A compression-resistant winding pipe and its production device and process

A production device and a technology for winding pipes, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of low pass rate, low degree of automation, complex production process, etc., and achieve high moment of inertia and ring stiffness, high degree of automation, Good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

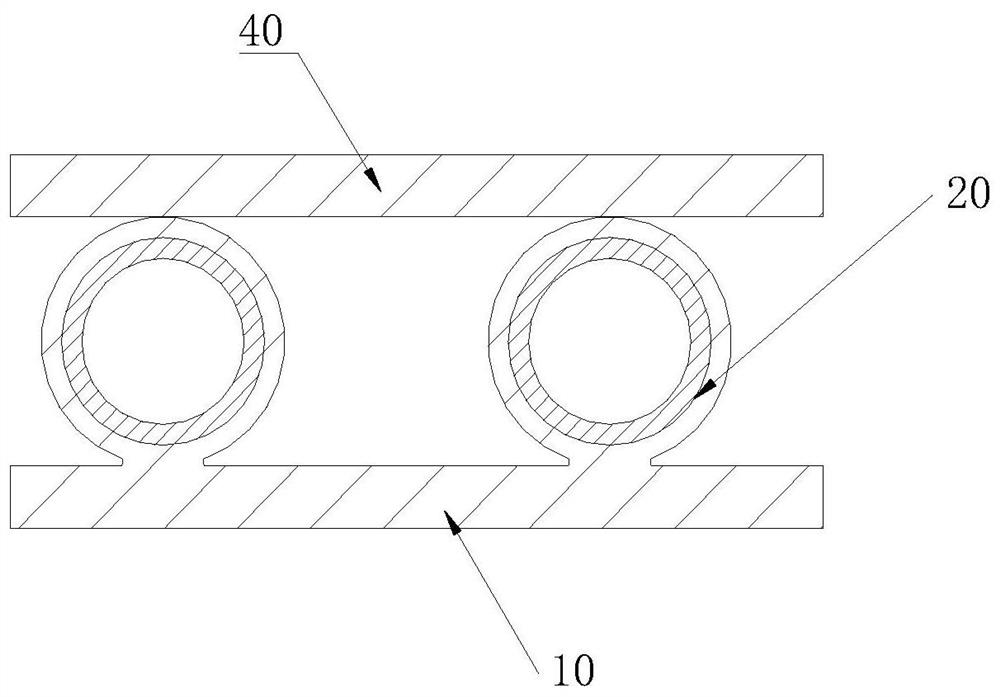

[0072] A pressure-resistant winding pipe, the winding pipe includes a pipe body 10 of the first solid wall layer and a pipe body 40 of the second solid wall layer, such as figure 1 , figure 2 As shown, the pipe body 10 of the first solid wall layer and the pipe body 40 of the second solid wall layer are provided with a first spiral hollow ribbed pipe 20 distributed in an array, and the pipe body 40 of the second solid wall layer is wrapped around Outside the first spiral hollow ribbed tube 20, the material of the tube body 10 of the first solid wall layer is: HMPP (high modulus polypropylene).

Embodiment 2

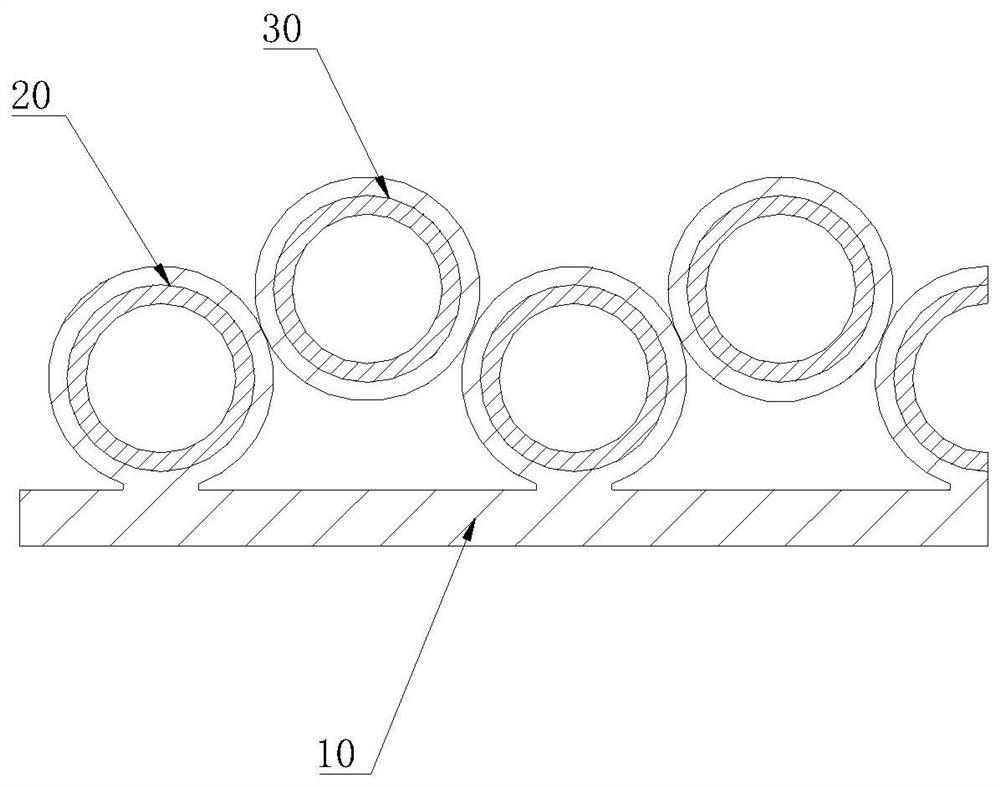

[0074] A pressure-resistant winding pipe, the winding pipe includes a pipe body 10 of the first solid wall layer and a pipe body 40 of the second solid wall layer, such as image 3 , Figure 4 As shown, the first spiral hollow ribbed tube 20 distributed in an array is arranged between the tube body 10 of the first solid wall layer and the tube body 40 of the second solid wall layer, and the first spiral hollow ribbed tube 20 is connected with the second solid wall layer. The second helical hollow ribbed tube 30 distributed in an array is wound between the tubes 40 of the wall layer, and the second helical hollow ribbed tube 30 is located between two adjacent first helical hollow ribbed tubes 20. The spiral hollow ribbed pipe 30 is not in contact with the pipe body 10 of the first solid wall layer, the pipe body 40 of the second solid wall layer is wrapped and wound outside the second spiral hollow ribbed pipe 30, and the pipe body 10 of the first solid wall layer The material...

Embodiment 3

[0076] A pressure-resistant winding pipe, the winding pipe includes a pipe body 10 of the first solid wall layer and a pipe body 40 of the second solid wall layer, such as Figure 5 , Figure 6 As shown, the first spiral hollow ribbed tube 20 distributed in an array is arranged between the tube body 10 of the first solid wall layer and the tube body 40 of the second solid wall layer, and the first spiral hollow ribbed tube 20 is connected with the second solid wall layer. The second helical hollow ribbed tube 30 distributed in an array is wound between the tubes 40 of the wall layer, and the second helical hollow ribbed tube 30 is located between two adjacent first helical hollow ribbed tubes 20. The spiral hollow ribbed tube 30 is not in contact with the tube body 10 of the first solid wall layer, and the third spiral hollow ribbed tube distributed in an array is wound between the second spiral hollow ribbed tube 30 and the tube body 40 of the second solid wall layer. The ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com