Power cable, photoelectric composite cable, communication optical cable and optical fiber ribbon

An integrated technology for power cables, applied in the direction of power cables, power cables including optical transmission components, insulated cables, etc., can solve the problems of single combination of inner and outer layers, inconvenient multi-turn expansion, large casing size, etc., to achieve heat dissipation Good effect, light weight, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

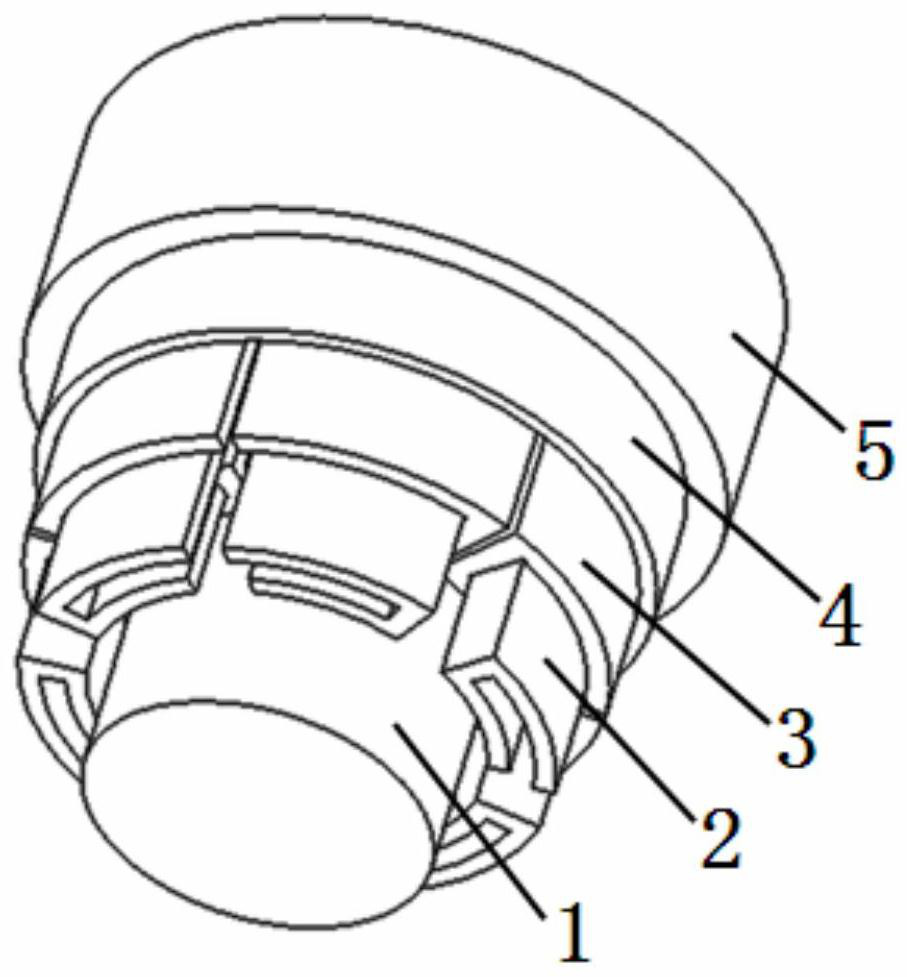

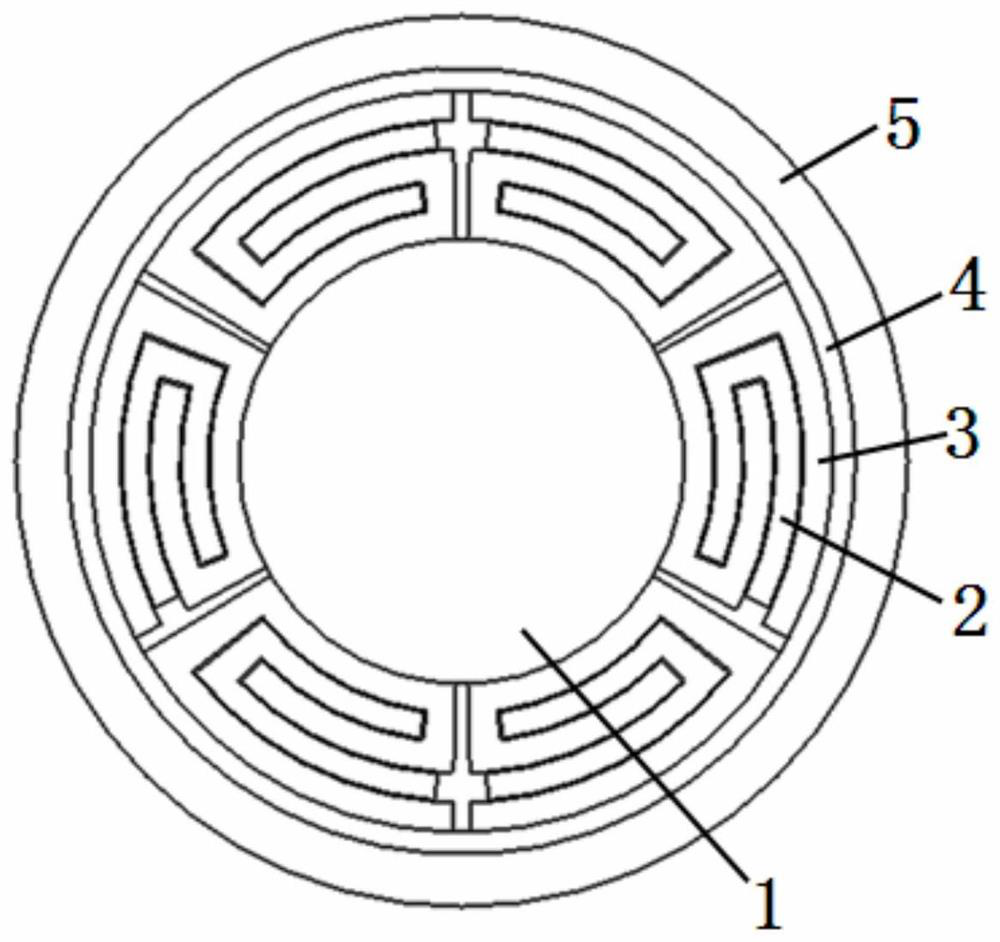

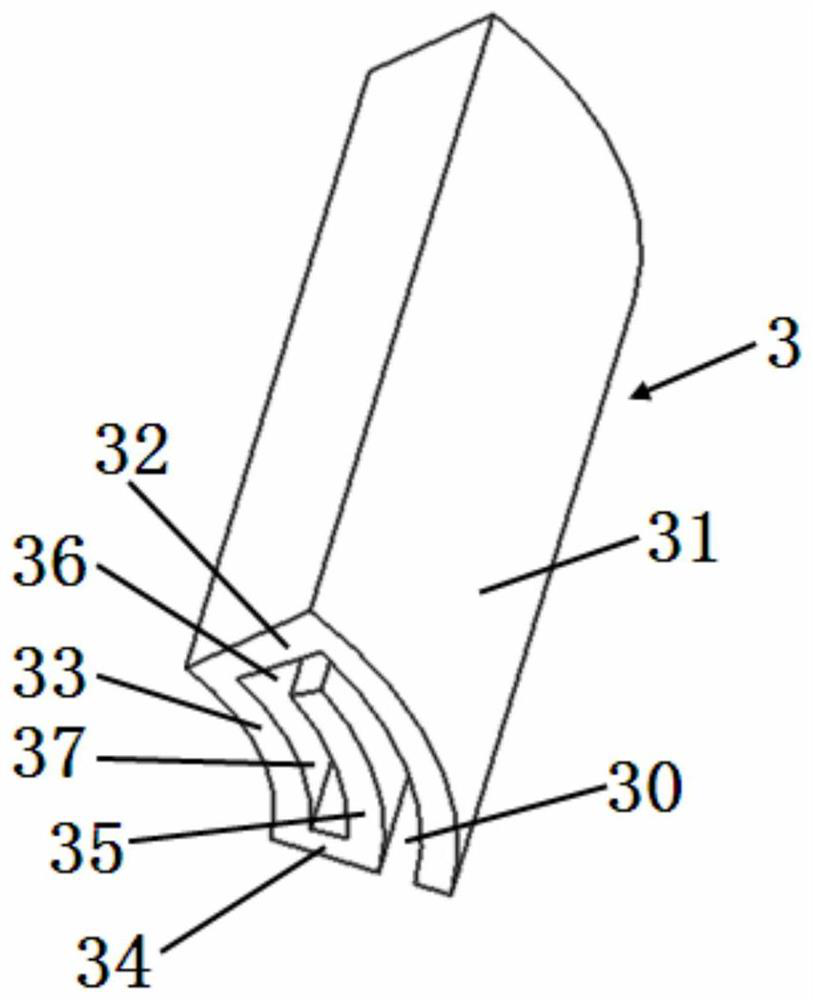

[0066] please see Figure 1 to Figure 8 , a power cable, with a strengthening part 1, six accommodating parts 3 distributed on the outer edge of the strengthening part, a protective layer 4 located outside all the accommodating parts, and an outer sheath 5 wrapped outside the protective layer, each There is a power transmission part 2 inside the accommodating part; it is characterized in that the accommodating part 3 is composed of a third bending part 31, a second connecting part 32, a fourth bending part 33, a third connecting part 34, and a fifth bending part connected in sequence. part 35, there is a second cavity 30 between the third bending part 31 and the fifth bending part 35, if the fifth bending part is not connected to the third bending part, the fifth bending part is not connected to the first bending part There is a fourth cavity 37 between the fourth bending part 33 and the fifth bending part 35, a third cavity 36 between the second connecting part 32 and the fif...

Embodiment 2

