the stress of the plate blanks is fully released and the influence of expansion with heat and contraction with cold on the lining plate is eliminated. The plate blanks are connected by hooks and iron bars to form a whole. A door shape is welded on an embedded steel plate on the upper part so as to reinforce the upper parts of the plate blanks. The method stabilizes the structure of the lining plate, enables the lining plate to resist impact, reduces the damage rate of the lining plate, prolongs the service life of the lining plate, is convenient for construction, and can save a large amount of fund.

Owner:TIANJIN TIANTIE METALLURGICAL GRP

Rotor shaft with oil pipe and machining process of rotor shaft

PendingCN113381555AFull stress releaseNo heat affected zoneManufacturing dynamo-electric machinesEngine componentsClassical mechanicsEngineering

The invention discloses a rotor shaft with an oil pipe and a machining process of the rotor shaft. The machining process of the rotor shaft comprises the following steps that: a hollow rotor shaft body is subjected to die forging, wherein the hollow rotor shaft body comprises a first hollow shaft section and a second hollow shaft section, and the pipe diameter of the first hollow shaft section is smaller than that of the second hollow shaft section; an oil pipe inserted with a mandrel is inserted into the hollow rotor shaft body, so that the first end of the oil pipe is matched with the first hollow shaft section; the first hollow shaft section is spun, so that partial area of the first hollow shaft section and the first end of the oil pipe are forged and pressed into a whole; the mandrel is taken out from the second end of the oil pipe; and the second hollow shaft section is spun, so that partial area of the second hollow shaft section and the second end of the oil pipe are forged and pressed into a whole to form a third hollow shaft section. With the rotor shaft with oil pipe and machining process of the rotor shaft adopted, the problem that an existing rotor shaft has internal stress due to the fact that the machining manufacturability of the rotor shaft is poor can be solved.

