Method for installing and fixing large lining plate

A fixing method and liner technology, which is applied in the direction of recycling technology, can solve the problems of cement pool wall damage, material waste, and affecting the effective volume of stuffy pools, and achieve the effects of less materials, reduced damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

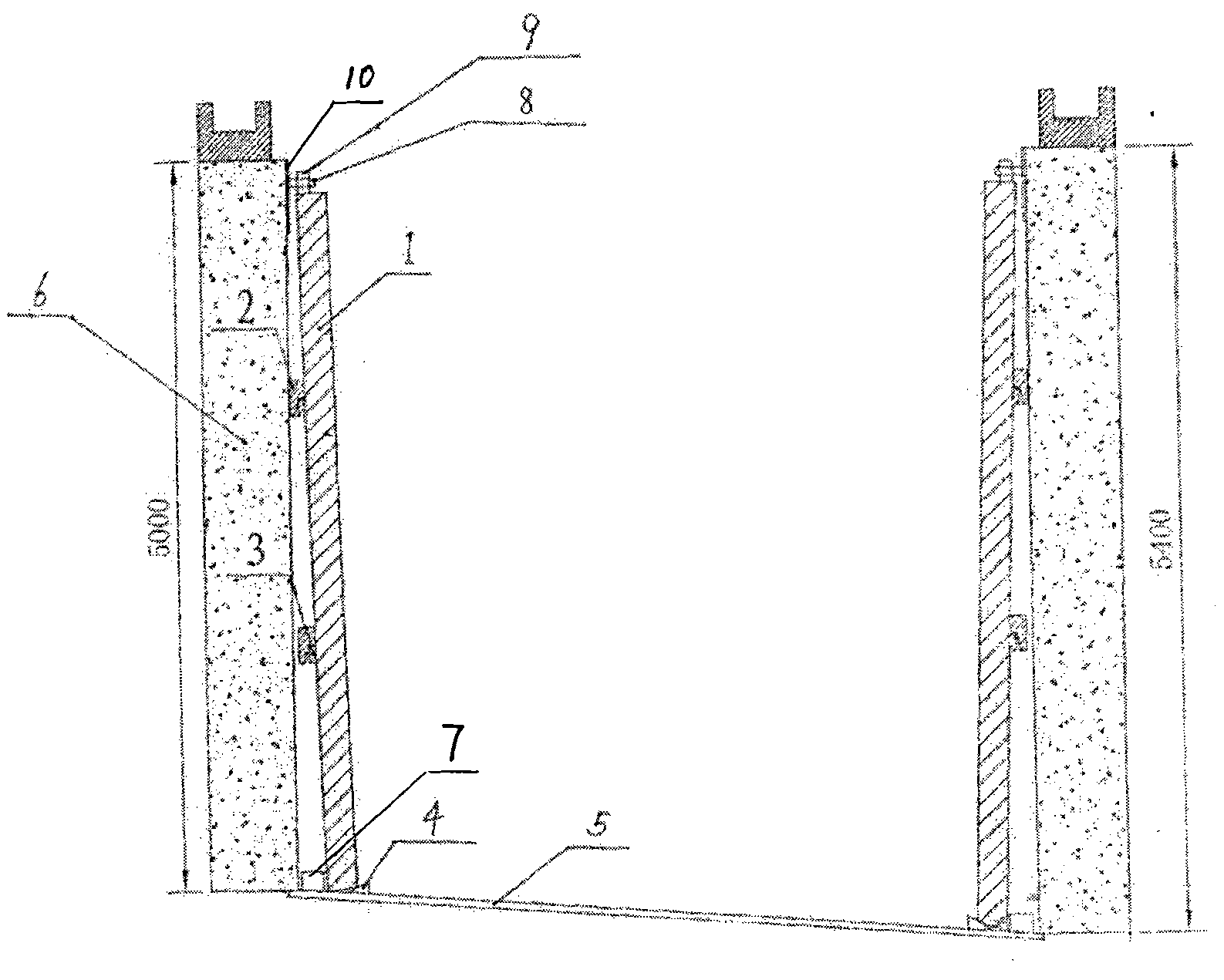

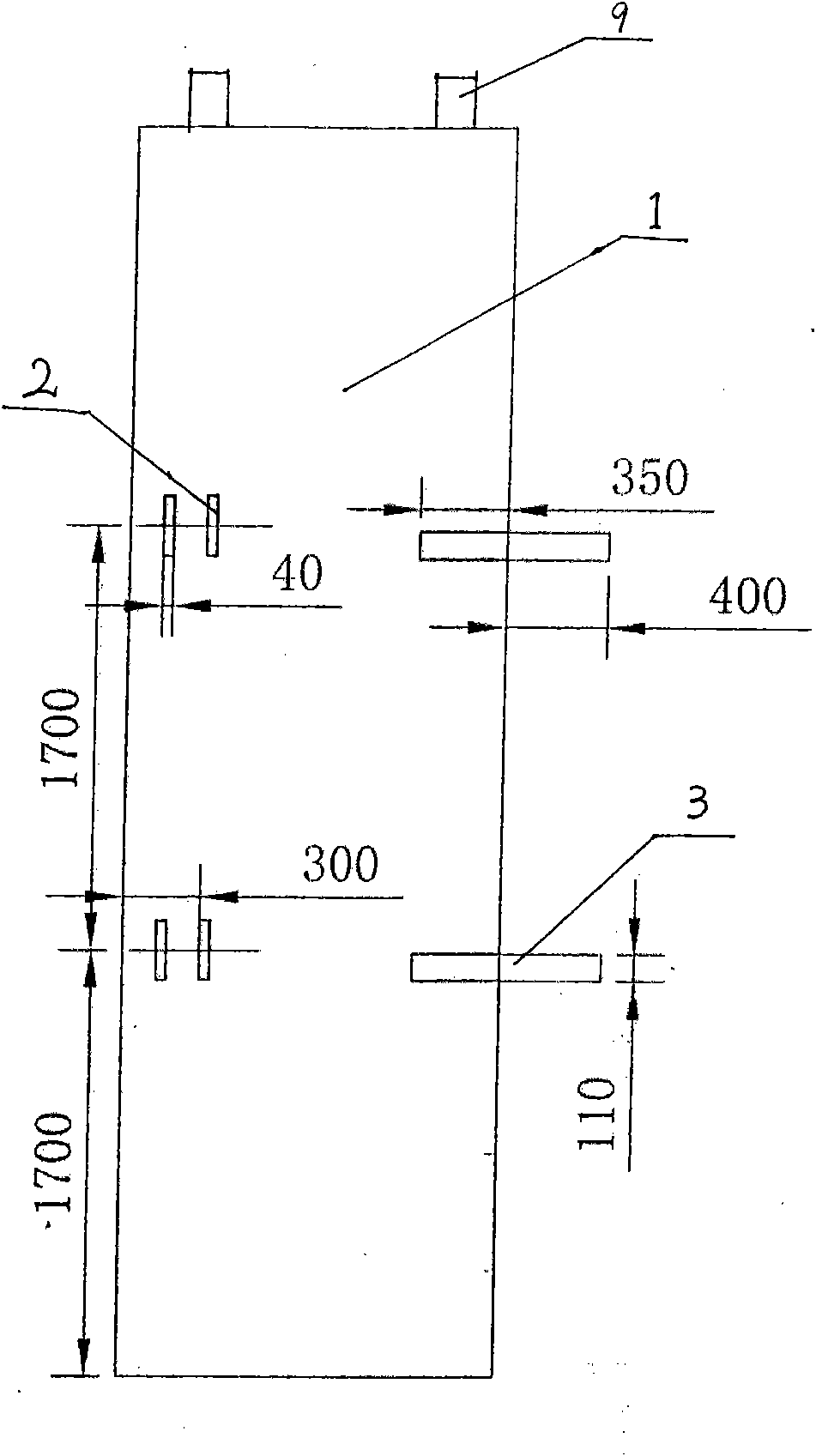

[0019] figure 1 In the process, several slabs (1) as liners lean against the embedded iron plate (10) of the hot stuffy pool wall (6) at a certain angle, and utilize their own weight to stabilize the structure. The bottom of the slab (1) leaves a distance of about 250 millimeters from the hot stuffy pool wall (6), utilizes the steel plate (5) at the bottom of the pool, and welds the iron (7) close to the outer side of the slab (1), and each slab ( 1) There are two or more welding rails (7), so that the billet (1) cannot be close to the pool wall (6) even when it is subjected to a relatively large impact force. The wedge iron (4) on the inner side of the slab (1), each Two or more pieces of slab (1) welding wedge iron (4) make the slab (1) not topple over to the center of the pool. In this way, an inner wedge and an outer stop are formed at the lower part of the slab (1), so as to control the degree of freedom of the slab without affecting its degree of expansion and contracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com