Method for preparing fewer-layer graphene on basis of biomass waste

A few-layer graphene and biomass technology, applied in the field of preparing few-layer graphene based on biomass waste, can solve the problems of unfriendly reagent environment, low graphene yield, high raw material cost, etc. High yield and low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

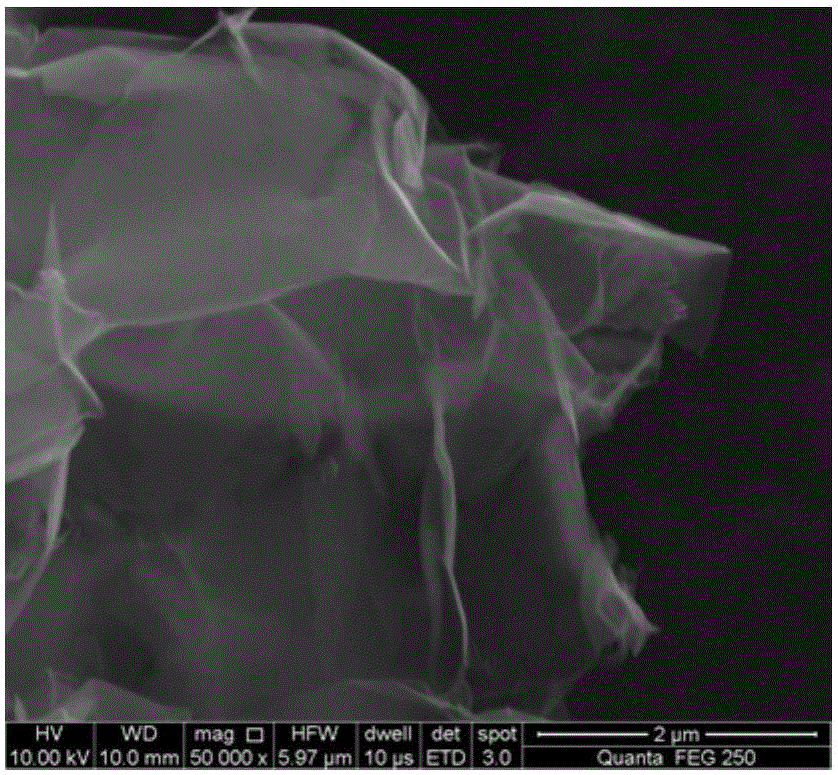

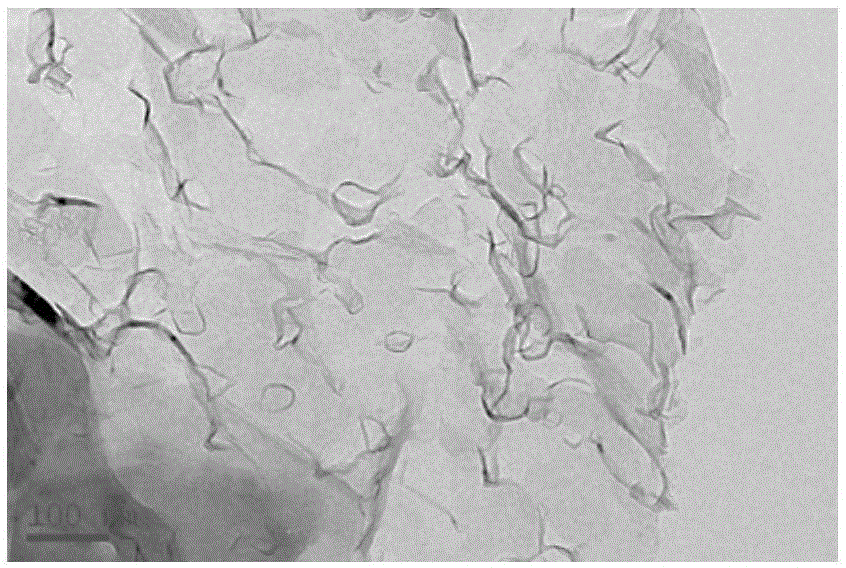

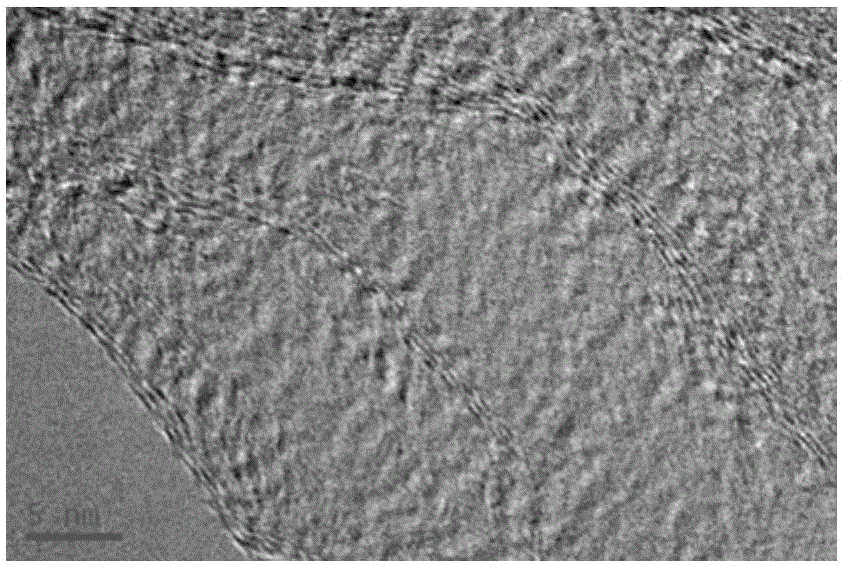

Embodiment 1

[0061] Take 40g of washed and dried wheat straw and place it in a hydrothermal reaction kettle, add 47.2g of potassium hydroxide and 280mL of distilled water, put the reaction kettle in an oven at 150°C for 6 hours, cool it down to room temperature naturally, filter and add Put 120mL of distilled water into an ultrasonic cleaner for ultrasonic treatment for 30min, filter and dry in an oven at 80°C for 48h to obtain pretreated straw; put the treated straw into a tube furnace, and 800 ℃ carbonization treatment for 3 hours, the air intake flow rate is 200 sccm, the heating rate is 5 ℃ / min, the obtained product is washed with 1 mol / L dilute hydrochloric acid for 1 hour, filtered and washed with distilled water until the pH is 7, and dried at 80 ℃ for 24 hours to obtain biomass carbon ; Finally, in an argon atmosphere, put the obtained biomass carbon into a high-temperature graphitization furnace, keep it warm for 10 minutes at 2600°C, with an air flow rate of 300sccm, a heating rat...

Embodiment 2

[0064] Take 40g of washed and dried wheat straw and place it in a hydrothermal reaction kettle, add 53.2g of sodium hydroxide and 300mL of distilled water, put the reaction kettle into an oven at 160°C for 4 hours, cool it down to room temperature naturally, filter and