A Grinding Process for Double Half Inner Rings of Angular Contact Ball Bearing Rings with Oil Grooves

A technology for bearing inner rings and bearing rings, which is applied in the field of grinding and processing of double-half inner rings of angular contact ball bearing rings with oil grooves. Slip marks are reduced and the shape is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

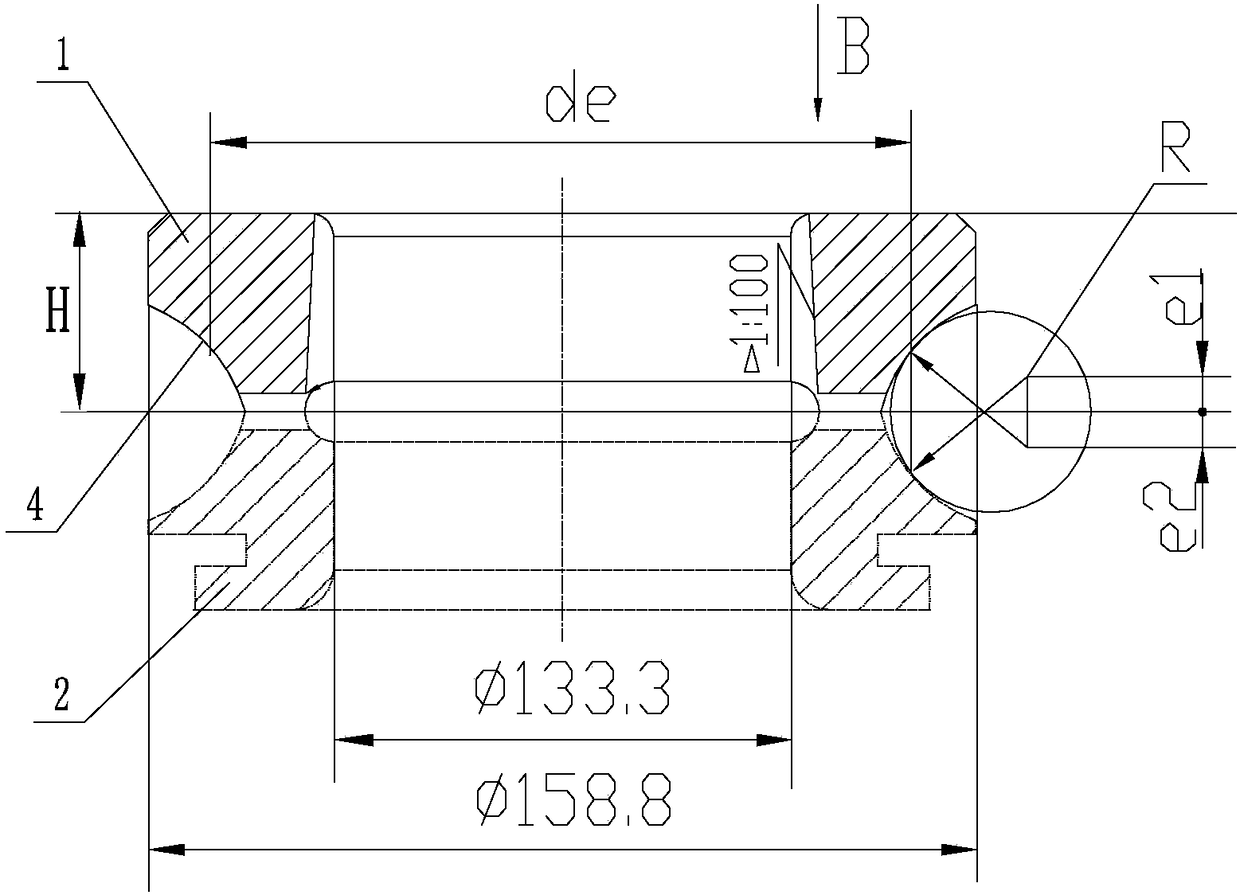

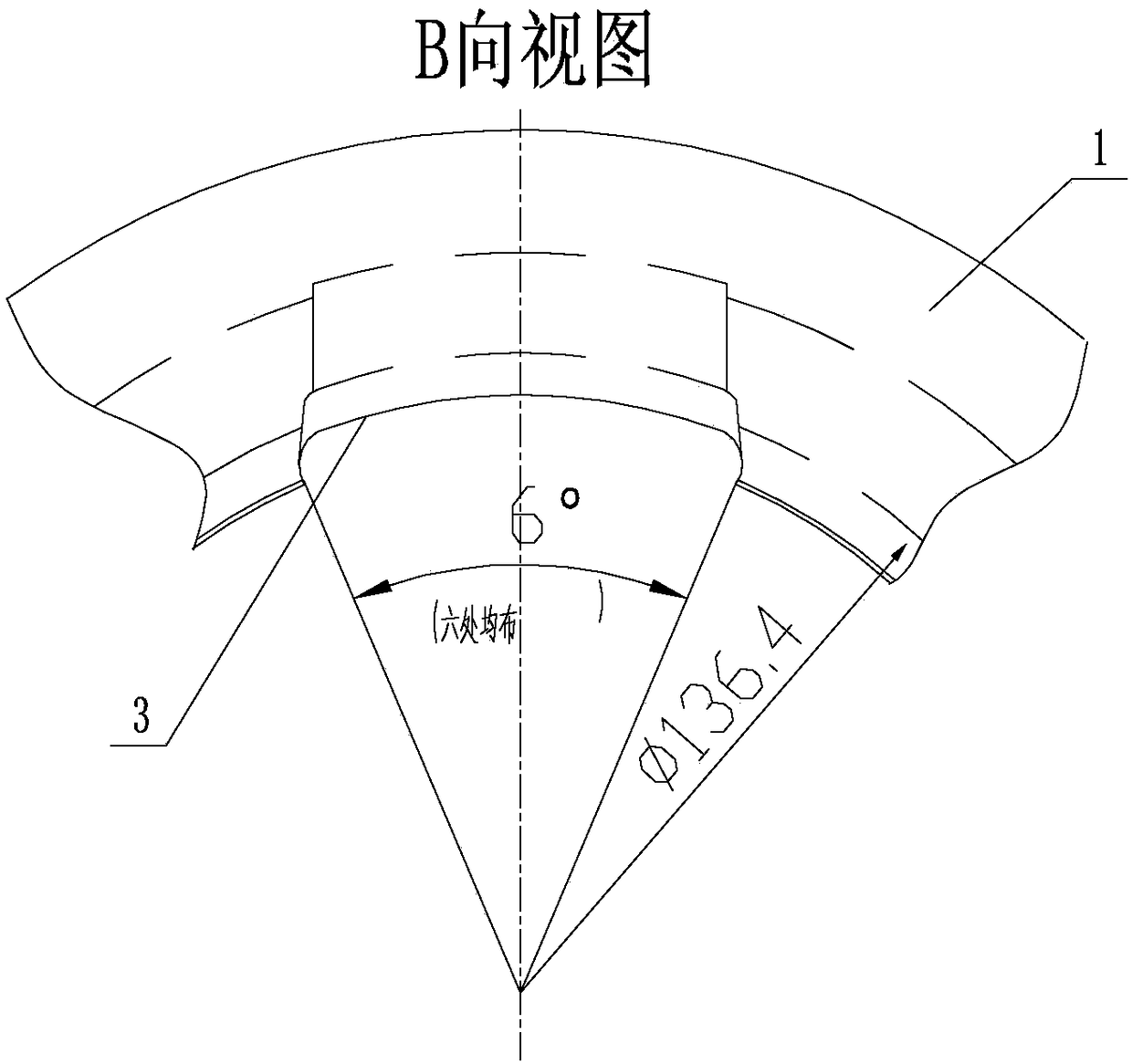

[0031] Specific implementation mode one: combine figure 1 Describe this embodiment, the processing step of this embodiment is as follows:

[0032] 1. First, process several first bearing inner rings 1 one by one:

[0033] (1) Coarse grinding: Coarsely grind the upper and lower end faces, outer diameter, inner hole, and inner channel of the first bearing inner ring 1 to meet the size requirements;

[0034] (2) High-temperature tempering: perform high-temperature tempering on the inner ring 1 of the first bearing, and the tempering temperature is 500°C±5°C;

[0035] (3) Fine grinding: finely grind the upper and lower end faces, outer diameter and inner hole of the inner ring 1 of the first bearing to meet the size requirements;

[0036] ⑷. Machining axial oil guide groove 3: wire cutting axial oil guide groove 3;

[0037] (5) Low-temperature tempering: low-temperature tempering is performed on the inner ring 1 of the first bearing, and the tempering temperature is 135°C±5°C; ...

specific Embodiment approach 2

[0053] Specific implementation mode two: combination figure 1 This embodiment is described. In this embodiment, the processing equipment in step ⑽ of step 1 adopts high-precision numerical control internal grinding machine SUU130B. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0054] Specific implementation mode three: combination figure 1 This embodiment is described. In this embodiment, the processing abrasive tool in step ⑽ of step 1 adopts a Talile 89A180K5V60 (S) grinding wheel. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com