Owner:EVERGRANDE NEW ENERGY AUTOMOTIVE INVESTMENT HLDG GRP CO LTD

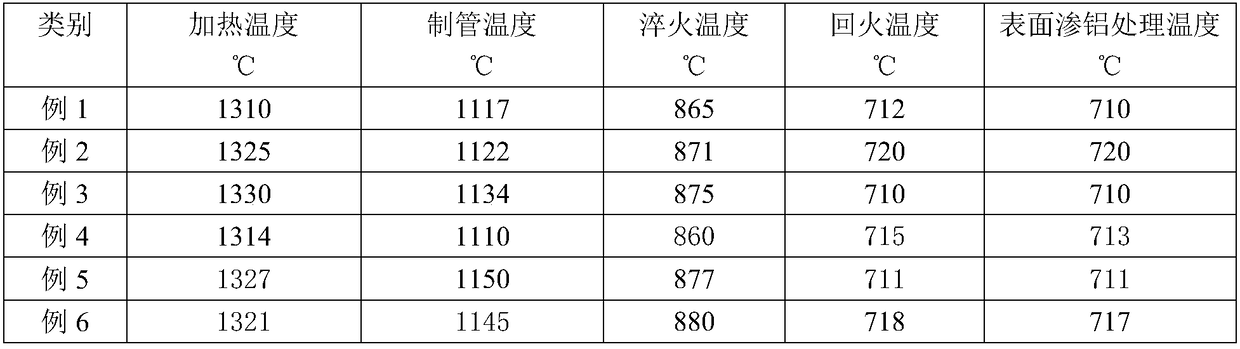

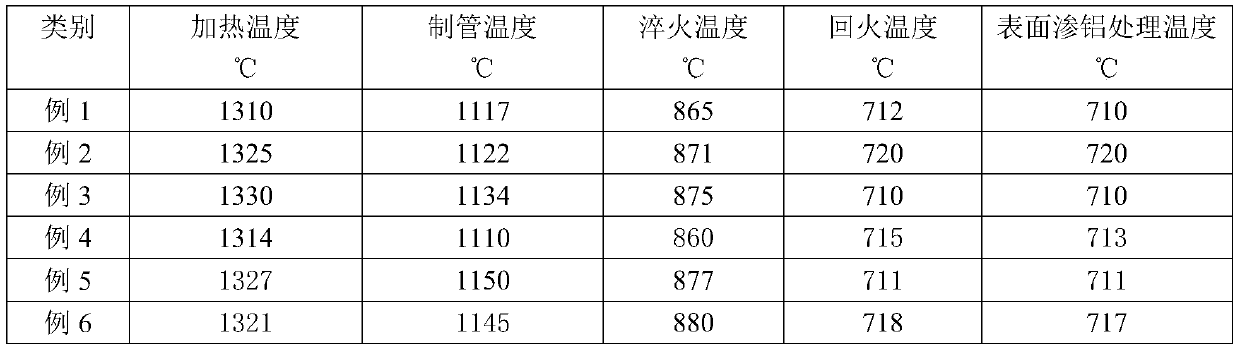

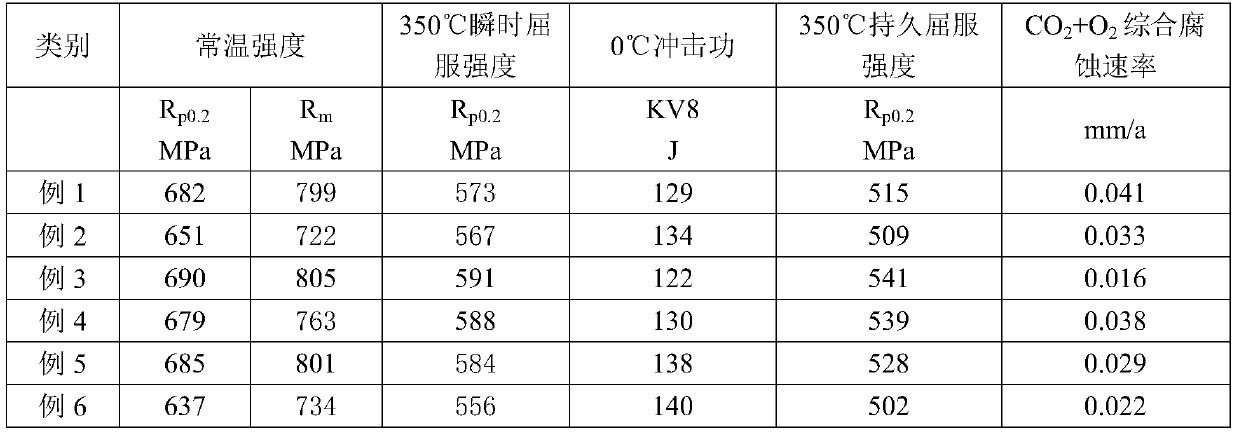

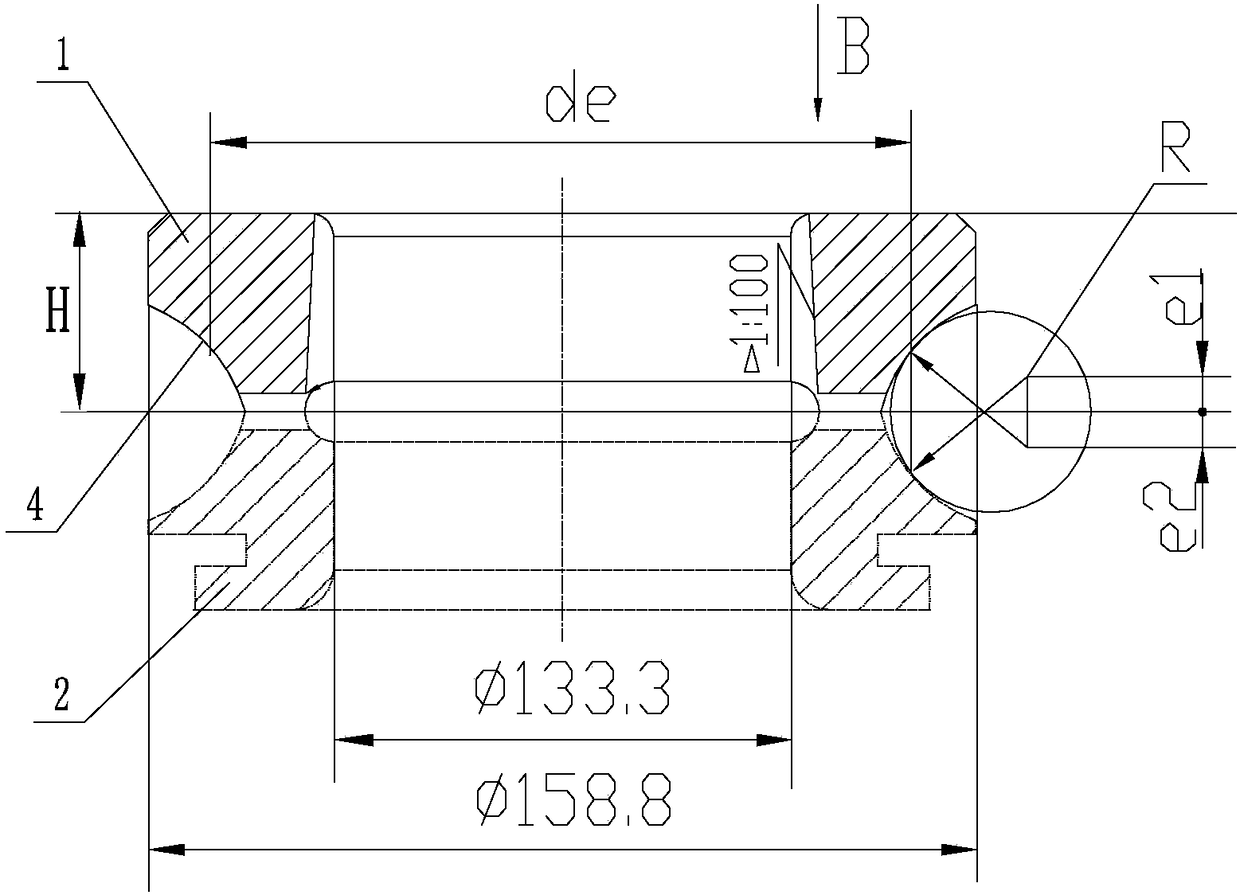

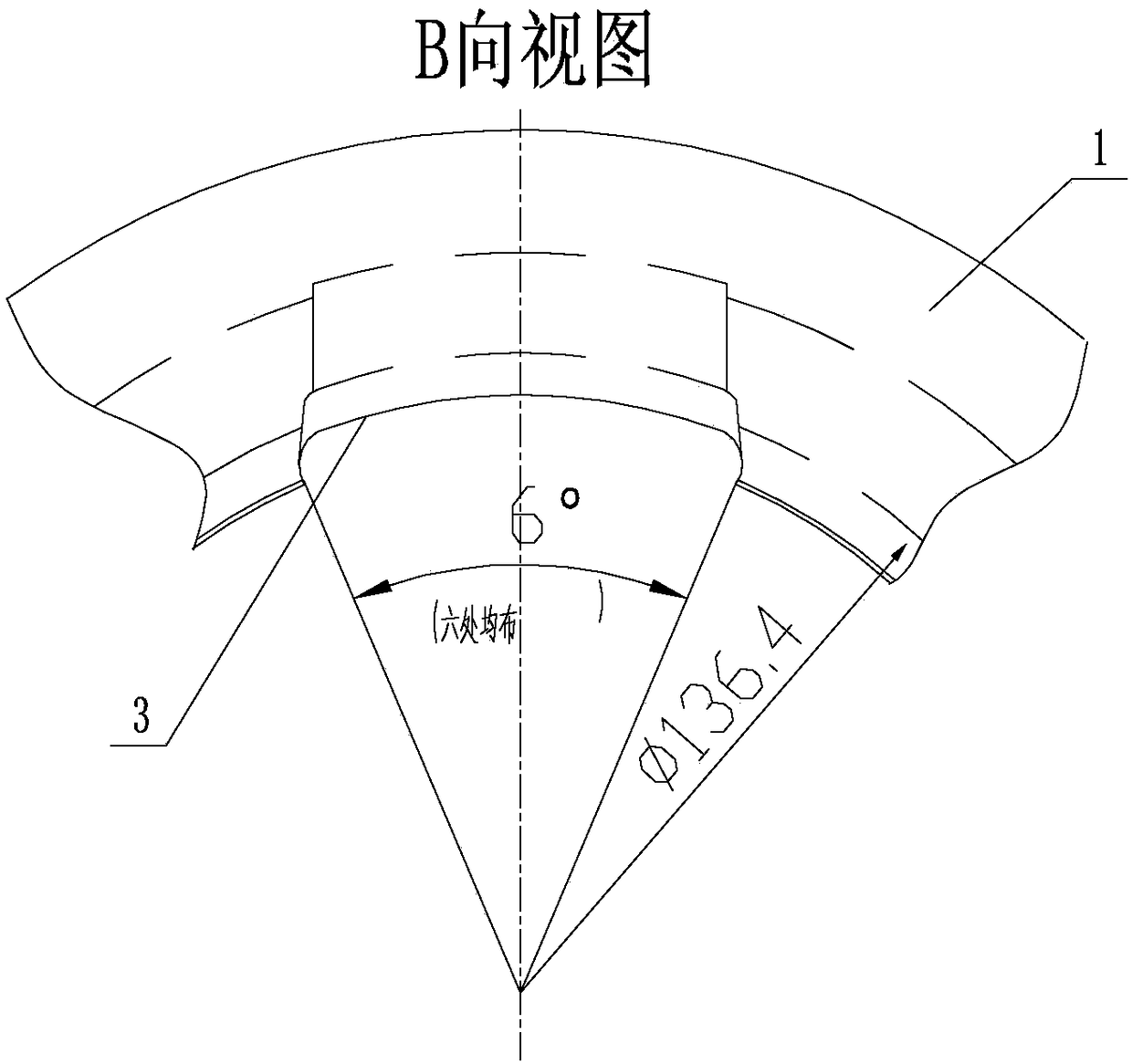

Oil well pipe for heavy oil thermal recovery well and manufacturing method

ActiveCN108588558ASolve the technical problems of comprehensive corrosionImprove high temperature resistanceSolid state diffusion coatingFurnace typesChemical compositionQuenching

The invention relates to an oil well pipe for a heavy oil thermal recovery well, and a manufacturing method. The oil well pipe comprises, by weight percent, 0.37 to 0.42% of C, 0.15 to 0.30% of Si, 0.60 to 0.80% of Mn, not larger than 0.02% of P, not larger than 0.01% of S, 0.8 to 1.5% of Cr, 0.04 to 0.06% of Nb, 0.04 to 0.06% of Ti and the balance Fe and inevitable impurities. The oil well pipe has the beneficial effects that the cost is low, the industrial batched production is easily achieved, through the heat treatment technology of subcritical quenching, superhigh temperature tempering and surface aluminizing, the structure of the steel pipe is fine and uniform, corrosion resistance is greatly improved, and the use needs of the current and future market for the oil well pipe with thehigh temperature resistance and corrosion resistance properties are met.

