Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

220results about How to "Stable cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

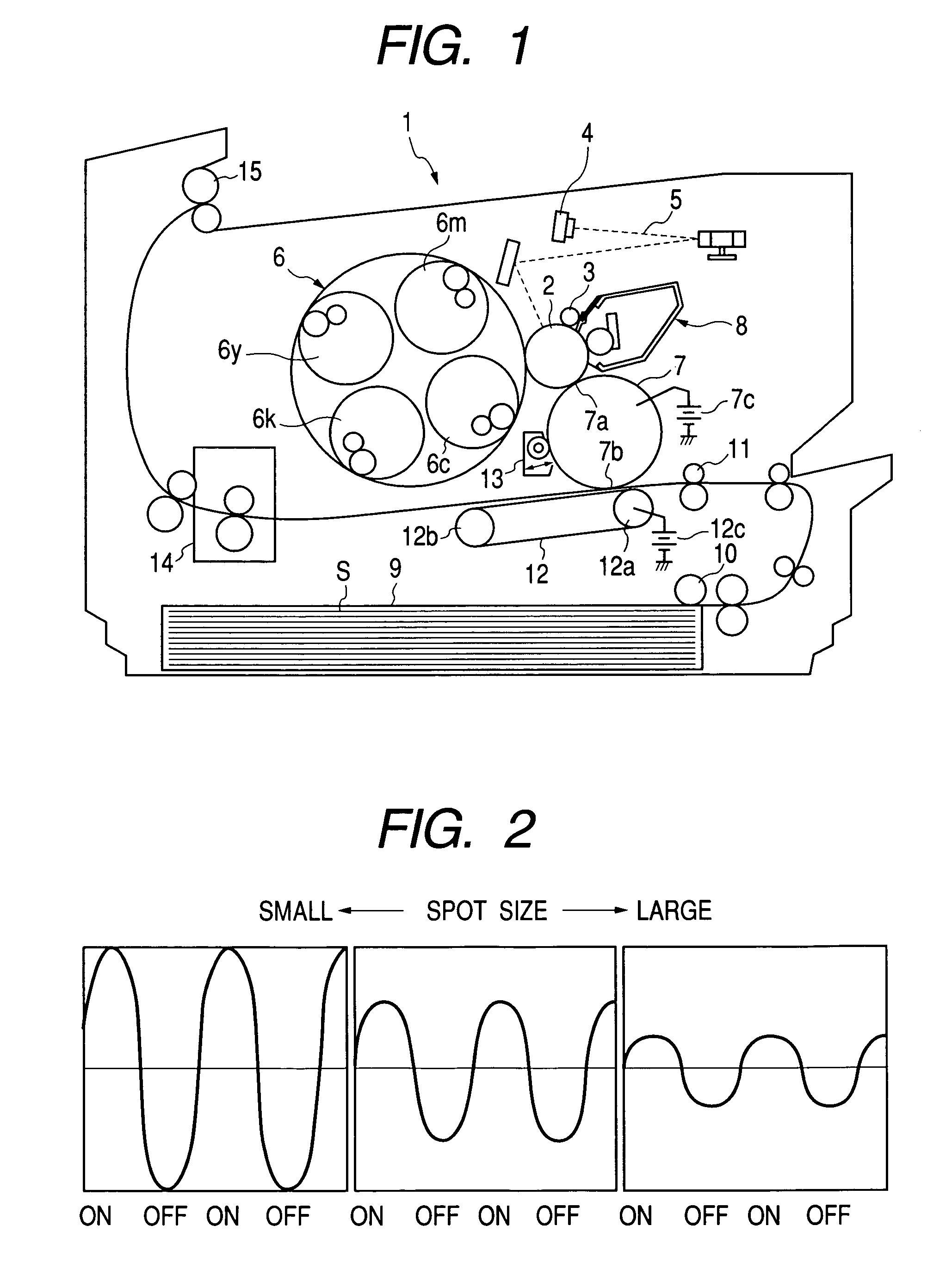

Electrophotographic toner and method for producing the electrophotographic toner

InactiveUS20080292985A1Improve productivityQuality improvementDevelopersOrganic solventAdditive ingredient

Provided are an electrophotographic toner and a method for producing the electrophotographic toner that satisfy high image quality, cleaning stability, and high productivity.The electrophotographic toner is produced by spray-drying a toner ingredient-containing liquid, wherein the toner ingredient-containing liquid dissolves or disperses at least a resin, a low molecular mass organic material, and a colorant in an organic solvent, the resin is soluble in the organic solvent, the low molecular mass organic material is a crystalline compound or a composition of crystalline compounds that is soluble in the organic solvent, the toner ingredient-containing liquid contains substantially no particles having a particle diameter of 500 nm or more, the crystalline compound or the composition of crystalline compounds crystallizes upon spray-drying to deform toner particles into a circularity of 0.93 or higher to 0.98 or less, and volume average particle diameter of the toner particles is 3.0 μm or higher to less than 7.0 μm.

