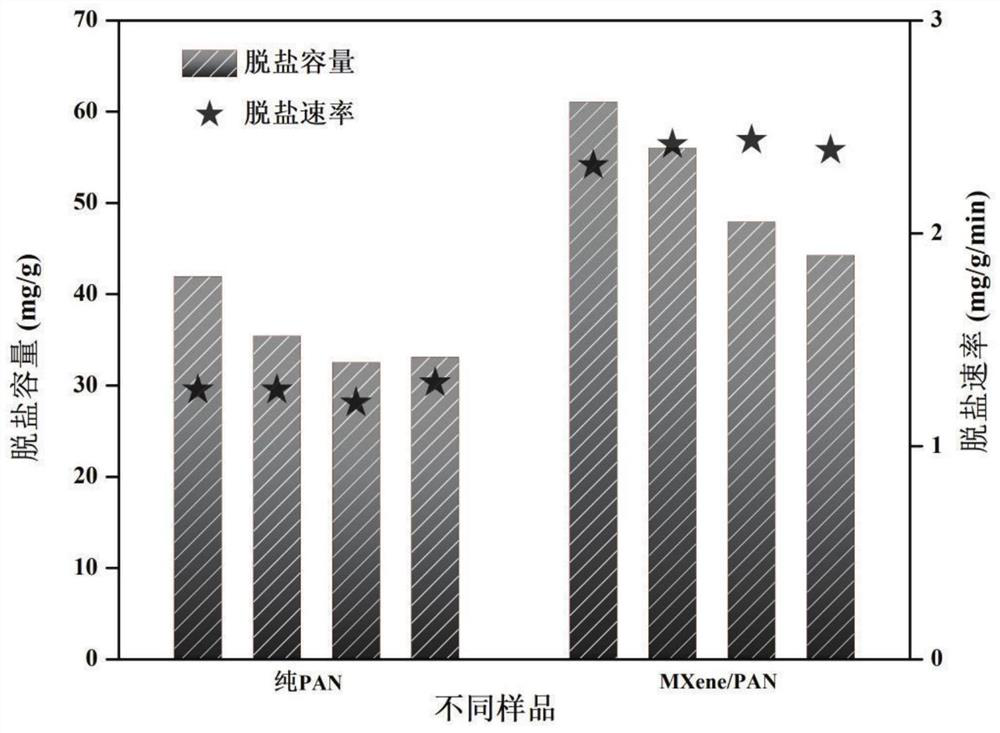

Preparation and application of novel MXene modified porous carbon fiber composite electrode

A porous carbon fiber and composite electrode technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, water/sludge/sewage treatment, etc., can solve the problems of dispersibility, poor formability, mechanical properties, desalination performance to be improved, and large energy consumption. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

