Flame-retardant cable, flame-retardant optical cable and flame-retardant optical fiber ribbon optical cable

A flame-retardant cable and integrated technology, applied in the field of electric power and communication, can solve the problems of unstable product quality, difficult assembly and maintenance, and unstable position, and achieve the effects of fast assembly and maintenance, flexible assembly, and convenient stripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

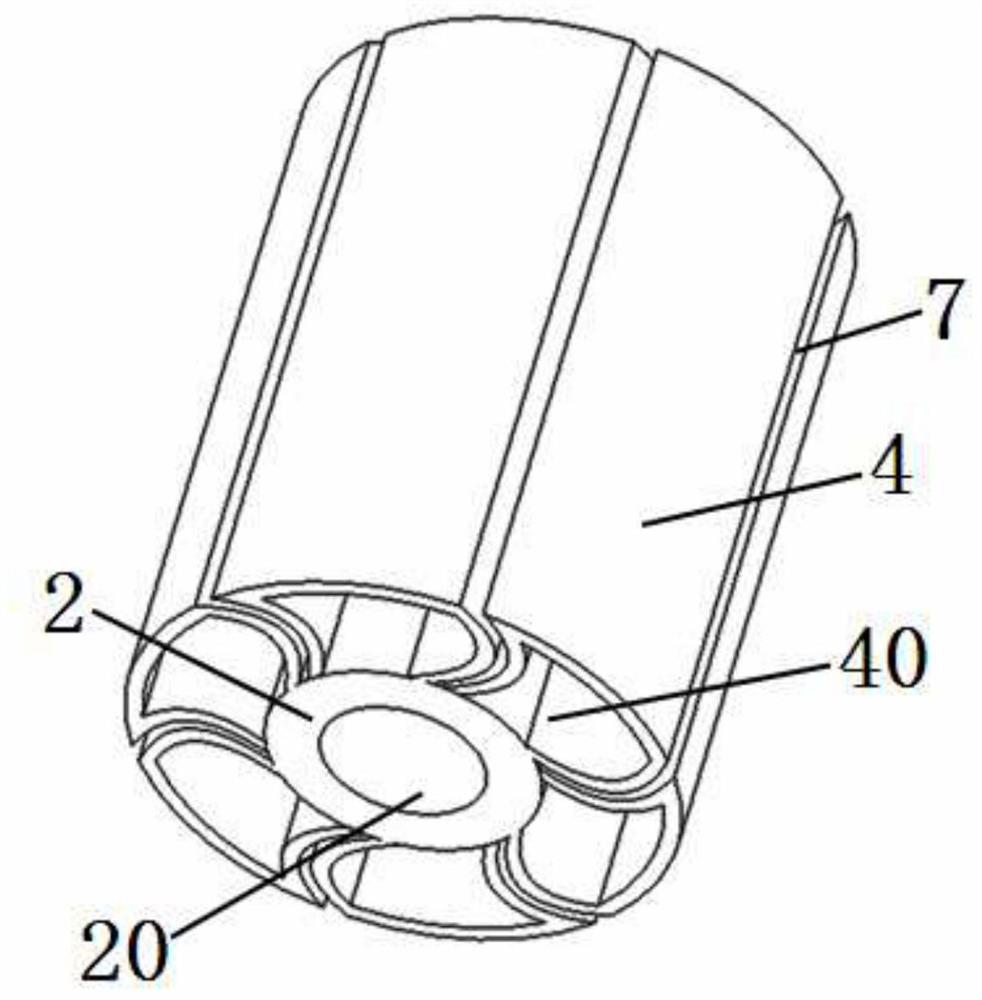

[0060] please see Figure 1 to Figure 6 , a flame-retardant cable having a plurality of conductors 3, a protective component, a central reinforcement 1, and an outer sheath 5, characterized in that:

[0061] The protection part is composed of a reinforcing sleeve 2 and a plurality of insulating sleeves 4. The reinforcing sleeve 2 has a reinforcing hole 20 inside, and the insulating sleeve 4 has a first insulating wall 41, a second insulating wall 42, and a third insulating wall 4 inside. wall 43 and a fourth insulating wall 44, the first insulating wall 41 and the second insulating wall 42 are located in the opposite position, the third insulating wall 43 and the fourth insulating wall 44 are located in the opposite position, one end of the first insulating wall 41 is connected to the fourth The other end of the insulating wall 44, one end of the fourth insulating wall 44 is connected to the other end of the second insulating wall 42, one end of the second insulating wall 42 i...

Embodiment 2

[0066] please see Figure 7 , and referring to Embodiment 1, a flame-retardant cable, which is basically the same as Embodiment 1, except that there is no fitting part.

Embodiment 3

[0068] please see Figure 8 and Figure 9 , and with reference to Embodiment 1 and Embodiment 2, a flame-retardant optical cable, the difference is that: the fitting element 31 replaces the conductor 3, and the fitting element 31 has a housing hole 30 inside, and there are multiple wires in the housing hole 30 Fiber 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com