Optical fiber ribbon optical cable with octahedral cylinder structure shell

An optical fiber ribbon and shell technology, applied in the field of optical fiber ribbon cable, can solve the problems of not giving the fiber core density of the optical fiber ribbon, not giving it, etc., and achieve the effect of convenient and fast connection, high space utilization rate, and improved stripping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

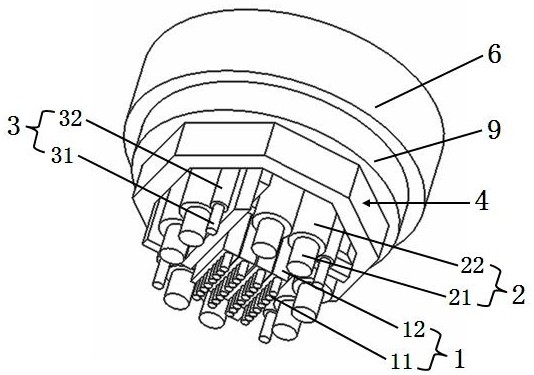

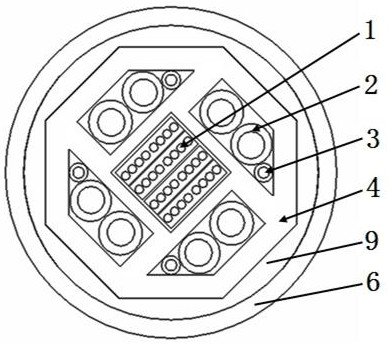

[0051] please see Figure 1 to Figure 4 , an optical fiber ribbon cable with an octahedral cylindrical shell structure, has an outer sheath 6 and a central optical fiber ribbon body 1, the central optical fiber ribbon body 1 is located in the outer sheath 6, and the central optical fiber ribbon body 1 is composed of at least one The central optical fiber ribbon is composed of at least two central optical fibers 11 and a central optical fiber ribbon cladding 12 wrapped outside the central optical fiber 11, which is characterized in that the outer sheath 6 and the central optical fiber ribbon body 1 The room is also provided with a shell 4;

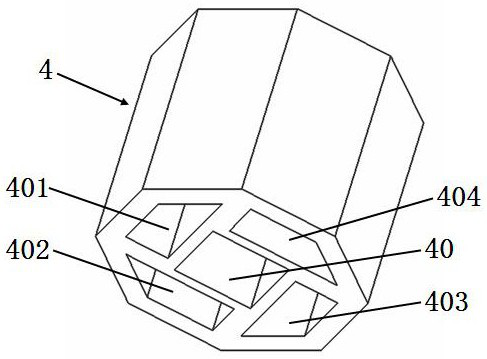

[0052] The shell 4 consists of a first top edge 41, a second outer edge 412, a second top edge 42, a third outer edge 423, a third top edge 43, a fourth outer edge 434, a fourth top edge 44 and Surrounded by the first outer side 441 and is a hollow octahedral cylinder, the middle part of the shell 4 is provided with a circle surrounded by ...

Embodiment 2

[0057] please see Figure 5 to Figure 11 , and refer to Figure 1 to Figure 4 , an optical fiber ribbon cable with an octahedral cylindrical shell structure, has an outer sheath 6 and a central optical fiber ribbon body 1, the central optical fiber ribbon body 1 is located in the outer sheath 6, and the central optical fiber ribbon body 1 is composed of at least one The central optical fiber ribbon is composed of at least two central optical fibers 11 and a central optical fiber ribbon cladding 12 wrapped outside the central optical fiber 11, which is characterized in that the outer sheath 6 and the central optical fiber ribbon body 1 There is also a shell 4 between them; the shell 4 is a hollow octahedron, and an octahedral shell cavity 45 is formed in the shell 4, and four isolation parts 5 are arranged in the shell cavity 45, and the isolation Part 5 is made up of a first straight side 51 and a second straight side 52, one end of the first straight side 51 is connected to ...

Embodiment 3

[0070] please see Figure 12 , and refer to Figure 1 to Figure 11 , an optical fiber ribbon cable with an octahedral cylindrical shell structure, has an outer sheath 6 and a central optical fiber ribbon body 1, the central optical fiber ribbon body 1 is located in the outer sheath 6, and the central optical fiber ribbon body 1 is composed of at least one The central optical fiber ribbon is composed of at least two central optical fibers 11 and a central optical fiber ribbon cladding 12 wrapped outside the central optical fiber 11, which is characterized in that the outer sheath 6 and the central optical fiber ribbon body 1 There is also a shell 4 between them; the shell 4 is a hollow octahedron, and an octahedral shell cavity 45 is formed in the shell 4, and four isolation parts 5 are arranged in the shell cavity 45, and the isolation Part 5 is made up of a first straight side 51 and a second straight side 52, one end of the first straight side 51 is connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com