Owner:ANGANG STEEL CO LTD

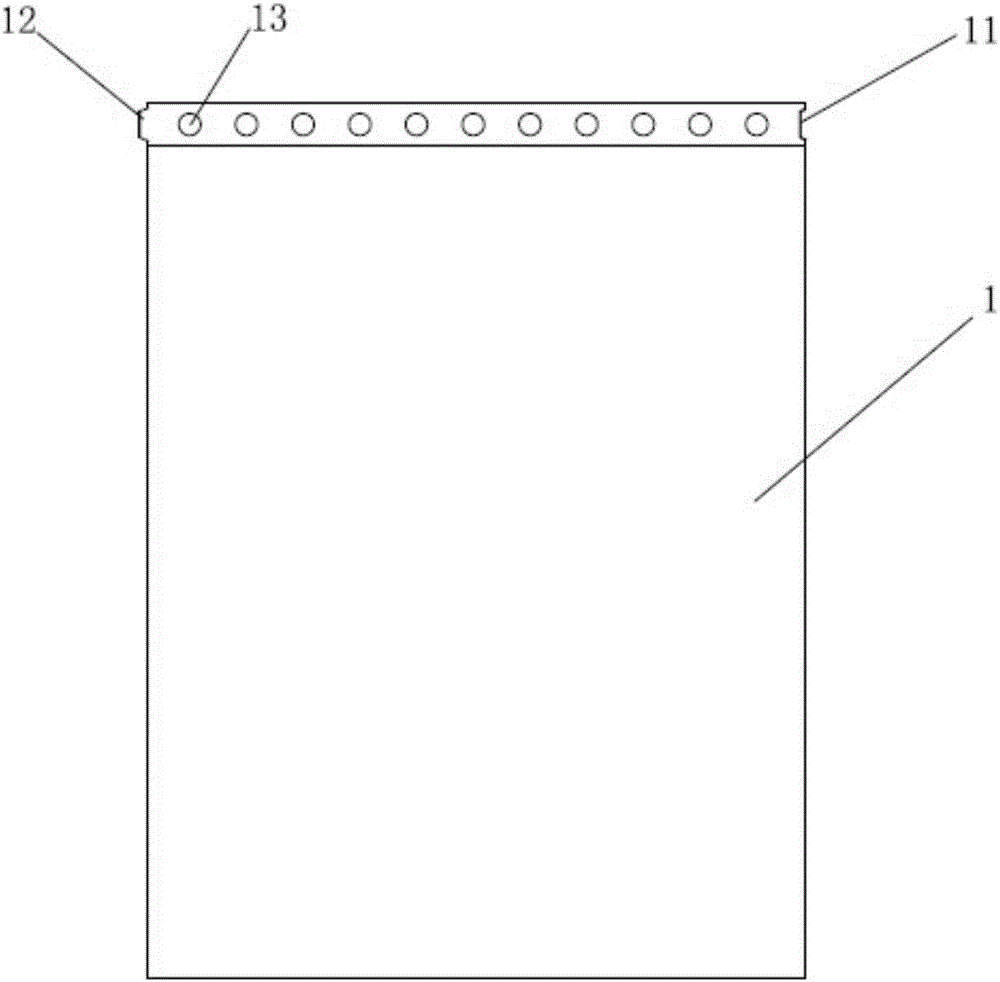

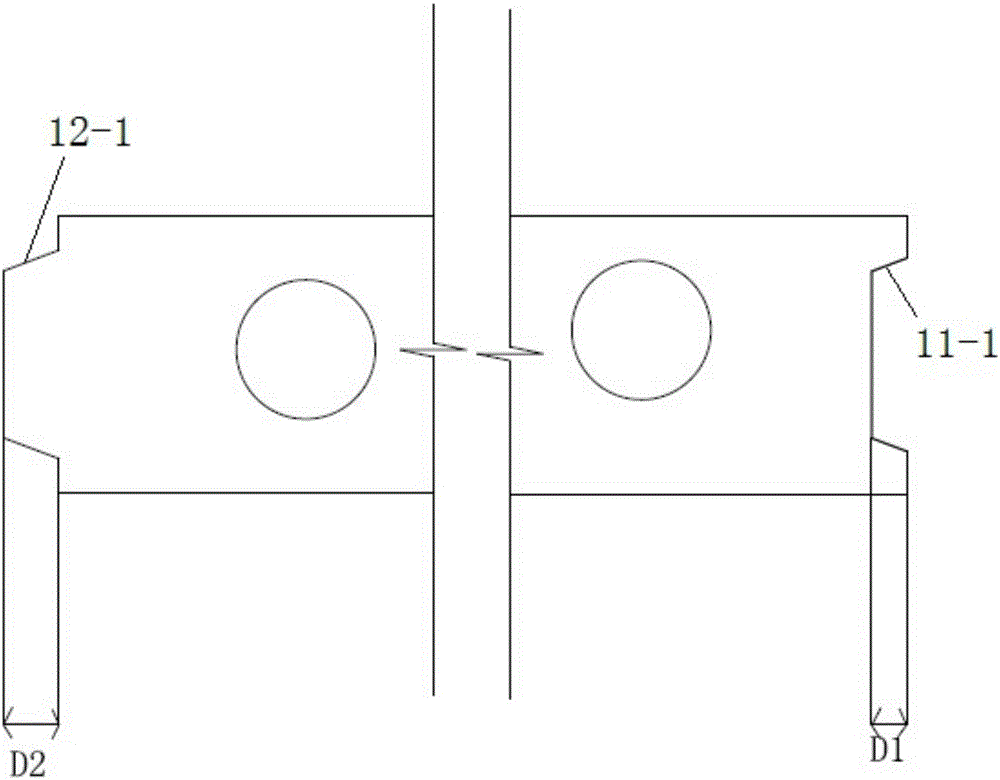

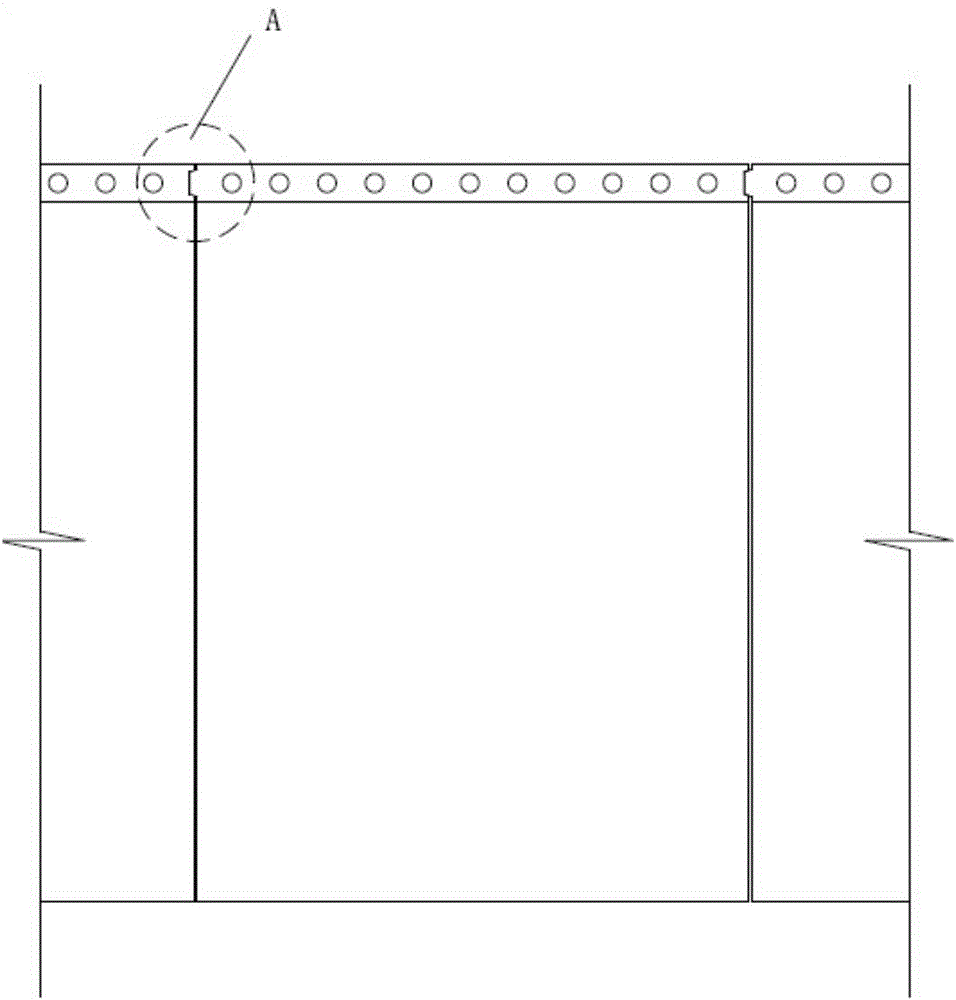

Light interior partition wall board and walling method for wall body

The invention discloses a light interior partition wall board and a walling method for the wall body. The wall board comprises a wall board body, wherein a groove and a protruding block are arranged on two longitudinal side faces of the wall board body respectively, and the widths of the groove and the protruding block are matched with each other; and the length D2 of the protruding block is 5-10 mm larger than the depth of the groove. According to the light interior partition wall board, the length of the protruding block is larger than the depth of the groove, so that not only splicing and fixing can be carried out, but also a gap can be formed, and during walling, two steps can be performed as follows: first, only the wall body is spliced, and second, grouting is carried out; and not only construction is facilitated, but also the fastness of the wall body is improved.

Owner:华夏 +1

Battery cell winding method and equipment

ActiveCN102683736BEvenly heatedImprove deformationFinal product manufactureSecondary cells manufactureElectric machineryProcess engineering

The invention discloses a battery cell winding method and equipment. According to the method, a positive pole piece and a negative pole piece are heated before winding, so the stress of the pole pieces is sufficiently released, the pole pieces are lengthened to a certain degree under the tensile action during winding, after the winding is finished, the pole pieces contract along with an isolation film in the cooling process, and the deformation of the battery cell is accordingly improved. The equipment comprises a machine frame, a motor arranged in the machine frame, a positive pole piece feeding mechanism, a negative pole piece feeding mechanism, an isolation film feeding mechanism and a winding mechanism which are fixedly connected with the machine frame respectively, wherein the machine frame is also connected with a positive pole piece heating mechanism and a negative pole piece heating mechanism. The beneficial effects of the technical scheme are as follows: the method is simple and practical, and can be applicable to automation continuous production; and the equipment is simple to operate, the heating mechanisms are easy, and the large-scale manufacturing is facilitated.

Owner:NINGDE AMPEREX TECH +1

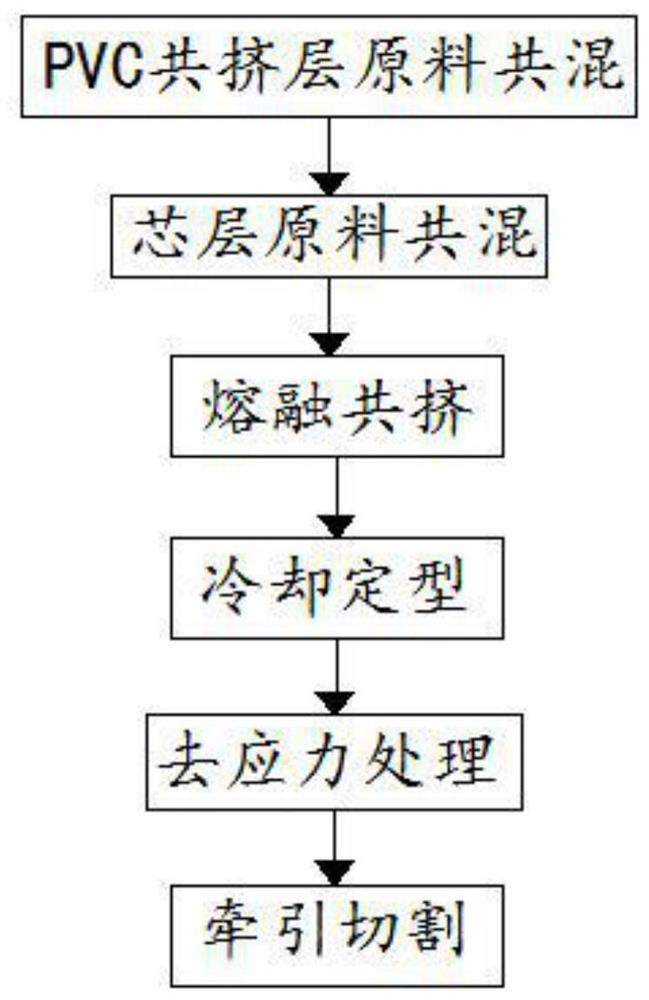

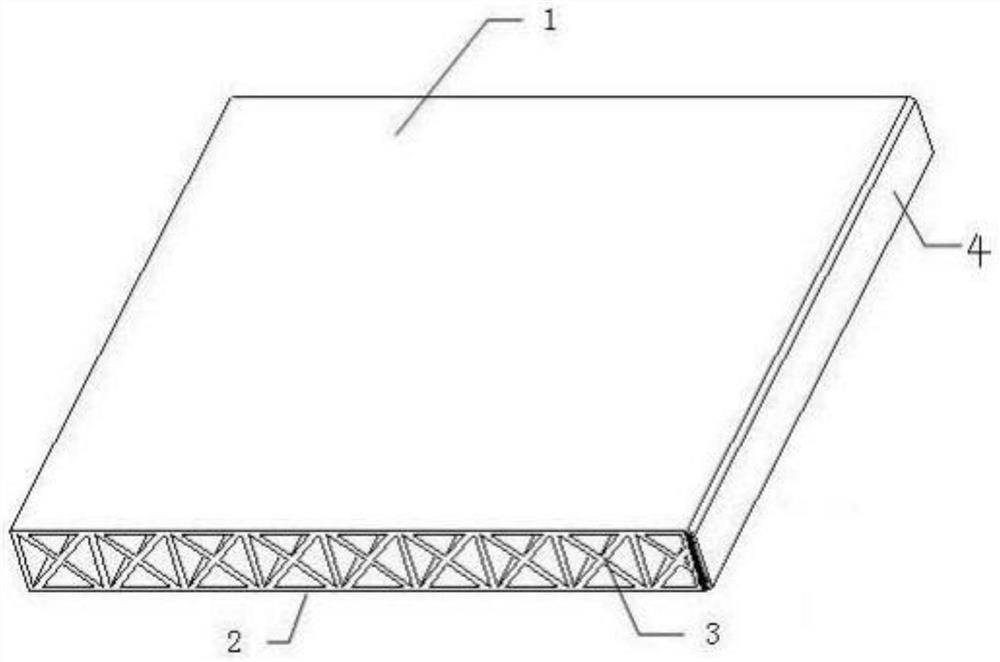

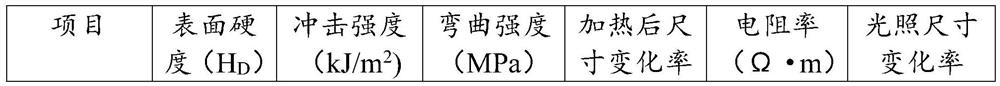

A processing technology of hollow building formwork

ActiveCN110591249BImprove wear resistanceHigh hardnessFlat articlesForming/stuttering elementsMonoglyceridePolyvinyl chloride

