Method for controlling brittle phases of titanium and stainless steel electronic beam welding joints adopting composite intermediate layers

A composite intermediate layer and electron beam welding technology, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

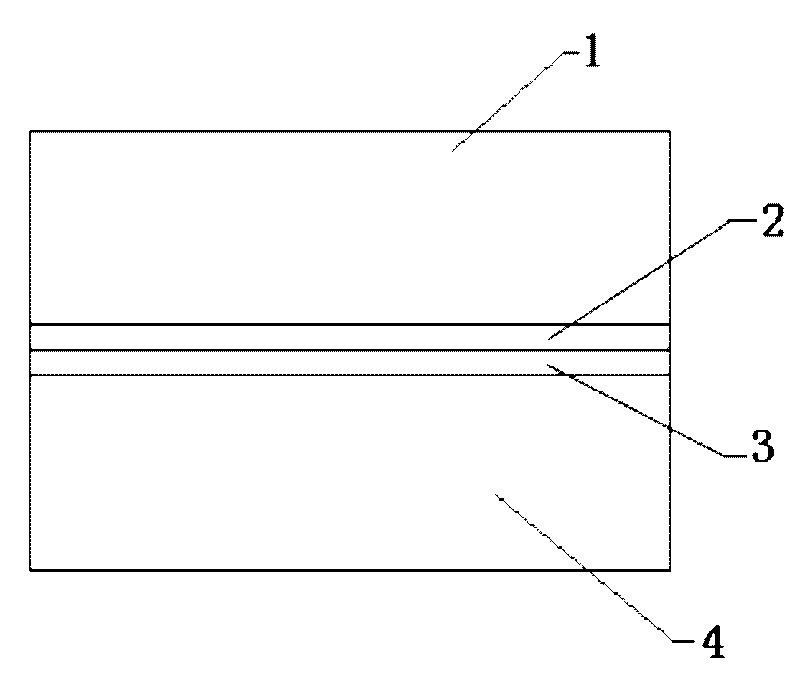

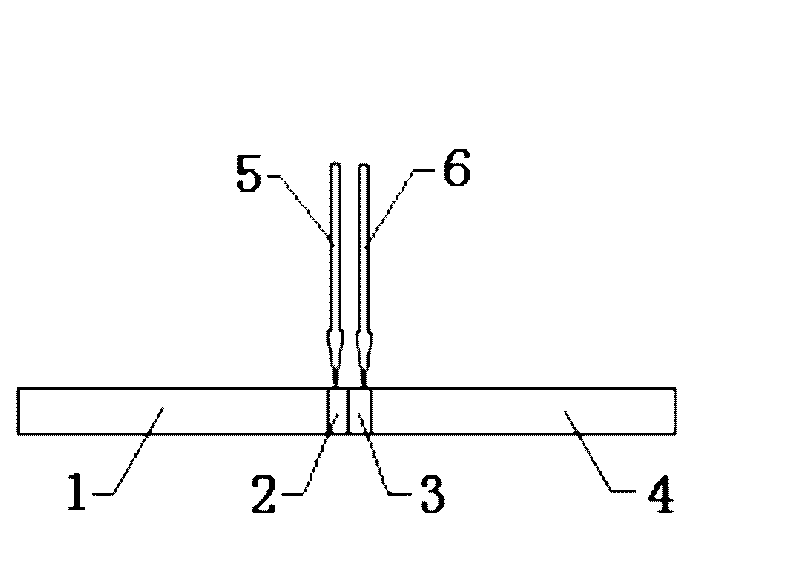

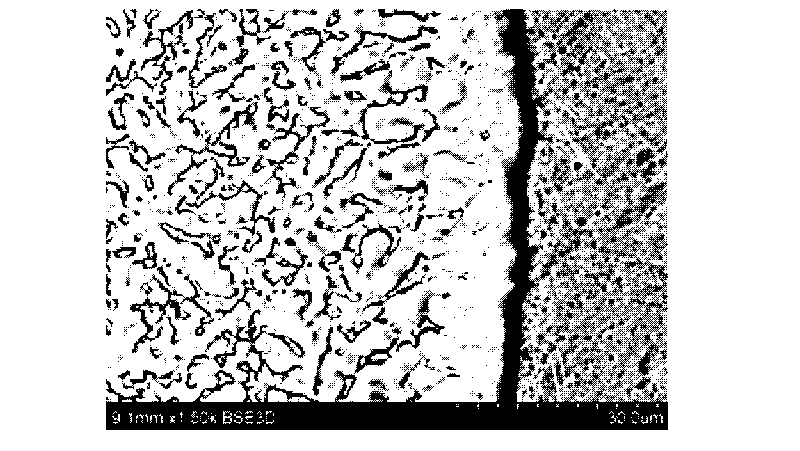

[0007] Specific embodiment one: In this embodiment, the brittle phase control method of the titanium metal material and the stainless steel electron beam welded joint of the composite intermediate layer is realized through the following steps: 1. Pure vanadium with a thickness of 0.3 to 0.6 mm and a thickness of 0.5 mm ~1.0mm pure copper is placed between the titanium metal material and the stainless steel connection surface as an intermediate layer, so that the pure copper is close to the stainless steel, and then fixed by TIG welding spot welding, so that the gap between each butt surface is less than 0.15mm, that is, the obtained Stainless steel-pure copper-pure vanadium-titanium metal materials (see figure 1 ) to be welded, and the titanium metal material is titanium or titanium alloy; 2. Then, the welded piece is ultrasonically cleaned with acetone, then pickled and washed with water, and then dried; 3. The rigid fixation method is used to process the The weldment is fixe...

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of pure vanadium in step 1 is 0.4 mm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the thickness of the pure vanadium described in step 1 is 0.5 mm. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com