Self-stripping waterproof coating and preparation method thereof

A waterproof coating and coating technology, which is applied in the direction of building components, building insulation materials, etc., can solve the problems of shortening the service life of waterproof coatings, affecting the waterproofness of coatings, and water seepage, so as to reduce further erosion and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

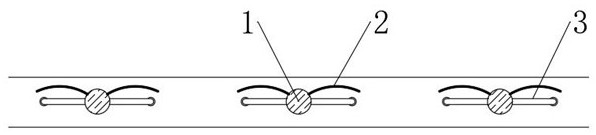

[0043] see figure 1 , a self-peeling waterproof coating, including a coating body and a plurality of self-peeling nets embedded in the coating body, the coating body includes the following raw materials in parts by weight: 20 parts of silicon acrylic emulsion, Portland cement 30 parts, 0.8 parts of ditetradecyl alcohol ester, 1 part of epoxy butyl oleate, 2 parts of cyclohexanol, 5 parts of talcum powder, 6 parts of fly ash, 0.5 parts of hydroxyethyl cellulose, 0.5 parts of dispersant 1 part, defoamer 1 part, filler 2 parts, film former 2 parts and deionized water 15 parts.

[0044] The dispersant is sodium metaphosphate dispersant, the filler is one or more of kaolin, lithopone or alumina, and the defoamer is at least one of silicone defoamer and polymer defoamer, The film former is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

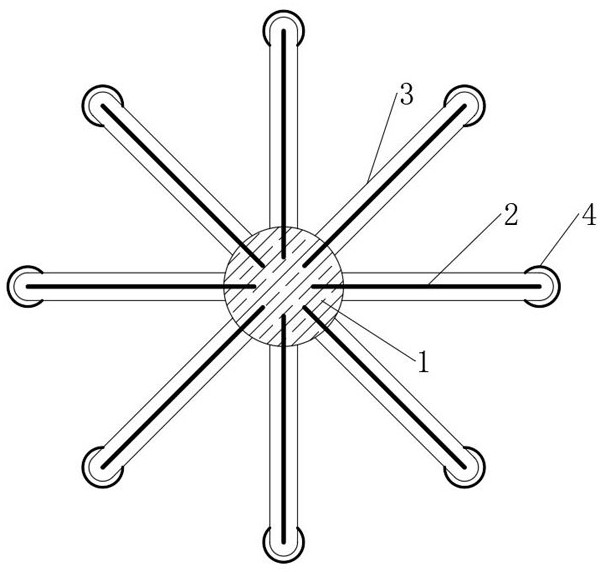

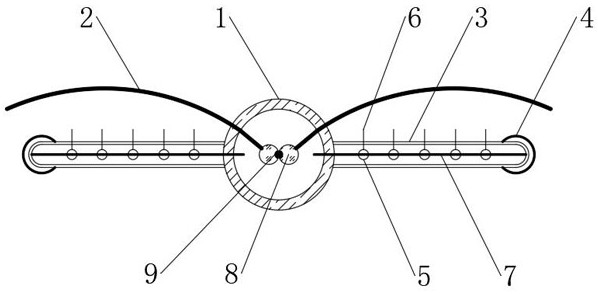

[0045] see figure 2 , the self-peeling net includes a water-collecting base ball 1, a plurality of water-absorbing fiber rods 2 and a trigger...

Embodiment 2

[0058] see figure 1 , a self-peeling waterproof coating, including a coating body and a plurality of self-peeling nets embedded in the coating body, the coating body includes the following raw materials in parts by weight: 25 parts of silicon acrylic emulsion, Portland cement 40 parts, 1.5 parts of ditetradecyl alcohol ester, 1.5 parts of epoxy butyl oleate, 2.5 parts of cyclohexyl alcohol, 8 parts of talcum powder, 7 parts of fly ash, 1 part of hydroxyethyl cellulose, 1 part of dispersant , 2 parts of defoamer, 3 parts of filler, 3 parts of film former and 20 parts of deionized water.

[0059] A method for preparing a self-stripping waterproof coating, comprising the following steps:

[0060] S1. Mix the raw materials of the coating body to prepare the coating, and divide the coating into two equal parts for later use;

[0061] S2. Take one part and spray it on the surface of the substrate, heat it at 50°C for 4 minutes until micro-cured to form a base layer, according to 1...

Embodiment 3

[0065] see figure 1 , a self-peeling waterproof coating, including a coating body and a plurality of self-peeling nets embedded in the coating body, the coating body includes the following raw materials in parts by weight: 30 parts of silicon acrylic emulsion, Portland cement 50 parts, 2 parts of ditetradecyl alcohol ester, 2 parts of epoxy butyl oleate, 3 parts of cyclohexanol, 10 parts of talcum powder, 8 parts of fly ash, 1.5 parts of hydroxyethyl cellulose, 2 parts of dispersant , 3 parts of defoamer, 4 parts of filler, 4 parts of film former and 25 parts of deionized water.

[0066] A method for preparing a self-stripping waterproof coating, comprising the following steps:

[0067] S1. Mix the raw materials of the coating body to prepare the coating, and divide the coating into two equal parts for later use;

[0068] S2. Take one part and spray it on the surface of the substrate, heat at 60°C for 5 minutes until micro-cured to form a base layer, according to 1 piece / 10c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com