Optical fiber ribbon optical cable easy to strip

A technology of optical fiber ribbon and optical cable, which is applied in the field of communication optical cable, can solve the problems of compact optical fiber ribbon and high fiber core density, and achieve the effects of convenient testing and construction, less material consumption, and better heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

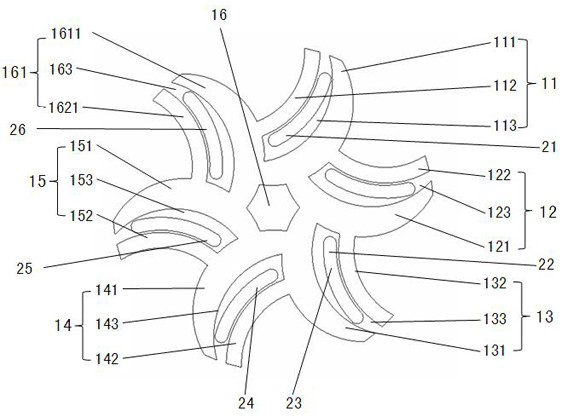

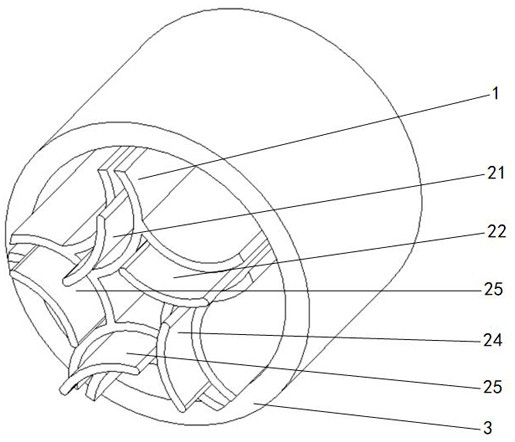

Embodiment 1

[0036] please see Figure 1 to Figure 3, an optical fiber ribbon cable that is easy to strip, has an accommodating housing 1, a first protective layer 3, a first optical fiber ribbon unit 21, a second optical fiber ribbon unit 22, a third optical fiber ribbon unit 23, and a fourth optical fiber ribbon unit 24. The fifth optical fiber ribbon unit 25, the first protective layer 3 is covered outside the housing case 1; it is characterized in that the housing case 1 has an integrated structure and is protected by the first protection unit 11 and the second protection unit 11. A unit 12, a third protection unit 13, a fourth protection unit 14, and a fifth protection unit 15; the first protection unit 11 is composed of a first protection wall 111 and a second protection wall 112 that form a first accommodation cavity 113 between them , the first protective wall 111 and the second protective wall 112 are curved structures with the same bending direction, the first optical fiber ribbo...

Embodiment 2

[0040] please see Figure 4 , an optical fiber ribbon cable that is easy to strip, basically the same as that of Example 1, the difference is that: the first protective layer 3 is wrapped around the outside of the housing, and the material of the first protective layer is preferably wire or rope Or yarn or cloth, such as cable ties, non-woven fabrics, resistance bands, polyester yarns, water-blocking yarns, etc.

Embodiment 3

[0042] please see Figure 5 , an optical fiber ribbon cable that is easy to strip, has an accommodating housing 1, a first optical fiber ribbon unit 21, a second optical fiber ribbon unit 22, a third optical fiber ribbon unit 23, and a fourth optical fiber ribbon unit 24; it is characterized in that The accommodating housing 1 is an integral structure and is composed of a first protection unit 11, a second protection unit 12, a third protection unit 13, and a fourth protection unit 14; The cavity 113 is composed of the first protective wall 111 and the second protective wall 112. The first protective wall 111 and the second protective wall 112 are curved structures with the same bending direction. The first optical fiber ribbon unit 21 is located between the first accommodating cavity 113. Inside; the second protection unit 12 is composed of a third protection wall 121 and a fourth protection wall 122 that form a second accommodating cavity 123 with each other. The third prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com