add Put 120mL of distilled water into an ultrasonic cleaner for ultrasonic treatment for 40min, filter and dry in an oven at 80°C for 48h to obtain pretreated straw; put the treated straw into a tube furnace, and heat it under the protection of high-purity nitrogen for 700 ℃ carbonization treatment for 3 hours, the air intake flow rate is 150 sccm, the heating rate is 4 ℃ / min, the obtained product is washed with 1.5mol / L dilute hydrochloric acid for 1 hour, filtered and washed with distilled water until the pH is 7, dried at 80 ℃ for 12 hours to obtain biomass carbon; finally, in an argon atmosphere, put the obtained biomass carbon into a high-temperature graphitization furnace, keep it warm for 15 minutes at 250...

Embodiment 3

[0066] Take 40g of washed and dried rice straw and place it in a hydrothermal reaction kettle, add 47.2g of potassium hydroxide and 280mL of distilled water, put the reaction kettle in an oven at 150°C for 6 hours, cool it down to room temperature naturally, filter and add Put 120mL of distilled water into an ultrasonic cleaner for ultrasonic treatment for 40min, filter and dry in an oven at 80°C for 48h to obtain pretreated rice straw; put the treated rice straw into a tube furnace, and 800 ℃ carbonization treatment for 4 hours, the gas flow rate was 200 sccm, and the heating rate was 5 ℃ / min, the product was washed with 1.5 mol / L dilute hydrochloric acid for 1.5 hours, filtered and washed with distilled water until the pH was 7, and dried at 80 ℃ for 24 hours to obtain the product Substance carbon; finally, in an argon atmosphere, put the obtained biomass carbon into a high-temperature graphitization furnace, keep it warm for 5 minutes at 2800°C, the air intake flow rate is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com