Owner:RICOH KK

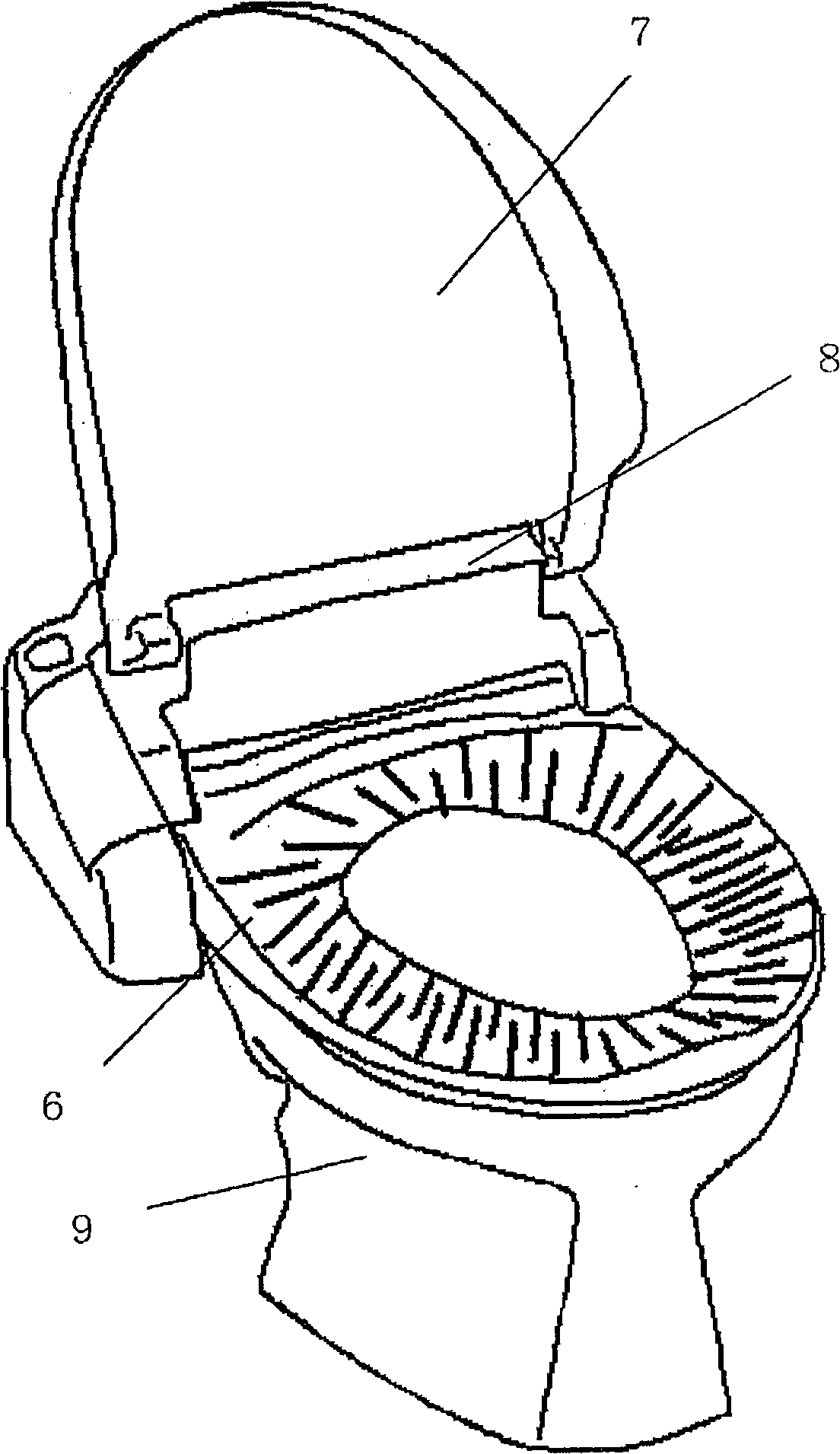

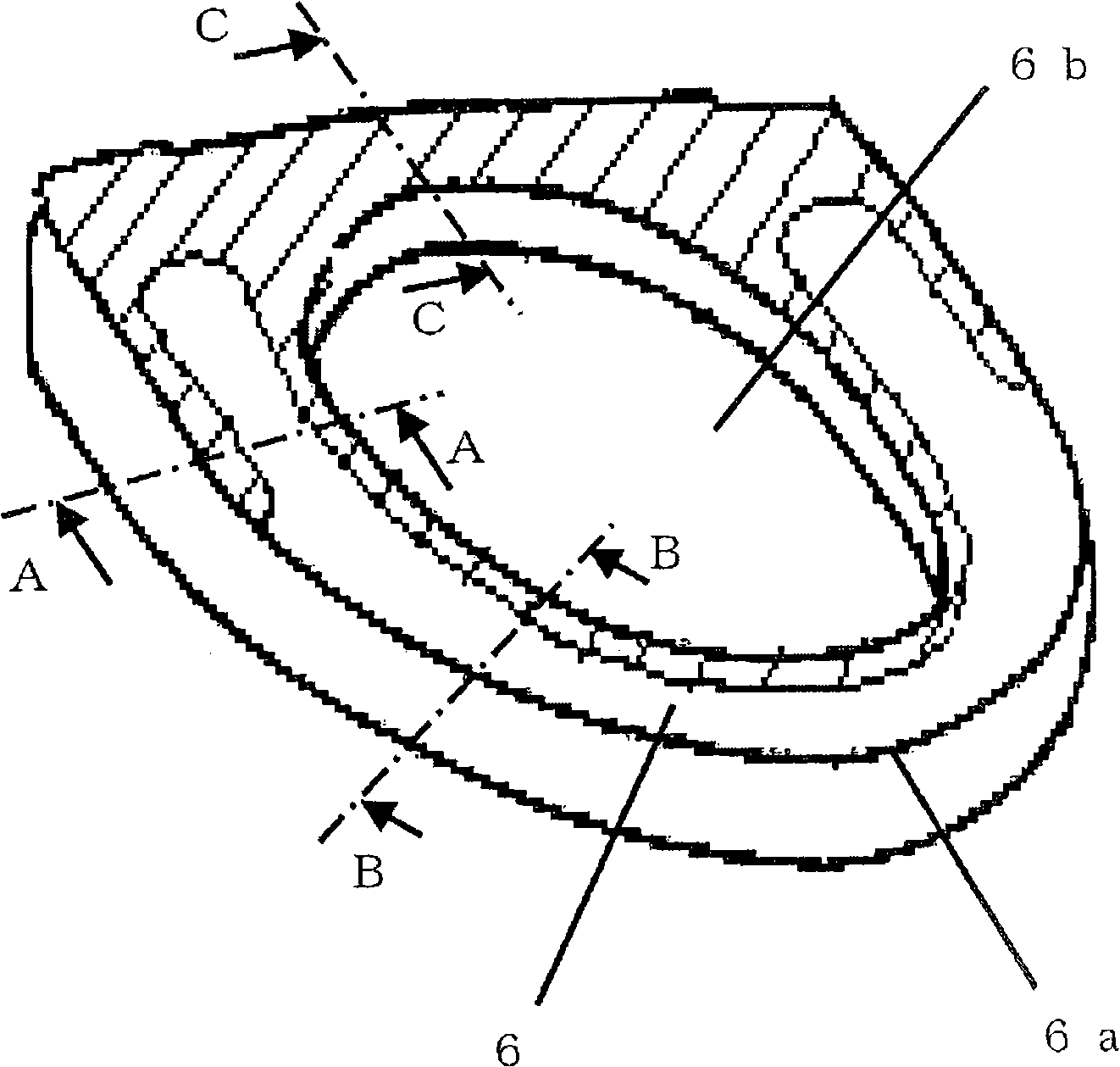

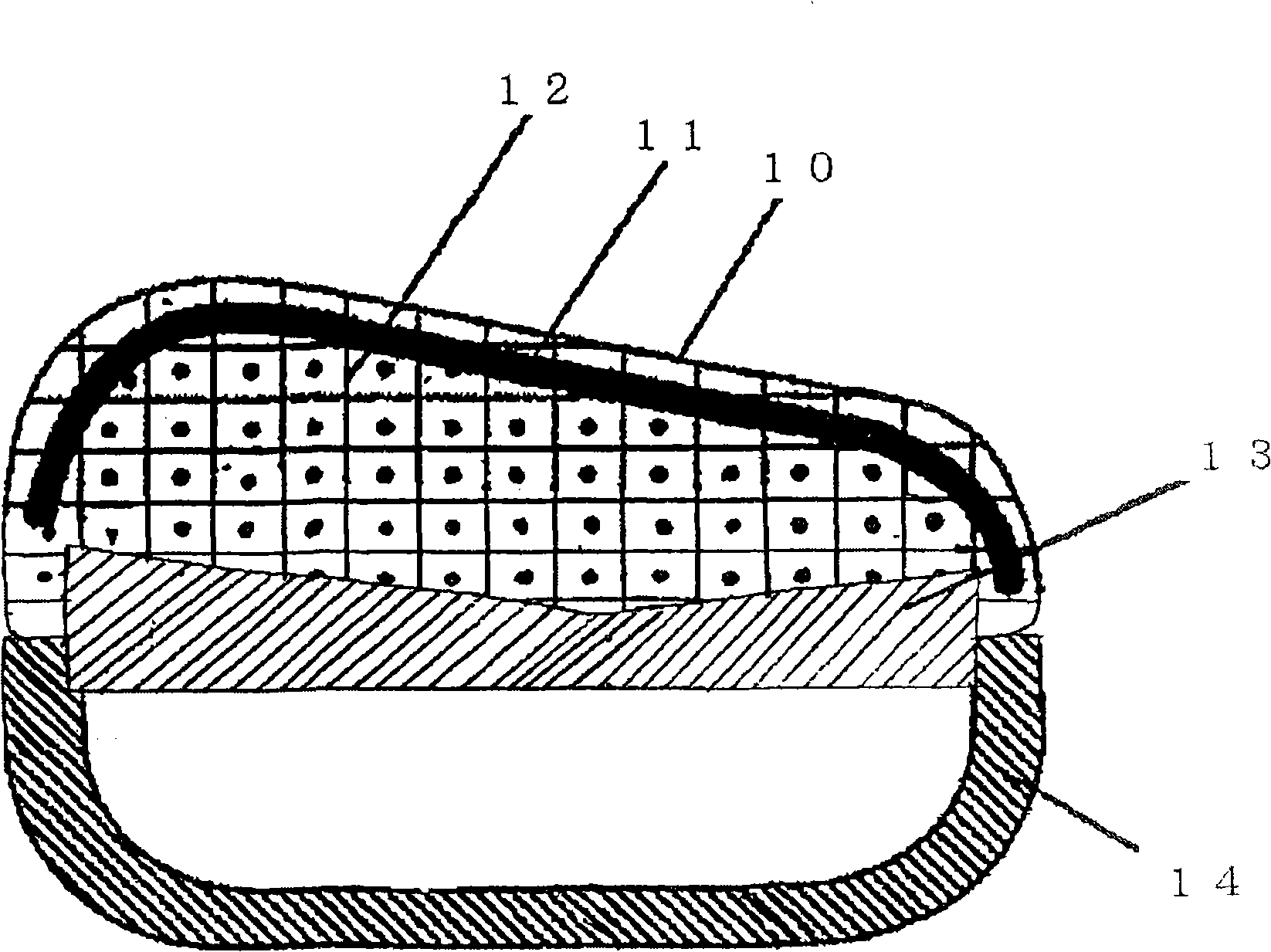

Toilet seat device

InactiveCN101282673AAppropriate cushioningImprove securityBathroom coversLavatory sanitoryBody shapeEngineering

A toilet seat device capable of absorbing impact caused when a user sits on a toilet seat and providing comfortable feeling to sit while the user sits thereon, and less affecting a human body even if the user sits thereon over a long period. At least a part of the toilet seat (7) is provided with an elastic body layer (12) which can be deformed along the body shape of the user. A reinforcement material (13) with elasticity and a toilet seat lower member (14) are disposed on the lower side of the elastic body layer (12) in this order to absorb impact caused when the user sits thereon by the elastic body layer (12) and the reinforcement material (13). Since the elastic body layer (12) is deformed along the hip part of the user, a pressure generated by sitting can be equalized and dispersed. As a result, the user can comfortably sits on the toilet seat over a long period.

