Degradable foaming material and preparation method thereof

A foaming material and foaming agent technology, applied in the field of foaming materials, can solve problems such as insufficient melt strength and difficult control of foaming agent decomposition

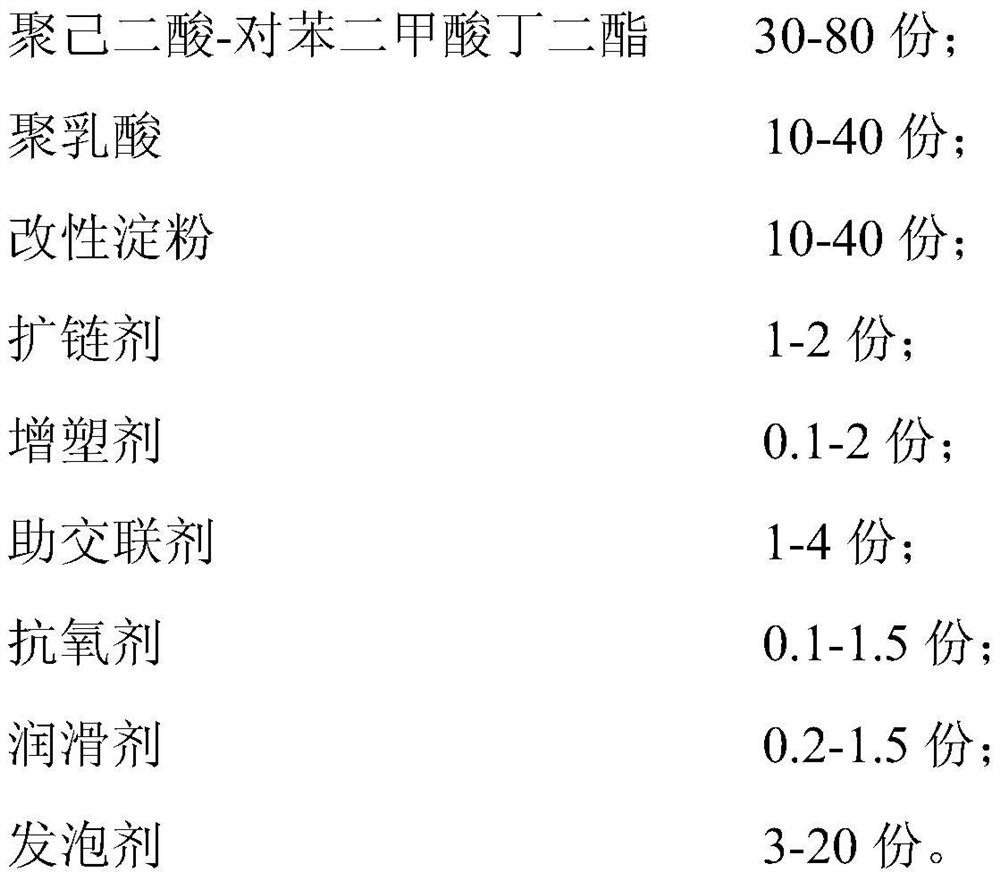

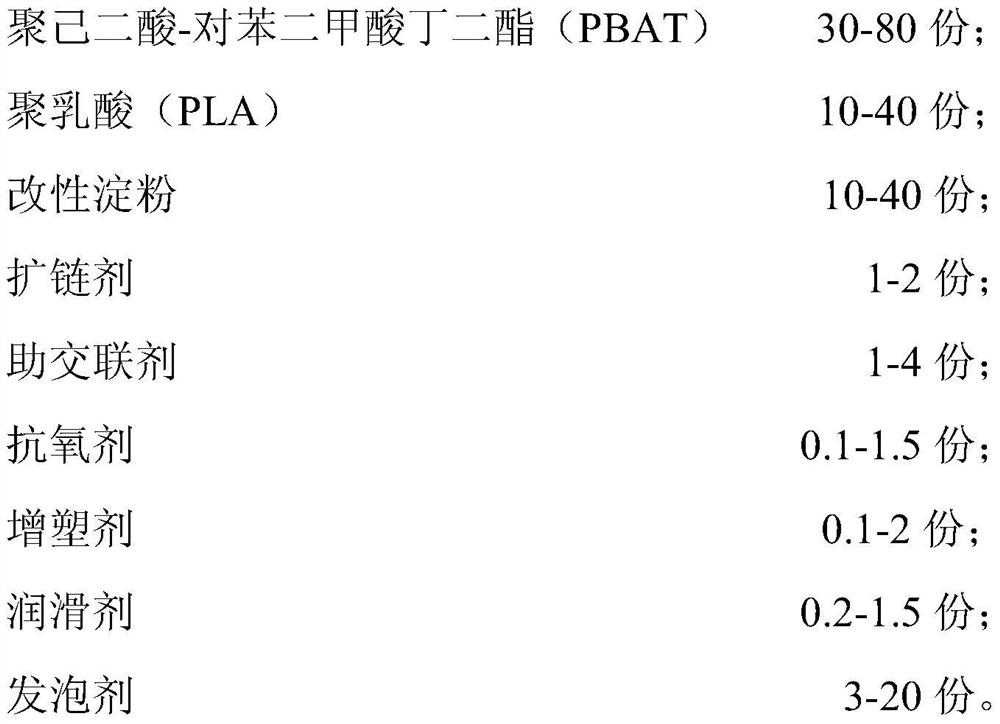

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

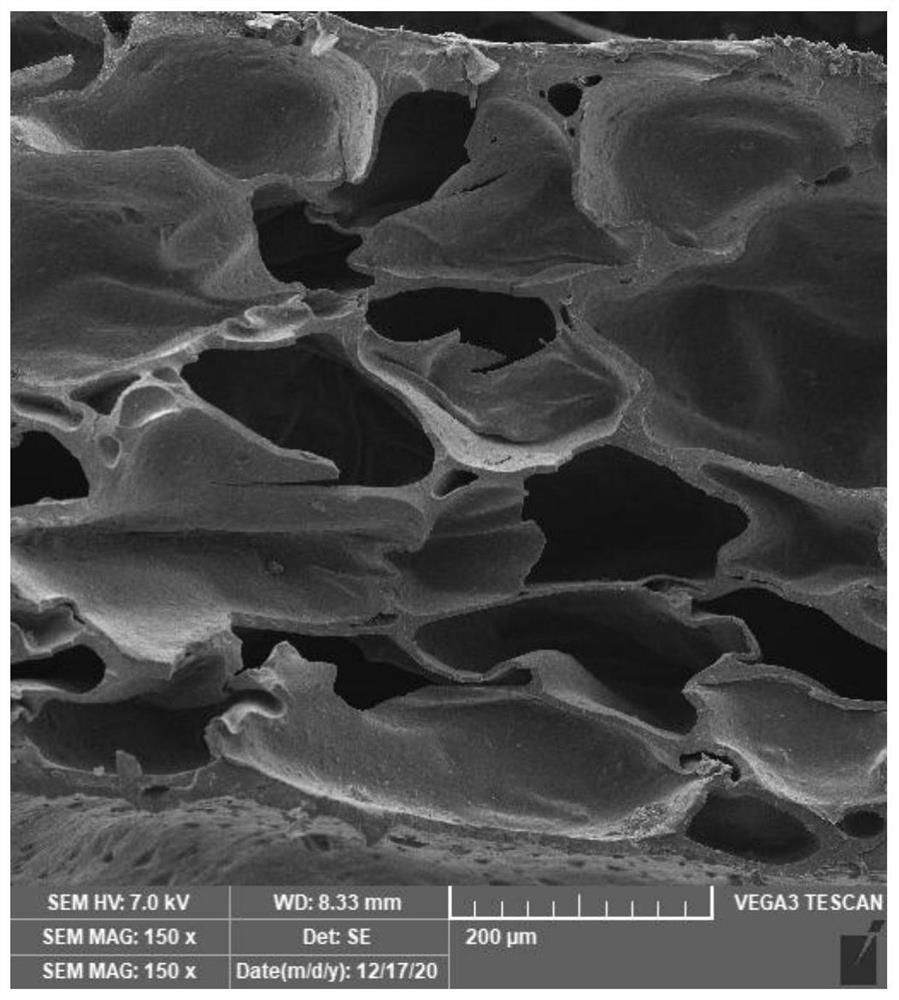

Image

Examples

Embodiment 1

[0046] (1) Take 10 parts of PBAT, 10 parts of PLA and 0.5 parts of glycerol triacetate to prepare modified particles through twin-screw extrusion granulation. The temperature of the feeding section of the twin-screw extruder is 160°C, and the temperature of the plasticizing section is 180°C. The homogenization section dimension is 190°C, and the extrusion die temperature is 180°C.

[0047] (2) Take 70 parts of PBAT, 10 parts of modified starch, 0.5 parts of chain extender ADR-4370S, 8 parts of AC foaming agent, 2 parts of auxiliary crosslinking agent, 0.7 part of antioxidant DLTDP, 0.7 part of antioxidant 1010 , 0.9 parts of zinc stearate lubricant was added to the banbury mixer, the banbury temperature was 110°C, and then the mixed material after banbury mixing was put into a single-screw extruder for extrusion and granulation to prepare foam masterbatches. The temperature of the first to third zones of the screw extruder is 110, 115, 120°C, and the die head temperature is 11...

Embodiment 2

[0051] (1) Take 30 parts of PBAT, 30 parts of PLA and 1.5 parts of glycerol triacetate to prepare modified particles through twin-screw granulation; The segment dimension was 190°C and the extrusion die temperature was 180°C.