[0092] please see Figure 9 , and refer to Figure 1 to Figure 8 , a power cable, basically the same as the implementation example 1, the difference is that: the opening ends of the second cavity are distributed along the same direction; Figure 9 The distribution can be clockwise or counterclockwise.

[0093] The power cable described above is characterized in that the lower surface of the first curved part of the first curved part in the second cavity is located above the lower surface of the third connecting part; the lower surface of the first curved part can also be connected to the third connecting part. The lower surfaces of the parts are in the same plane, which increases the area of the first bending part, that is, the area of the conductor, that is, the conductive capacity.

Embodiment 3

[0095] please see Figure 10 , and refer to Figure 1 to Figure 9 , a power cable, basically the same as the implementation example 1, the difference is that: there are three accommodating parts 3 outside the reinforcing part 1, and each accommodating part has a power transmission part 2 inside, and the three accommodating parts of the inner ring are outside The part is the same as that of implementation example 1.

[0096] Certainly, there may be multiple accommodating parts for the inner ring.

[0097] Of course, the distribution of the opening ends of the second cavities of the housing parts of the inner ring can also be distributed in the same direction as in Example 2, or not in the same direction; similarly, the distribution of the second cavities of the housing parts of the outer ring The distribution of the opening ends may also be distributed along the same direction as in Embodiment 2, or may not be distributed in the same direction.

[0098] This implementation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com