Owner:界首市亚鑫塑业科技有限公司

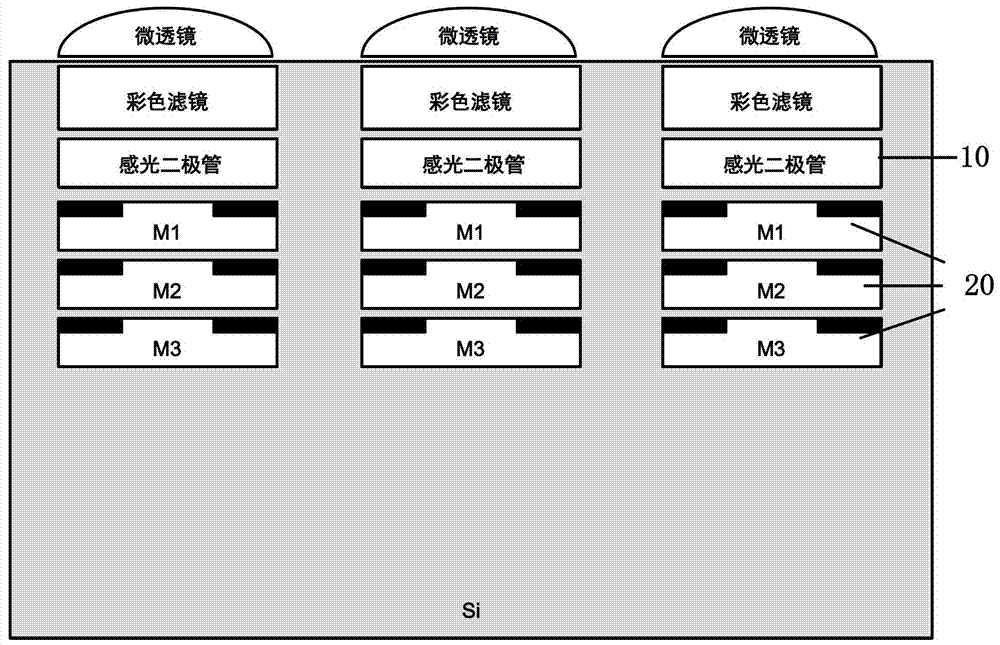

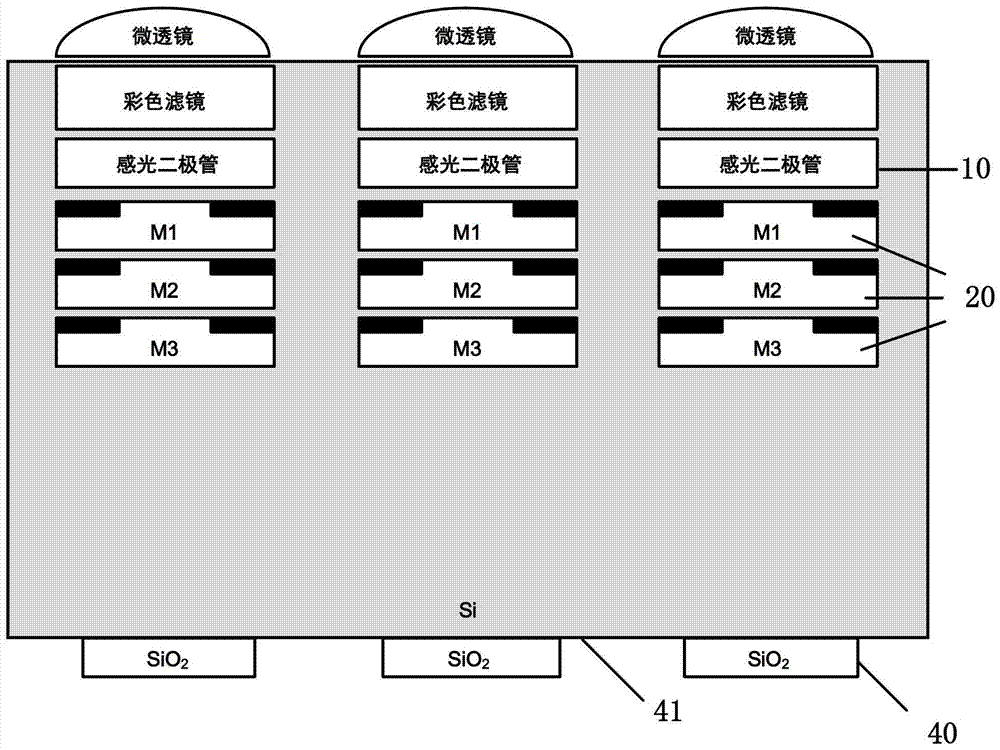

A method of manufacturing a back-illuminated cmos image sensor

ActiveCN102891158BAchieve zero mismatchReduce process complexityRadiation controlled devicesCMOSMetal interconnect

The invention discloses a method for manufacturing a back-illuminated CMOS image sensor, which comprises sequentially forming a photosensitive diode region and at least one metal interconnection layer in a substrate; An opening area is formed between the metal interconnection layers, and the metal interconnection lines of the metal interconnection layer are drawn out through the opening area; a porous silicon structure is formed in the opening area, and the depth of the porous silicon structure is the depth from the lower surface of the substrate to the metal interconnection line; the dielectric layer is removed; and filling the porous silicon structure with conductive material. The invention has simple process and low cost, and the stress between the porous silicon structure and the substrate in the manufactured image sensor is very small, and zero mismatch can be realized.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

High-temperature-resistant transparent conductive shielding structure and preparation method thereof

PendingCN114464368AIncrease contact areaImprove adhesionMagnetic/electric field screeningCable/conductor manufactureHeat resistanceNetwork structure

The invention discloses a high-temperature-resistant transparent conductive shielding structure and a preparation method thereof.The preparation method of the high-temperature-resistant transparent conductive shielding structure comprises the steps that (1) glass is prepared, a plurality of thin grooves are formed in the glass, and the thin grooves are connected with one another to form a hollow network structure; and (2) filling conductive ink into the thin groove through the soft scraping strip, and heating and sintering to form a conductive network body. Correspondingly, the invention also provides the high-temperature-resistant transparent conductive shielding structure prepared by the method. The high-temperature-resistant transparent shielding film has good transparency, shielding effect and heat resistance, ensures the performance stability of the product at high temperature, and avoids the risks of failure, fire and the like.

Owner:广东中科半导体微纳制造技术研究院 +1

A kind of winding type lithium ion electric core and preparation method thereof

InactiveCN109361011BAvoid Position CorrectionFull stress releaseFinal product manufactureSecondary cellsEngineeringLithium-ion battery

The invention provides a wound lithium ion battery cell and a preparation method thereof, belonging to the technical field of lithium ion batteries. It solves the problem of high defect rate of existing technical products. The preparation method of the wound lithium-ion battery cell comprises the following steps: unwinding the diaphragm roll with a diaphragm tape; unwinding the positive electrode roll and the negative electrode roll in the conveying direction of the diaphragm tape and cutting them by a shearing mechanism. Positive electrode monolith and negative electrode monolith; the surface of the same side of the diaphragm belt is alternately provided with positive electrode regions and negative electrode regions; a corresponding electrode monolith is placed on the first region of the diaphragm strip, and each positive electrode region and each Two corresponding electrode sheets are placed in the negative electrode area; the separator belt with the positive electrode sheet and the negative electrode sheet is directly sent to the composite mechanism and the winding mechanism for winding to prepare a wound lithium ion battery. A wound lithium-ion cell is also proposed. The invention can improve production efficiency and product qualified rate.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

A kind of anti-deformation composite solid wood floor

ActiveCN103835475BReduce multi-layer compoundingLower technical standardsFlooringSolid woodEngineering

The invention discloses a deformation-resistant composite solid wood floor board. Two first grooves in uniform distribution are formed at the bottom of the composite solid wood floor board, a second groove is formed on one end face of the composite solid wood floor board, a protrusion is arranged on the other opposite end face of the composite solid wood floor board and can be contained in the second groove when two composite solid wood floor boards are spliced, and the first grooves, the second groove and the outer edge of the protrusion jointly form a four-point balance stress groove of the composite solid wood floor board. By the four-point balance stress groove, deformation-resistant standard is enhanced, stress is fully released, and the objective of deformation preventing is achieved.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

