Microalgae-based nano carbon quantum dot solid powder as well as preparation method and application thereof

A technology of solid powder and carbon quantum dots, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of uneven particle size distribution of carbon quantum dots, poor stability of carbon quantum dots, and low fluorescence quantum yield and other problems, to achieve the effect of high production efficiency, cheap raw materials, and good luminescence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

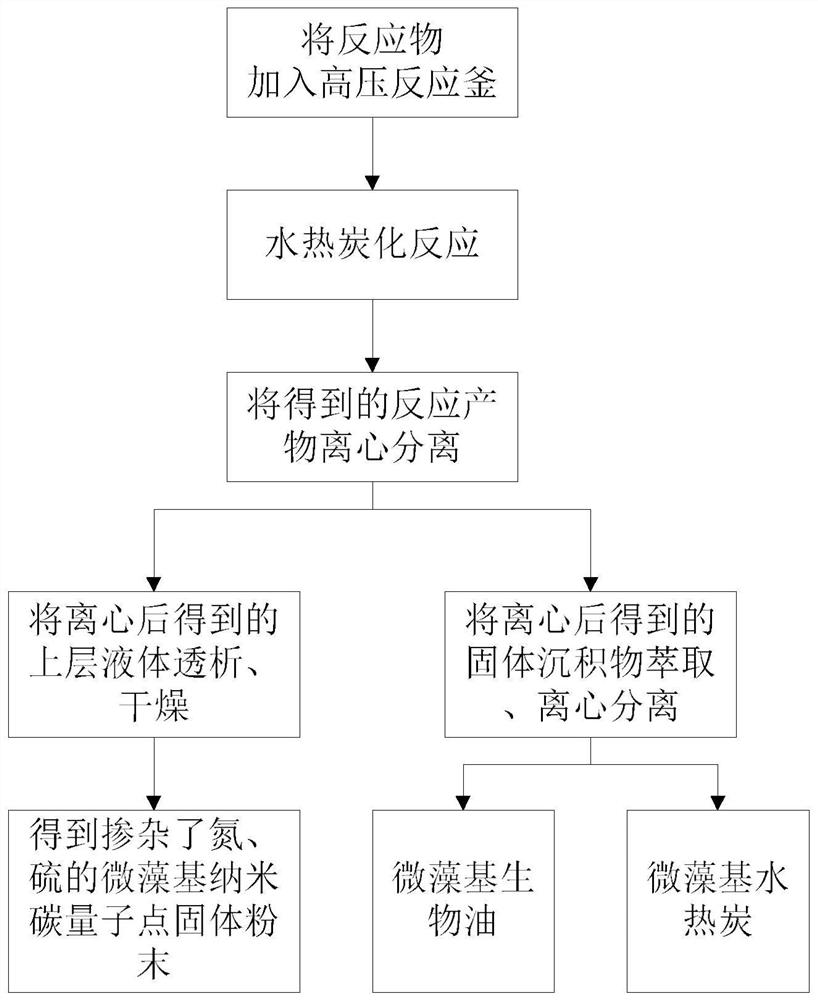

[0035] see figure 1 , a preparation method of microalgae-based nano-carbon quantum dot solid powder, the steps are as follows:

[0036] Step 1: Add 1.5g of dry chlorella powder and 25g of deionized water into the reactor, close the reactor, open the inlet valve, and let in nitrogen to replace the air in the reactor.

[0037] Step 2: Magnetic stirring at 250r / min and hydrothermal reaction at 230°C. During the hydrothermal carbonization process, functional groups such as nitrogen and sulfur contained in chlorella combine with functional groups on the surface of carbon quantum dots to form nitrogen-doped , Sulfur fluorescent nano-carbon material; after hydrothermal carbonization for 6 hours, stop heating. After cooling to about 150°C, rinse and cool the reactor body with flowing cold water.

[0038] Step 3: Open the reaction kettle, pour the reaction mixture into a centrifuge tube, and centrifuge at 8000r / min for 20min.

[0039]Step 4: Pour the upper liquid obtained after cent...

Embodiment 2

[0043] A preparation method of microalgae-based nano carbon quantum dot solid powder is carried out as follows:

[0044] Step 1: Take 26.5g of chlorella algae pulp aqueous solution (the mass ratio of water to chlorella is 20:1) into the reactor, close the reactor, open the air inlet valve, let in nitrogen, and replace the air in the reactor.

[0045] Step 2: Magnetic stirring at 250r / min and hydrothermal reaction at 230°C. During the hydrothermal carbonization process, functional groups such as nitrogen and sulfur contained in chlorella combine with functional groups on the surface of carbon quantum dots to form nitrogen-doped , Sulfur fluorescent nano-carbon material; after hydrothermal carbonization for 2 hours, stop heating. After cooling to about 150°C, rinse and cool the reactor body with flowing cold water.

[0046] Step 3: Open the reaction kettle, pour the reaction mixture into a centrifuge tube, and centrifuge at 8000r / min for 20min.

[0047] Step 4: Pour the upper ...

Embodiment 3

[0053] A preparation method of microalgae-based nano carbon quantum dot solid powder is carried out as follows:

[0054] Step 1: Add 1.5g of dry chlorella powder and 25g of deionized water into the reactor, close the reactor, open the inlet valve, and let in nitrogen to replace the air in the reactor.

[0055] Step 2: Magnetic stirring at 250r / min and hydrothermal reaction at 230°C. During the hydrothermal carbonization process, functional groups such as nitrogen and sulfur contained in chlorella combine with functional groups on the surface of carbon quantum dots to form nitrogen-doped , Sulfur fluorescent nano-carbon material; stop heating after hydrothermal carbonization for 10 hours. After cooling to about 150°C, rinse and cool the reactor body with flowing cold water.

[0056] Step 3: Open the reaction kettle, pour the reaction mixture into a centrifuge tube, and centrifuge at 6000-8000 r / min for 20-40 minutes.

[0057] Step 4: Pour the upper liquid obtained after centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com