Production process of alumina template with nano holes

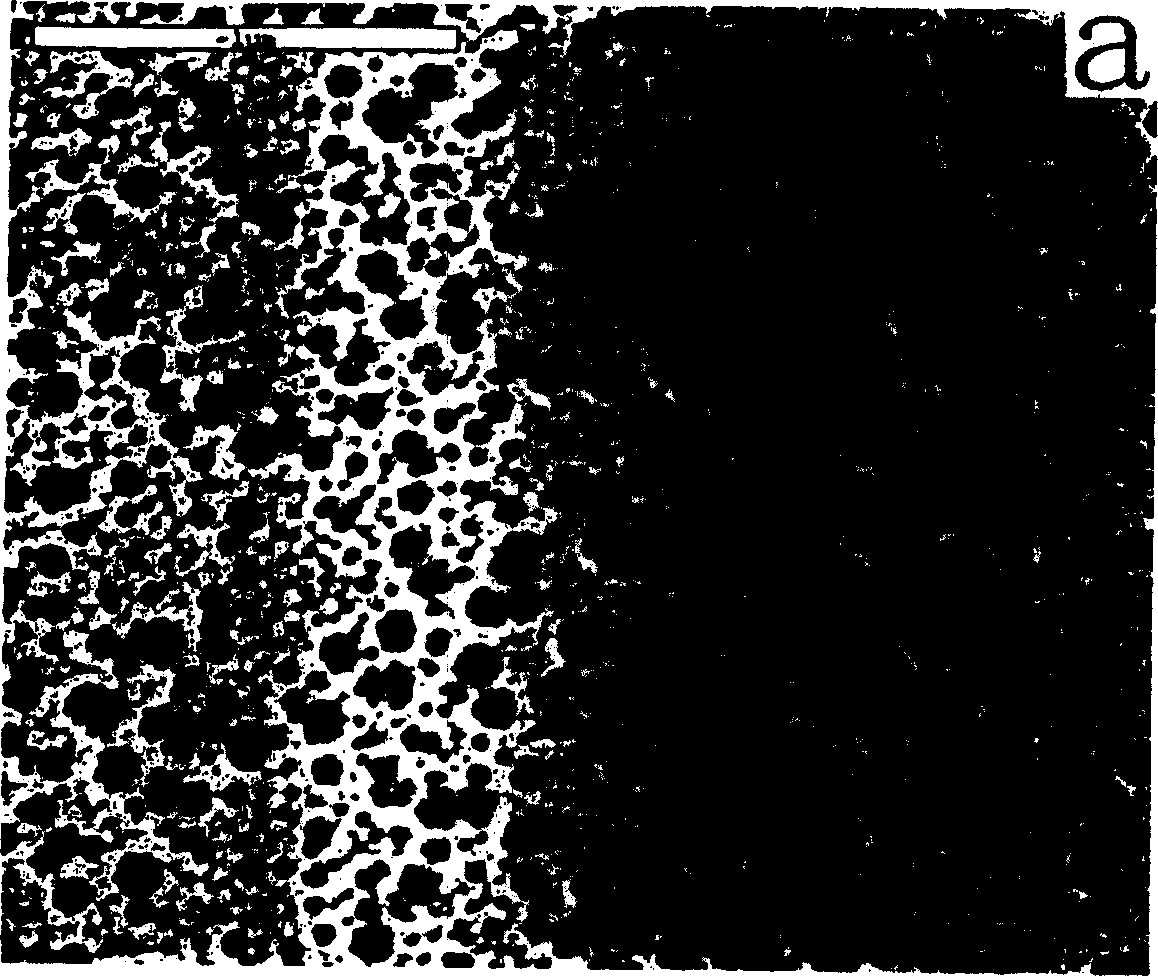

A kind of technology of alumina template and production process, which is applied in the direction of anodic oxidation, etc., can solve the problems of endangering the health of operators, uneven distribution of holes, poisonous mercury chloride, etc., and achieve good order and uniformity of holes, breakthrough Confinement, effect of high hole density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1) Material selection: The aluminum foil used is high-purity aluminum foil, the mass percentage of aluminum is 99.999%, and the thickness is 0.5 mm. The surface is required to be smooth and clean without bumps, scratches, pits, edge burrs, peeling and other defects.

[0054] 2) Pretreatment: Degrease the selected aluminum foil with acetone and alcohol, rinse with water, and then anneal at 500°C for 3 to 4 hours under nitrogen protection or a vacuum environment. Finally, the volume ratio is H 2 SO 4 (Dense): H 3 PO 4 (Dense): H 2 Electrochemical polishing is carried out in a polishing solution of O=4:4:2 for 2-3 minutes, rinsed with water, and dried.

