Power cable, photoelectric composite cable, communication optical cable and optical fiber ribbon

A power cable, integrated technology, applied in the direction of power cables, power cables including optical transmission components, insulated cables, etc., can solve the problems of large casing size, inflexible application, and difficult to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

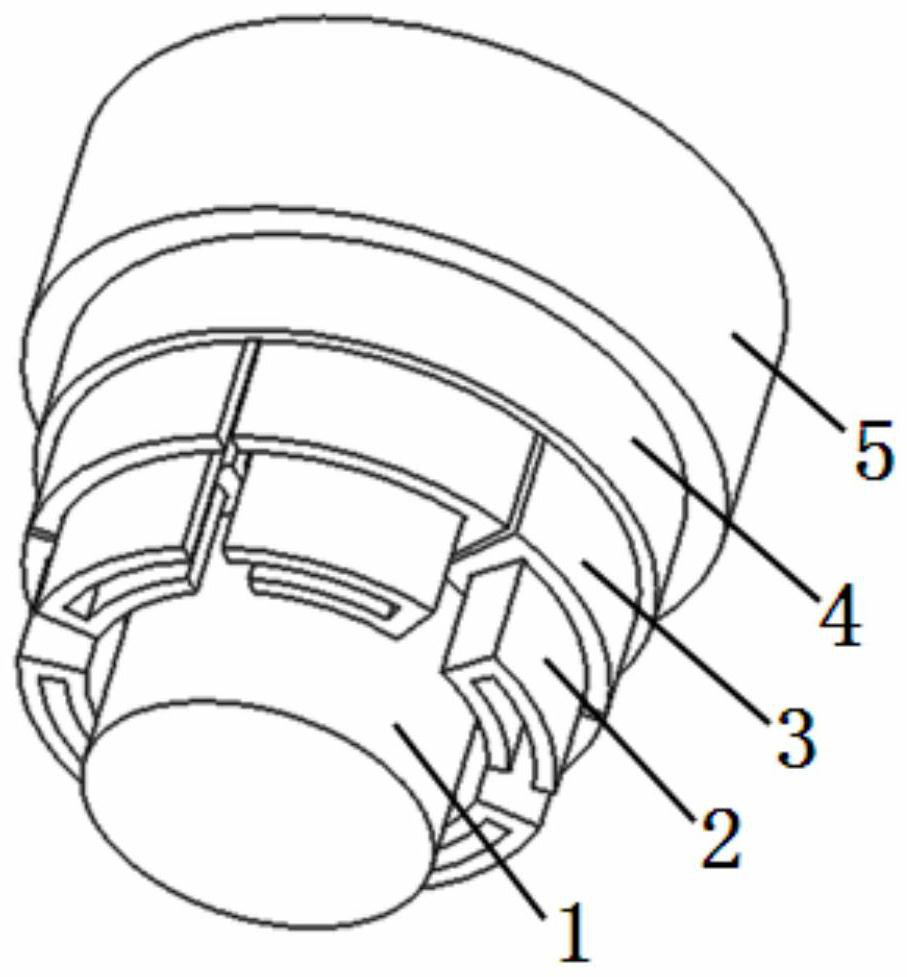

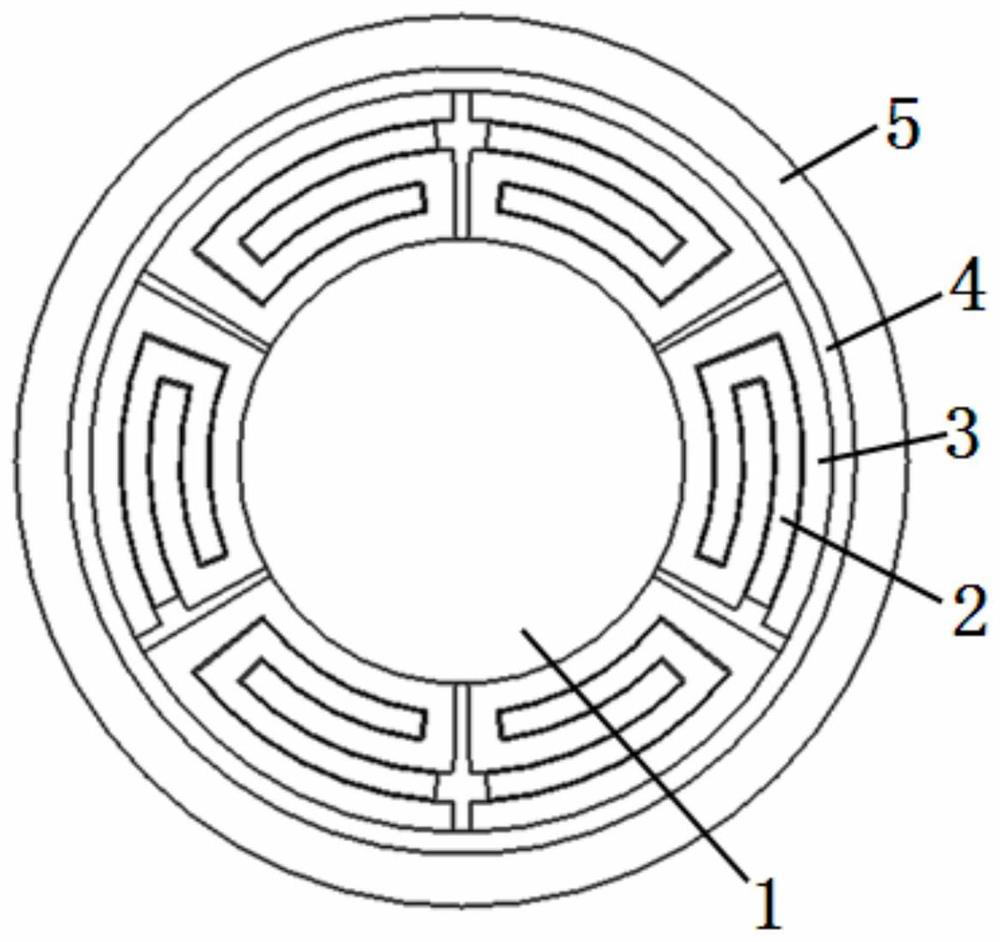

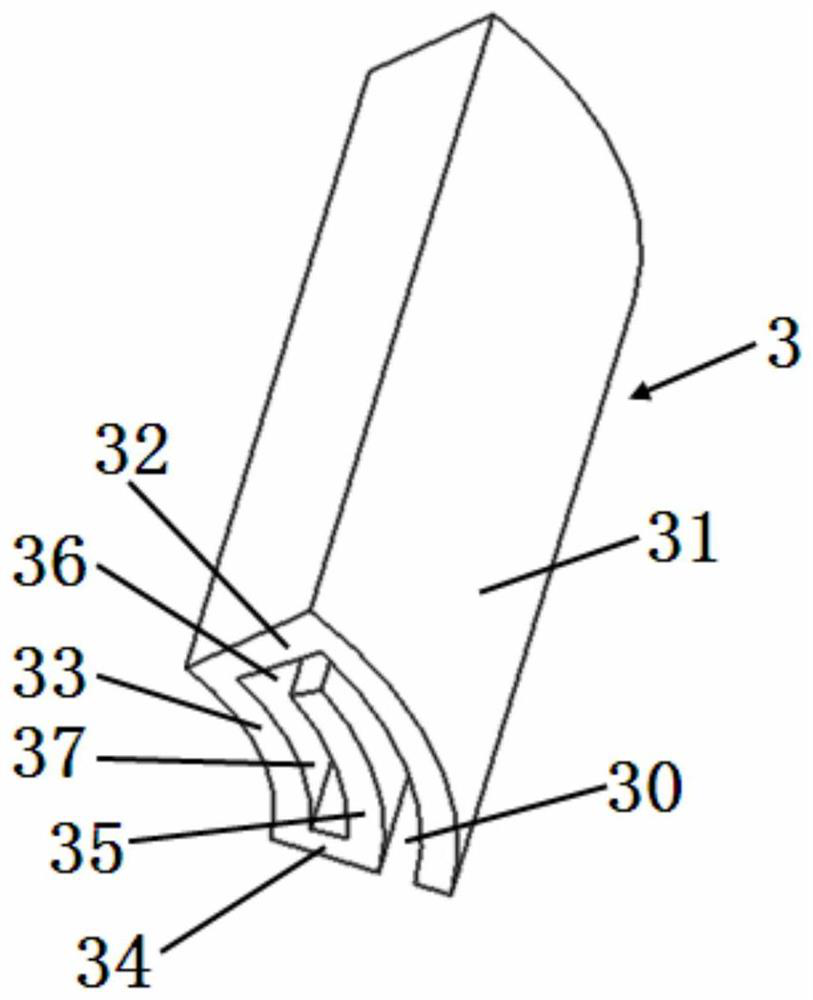

[0066]Please seeFigure 1 to Figure 8 , A power cable with a reinforcing part 1, six accommodating parts 3 distributed on the outer edge of the reinforcing part, a protective layer 4 located outside all the accommodating parts, and an outer protective layer 5 covering the protective layer, each The accommodating component has a power transmission component 2 inside; it is characterized in that the accommodating component 3 is sequentially connected by a third bending portion 31, a second connecting portion 32, a fourth bending portion 33, a third connecting portion 34, and a fifth bending portion. The second cavity 30 is formed between the third bending portion 31 and the fifth bending portion 35. The fifth bending portion is not connected to the third bending portion, and the fifth bending portion is not connected to the first bending portion. There is a fourth cavity 37 between the fourth curved portion 33 and the fifth curved portion 35, a third cavity 36 is provided between the s...

Embodiment 2

[0092]Please seePicture 9 And refer toFigure 1 to Figure 8 , A power cable, basically the same as the first embodiment, except that the open ends of the second cavity are distributed in the same direction;Picture 9 The middle is distributed clockwise or counterclockwise.

[0093]The above-mentioned power cable is characterized in that the lower surface of the first bending portion of the first bending portion in the second cavity is located above the lower surface of the third connecting portion; the lower surface of the first bending portion can also be connected to the third The lower surface of the part is in the same plane, which increases the area of the first curved part, that is, the conductor area, that is, the conductive capacity.

Embodiment 3

[0095]Please seePicture 10 And refer toFigure 1 to Figure 9 , A power cable, basically the same as the first embodiment, the difference is: there are three accommodating parts 3 outside the reinforcing part 1, each accommodating part has a power transmission part 2 inside, and the three accommodating parts outside the inner ring The part is the same as that of Example 1.

[0096]Of course, there can also be multiple accommodating parts in the inner ring.

[0097]Of course, the distribution of the opening ends of the second cavity of the accommodating part of the inner ring can also be distributed in the same direction as in Example 2, or not in the same direction; similarly, the distribution of the second cavity of the accommodating part of the outer ring The distribution of the open ends may also be distributed in the same direction as in Embodiment 2, or may not be distributed in the same direction.

[0098]In this embodiment, the power transmission capacity is increased, and in addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com