Ionic liquid modified graphene oxide/natural rubber vulcanized rubber and preparation method thereof

An ionic liquid and natural rubber technology, applied in the field of graphene oxide/natural rubber vulcanizate and its preparation, can solve the problems of increasing reduction steps, increasing cost, complex preparation process, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

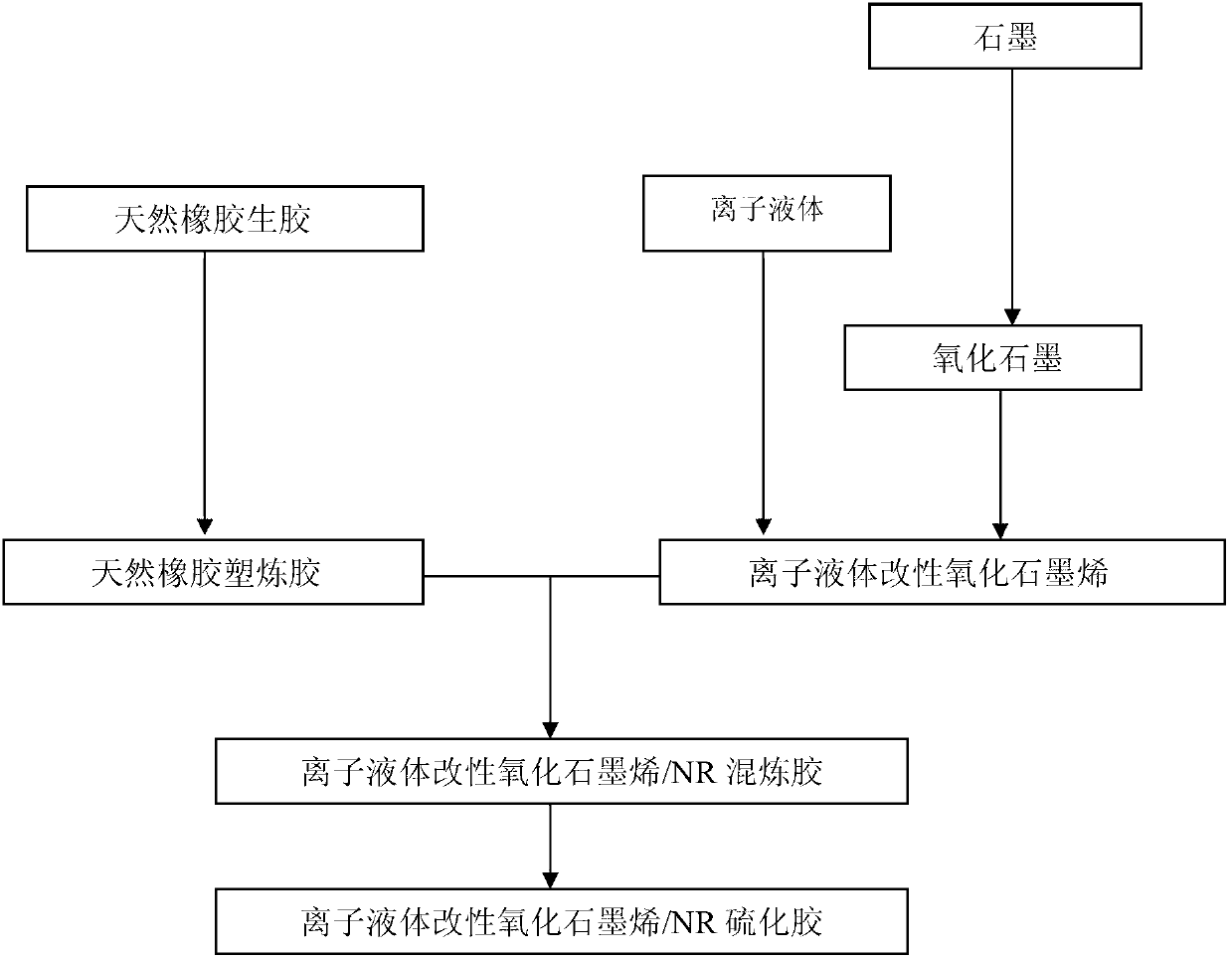

[0019] A kind of preparation method containing ionic liquid modified graphene oxide / natural rubber vulcanizate, specifically comprises the following steps:

[0020] Step 1: Preparation of graphite oxide: Measure 100-150mL of concentrated sulfuric acid in a four-neck flask, place it in an ice bath, and lower it to 0-4°C. Add 5-10g of graphite and 2-5g of sodium nitrate in sequence, and stir for 15-30min. Then slowly add 10-20g KMn0 4 , keep the temperature below 20°C. Then the temperature was raised to 35-40°C and kept for 2-4h. After the reaction is completed, slowly add 200-400mL of deionized water. During this process, keep the solution temperature below 100°C for 15-30min. Transfer the reaction liquid to a beaker, add 700-1000mL deionized water to dilute. Then add 700-1000mL of 5% hydrogen peroxide solution, filter with suction, wash with 5% hydrochloric acid and deionized water respectively, and then dry in a vacuum oven at a temperature of 60-80°C for later use;

[0...

Embodiment 1

[0027] Preparation of modified graphene oxide / natural rubber compounds. Measure 100-150mL of concentrated sulfuric acid in a four-necked flask, and cool it to 0-4°C in an ice bath. Add 5-10g of graphite and 2-5g of sodium nitrate in sequence, and stir for 15-30min. Then slowly add 10-20g KMn0 4, keep the temperature below 20°C. Then the temperature was raised to 35-40°C and kept for 2-4h. After the reaction is completed, slowly add 200-400mL of deionized water. During this process, keep the solution temperature below 100°C for 15-30min. Transfer the reaction liquid to a beaker, add 700-1000mL deionized water to dilute. Then add 700-1000mL of 5% hydrogen peroxide solution and then filter with suction, wash with 5% hydrochloric acid and deionized water respectively, and then dry in a vacuum oven at a temperature of 60-80°C for subsequent use; the prepared graphite oxide Grind it into powder in an agate mortar, weigh a certain amount of graphite oxide powder in the mortar, a...

Embodiment 2

[0029] Repeat the method of Example 1 according to the specified content of each component, but adopt 1 part of modified graphene oxide in the formula, the tensile strength of the obtained vulcanizate is 22.40MPa, the elongation at break is 444%, and the tear strength is 48.32 N / mm, thermal oxygen aging coefficient 79%, thermal conductivity 0.4800 W / (mK).

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com