Ionic liquid modified graphene oxide/natural rubber vulcanized rubber and preparation method thereof

An ionic liquid and natural rubber technology, applied in the field of graphene oxide/natural rubber vulcanizate and its preparation, can solve the problems of complex preparation process, increase of reduction steps, increase in cost, etc., and achieves simple process, simple method, and improved thermal conductivity. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

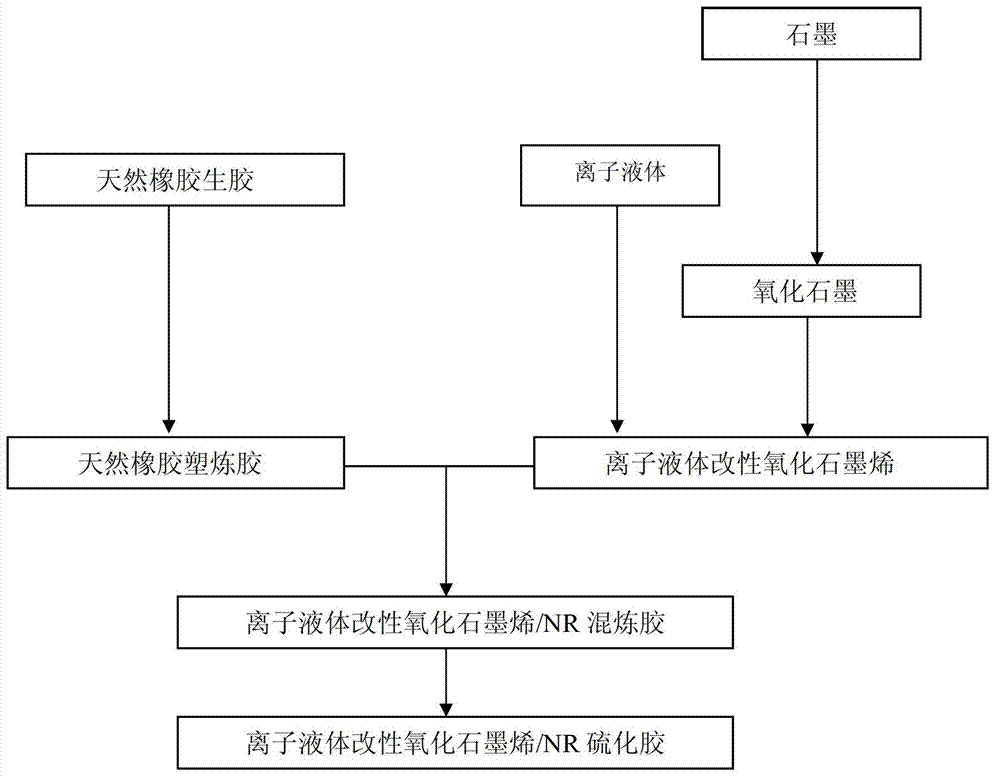

[0018] A kind of preparation method containing ionic liquid modified graphene oxide / natural rubber vulcanizate, specifically comprises the following steps:

[0019] Step 1: Preparation of graphite oxide: Measure 100-150mL of concentrated sulfuric acid in a four-neck flask, place it in an ice bath, and lower it to 0-4°C. Add 5-10g of graphite and 2-5g of sodium nitrate in sequence, and stir for 15-30min. Then slowly add 10-20g KMn0 4 , keep the temperature below 20°C. Then the temperature was raised to 35-40°C and kept for 2-4h. After the reaction is completed, slowly add 200-400mL of deionized water. During this process, keep the solution temperature below 100°C for 15-30min. Transfer the reaction liquid to a beaker, add 700-1000mL deionized water to dilute. Then add 700-1000mL of 5% hydrogen peroxide solution, filter with suction, wash with 5% hydrochloric acid and deionized water respectively, and then dry in a vacuum oven at a temperature of 60-80°C for later use;

[0...

Embodiment 1

[0026] Preparation of modified graphene oxide / natural rubber compounds. Measure 100-150mL of concentrated sulfuric acid in a four-necked flask, and cool it to 0-4°C in an ice bath. Add 5-10g of graphite and 2-5g of sodium nitrate in sequence, and stir for 15-30min. Then slowly add 10-20g KMn0 4, keep the temperature below 20°C. Then the temperature was raised to 35-40°C and kept for 2-4h. After the reaction is completed, slowly add 200-400mL of deionized water. During this process, keep the solution temperature below 100°C for 15-30min. Transfer the reaction liquid to a beaker, add 700-1000mL deionized water to dilute. Then add 700-1000mL of 5% hydrogen peroxide solution and then filter with suction, wash with 5% hydrochloric acid and deionized water respectively, and then dry in a vacuum oven at a temperature of 60-80°C for subsequent use; the prepared graphite oxide Grind it into powder in an agate mortar, weigh a certain amount of graphite oxide powder in the mortar, a...

Embodiment 2

[0028] Repeat the method of Example 1 according to the specified content of each component, but adopt 1 part of modified graphene oxide in the formula, the tensile strength of the obtained vulcanizate is 22.40MPa, the elongation at break is 444%, and the tear strength is 48.32 N / mm, thermal oxygen aging coefficient 79%, thermal conductivity 0.4800 W / (mK).

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com