Thick steel plate and manufacturing method thereof

A manufacturing method and thick-gauge technology, applied in the field of iron and steel metallurgy, can solve problems such as poor performance uniformity, high production cost, and low pass rate, and achieve the effect of improving austenite recrystallization effect, ensuring purity, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

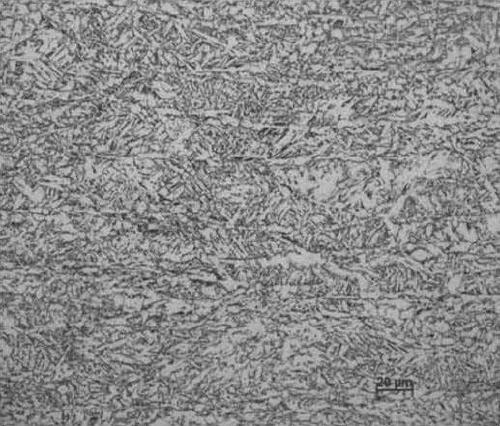

Embodiment 1

[0036] A thick gauge steel plate containing chemical composition, carbon equivalent (Ceq) and weld crack susceptibility index (CE pcm ) see Attached Table 2, and the rest are iron and unavoidable impurity elements. The applicable thickness of the steel plate is 60mm. According to the compositional design requirements of the steel plate of the present invention, the manufacturing method adopts the following steps: firstly, carry out KR pre-desulfurization of molten iron, converter smelting, LF refining, RH vacuum treatment, wire feeding and soft stirring treatment in order to ensure the purity and cleanliness of the steel , wherein, after the KR desulfurization treatment of the molten iron, the S content of the molten iron is 0.006wt.%; after the LF refining treatment, the S content of the molten steel is 0.002wt.%; after the RH vacuum treatment, the H content in the steel is 1.6ppm; during the wire feeding stage, Feed pure Ca wire 400m and perform soft stirring for 12min. Su...

Embodiment 2

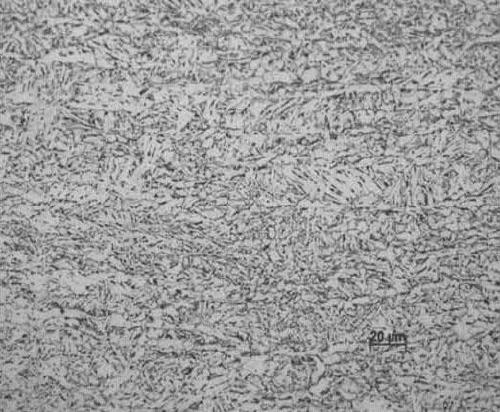

[0038] A thick gauge steel plate containing chemical composition, carbon equivalent (Ceq) and weld crack susceptibility index (CE pcm ) see Attached Table 2, and the rest are iron and unavoidable impurity elements. The applicable thickness of the steel plate is 60mm. According to the compositional design requirements of the steel plate of the present invention, the manufacturing method adopted is the same as in Example 1, the difference is that after RH vacuum treatment, the H content in the steel is 1.5ppm; in the wire feeding stage, 350m of pure Ca wire is fed. The superheat of the tundish in the slab continuous casting stage is controlled at 26°C. In the slab reheating stage, the temperature is controlled at 1185°C; in the rough rolling stage, the rough rolling temperature is controlled at 1055°C; in the finish rolling stage, the finish rolling temperature is controlled at 850°C, and the finish rolling temperature is controlled at 802°C. In the ACC accelerated cooling tre...

Embodiment 3

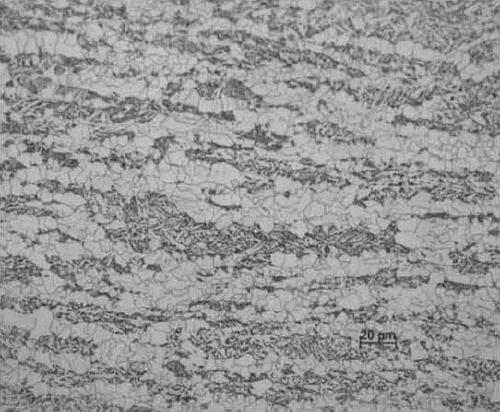

[0040] A thick gauge steel plate containing chemical composition, carbon equivalent (Ceq) and weld crack susceptibility index (CE pcm ) see Attached Table 2, and the rest are iron and unavoidable impurity elements. The applicable thickness of the steel plate is 60mm. According to the compositional design requirements of the steel plate of the present invention, the manufacturing method adopted is the same as in Example 1, the difference is that after the KR desulfurization treatment, the S content of the molten iron is 0.005wt.%; after the RH vacuum treatment, the H content in the steel is 1.5ppm. The superheat of the tundish in the slab continuous casting stage is controlled at 25°C. In the slab reheating stage, the temperature is controlled at 1177°C; in the rough rolling stage, the rough rolling temperature is controlled at 1053°C; in the finish rolling stage, the finish rolling temperature is controlled at 856°C, and the finish rolling temperature is controlled at 813°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com