[0052] (2) Take 30 parts of PBAT, 10 parts of modified starch, 0.5 parts of chain extender, 8 parts of AC foaming agent, 2 parts of co-crosslinking agent, 0.7 part of antioxidant DLTDP, 0.7 part of antioxidant 1010, 1 part The zinc stearate lubricant was added into the banbury mixer, and the banbury temperature was 115°C, and then the banbury mixed materials were put into a single-screw extruder for extrusion and granulation to prepare foam masterbatches. The temperatures of the first to third zones of the single-screw extruder are 110, 115, and 120°C, and the die head temperature is 110°C.

[0053] (3) Stir and blend the modified particles and the foam masterbatch with a stirrer at a stirring speed of 100 r / min. Coils were prepared by extruding throu...

Embodiment 3

[0057] (1) Take 40 parts of PBAT, 40 parts of PLA and 2 parts of glycerol triacetate to prepare modified particles through twin-screw granulation; The segment dimension was 190°C and the extrusion die temperature was 180°C.

[0058] (2) Take 20 parts of PBAT, 10 parts of thermoplastic starch masterbatch, 0.5 parts of chain extender ADR-4370S, 8 parts of AC foaming agent, 2 parts of crosslinking agent, 0.7 parts of antioxidant DLTDP, 0.7 parts of antioxidant 1010, 1.2 parts of zinc stearate lubricant was added to the internal mixer, the internal mixing temperature was 120°C, and then the mixed material after internal mixing was put into the single-screw extruder for extrusion and granulation to prepare foam masterbatch. The temperatures of the first to third zones of the single-screw extruder are 115, 120, and 125°C, and the die head temperature is 120°C.

[0059] (3) Stir and blend the modified particles and the foam masterbatch with a stirrer at a stirring speed of 100 r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com