Owner:PANASONIC CORP

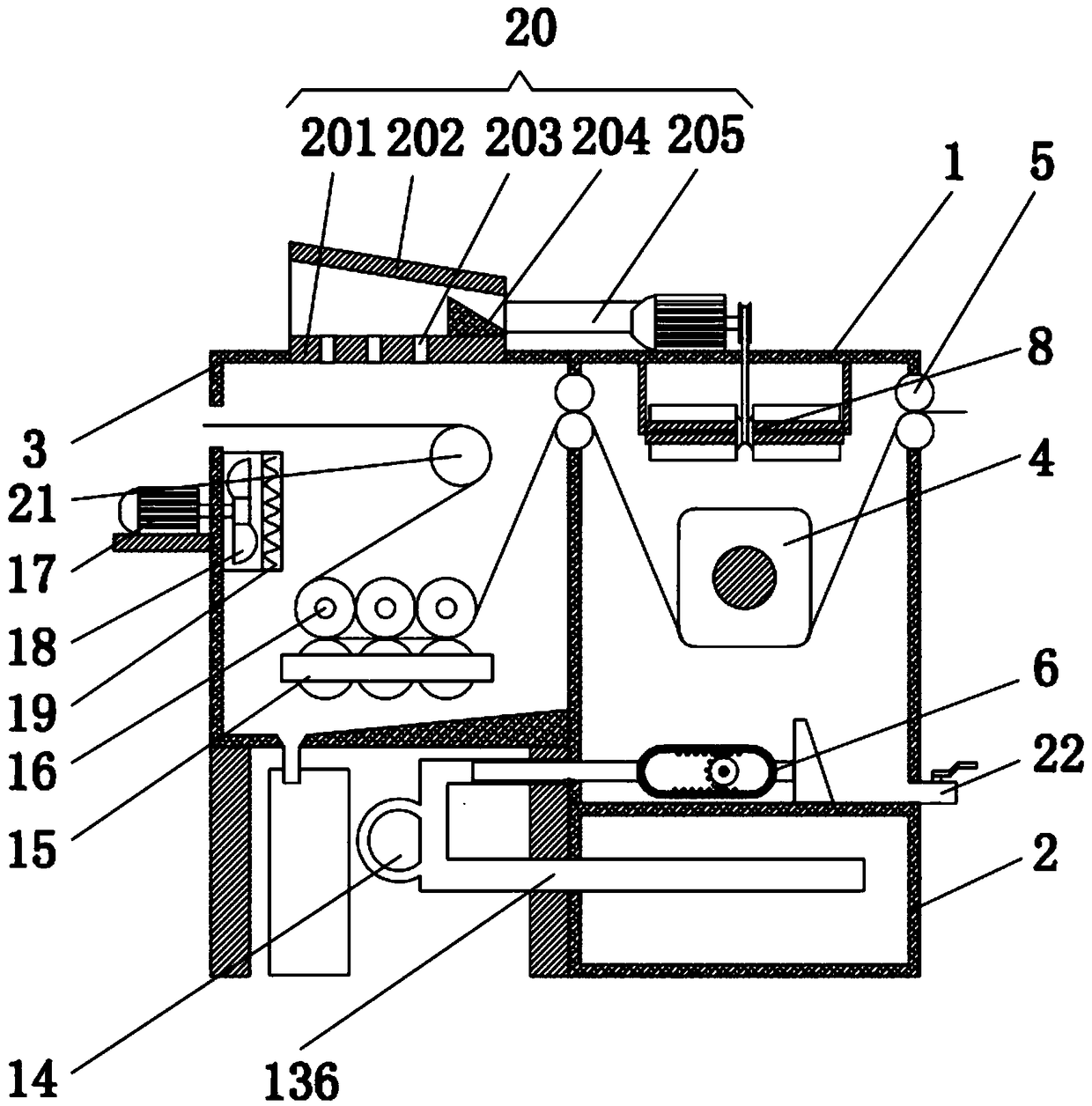

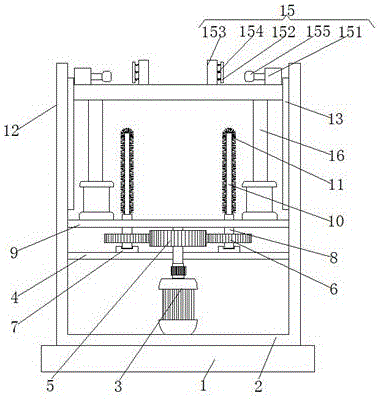

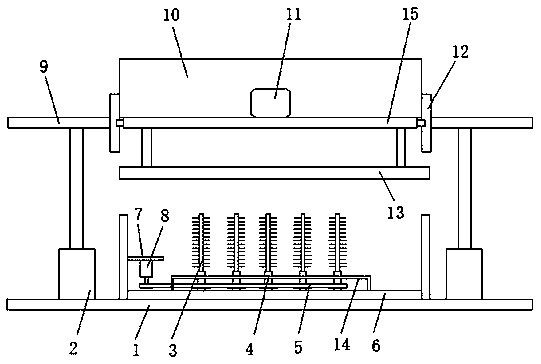

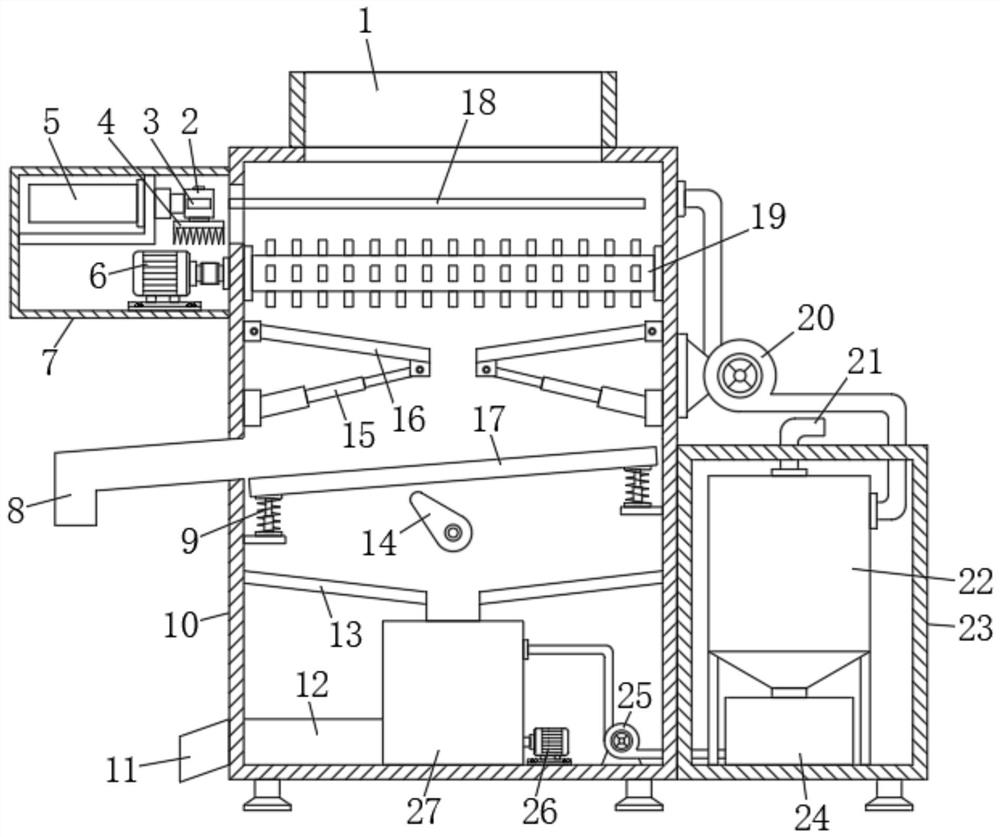

Bar surface cleaning device

ActiveCN105665328AStable cleaningEasy to cleanDrying gas arrangementsCleaning using toolsSurface cleaningEngineering