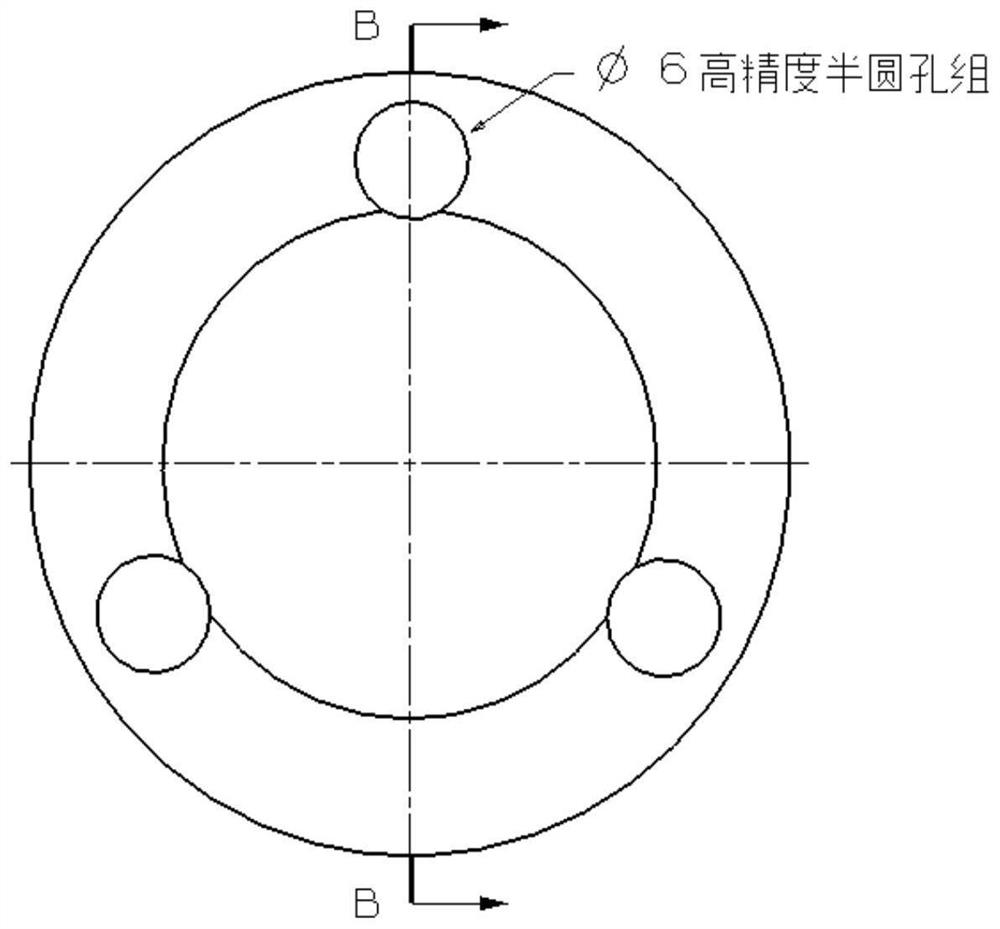

A boring and milling method for high-precision semicircular hole group

ActiveCN108942088BOptimizing roughing and finishing allowancesReduce the influence of chip breaking and cutting deformationMachiningIndustrial engineering

The invention belongs to the field of machining and discloses a boring-milling machining method of a high-precision semicircular hole group. To meet machining requirements of the high-precision semicircular hole group in an aviation electromechanical product, reduce chip breaking cutting deformation caused by semicircular structures, improve the machining quality, reduce unnecessary rework, repairand rejection, solve the problem of a low part survive rate under a traditional machining method condition, machining of the high-precision semicircular hole group is achieved through the method comprising the following steps that (1) rough machining and finish machining procedures are reasonably arranged; (2) the rough machining allowance and the finish machining allowance are optimized; and (3)cutting machining parameters are set. Through machining according to the method, boring-milling machining of the high-precision semicircular hole group can be achieved, the product quality is improved, the production cycle is shortened, and the product cost is lowered.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

Oil well pipe for heavy oil thermal recovery well and its manufacturing method

ActiveCN108588558BLow costEasy to achieve industrial mass productionSolid state diffusion coatingFurnace typesTemperingThermodynamics

The invention relates to an oil well pipe for a heavy oil thermal recovery well, and a manufacturing method. The oil well pipe comprises, by weight percent, 0.37 to 0.42% of C, 0.15 to 0.30% of Si, 0.60 to 0.80% of Mn, not larger than 0.02% of P, not larger than 0.01% of S, 0.8 to 1.5% of Cr, 0.04 to 0.06% of Nb, 0.04 to 0.06% of Ti and the balance Fe and inevitable impurities. The oil well pipe has the beneficial effects that the cost is low, the industrial batched production is easily achieved, through the heat treatment technology of subcritical quenching, superhigh temperature tempering and surface aluminizing, the structure of the steel pipe is fine and uniform, corrosion resistance is greatly improved, and the use needs of the current and future market for the oil well pipe with thehigh temperature resistance and corrosion resistance properties are met.

Owner:ANGANG STEEL CO LTD

Method for regulating and controlling integrated casting composite interface of nickel-based high-temperature alloy/SiC ceramic composite component

The invention discloses a method for regulating and controlling an integrated casting composite interface of a nickel-based high-temperature alloy / SiC ceramic composite component, and belongs to the field of casting equipment and processes. According to the method, a metal net structure woven by a single-layer multi-thread transverse and longitudinal weaving process is matched with non-poured ceramic for use, so that the problems of large residual stress and uneven distribution in an interface after casting forming under the background that parts need to be additionally arranged on the interface joint of the existing nickel-based high-temperature alloy / SiC ceramic composite component are solved. Metal warps of the metal net structure are pure copper wires, platinum-rhodium wires and singleNiTi alloy wires in sequence, wherein the NiTi alloy wires are wound around the platinum-rhodium wires and the copper wires. Metal wefts are sequentially composed of a single NiTi alloy wire, a platinum-rhodium wire around which a fine NiTi alloy wire is wound and a single NiTi alloy wire, and the specification of the metal wefts is the same as that of the metal warps. The method also has the advantages that existing equipment does not need to be replaced, the adopted materials are all conventional materials, and the applicability is wide.

Owner:HARBIN INST OF TECH

A Grinding Process for Double Half Inner Rings of Angular Contact Ball Bearing Rings with Oil Grooves

The invention discloses a grinding machining process of two half inner rings of an angular contact ball bearing ring with an oil tank, and relates to the field of bearing ring machining. The grinding machining process aims at solving the problem that two half inner rings of an existing bearing ring are likely to be subjected to channel sliding. The grinding machining process comprises the first step of gradually machining multiple first bearing inner rings and the second step of gradually machining multiple second bearing inner rings 2; the first step comprises the substeps of 1, coarse grinding; 2, high-temperature tempering; 3, fine grinding; 4, machining of an axial oil guide groove; 5, low-temperature tempering; 6, fine grinding of end faces and the outer diameter; 7, fine grinding of the inner diameter; 8, grouping; 9, initial workpiece detection; and 10, fine grinding of an inner channel; and the second step comprises the substeps of 1, coarse grinding; 2, high-temperature tempering; 3, fine grinding of end faces and the outer diameter; 4, fine grinding of the inner diameter; 5, machining of the first bearing inner rings and the second bearing inner rings; 6, grouping; 7, initial workpiece detection; 8, fine grinding of a channel; and 9, obtaining of the qualified two half inner rings of the angular contact ball bearing ring with the oil tank after fine grinding of the channel. The grinding machining process is used for grinding the bearing ring.

