Optical fiber stripping equipment and optical fiber stripping and cutting system

A cutting system and stripping technology, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of high labor cost, lifting, and difficulty in continuously and accurately controlling the length of the coating layer manually

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

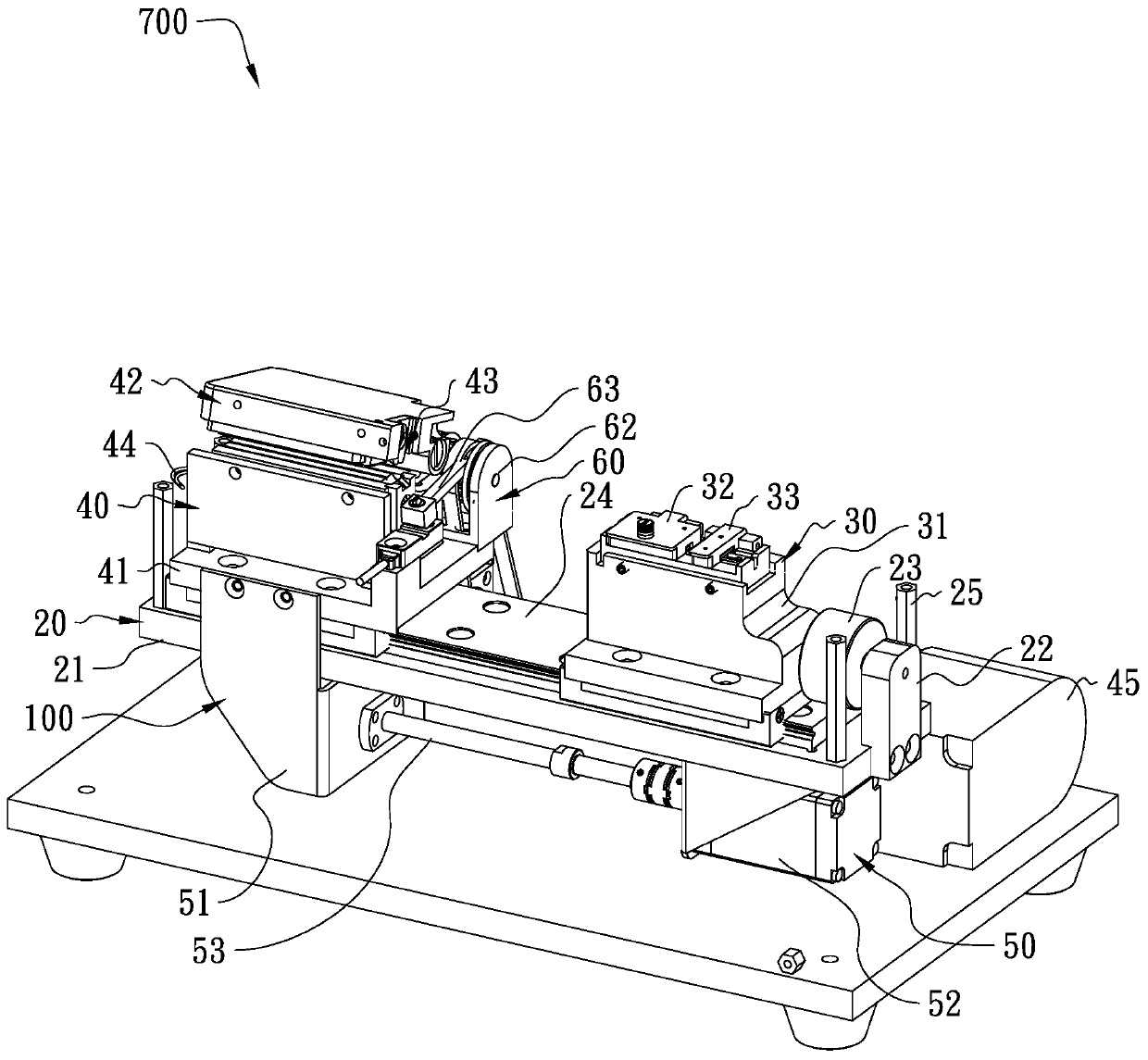

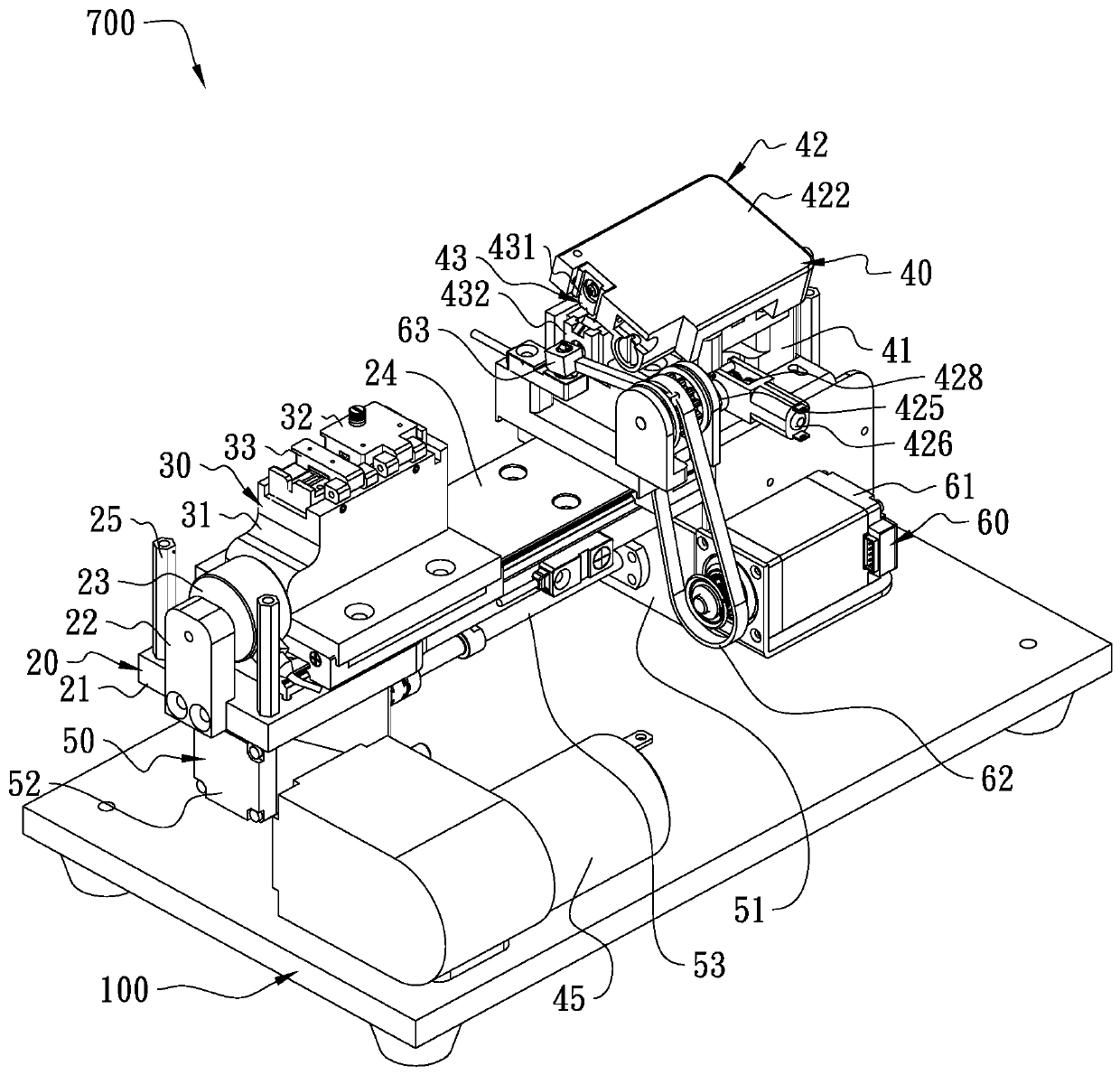

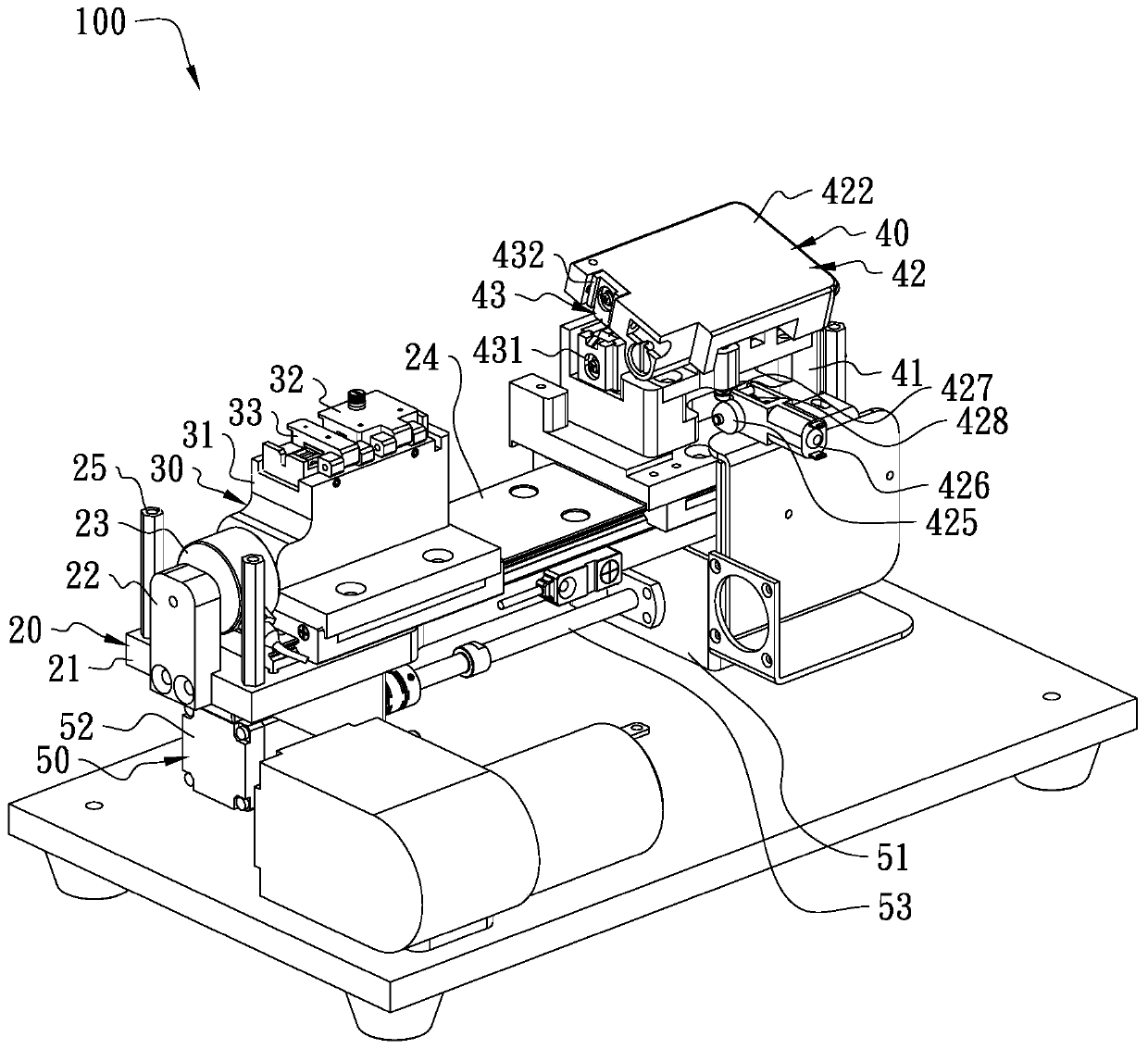

Image

Examples

other Embodiment approach

[0071] In other embodiments, in order to realize the compression and buffering of the optical fiber, a retractable cam with an elastic edge can also be used, and the deformation of the edge of the retractable cam can avoid a large pressure change on the optical fiber caused by the small rotation of the retractable cam 425 . In other implementation manners, the retractable ejector pin 427 can also be used to provide a buffering effect for the pressing of the optical fiber.

[0072] see Figure 10 , in one of the embodiments, the cutter device 60 includes a cutting driver 61 installed on the first base 41, a transmission mechanism 62 connected to the cutting driver 61, and a pendulum knife 63 installed on the transmission mechanism 62; the pendulum knife 63 There is a cutter head 631 on it; the cutting drive 61 drives the swing knife 63 to deflect through the transmission mechanism 62 ; the swing range of the cutter head 631 is between the blade stripping mechanism 43 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com