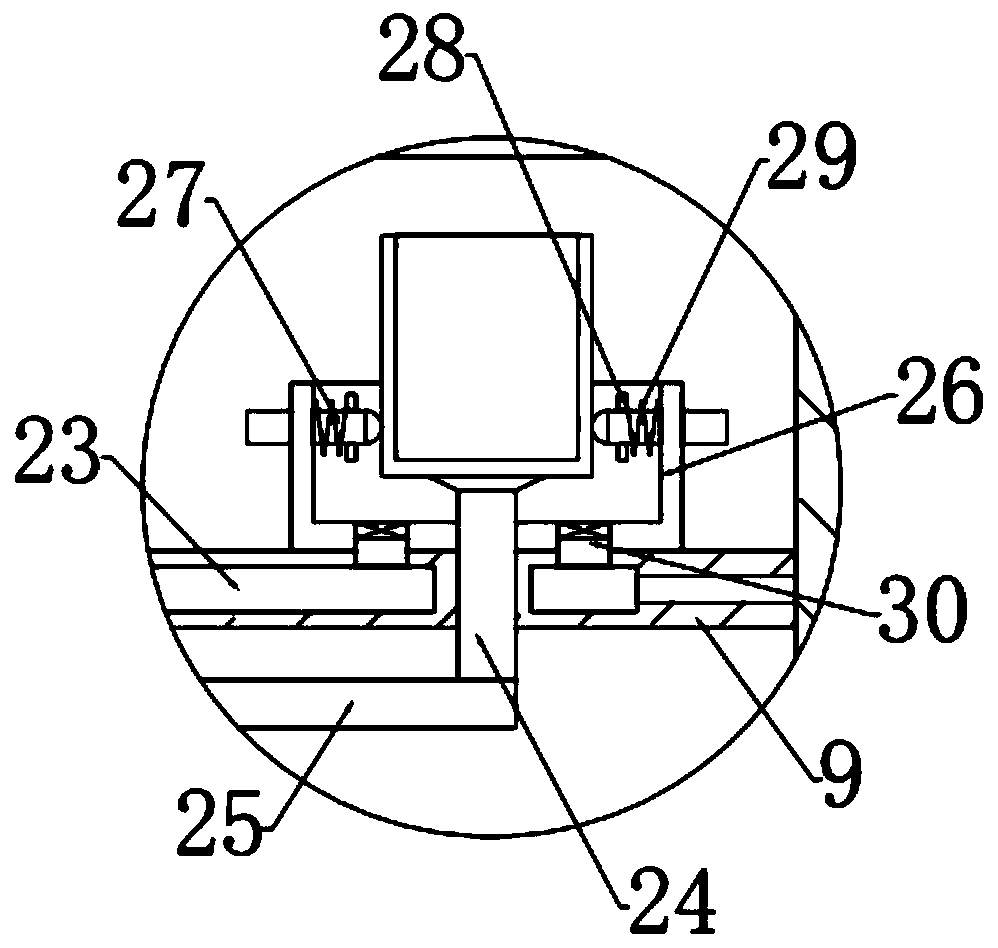

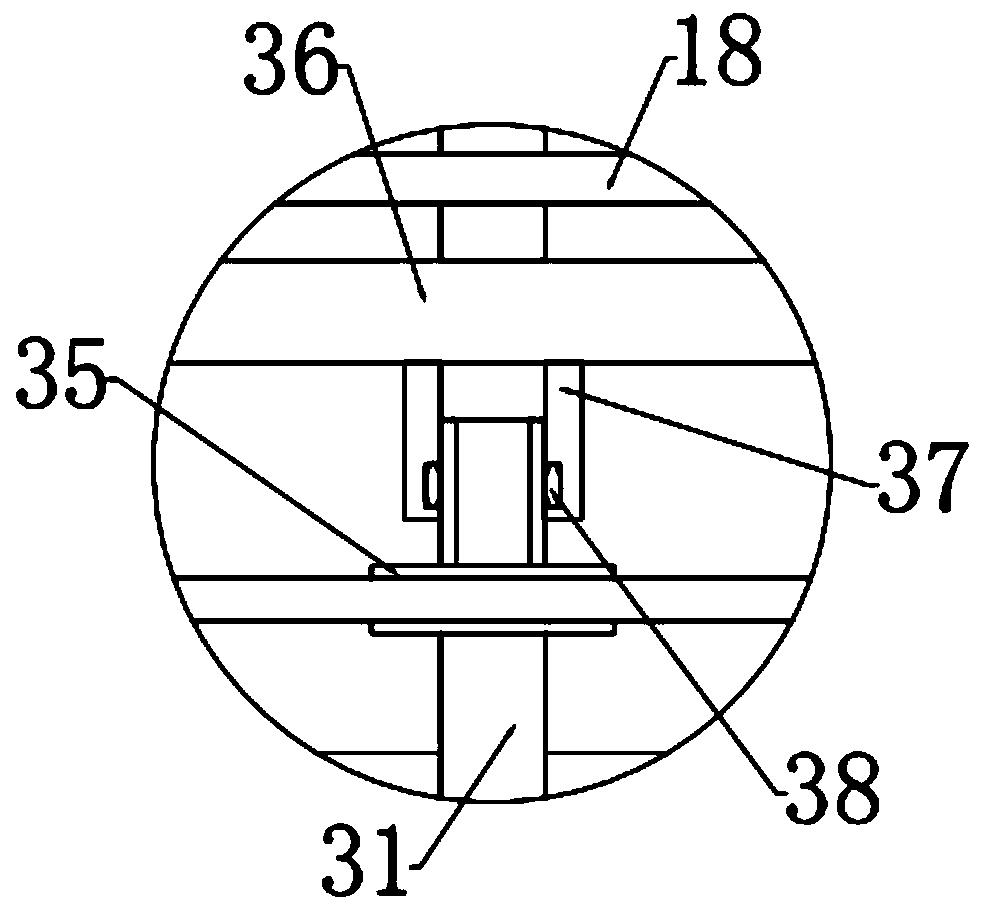

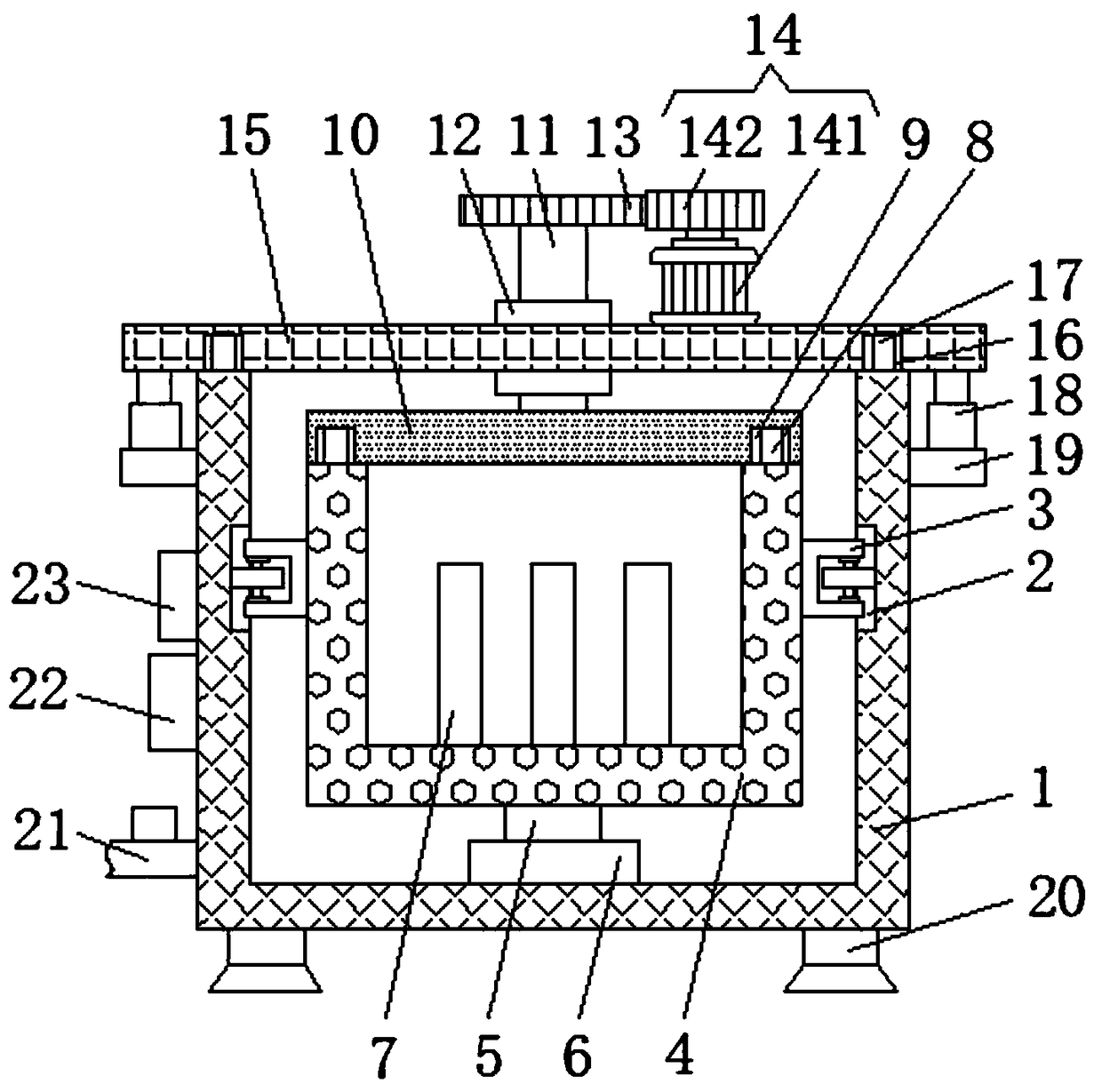

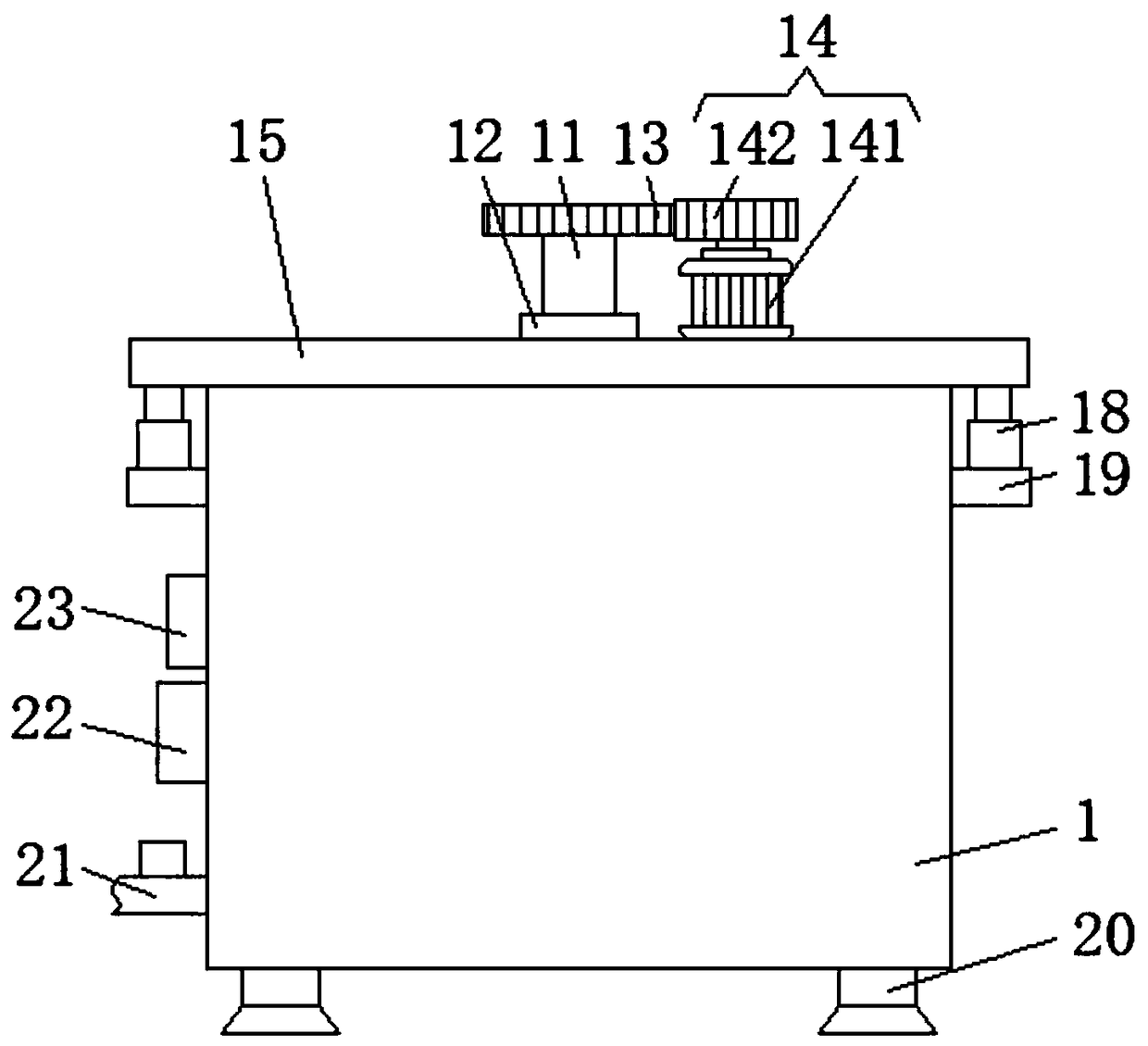

The invention discloses a bar surface cleaning device which comprises a machine frame. A cleaning box is arranged on the machine frame. A rotary cleaning device, a spray cleaning device, a scrubbing device and a drying device are arranged in the cleaning box. An automatic cutting-off mechanism is arranged outside the cleaning box. The rotary cleaning device is composed of two through holes, a bearing, a rotating drum, a ratchet, a bearing A, a swing rod, a pin hole, a rotary shaft, a movable block, a first rotating motor, a rocking bar and a pushing rod, wherein the two through holes are formed in the opposite surfaces of the interior of the cleaning box; the bearing is inserted in one through hole; a part of the rotating drum is inserted in the other through hole; one end of the rotating drum is sleeved with the ratchet; the rotating drum is sleeved with the bearing A, and the bearing A is close to the ratchet; the bearing A is sleeved with the swing rod; the pin hole is formed in the swing rod; a part of the rotary shaft is inserted in the pin hole; one end of the rotary shaft is sleeved with the movable block; the first rotating motor is arranged on the inner surface of the cleaning box; the rotating end of the first rotating motor is sleeved with the rocking bar; and one end of the pushing rod is connected with the swing rod through a hinge, and the other end of the pushing rod is connected with the rocking bar through a hinge. The bar surface cleaning device has the beneficial effects of being simple in structure and high in practicability.

