Radiation-curable optical glass fiber coating compositions, coated optical glass fibers, and optical glass fibers, and optical glass fiber assemblies

a technology of coating composition and coating glass fiber, which is applied in the direction of fibre mechanical structure, etc., can solve the problems of compromising the strength of connection, affecting the signal transmission capability of coated optical glass fiber, and affecting the splicing operation of optical glass fiber ribbon mass fusion, so as to improve the capability of ribbon stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 2-2 and 2-3

, and Comparative Examples B-3 and B-4

[0202]These Examples and Comparative Examples were conducted to demonstrate the effect of the composite oligomer on glass plate adhesion. The formulations shown in Table 3 were prepared in the same manner as in Example 2-1 and Comparative Examples B-1 and B-2. The silicone silane acrylate oligomer was prepared in the same manner as in Example 2-1, except that a silicone diol HSi-2111 (Tego Chemie) was used instead of Q4-3667 (Dow Corning).

[0203]Films of the coating materials (75 microns thick) were prepared on microscope slides and then cured by exposure to UV light. A commercially available outer primary coating was formed on top of the coatings. The films were soaked in water at 60 C and then examined for delamination. In addition, dry and wet adhesion was measured at 50% and 95% relative humidity (RH), respectively. The results are summarized in Table 3.

[0204]Dry (50% RH) and wet (95% RH) adhesion can be measured by recognized test methods. F...

example 2-4

[0209]The formulation shown in Table 4 was prepared in the same manner as in Example 2-1. The silicone silane acrylate oligomer was the same as that prepared in Example 2-1.

[0210]A film of the coating material (75 micron thick) was prepared on glass plates and then cured by exposure to UV light in the same manner as above. The tensile strength, elongation and modulus were measured.

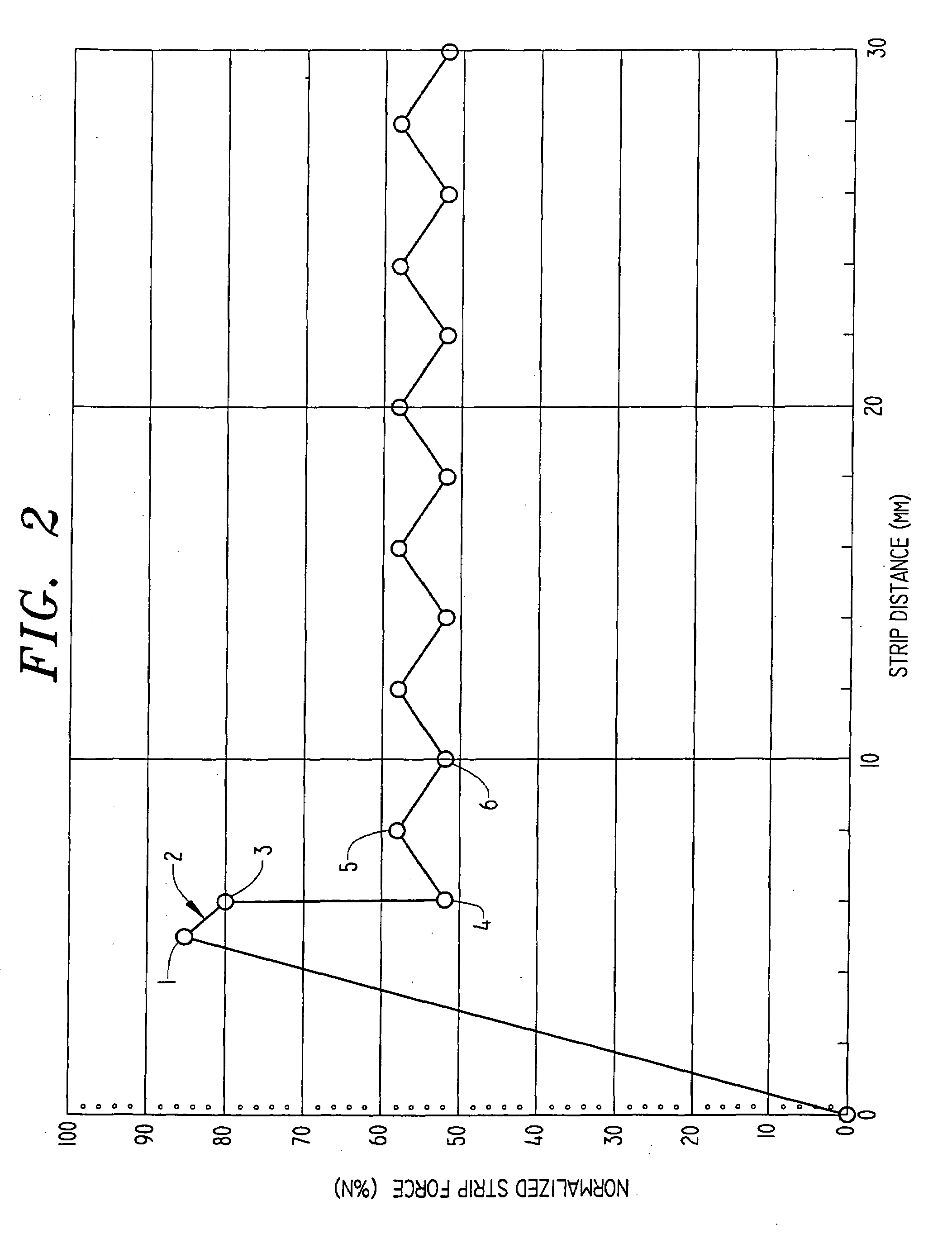

[0211]A 75 micron film of the coating material was also prepared and suitably cured. The crack propagation was then measured. A fiber pull-out friction test was also conducted, as described herein. The predicted ribbon strip cleanliness was calculated. The results are shown in Table 4.

TABLE 4Example2-4Component(Amount in % by weight of total composition)H-I-(PTGL2000-I)2-H49.24Ethoxylated Nonylphenol Acrylate Ester25.46Diphenyl(2,4,6-trimethylbenzoyl) Diphenyl3Phosphine Oxide and 2-Hydoxy-2-Methyl-1-Phenyl-1-Propanone blendLauryl Acrylate16Thiodiethylene bis(3,5-di-Tert-Butyl-4-0.5Hydroxy)hydrocinnamateH-I...

examples 3-1 through 3-4

[0302]The components shown in Table 6 were combined to form four inner primary coating compositions. Drawdowns of the inner primary coating compositions were made and then cured by exposure to UV light from a Fusion D lamp, under a nitrogen atmosphere. The crack propagation and fiber friction for each of the films were tested in the same manner as above, and the predicted strip cleanliness was calculated. The results are shown in Table 6.

TABLE 6ExampleExampleExampleExample3-13-23-33-4COMPONENT(Amount in % by weight of totalcomposition)Linear Urethane Acrylate23———Oligomer Having a Weight AverageMolecular Weight of 5000,Urethane Acrylate Oligomer—51.942.342.3H-I-PTGL2000-I-PTGL2000-I-HLauryl Acrylate—16——Ethoxylated Nonylphenol Acrylate64.425.646.246.2Glyceryl Propoxy Triacrylate8———Phenoxyethyl Acrylate——552,4,6,-Trimethyl3333PhenylbenzoylDiphenyl Phosphine OxideThiodiethylene bis (3,5-di-tert-.50.50.50.5butyl-4-hydroxy)hydrocinnamatePolyethylene / maleic anhydride.1———copolymer wax (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com