Welding fixture of carrier roller bracket robot

A technology of robotic welding and idler support, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of high technical requirements for personnel, weak commonality of welding fixtures, and only riveting and welding of specified products for a single fixture. and other problems, to achieve the effect of strong commonality, improved welding quality and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The robot welding jig of the idler bracket of the present invention will be further described in detail below in conjunction with the accompanying drawings.

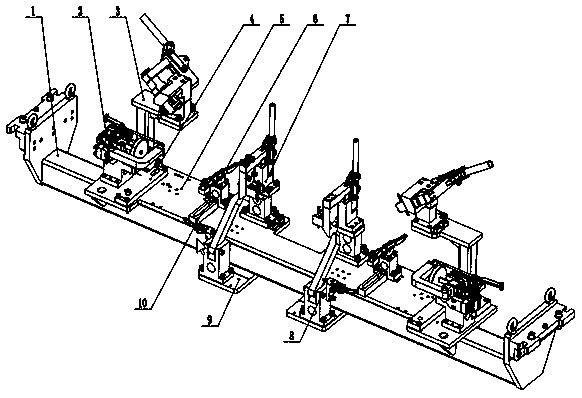

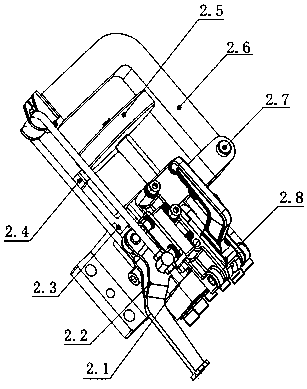

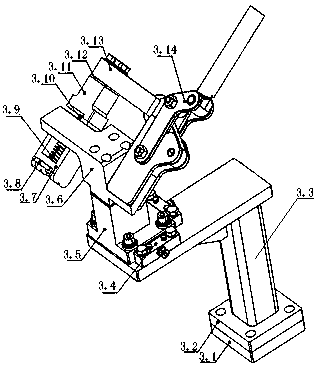

[0025] Such as figure 1 As shown, the robot welding fixture of the idler bracket of the present invention includes a common bottom beam, and the public bottom beam ( figure 2 There are side plates on both sides of the side plate, and lifting lugs are installed on the side plates to facilitate the hoisting and transportation of the entire equipment. There is a positioning groove on the outside of the mounting plate, and an L-shaped connecting plate for quick connection with the positioner is arranged in the positioning groove. The L-shaped connecting plate is provided with positioning pins for quick positioning, and the common bottom beam is provided with positioning mounting holes for replacing the quick-change platform.

[0026] The quick-change platform is installed on the front of the common bottom beam throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com