Owner:湖州中合鑫顺特钢股份有限公司

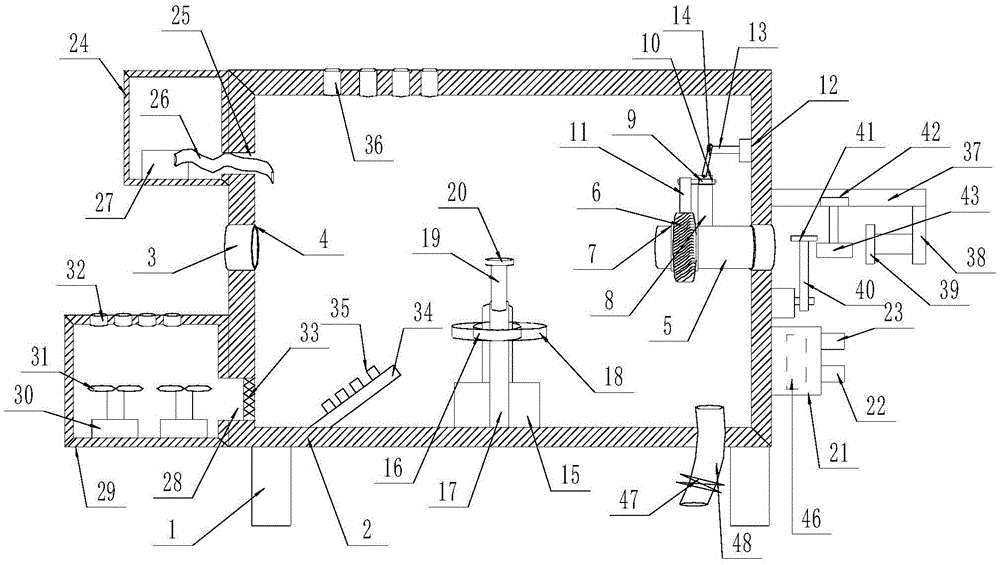

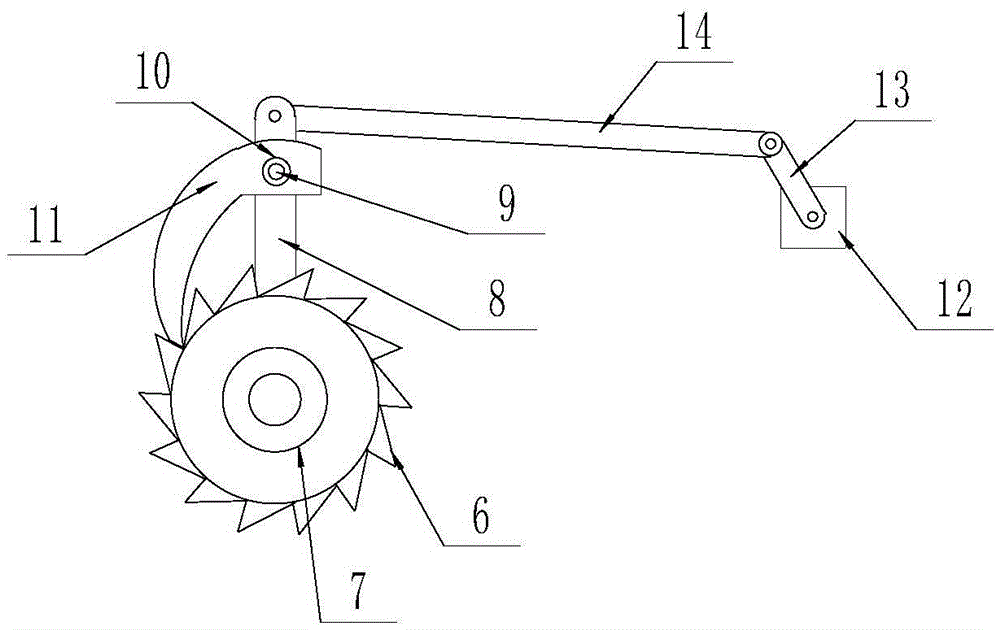

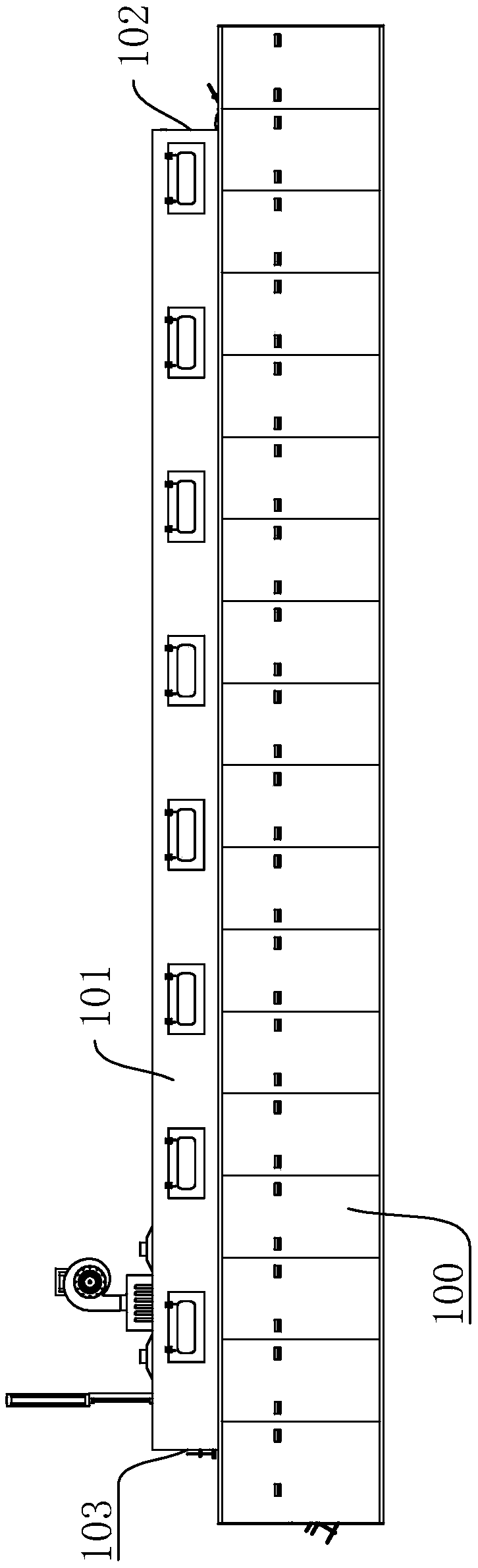

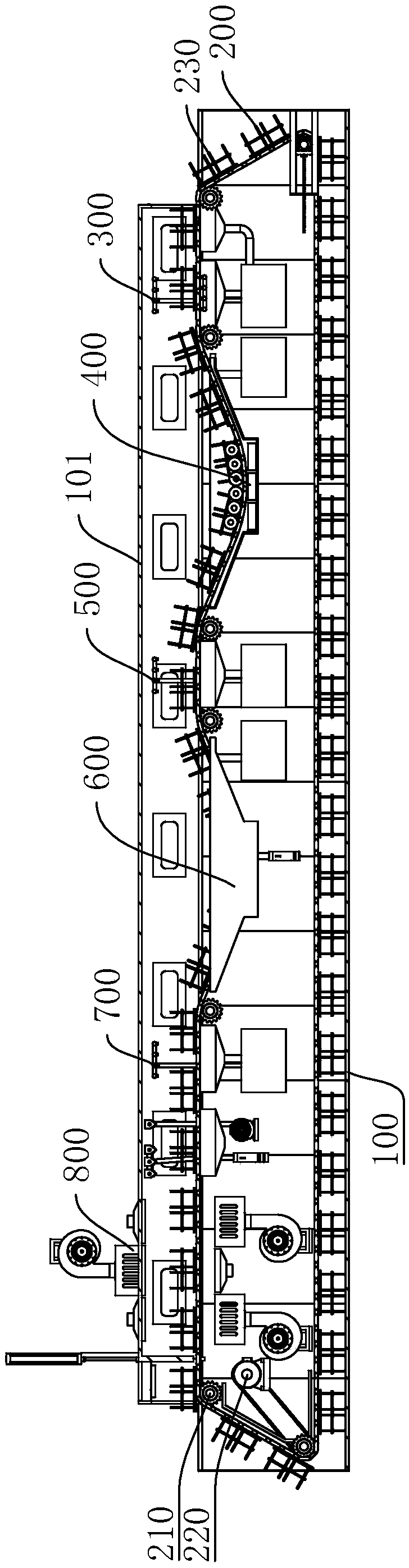

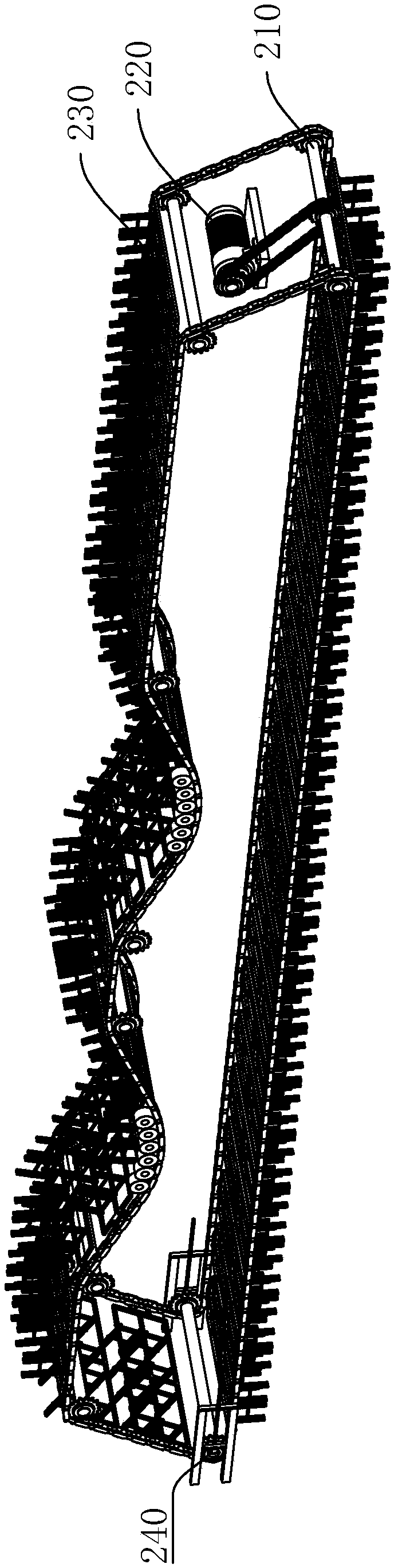

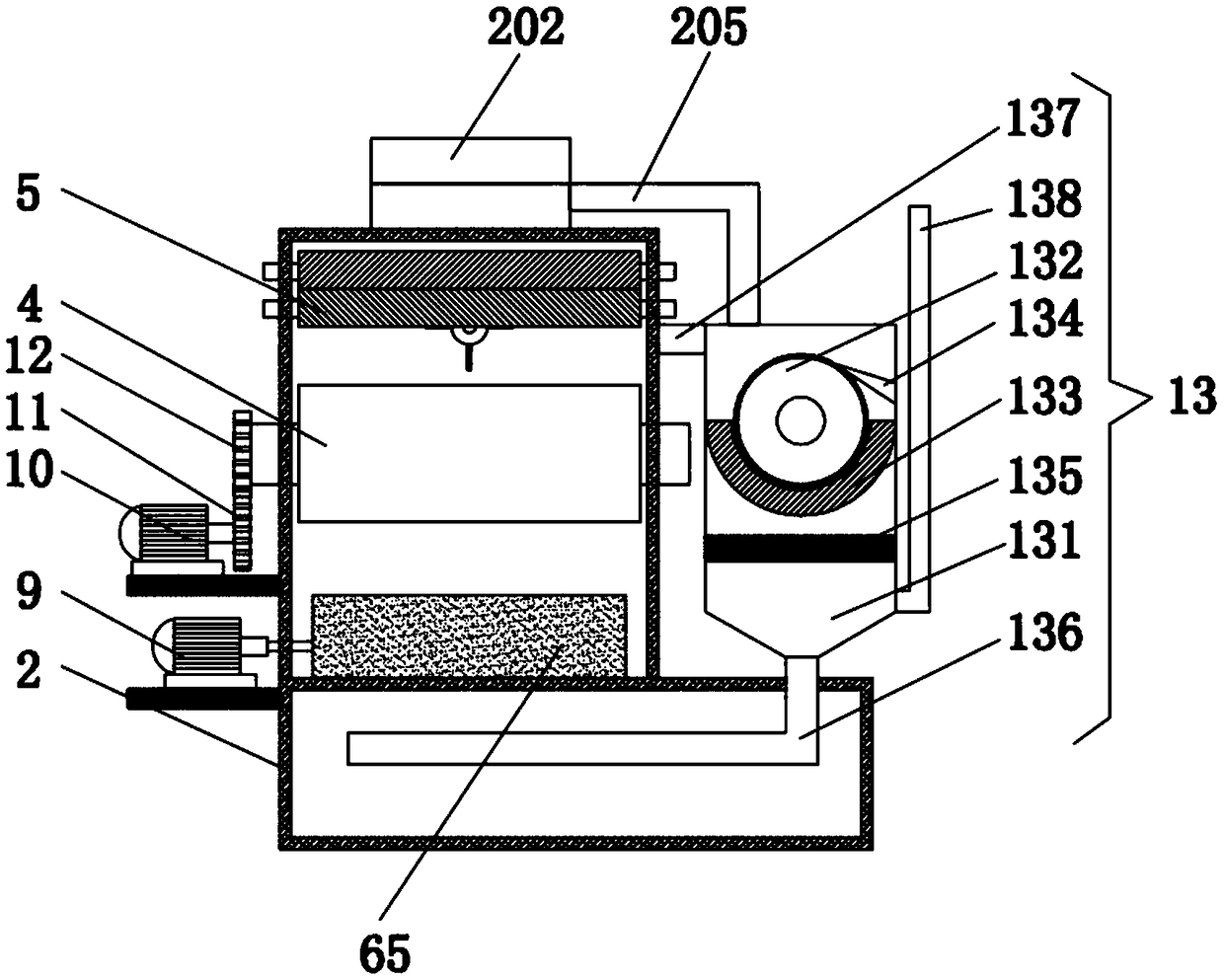

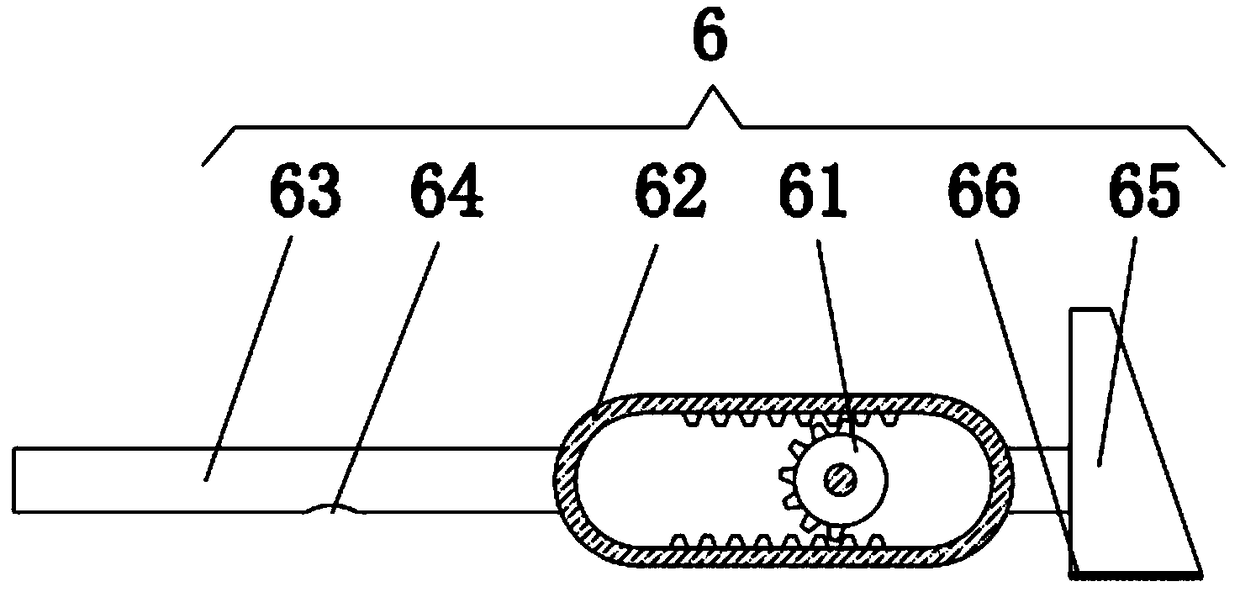

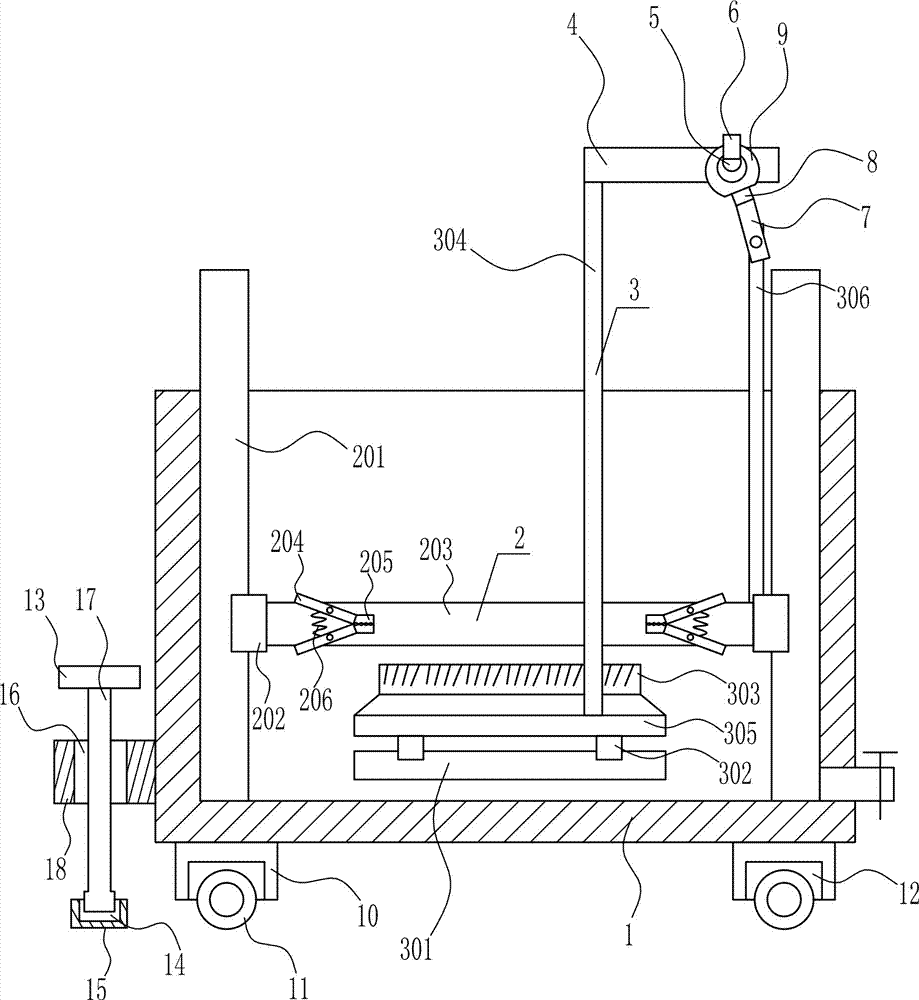

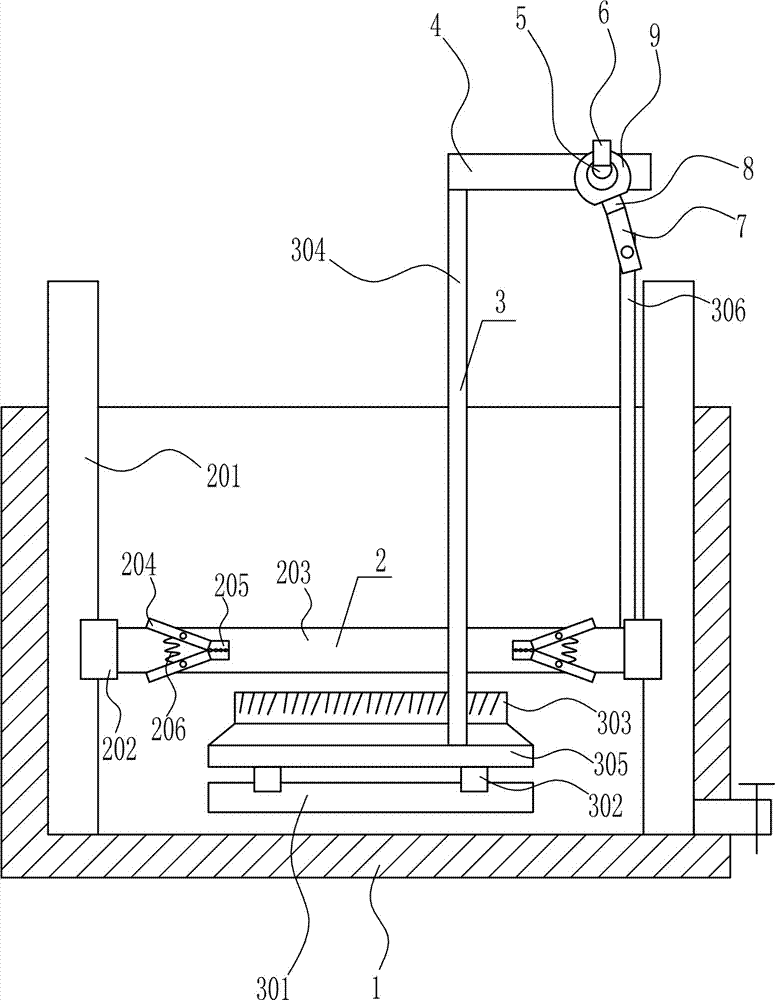

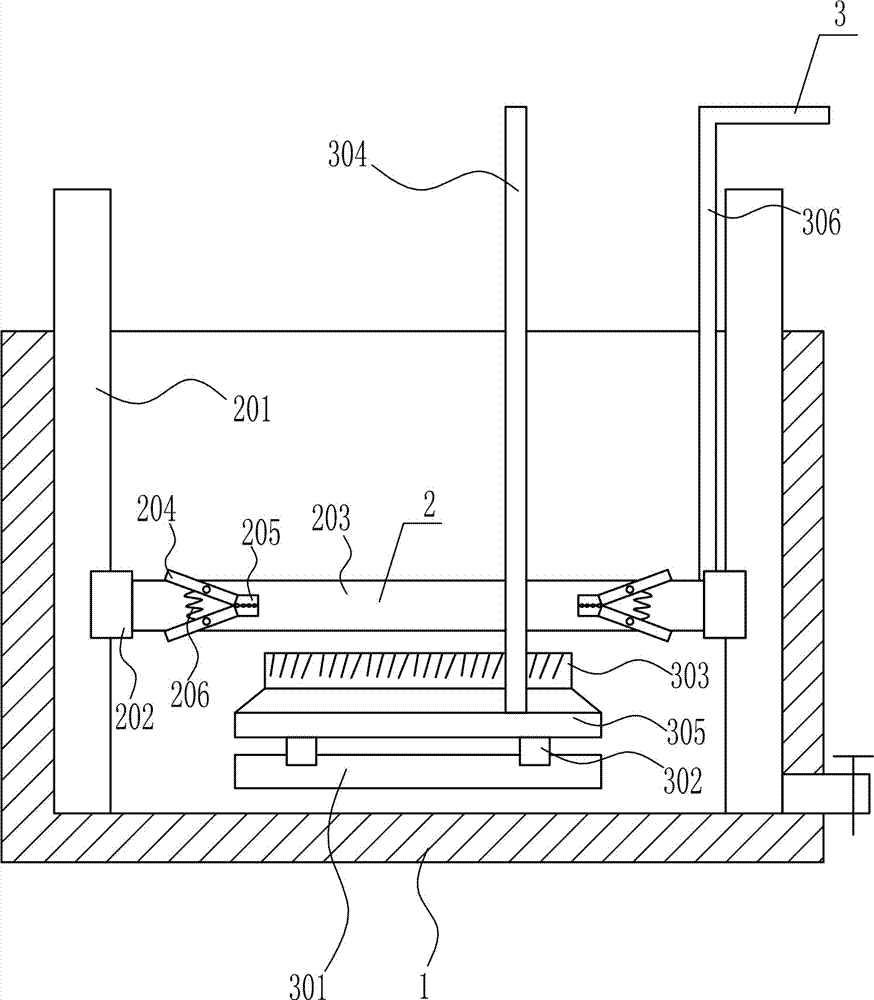

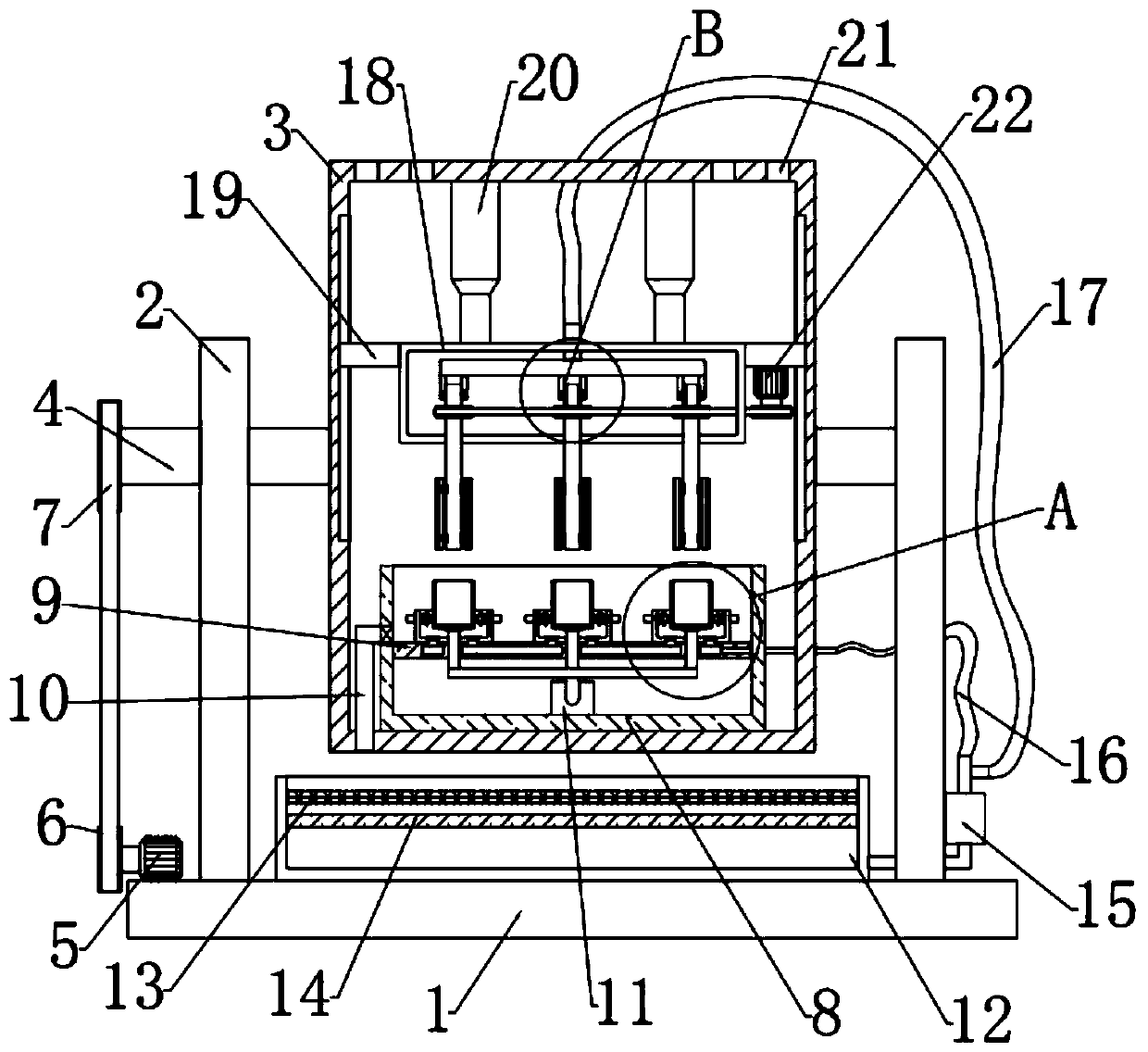

Automobile part washing production line and washing method

PendingCN108856095AReduce intrusionStable clampingConveyorsDrying gas arrangementsProduction lineMotor vehicle part

The invention discloses an automobile part washing production line and a washing method, belongs to the field of automobile part machining, and aims at providing the automobile part cleaning production line capable of washing automatic parts many times and avoiding that oil contaminates other automobile parts. The washing production line is characterized by comprising a base, the base is covered with an engine cover, and a conveying device used for conveying the automatic