Seed cotton foreign fiber separator

A technology of foreign fiber and separator, which is applied in the direction of separating plant fiber from seeds, fiber treatment, fiber cleaning, etc., to achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

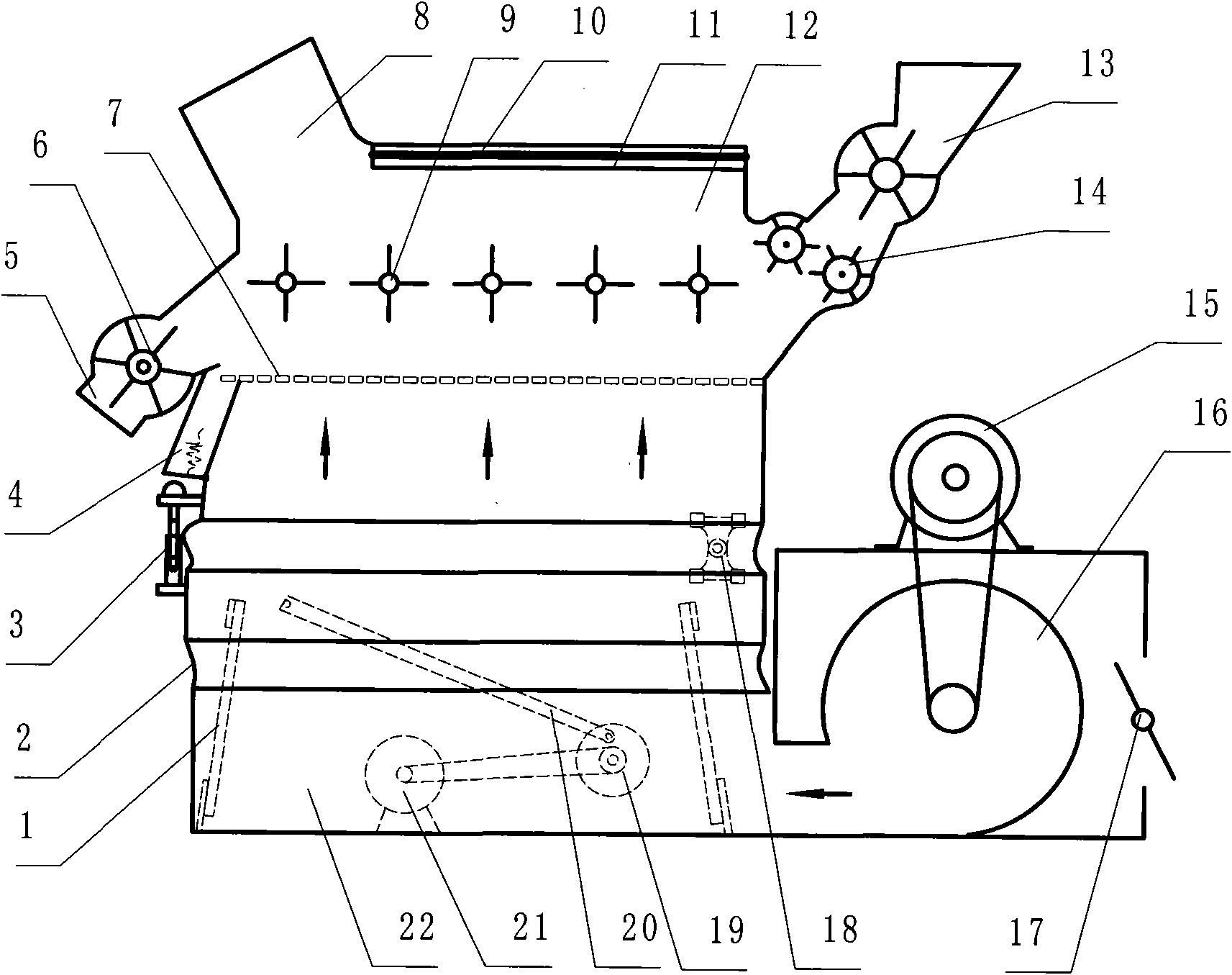

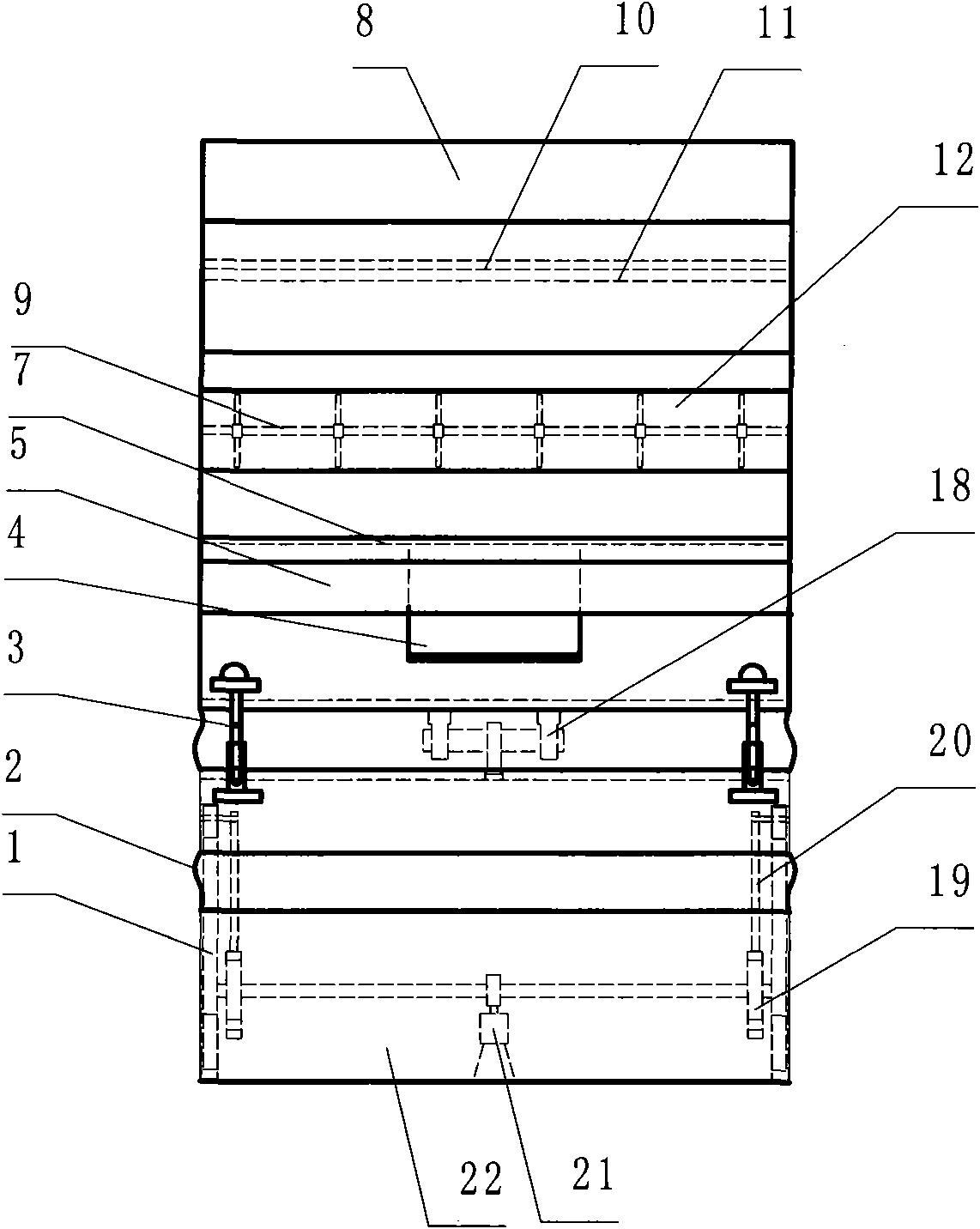

[0021] Refer to attached figure 1 , figure 2 , is a structural schematic diagram of Embodiment 1 of the present invention, including a separation chamber 12 composed of an electrode plate group and a box, a fan 16 and an air chamber 22, a fan 16, and the fan 16 is installed in a closed box, and the air inlet is provided with an air volume regulating plate 17 , to control the air intake, the fan is driven by a motor 15, the separation chamber 12 is provided with a feed inlet 13, a discharge outlet 5 and a miscellaneous outlet 8, and the miscellaneous outlet 8 is located on the oblique upper side of the separation chamber 12, and the The passages of the feed inlet 13 and the discharge outlet 5 are equipped with air locks to prevent the air volume in the separation chamber from being lost and cause insufficient air volume for exhausting impurities. Effective removal, the above-mentioned discharge port is connected with the cathode plate to be provided with a stone discharge por...

