Optical fiber guide type high-power optical fiber cladding light stripper for deep stripping

A fiber cladding, high-power technology, applied in the direction of light guides, lasers, laser components, etc., can solve problems such as high temperature, difficult heat dissipation, and limited power carrying level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Aiming at high-power fiber laser cladding light stripping, the present invention invents a new method based on cladding light-guiding fiber-guided stripping, which better realizes high load-carrying stripping power and avoids local fine fiber The heat accumulation effect of the method is more scientific and convenient, and the specific implementation method is set forth below.

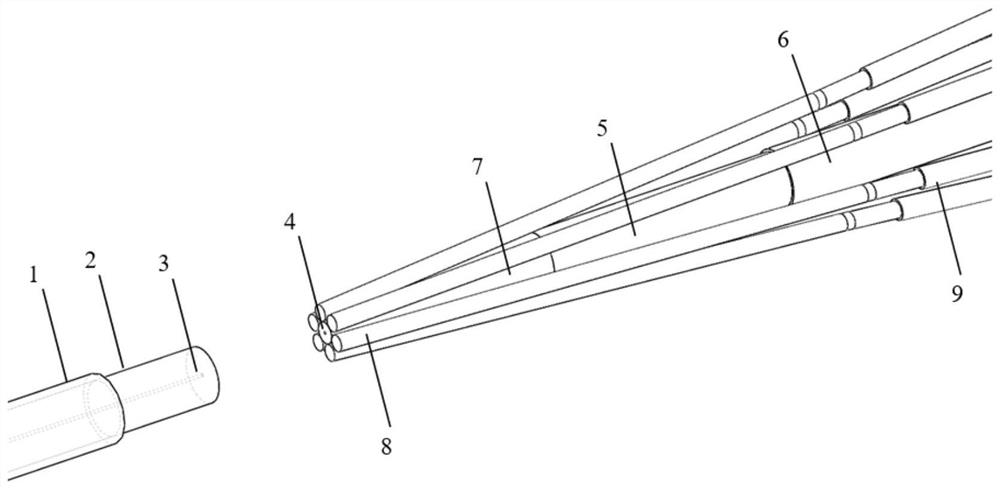

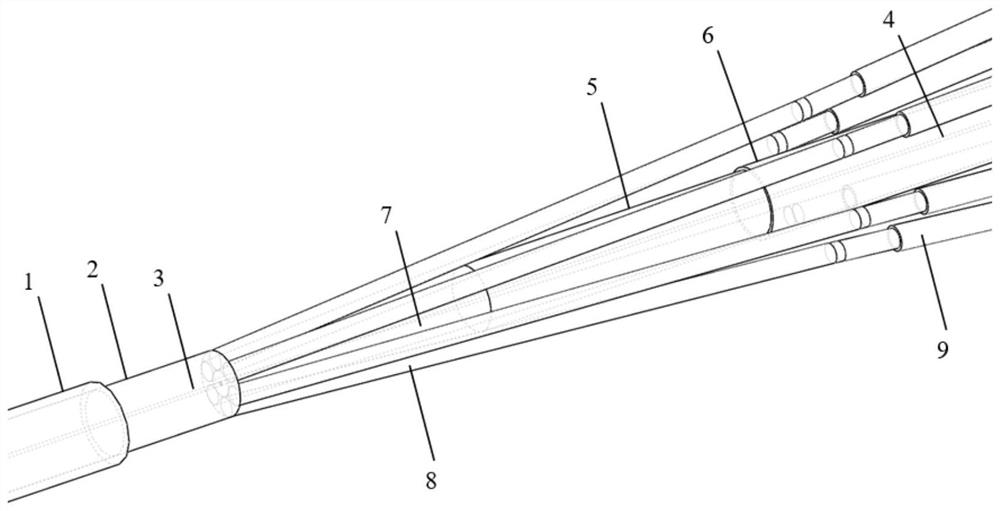

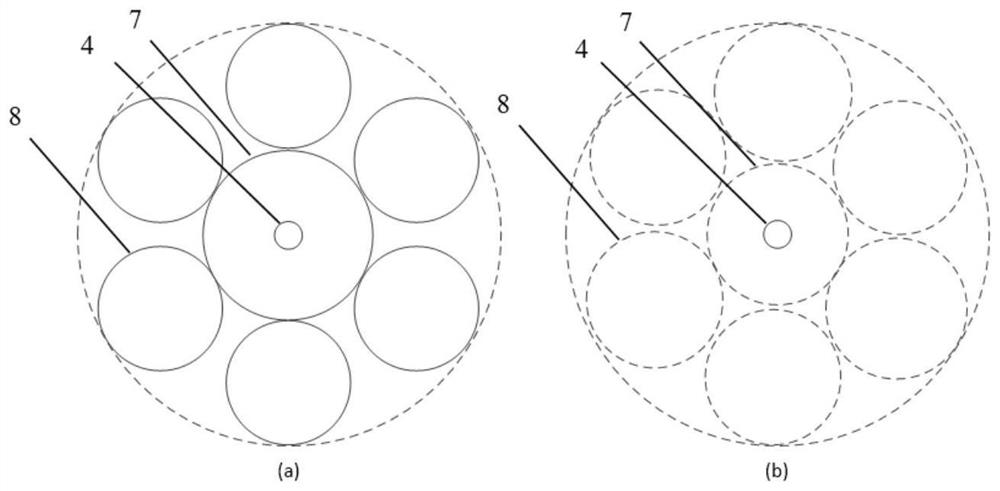

[0041] First cut the transmission fiber into two parts, one is the left laser input end (label 1-3), and the other is the right laser transmission end (label 4-7); among them, remove the coating layer from the left laser input end , and cut the end into a planar structure such as Figure 4 (a) or etched by hydrofluoric acid into a tapered structure such as Figure 4 (b), this paper uses Figure 4 (a) The flat head is taken as an example to describe the implementation; in addition, the coating layer is removed from the laser transmission end on the right side, and the tapered structure is etche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com