Owner:AVIC HARBIN BEARING

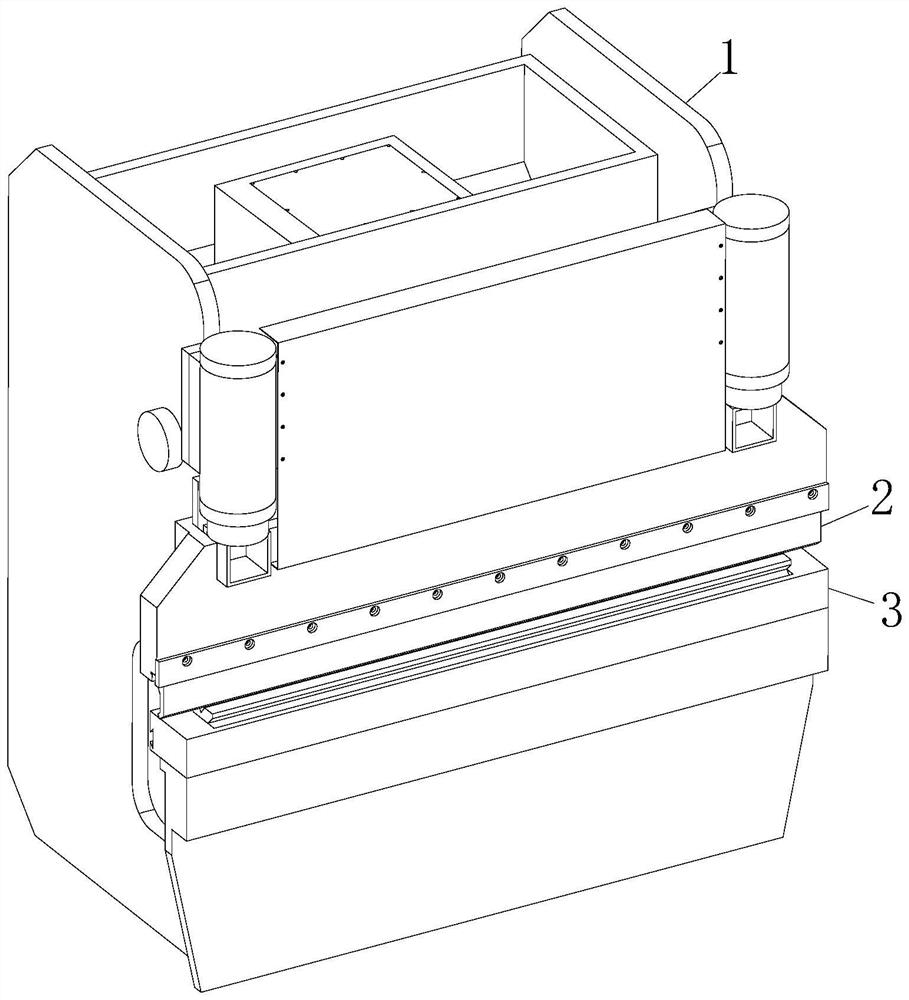

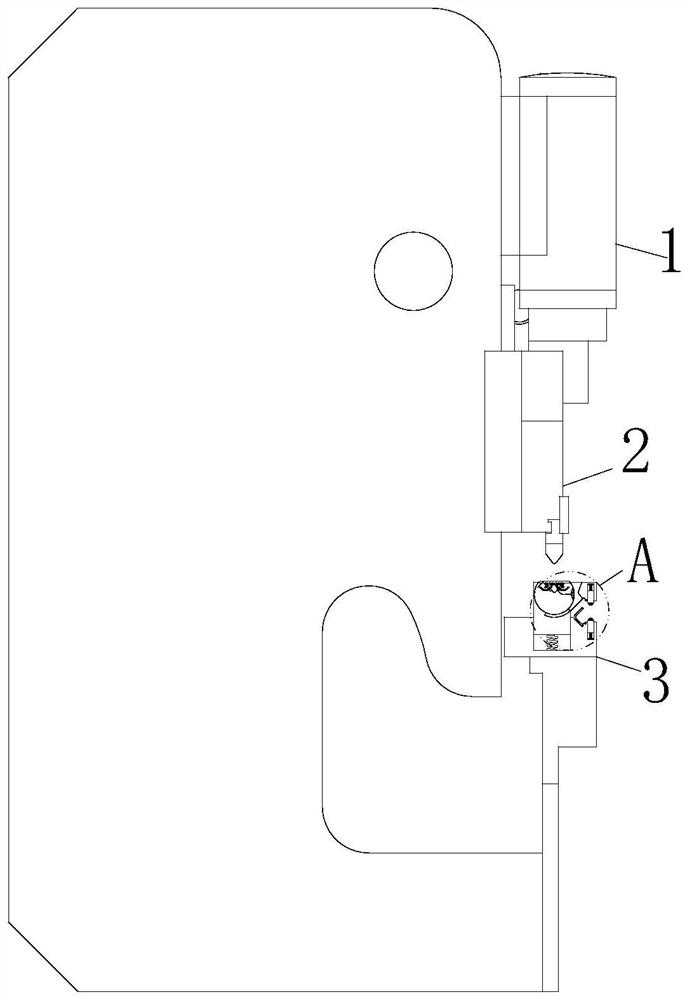

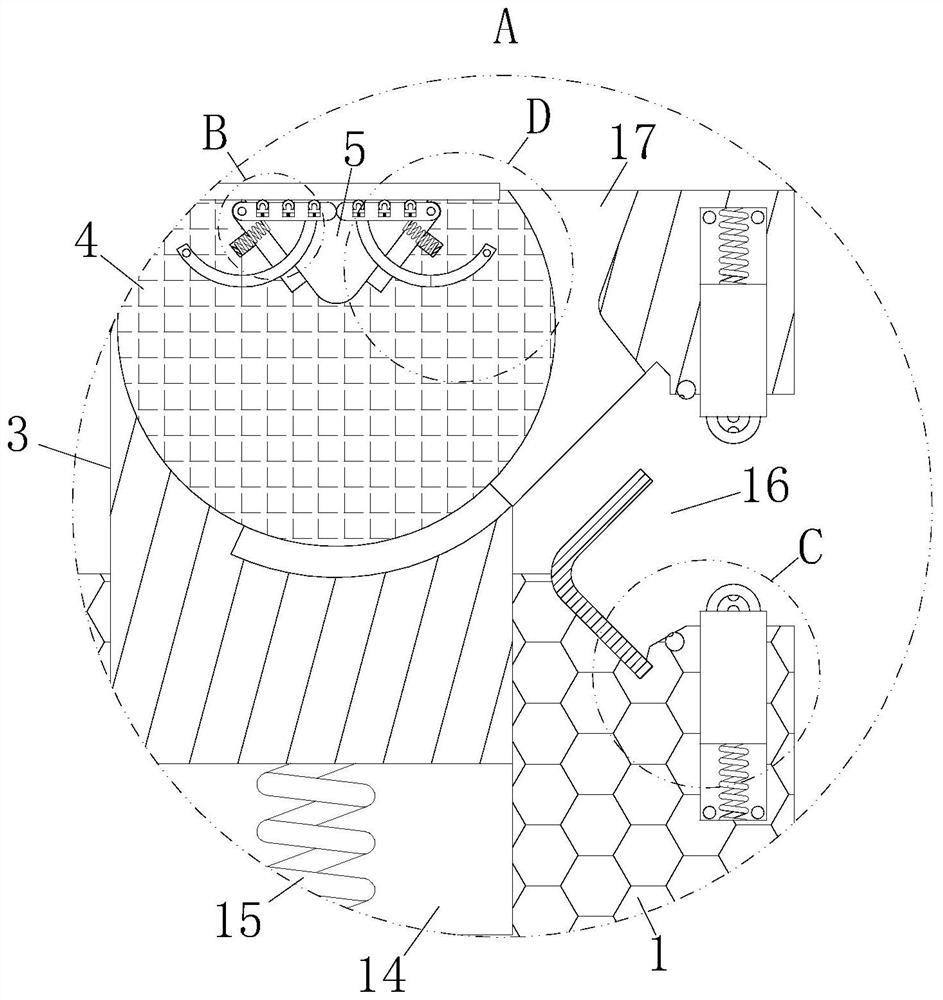

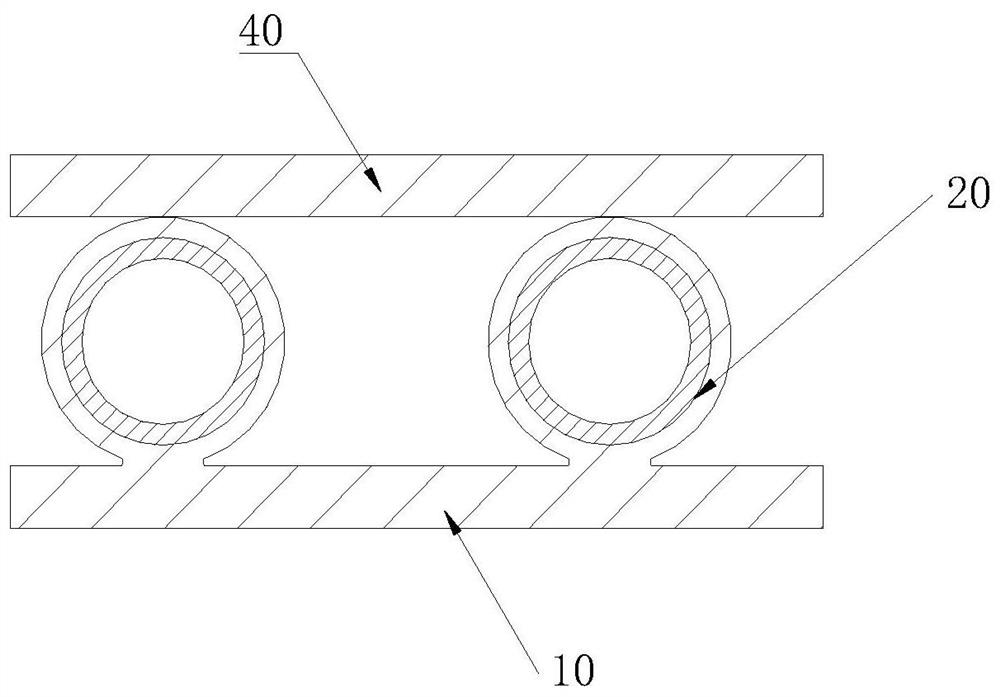

L-shaped aluminum profile arc bending die

ActiveCN114850269AIncrease contact areaReduce local deformationShaping toolsMechanical engineeringPhysics

The invention belongs to the field of arc bending dies, and particularly relates to an L-shaped aluminum profile arc bending die which comprises a machine body, an upper die plate and a lower die plate. The surface of the machine body is in sliding connection with an upper template; a lower template is arranged on the surface of the machine body and at the bottom of the upper template; a block is arranged on the top surface of the lower template; a shape groove is formed in the top surface of the shape block; a rotating groove is formed in the inner surface of the shaped groove; a rotating plate is rotationally connected into the rotating groove; a mounting groove is formed in the groove bottom of the rotating groove; a first spring is fixedly connected to the interior of the mounting groove, and the first spring is fixedly connected with the rotating plate; through rotation of the rotating plate, a large contact area is always kept between the rotating plate and the bottom face of the aluminum template, the problems of local concentrated stress of the aluminum template and change of the local stress position are reduced, then the problems of local deformation of the aluminum template and scratching of the surface of the aluminum template are reduced, and the forming quality of the aluminum template is improved.

Owner:江苏科力西铝业有限公司

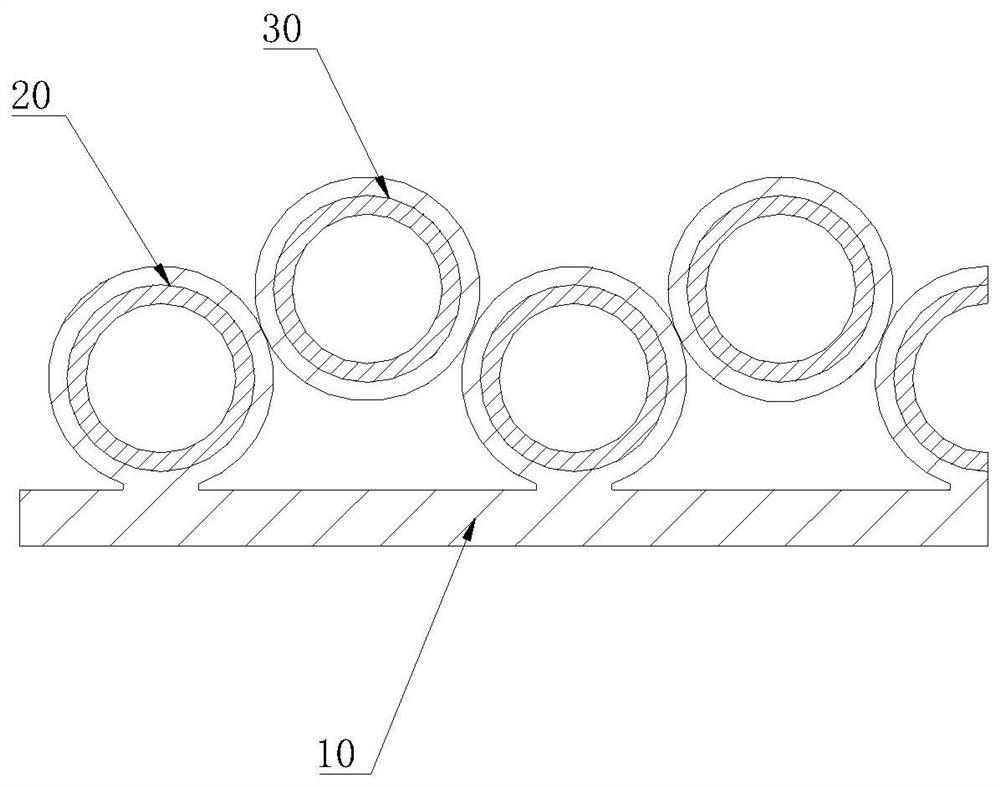

A compression-resistant winding pipe and its production device and process

ActiveCN113002033BAvoid deformationIncreased ring stiffnessRigid pipesTubular articlesSolid wallEngineering

