Preparation method of high-temperature oxide nano-particle spaced vermiculite micro-nano sheet

A technology of high-temperature oxides and nanoparticles, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve problems such as difficult separation, and achieve a good peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

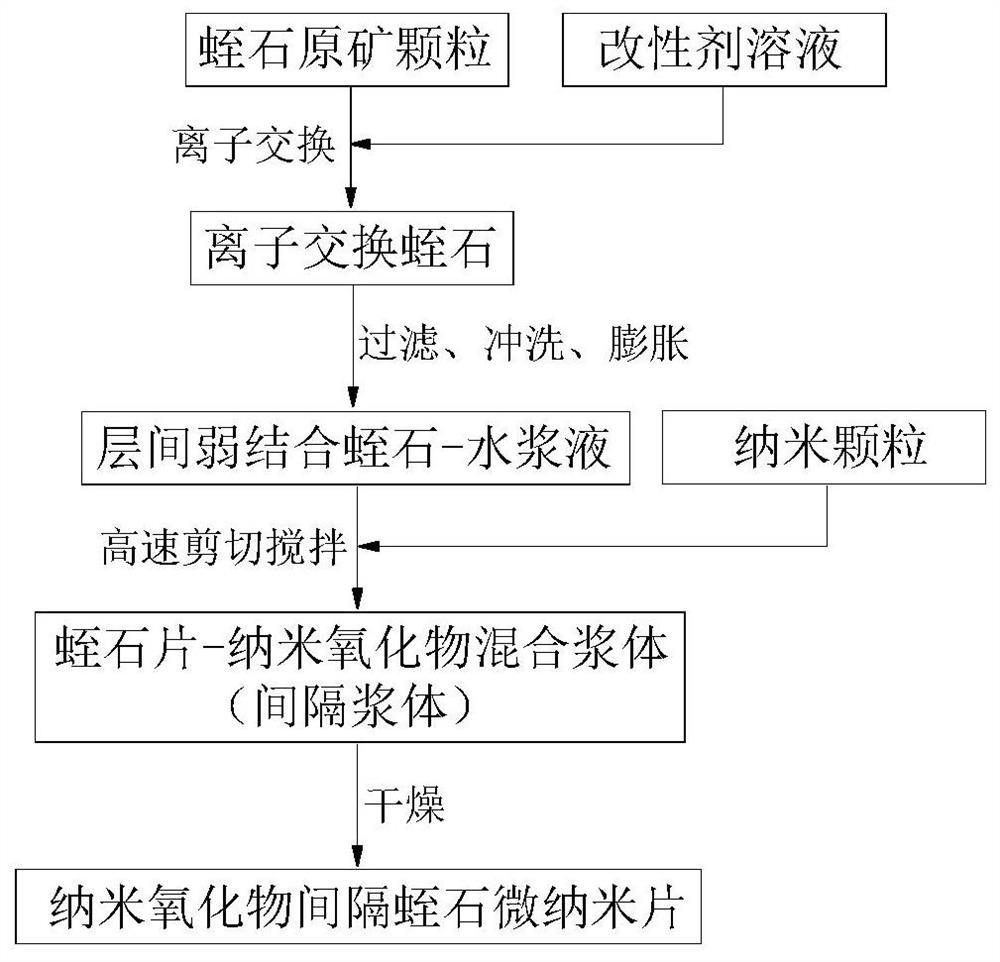

[0023] The invention provides a method for preparing vermiculite micro-nano sheets spaced by high-temperature oxide nanoparticles, the process flow of which is as follows figure 1 shown. Choose raw materials such as quartz and clay with an impurity content of less than 0.5%, and fine-grained, ultra-fine-grained or micro-grained natural vermiculite raw ore with a particle size of less than 10 mesh on a standard sieve. After washing with deionized water for 1 to 3 times, centrifuge or vacuum dehydrate and set aside. In the vermiculite raw ore particles, the vermiculite mineral content is more than 50%, and it is better to use more pure vermiculite with a vermiculite content of more than 90% as the vermiculite raw material. Ca 2+ , Mg 2+ , Fe 2+ Etc replacement, soluble Li salt or Na salt as a chemical modifier, such as lithium citrate, sodium citrate, lithium ethylenediaminetetraacetate, sodium ethylenediaminetetraacetate, lithium nitrilotriacetate, sodium nitrilotriacetate,...

Embodiment 1

[0029] Wash the raw natural vermiculite whose particle size is between 20 mesh and 40 mesh on a standard sieve with deionized water for 2 to 3 times, and dry it in an oven at 60°C for easy measurement. Mix 15g of dried vermiculite with 1M lithium citrate solution at a ratio of 1:7, soak in a constant temperature water bath at 80°C, and keep stirring for 1 hour, then filter out the soaking solution. The vermiculite particles were washed twice with 200 ml of deionized water, and the cleaning solution was filtered out to obtain lithiated vermiculite. Brew the lithiated vermiculite with 95-100°C hot deionized water of 30 times the mass of the vermiculite. The brewing process is firstly stirred at a constant temperature for 10 minutes, and then allowed to stand at the same temperature for 30 minutes. After standing, the water in the upper layer was filtered out. Repeat the above brewing process 5 times, and the expansion of vermiculite after each brewing is 3.65, 5.00, 5.65, 6.12,...

Embodiment 2

[0032] Other conditions were the same as in Example 1, except that the modifier solution was changed to 3M sodium chloride solution, mixed with vermiculite at a ratio of 1:2, and the temperature of the constant temperature water bath was changed to 100°C. Sodiumized vermiculite is brewed three times with hot deionized water, and its volume expansion multiple is 2.01 times.

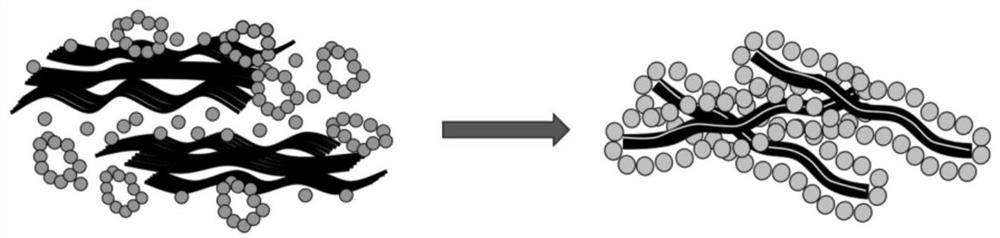

[0033] Mix the brewed and expanded vermiculite with deionized water of 5 times the mass of vermiculite to form a weakly bonded vermiculite-water slurry between layers. Take by weighing the same mass of silicon dioxide nanoparticles as vermiculite (specific surface area 380m 2 / g of fumed silica), added to the above slurry, first stirred at a low speed of 500rpm until the nanoparticles were dispersed, and then stirred with a high-speed shear mixer at a speed of 2000rpm for 60min to obtain viscous vermiculite flakes-nano-oxidized Mixed slurry. The mixed slurry was observed under an optical microscope, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com