Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

A technology of fine fiber and stone bone, applied in the field of modified stone aggregate, can solve the problems of easy cracking, adverse effect of interface bonding, low strength of interface transition zone, etc., achieves simple construction at room temperature, and inhibits alkali-aggregate reaction. Good effect, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

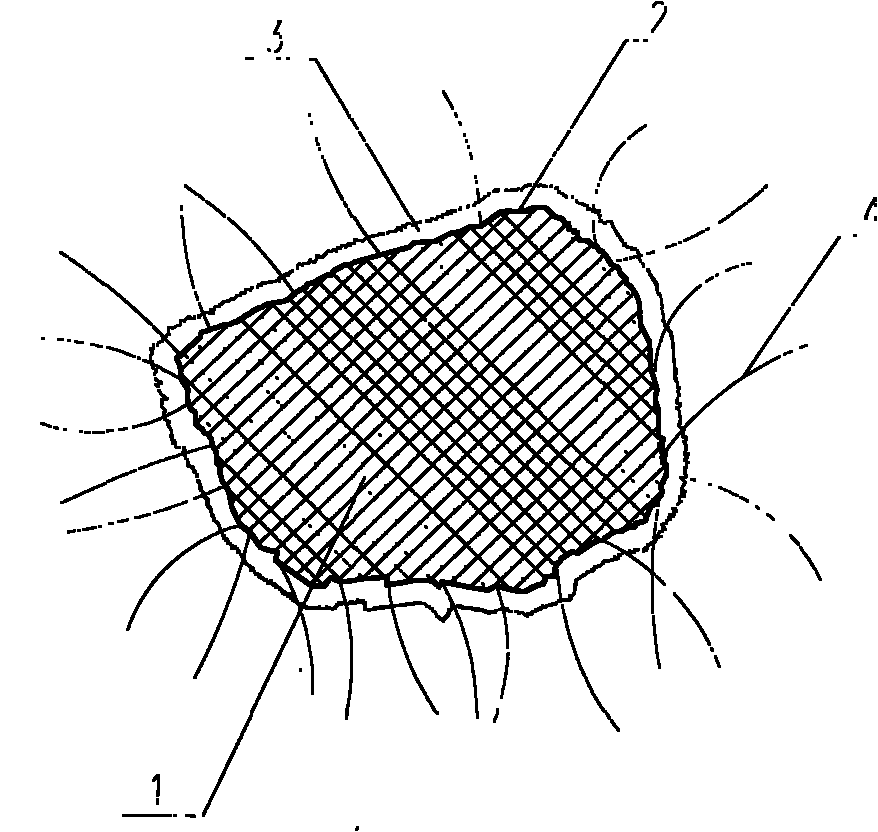

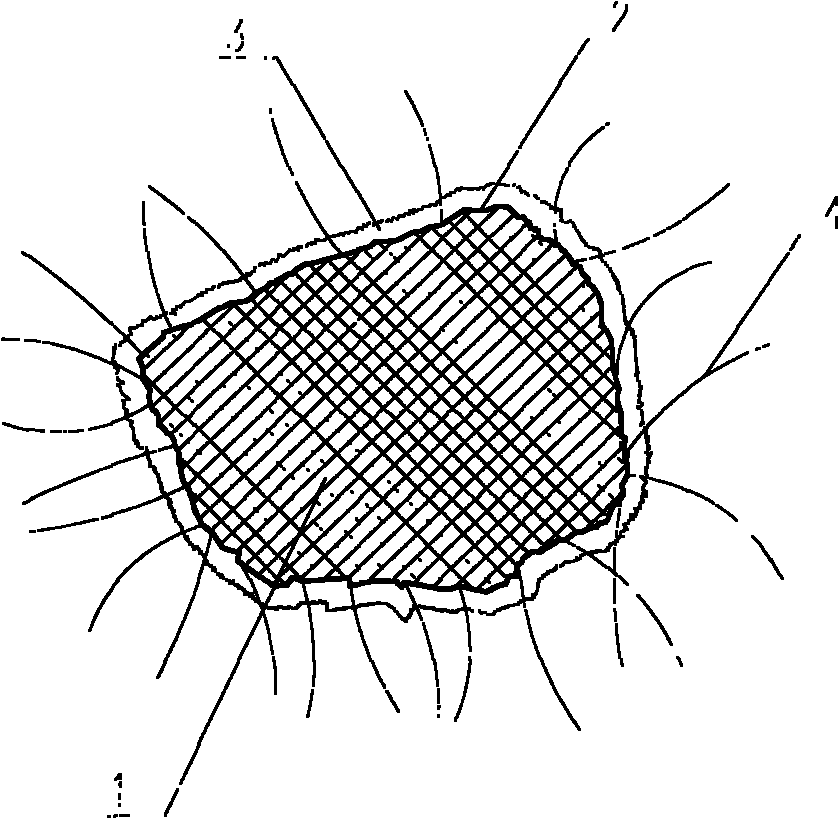

[0025] A stone aggregate coated with a thin layer of microfiber polymer mortar, comprising: a stone aggregate core 1, an adhesive inner coating layer 2 is wrapped on the outer surface of the stone aggregate core 1, and the adhesive inner coating layer 2 is outside A polymer cement mortar outer coating 3 is wrapped on the surface, an adhesive microfiber batt 4 is connected to the adhesive inner coating 2 and the fibers on the adhesive microfiber batt 4 extend to the polymer cement mortar The exterior of the outer wrap 3.

Embodiment 2

[0027] A method for preparing stone aggregate covered with a thin layer of fine fiber polymer mortar,

[0028] Step 1 Wash and dry the stone aggregate core 1 and spray organic adhesive on the surface of the stone aggregate core 1 or immerse the washed and dried stone aggregate core 1 in the organic adhesive to form on the surface of the stone aggregate core 1 A layer of adhesive inner coating 2 with a thickness of 20μm~30μm,

[0029] Step 2 While stirring the stone aggregate with adhesive, spray the fine fiber while mixing it evenly to form the stone aggregate glued fine fiber hair layer 4.

[0030] Step 3 The polymer cement mortar outer coating layer 3 uses the organic and inorganic polymer cement paste as the outer coating material, and the polymer cement paste is covered on the surface with the adhesive inner coating layer 2 On the core 1 of the stone aggregate,

[0031] Step 4 Put the stone aggregate obtained in step 3 into the steam curing tank, stop for 1 hour, raise the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com