The invention discloses a compression-resistant winding pipe and a production device and process thereof. The winding pipe comprises a pipe body of a first solid wall layer and a pipe body of a second solid wall layer, a pipe body of the first solid wall layer and a second solid wall layer. There are spiral hollow rib tubes distributed in an array between the tubes of the wall layer; the production device includes a support piece, and a drive connection piece and a drive piece are rotated on the support piece, and the drive piece drives the drive connection piece to rotate on the support piece, and the support piece rotates. A winding roller is arranged on the rotating part, and the winding roller is provided with an array of rib tube support disks. pieces. The compression-resistant winding tube of the present invention is released by the heat of the upper layer, the shape of the reinforced rib tube is not easily deformed by heat accumulation, and the cross section has a higher moment of inertia and ring stiffness; the production equipment of the compression-resistant winding tube of the present invention is more automated than High, improve the production efficiency of the pipe body, and improve the qualification rate of the product.

Owner:海宁亚大塑料管道系统有限公司

Method for reducing same plate difference of rolling temperature of ultra-long TMCP plate

The invention discloses a method for reducing the same plate difference of the rolling temperature of an ultra-long TMCP plate. The process route comprises the steps of molten iron KR pre-desulfurization, converter smelting, LF refining, soft stirring, plate blank continuous casting, plate blank reheating, rough rolling, intermediate blank temperature cooling, finish rolling, steel plate water cooling, steel plate hot straightening, offline stack cooling and discharging for cooling on a cooling bed to 80 DEG C, steel plate ultrasonic flaw detection, shot blasting, normalizing, steel plate accelerated cooling, shearing and warehousing.

