Production method of thin and long thin-plate type part

A production method and thin plate technology, applied in the direction of machine tools, furnace types, furnaces, etc. suitable for grinding workpiece planes, can solve the problems of wear-resistant slides relying on imports, wearing parts of wear-resistant slides, and expensive prices, etc., to increase Effect of natural aging process, increasing press pressure, and preventing quenching and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

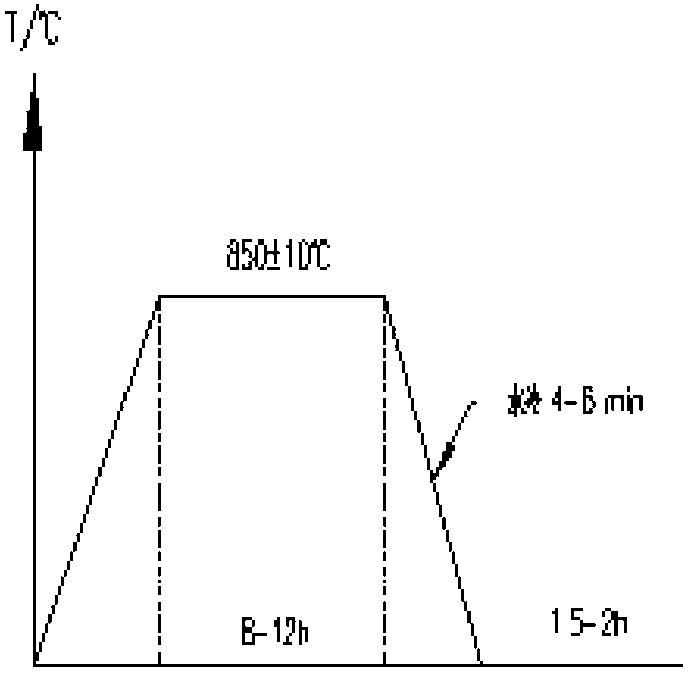

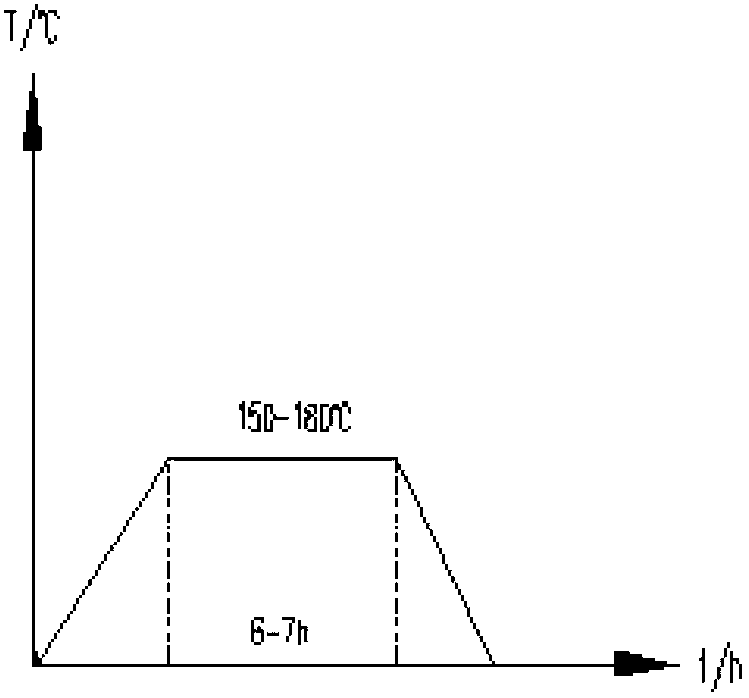

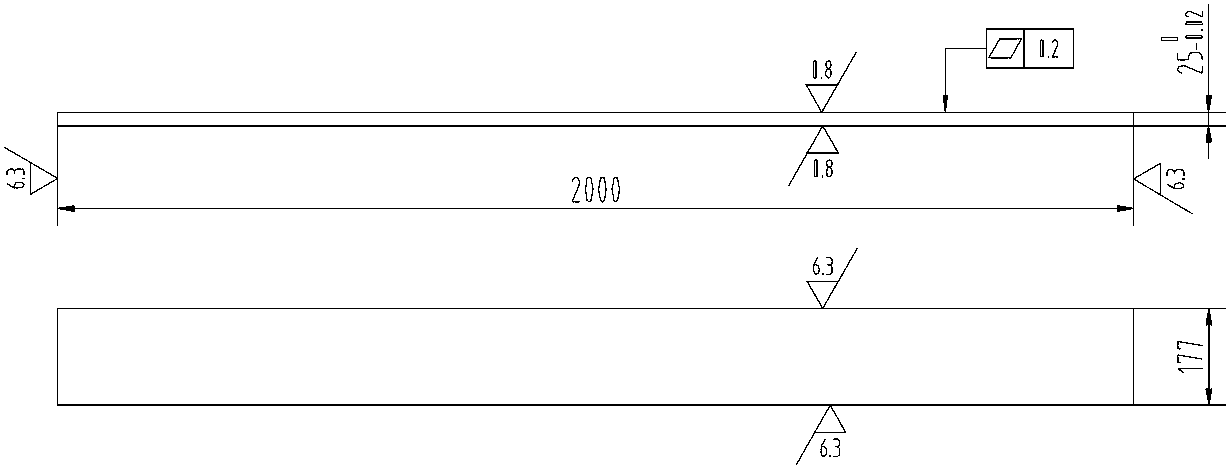

[0017] The present invention takes the 65Mn slender thin plate with length × width × height = 2000 × 177 × 25mm as an example. 8 to 12 hours; use a press to press the quenching, press the pressure to 10Mpa, use water cooling, water temperature 20 to 40 ° C, time 4 to 6 minutes; immediately temper within two hours after quenching, tempering temperature 150 ~180°C, holding time 6-8 hours, the measured deformation is less than 3mm; use grinding method for finishing, finishing includes: rough grinding, natural aging, fine grinding, rough grinding: the front and back of the part are exposed to light, the front and back Repeated grinding 4 to 5 times, the processing amount is 1.8 mm to 2 mm; natural aging: the parts are placed on a flat plate or hang vertically, and the natural aging is 24 hours; fine grinding: the front and back sides are repeatedly ground 2 to 3 times, and the processing amount is 1 to 1.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com