parts is arranged on the base in the length direction; a spraying washing assembly, an ultrasonic washing assembly, a clearwater spraying rinsing assembly, a bubbling washing assembly, a clear water spraying rinsing assembly and an air drying device are successively arranged on the base in the conveying direction of theautomobile parts. Through the arrangement of the conveying device, the automobile parts can be conveyed to a corresponding assembly for washing. The invention discloses the automobile part washing method, belongs to the field of automobile part machining, and aims at providing the automobile part washing method capable of washing the automatic parts many times and avoiding that the oil contaminates other automobile parts.

Owner:无锡邦得机械有限公司

Cleaning device for inner walls of steel pipes

The invention relates to a cleaning device for inner walls of steel pipes. The cleaning device comprises a shell; a first mounting cavity, an impeller cavity and a second mounting cavity are arrangedin the shell in sequence from top to bottom; a flow separation piece is fixedly arranged in the first mounting cavity; a water inlet ring cavity is formed between the periphery of the flow separationpiece and the inner wall of the first mounting cavity, and communicates with the impeller cavity; a guide piece is fixedly arranged at the lower end of the shell, and is positioned in the second mounting cavity; a guide cavity is formed between the periphery of the guide piece and the inner wall of the second mounting cavity, and communicates with the impeller cavity; water leakage ports are formed in the shell around the guide cavity; a rotatable impeller is arranged in the impeller cavity, and is connected with a rotating shaft; and the lower end of the rotating shaft penetrates through theguide piece to form a torsion output end. The cleaning device can move in pipes for cleaning; the source of working power of the whole cleaning device depends on impact force of water currents introduced into the cleaning device, so that the power source of the cleaning device is more energy-saved and environment-friendly; and the cleaning device cleans in pipes fully filled with water, and realizes high-quality cleaning of the inner walls of the pipes.