Owner:SHAGANG GROUP +1

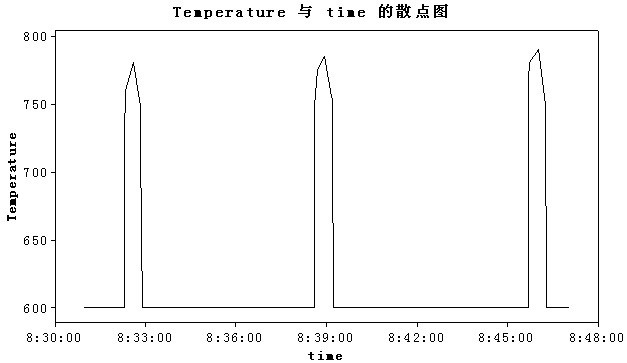

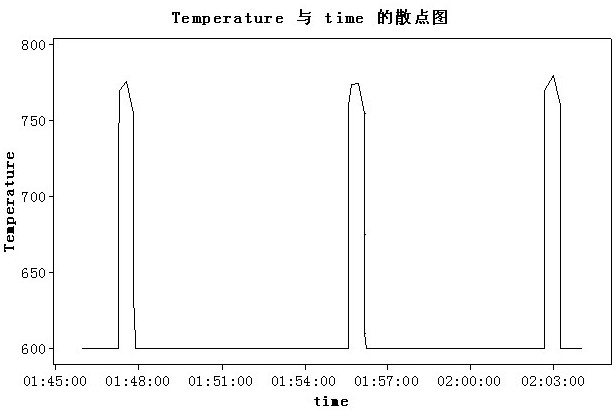

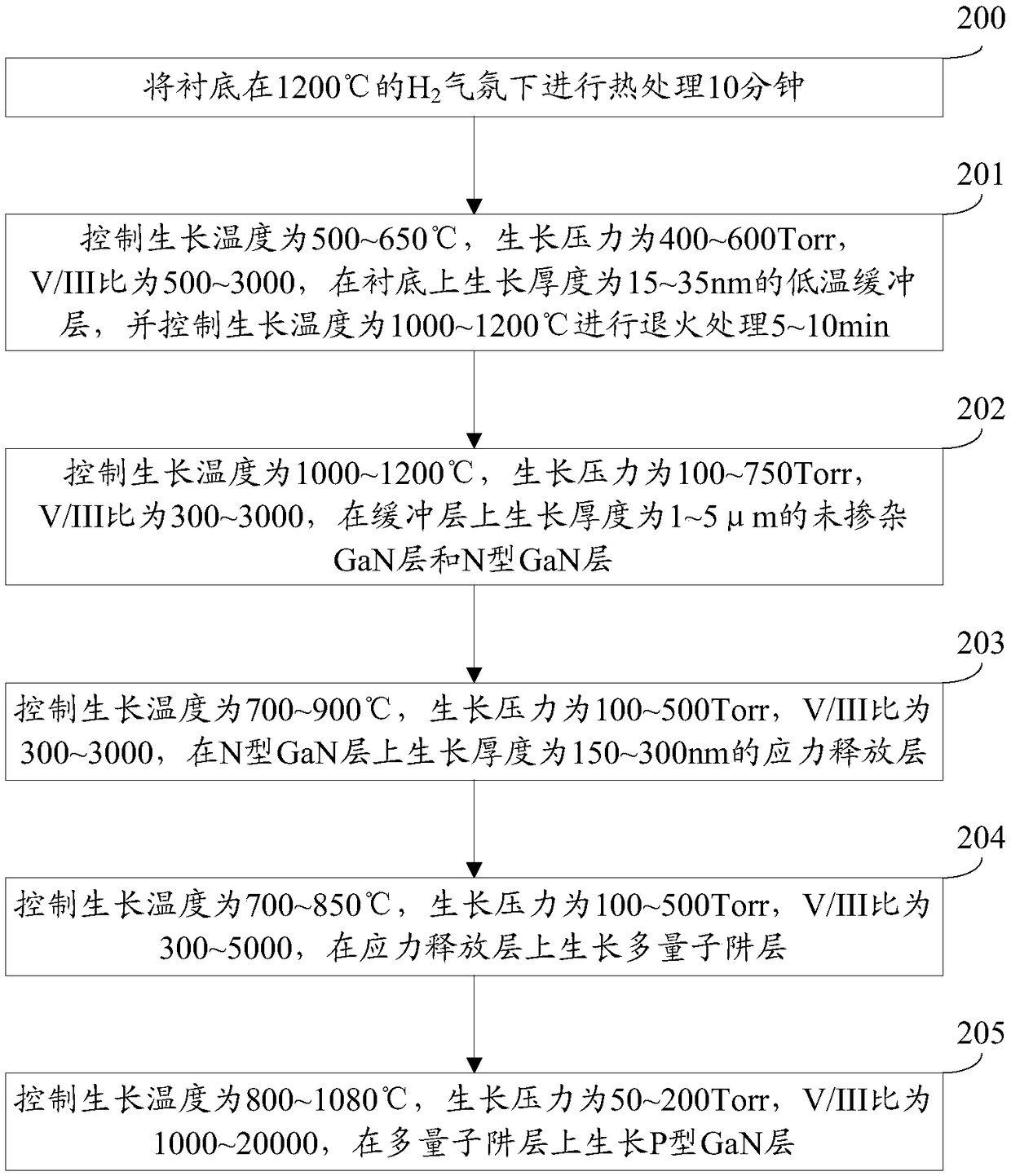

A kind of manufacturing method of light-emitting diode epitaxial wafer

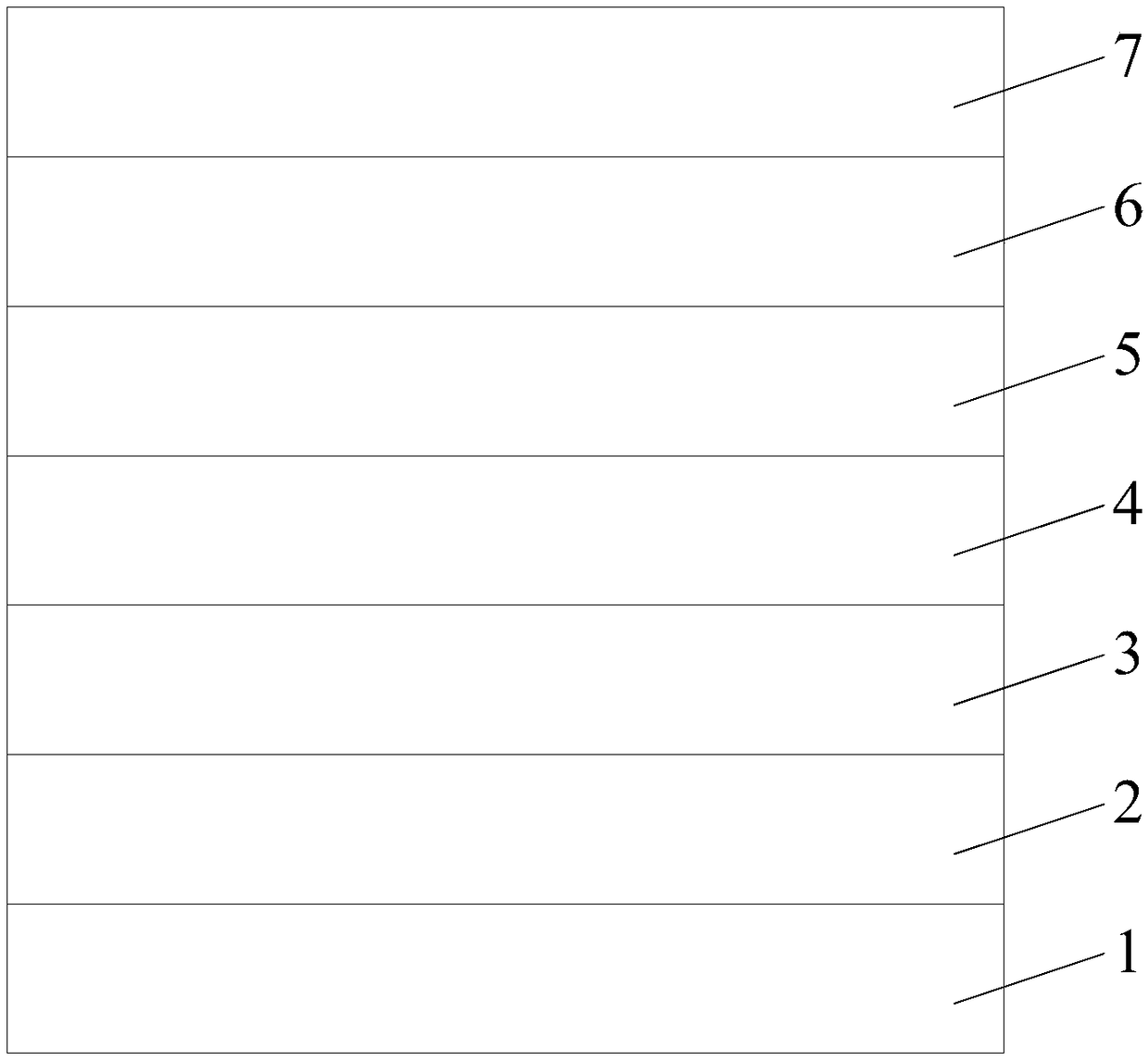

ActiveCN106684222BQuality improvementFull stress releaseSemiconductor devicesQuantum wellGallium nitride

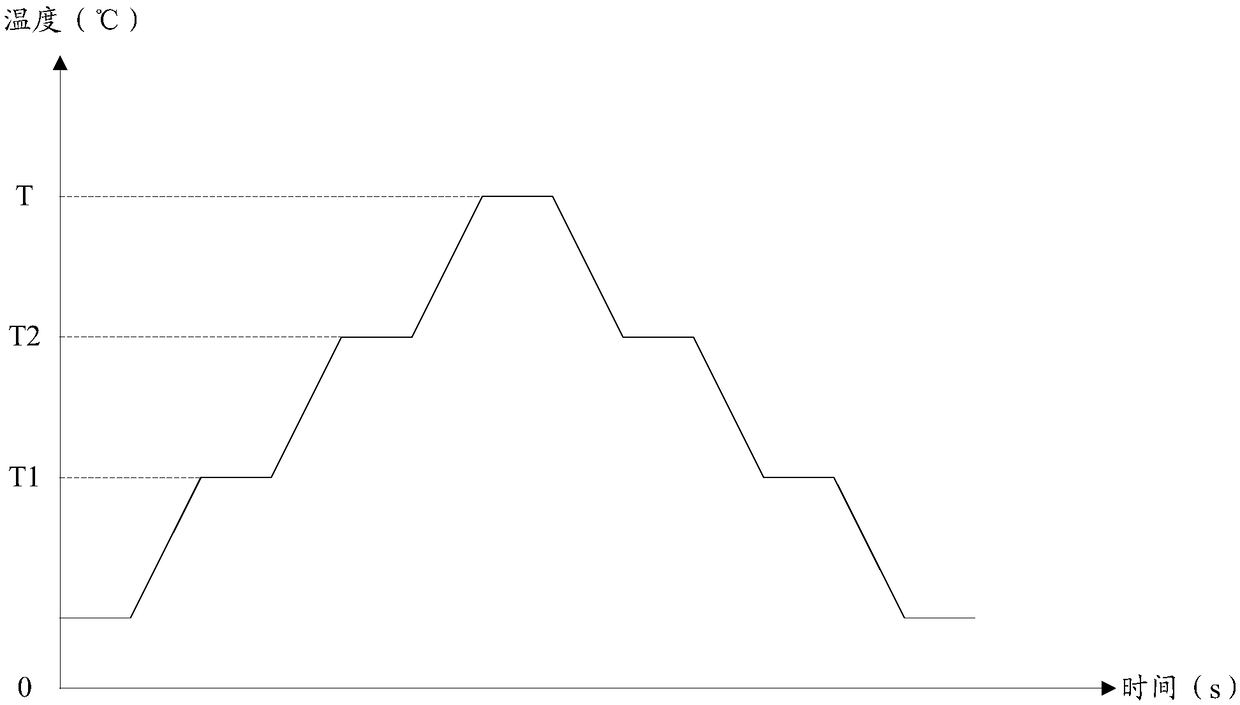

The invention discloses a manufacturing method of a light-emitting-diode epitaxial wafer and belongs to the semiconductor technology field. The manufacturing method comprises the following steps that a low temperature buffer layer, a un-doped GaN layer, an N type GaN layer, a stress release layer, a multi-quantum well layer and a P type GaN layer are successively grown on a substrate, wherein the stress release layer includes an InGaN layer and an AlxGaN layer which are alternatively stacked, and the x is greater than or equal to 0 and is less than 0.3; and during a growing process of the AlxGaN layer, a growth temperature of the AlxGaN layer reaches a maximum temperature from a growth temperature of the InGaN layer through several stages of heating and then reaches the growth temperature of the InGaN layer from the maximum temperature through several stages of cooling, and the temperature in a same stage is constant and the temperatures of the two adjacent stages are different. In the invention, through slow changes of the temperature, a stress in a gallium nitride layer is fully released, a polarized effect is reduced, V-shaped dislocation and linear dislocation in the epitaxial layer are decreased, and crystal quality is increased.

Owner:HC SEMITEK ZHEJIANG CO LTD

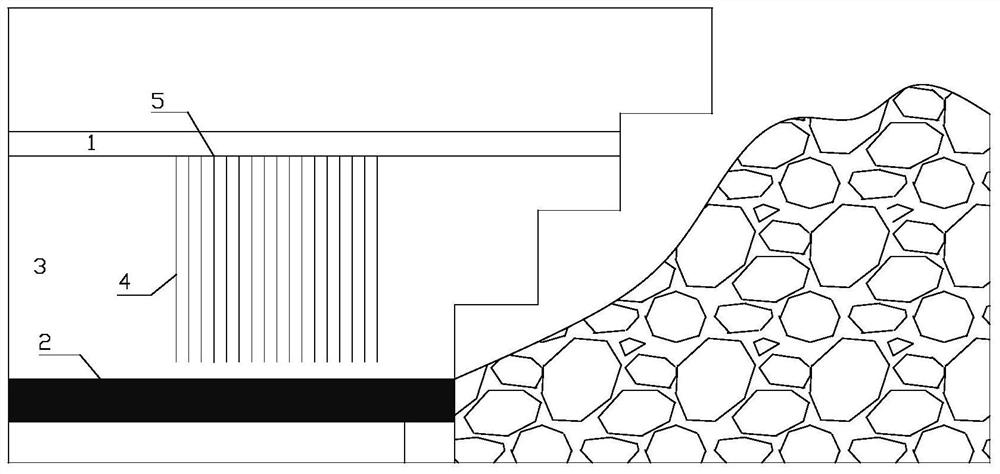

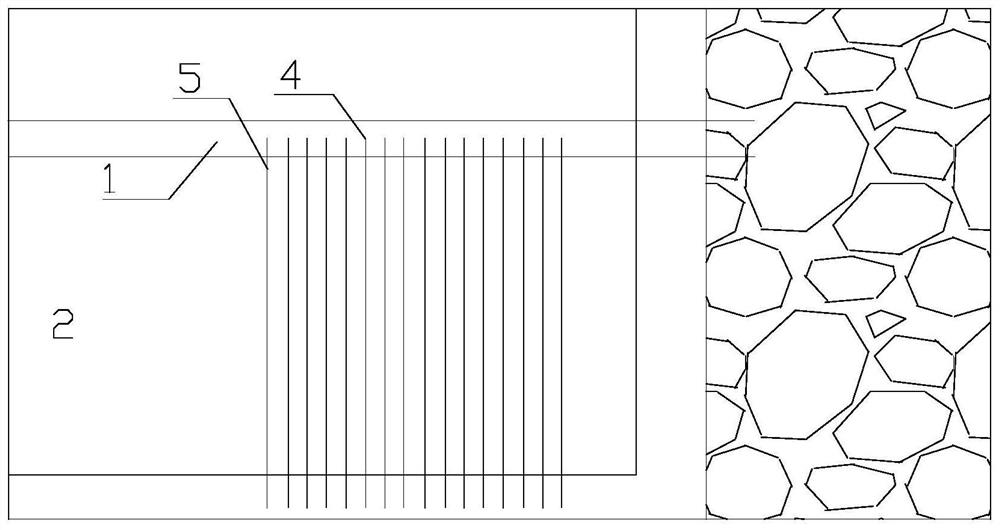

Method for improving gas extraction efficiency of high extraction roadway

ActiveCN113062762AFull stress releasePrevent overrunningFluid removalDesign optimisation/simulationMining engineeringMechanical engineering

The invention discloses a method for improving the gas extraction efficiency of a high extraction roadway. The method mainly comprises the following steps of arranging the high extraction roadway on a to-be-extracted working face adjacent to a rock stratum, calculating and determining a drilling distance and a roof caving step pitch, drilling two main and auxiliary holes in the high extraction roadway at intervals, and directly and circularly drilling downwards in the high extraction roadway, wherein the end hole position of a drill hole is on the working face and is parallel to the coal wall of the working face, then a silent breaking and expanding agent is used in the mode that a main hole is charged and an auxiliary hole is not filled, and after the silent breaking and expanding agent is filled, cracks are formed in the direct roof and the basic roof in advance, i.e. the main hole presplits the roof, and the auxiliary hole pumps and discharges gas on the working face. According to the method, the suspended roof fissure ratio is increased on the basis of extracting goaf gas and adjacent layer and surrounding rock gas of the high drainage roadway, the purposes of presplitting the roof and diluting and discharging the gas on the working face are achieved, and gas overrun is prevented.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com