Magnetic core

A magnetic core and toroidal core technology, applied in the field of magnetic integration, can solve the problems of complex production and assembly processes, loss of the inherent function of the magnetic core, and further rise, and achieve the effects of simple structure, easy processing and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

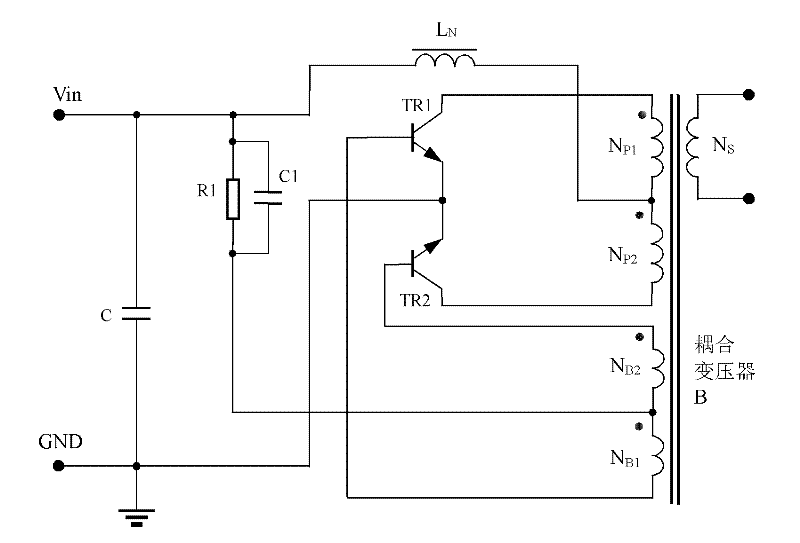

[0047] Figure 4 It is a perspective view of the first embodiment of the present invention. Below to Figure 4 Taking the first embodiment as an example, it shows that the transformer or the common mode inductor and the magnetic flux line between the inductor are independent, Figure 6 for Figure 4 Arrow 61 is a schematic diagram of the diameter of the magnetic ring. Arrow 61 extends out of the magnetic material along the direction of arrow 62. Along the diameter direction of the annular magnetic core, a cylindrical magnetic column of the same material extends outward from the outer surface of the closed magnetic core with no air gap magnetic circuit. , to achieve Figure 4 The first embodiment of . Winding a coil on a magnetic core can realize an integrated device of a transformer and an inductor, see Figure 7 , wherein, 71 is a winding of the transformer, 72 is another winding of the transformer, and 73 is an inductor; Figure 7 It is also possible to realize the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com