Dielectric layer for semiconductor device and method of manufacturing the same

A dielectric layer and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems related to dielectric materials, reduce channel mobility, and reduce device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides a stable (noble) dielectric layer structure and a manufacturing method thereof. In the following description, many specific details are explained to provide a comprehensive understanding of the present invention. However, those of ordinary skill in the art should understand that the present invention can still be implemented without using these details. In some examples, well-known process steps, device structures and technologies are not shown in detail to avoid making the present invention difficult to understand.

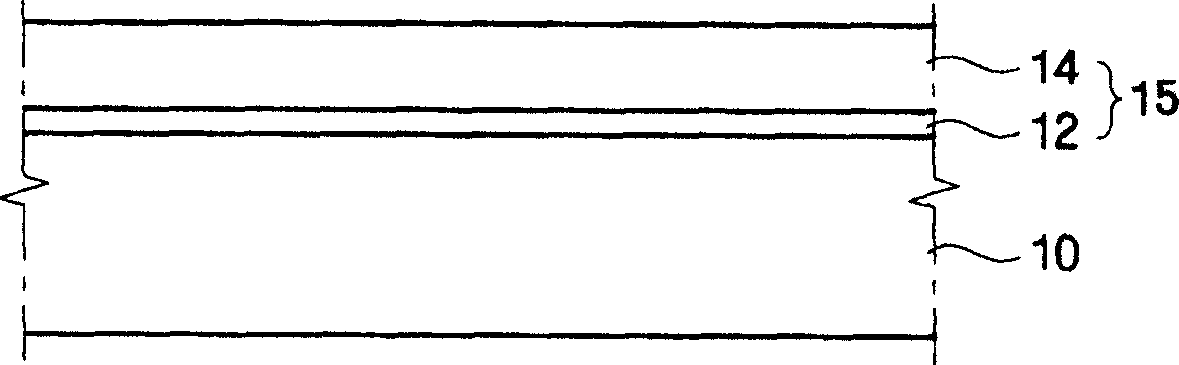

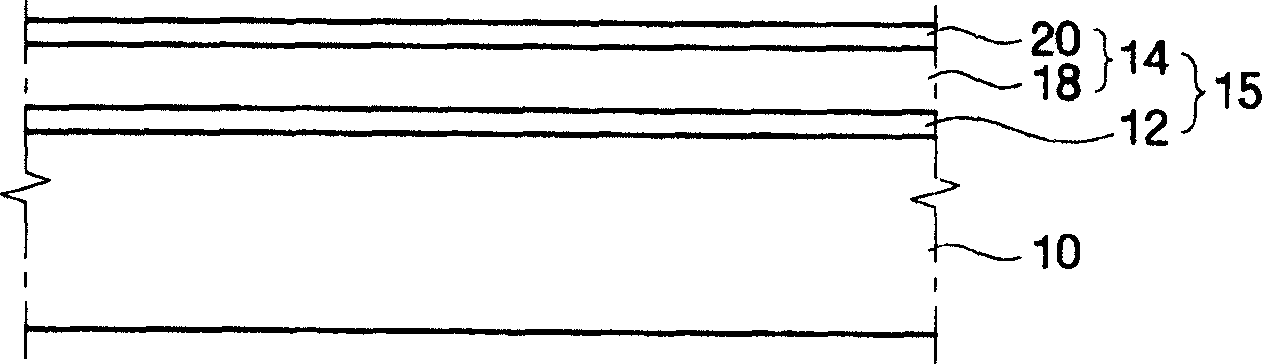

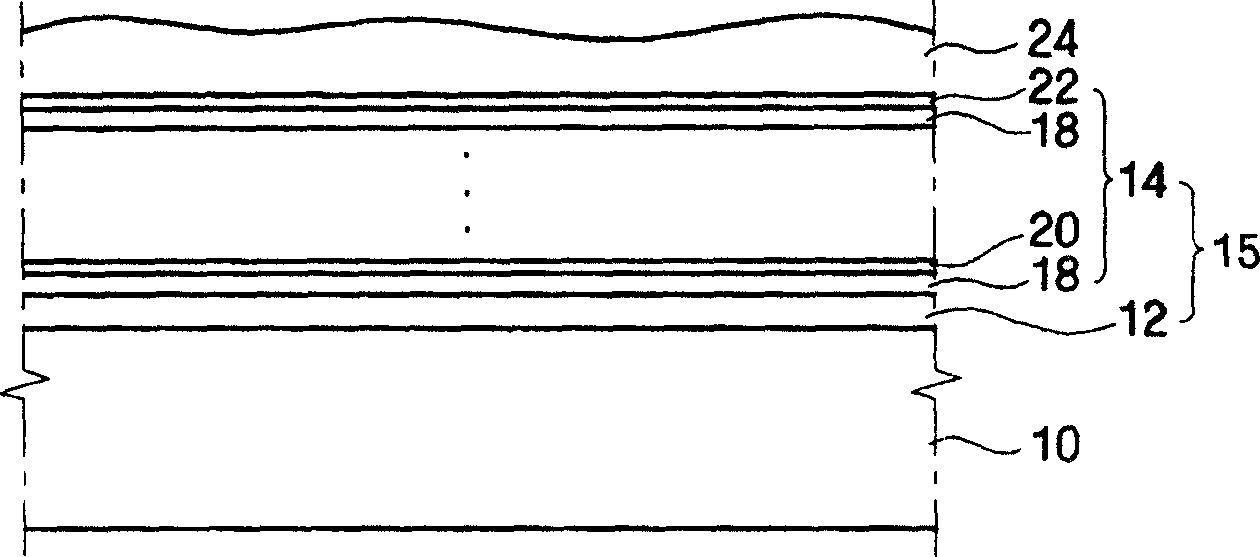

[0018] reference figure 1 According to an embodiment of the present invention, the silicate interface layer 12 formed of silicate material may be disposed on the conductive layer or the semiconductor substrate 10, such as a silicon substrate. The dielectric constant of the silicate interface layer 12 is preferably greater than any one of silicon oxide, silicon nitride, or silicon oxynitride. Preferably, the silicate interface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com