Embodiment 2

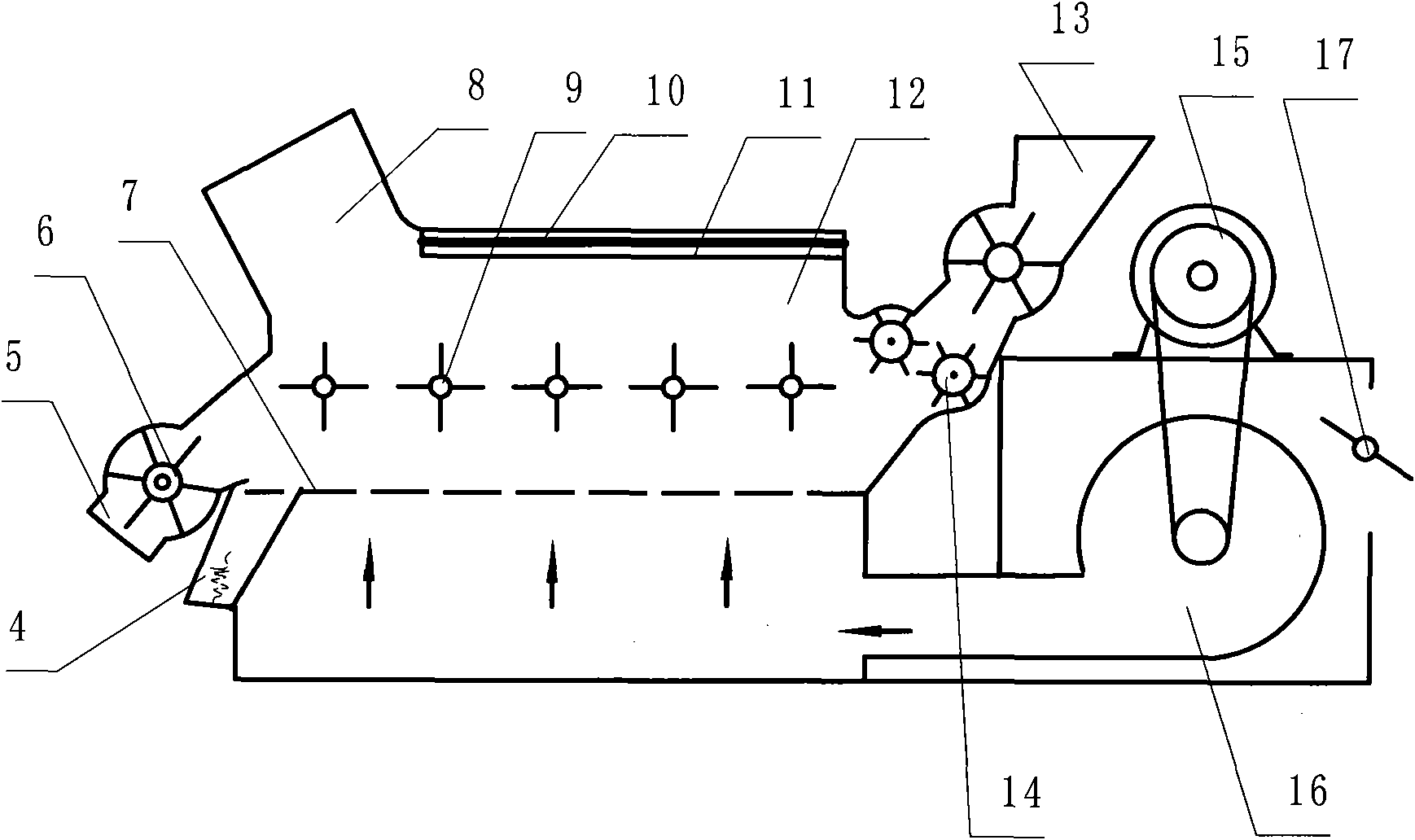

[0023] refer to image 3 , is a structural schematic diagram of Embodiment 2 of the present invention. This embodiment includes a separation chamber 12, a fan 16, and an air chamber 22 composed of an electrode plate group and a box body. The fan 16 is installed in a closed box, and the air inlet is provided with an air volume. Adjusting plate 17, fan is driven by motor 15, and separation chamber 12 is provided with feed inlet 13, discharge outlet 5 and miscellaneous outlet 8, and miscellaneous discharge opening 8 is located at the oblique top of separation chamber 12 side, and described The passages of the feed port 13 and the discharge port 5 are provided with an air lock, and the joint between the discharge port and the cathode plate is provided with a stone discharge port 4, and the stone discharge port is provided with a closeable stone discharge gate. Also be provided with conveying pair roller 14 in the channel of mouth 13, described electrode plate group is made up of a...

Embodiment 3

[0025] refer to Figure 4 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the vibrating device under the separation chamber is mainly composed of a crank 19, a connecting rod 20 and a motor 21, and the cathode plate 7 and The stirring device is arranged on a suspended underframe 23 inside the separation chamber 12 , and the connecting rod 20 is connected with the suspension frame 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com