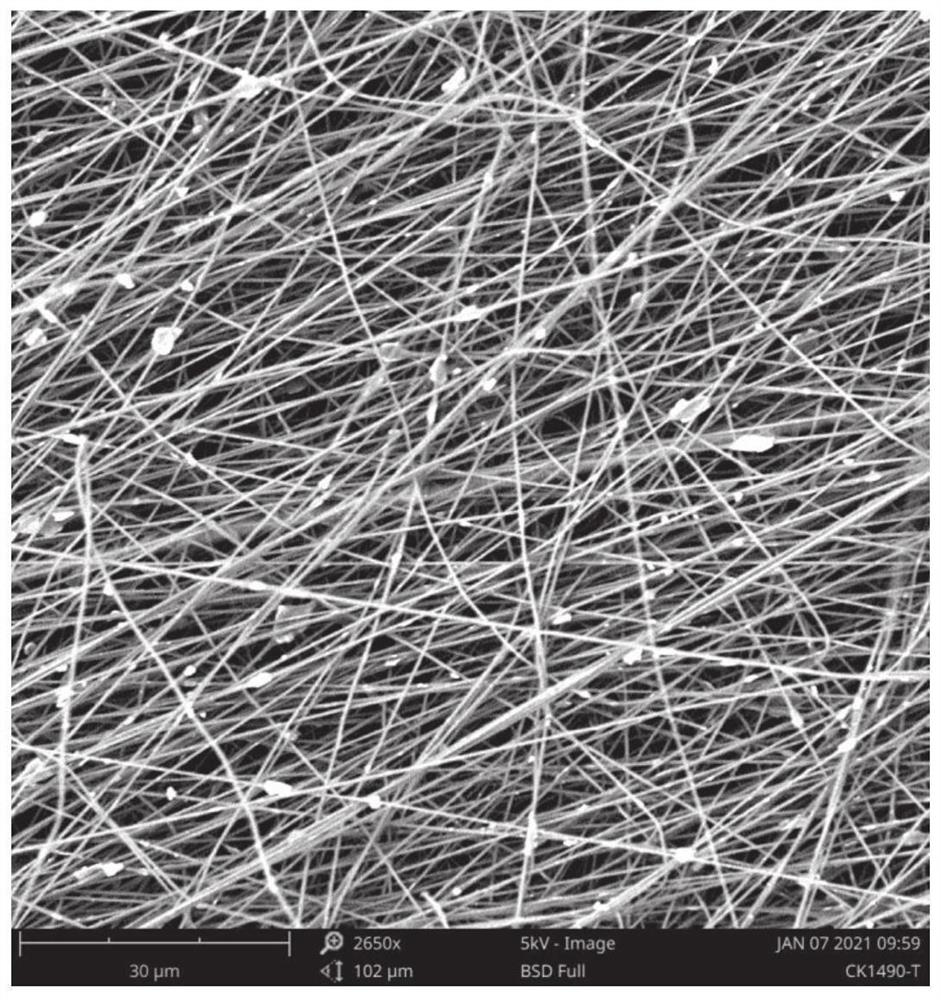

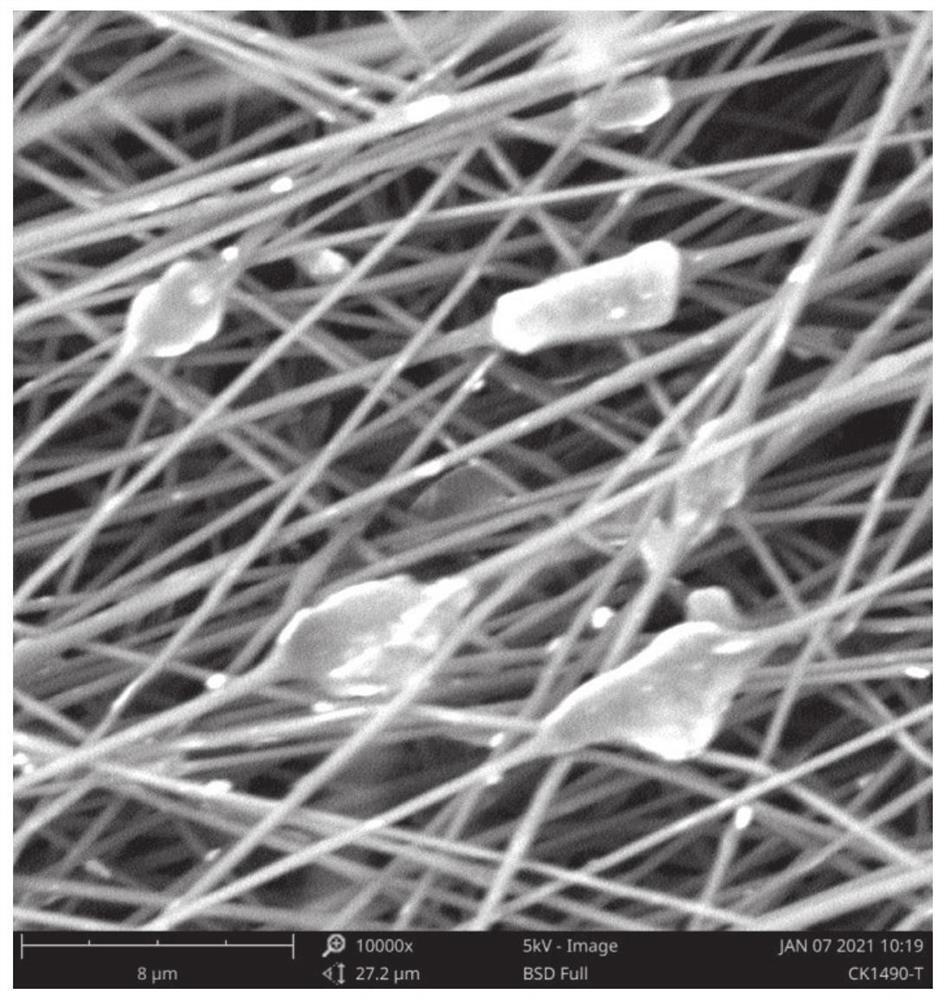

[0033] The preparation method of the novel MXene-modified porous carbon fiber composite electrode of the present embodiment comprises the steps:

[0034] (1) Slowly dissolve 1gLiF in 20mL of hydrochloric acid with a concentration of 9mol / L, stir for 30min, and slowly add 1gTi 3 AlC 2 , Stirring at 40°C for 24h. Then centrifugally wash with deionized water for 6 to 8 times, then centrifugally wash with DMF for no less than 5 times, collect the precipitate, and dissolve it in 50 mL of DMF;

[0035] (2) Take the DMF solution of 5mLMXene in a 10mL beaker, then put it into a 250mL beaker filled with smoothies and process it with an ultrasonic cell pulverizer. The total processing time is 20 minutes;

[0036] (3) Add 0.9g PAN (molecular weight: 150,000) to the above 5mL single-layer MXene / DMF mixed solution, and stir at room temperature for 12h to obtain the spinning precursor solution;

[0037] (4) Inject the spinning solution into a 5mL syringe, select a No. 22 stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com