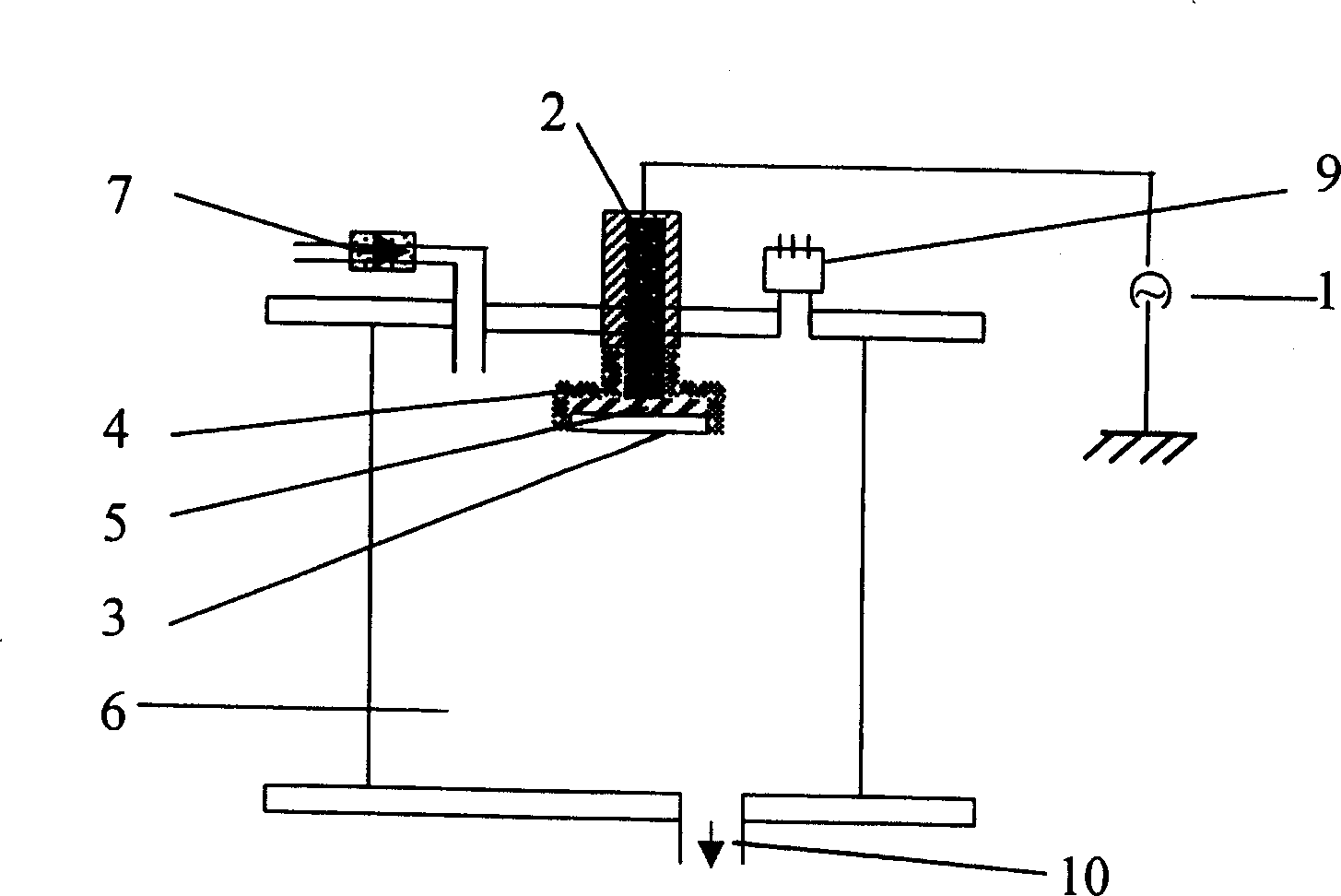

[0055] 3) Anodizing: Continuously anodize with direct current in an electrolytic solution made of sulfuric acid and water to form a porous aluminum oxide film on the surface of the aluminum foil. The oxidation is carried out in an electrolytic oxidation tank. The moles of sulfuric acid in the oxidation solution The concentrati...

Embodiment 2

[0063] 1) Material selection: The aluminum foil used is high-purity aluminum foil, the mass percentage of aluminum is 99.999%, and the thickness is about 0.5 mm. The surface is required to be smooth and clean without bumps, scratches, pits, edge burrs, peeling and other defects.

[0064] 2) Pretreatment: Degrease the selected aluminum foil with acetone and alcohol, rinse with water, and then anneal at 500°C for 3 to 4 hours under nitrogen protection or a vacuum environment. Finally, the volume ratio is H 2 SO 4 (Dense): H 3 PO 4 (Dense): H 2 Electrochemical polishing is carried out in a polishing solution of O=4:4:2 for 2-3 minutes, rinsed with water, and dried.

[0065] 3) The first step of anodizing: the first step of anodizing is continuously carried out in an electrolytic solution made of sulfuric acid and water with direct current to form a porous aluminum oxide film on the surface of the aluminum foil. The oxidation is carried out in an electrode oxidation tank. The molar co...

Embodiment 3

[0074] 1) Material selection: The aluminum foil used is high-purity aluminum foil, the mass percentage of aluminum is 99.999%, and the thickness is about 0.5 mm. The surface is required to be smooth and clean without bumps, scratches, pits, edge burrs, peeling and other defects.

[0075] 2) Pretreatment: Degrease the selected aluminum foil with acetone and alcohol, rinse with water, then anneal at 500°C for 3 to 4 hours under nitrogen protection or a vacuum environment, and finally set the volume ratio to H 2 SO 4 (Dense): H 3 PO 4 (Dense): H 2 Electrochemical polishing is performed in a polishing solution of O=4:4:2 for 2-3 minutes, rinsed with water, and dried.

[0076] 3) The first step of anodizing: the first step of anodizing is continuously carried out in an electrolytic solution made of oxalic acid and water with direct current to form a porous aluminum oxide film on the surface of the aluminum foil. The oxidation is performed in an electrode oxidation tank. The molar conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com