Owner:江苏博隆锦欣环保设备有限公司

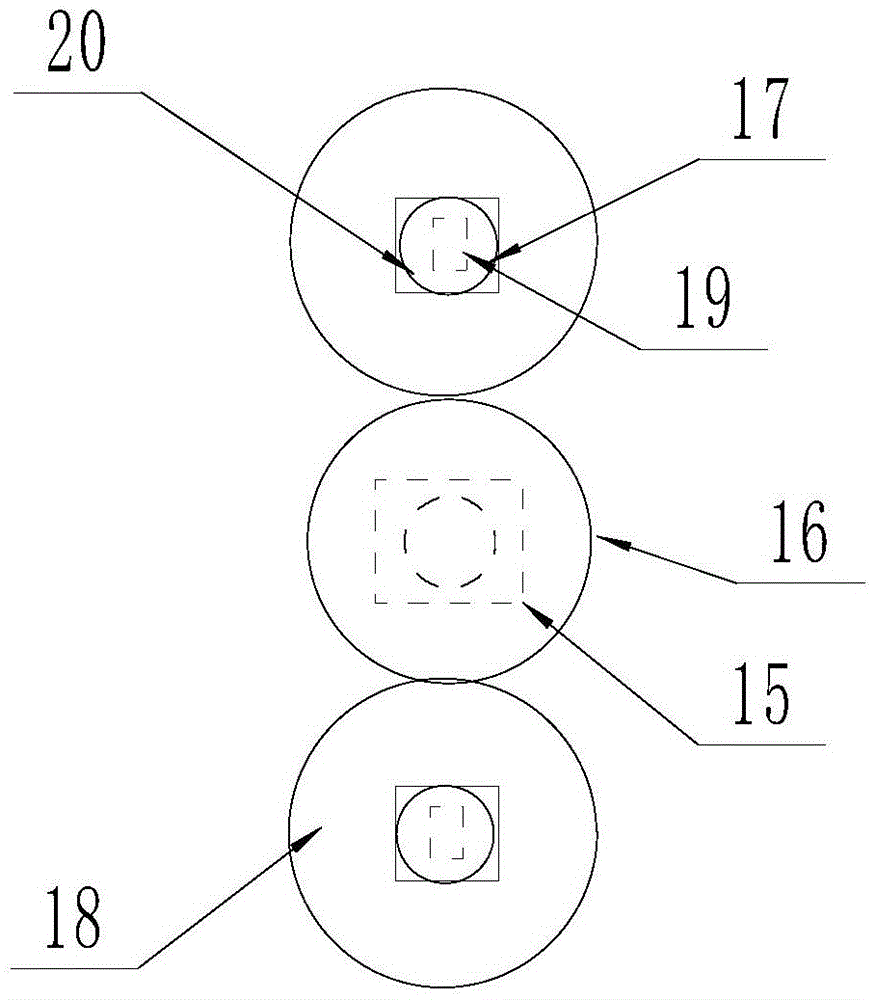

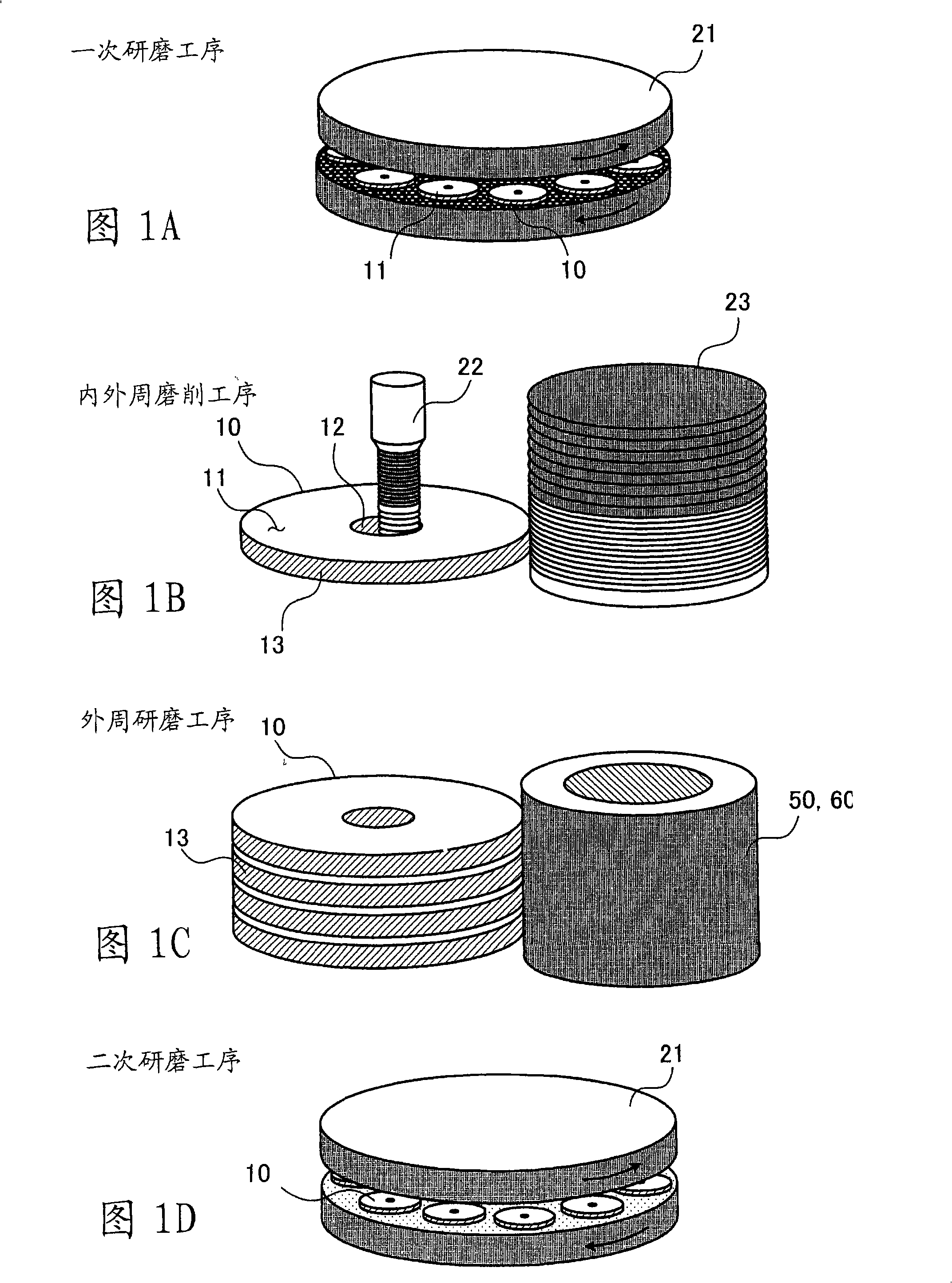

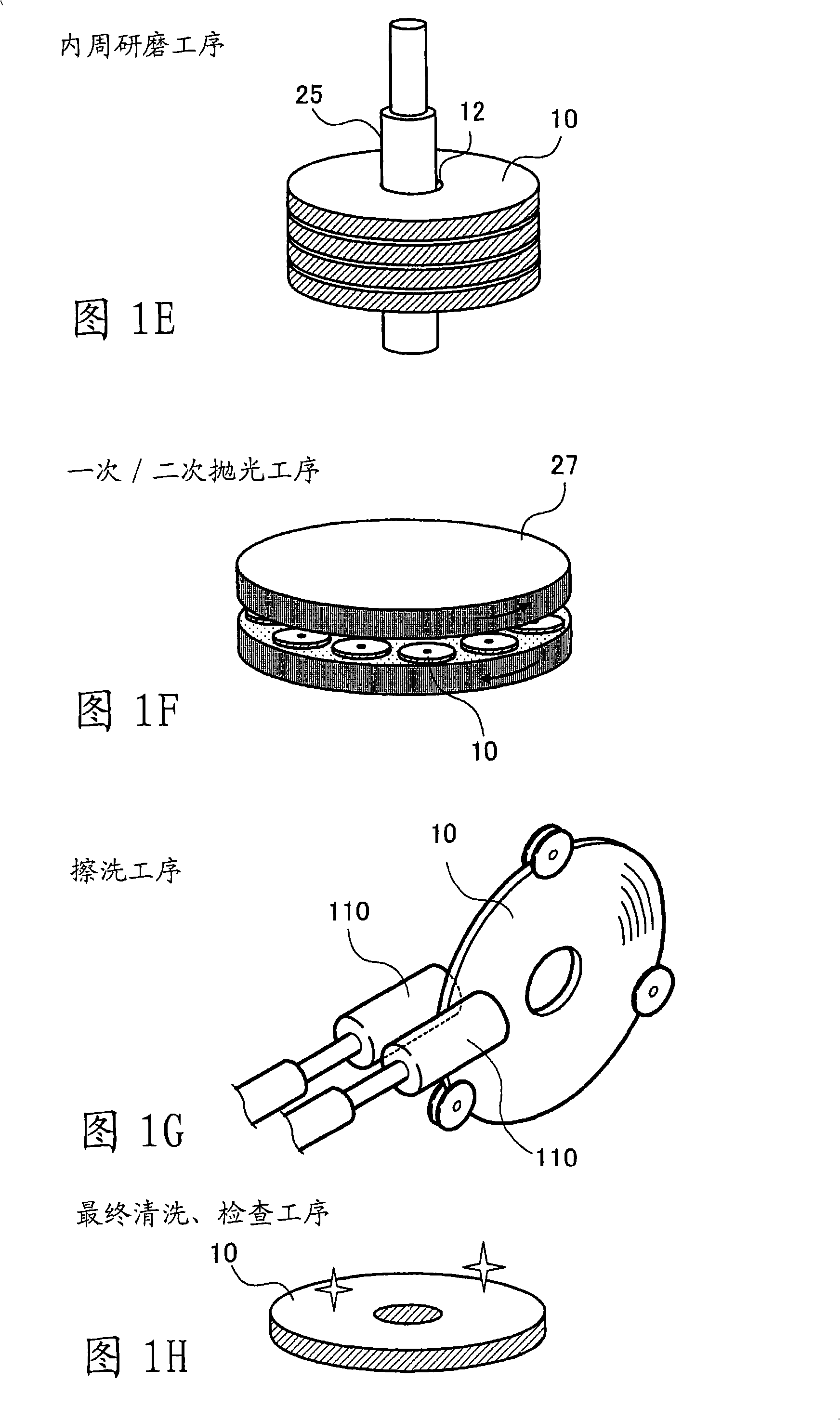

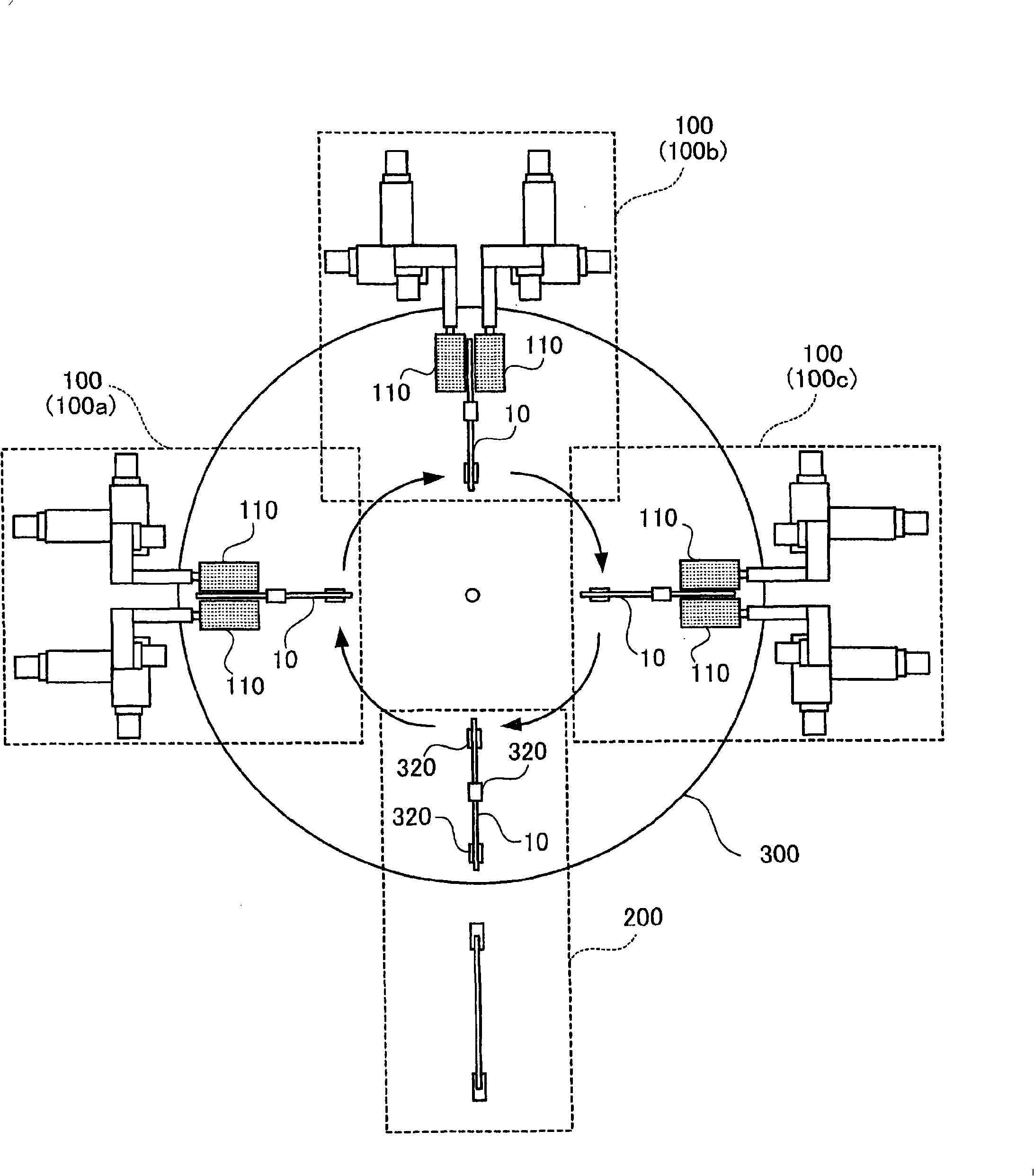

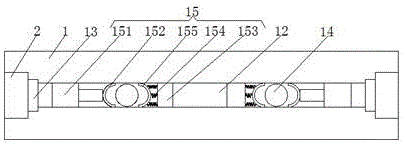

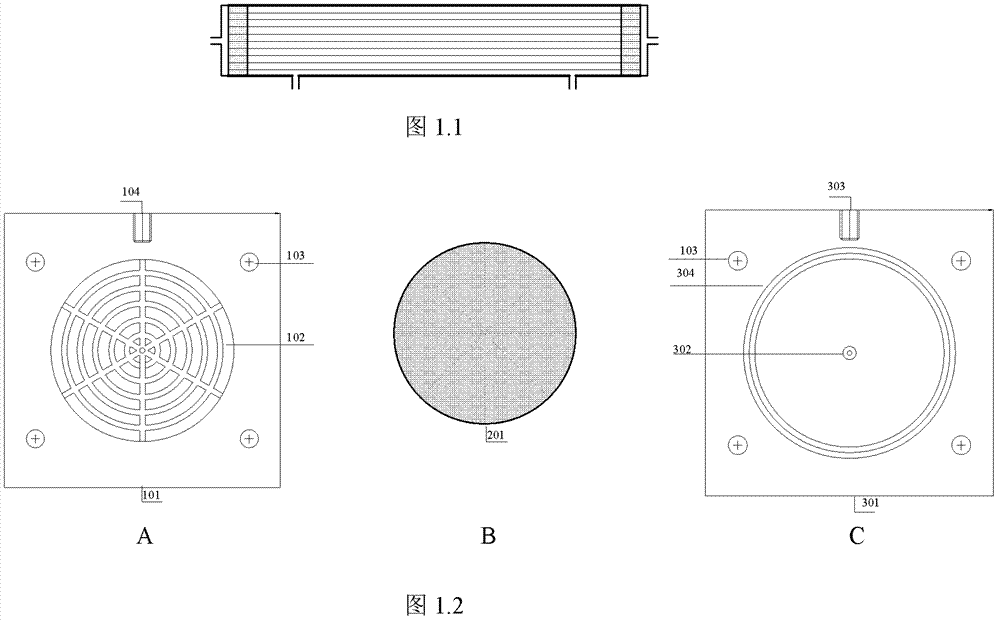

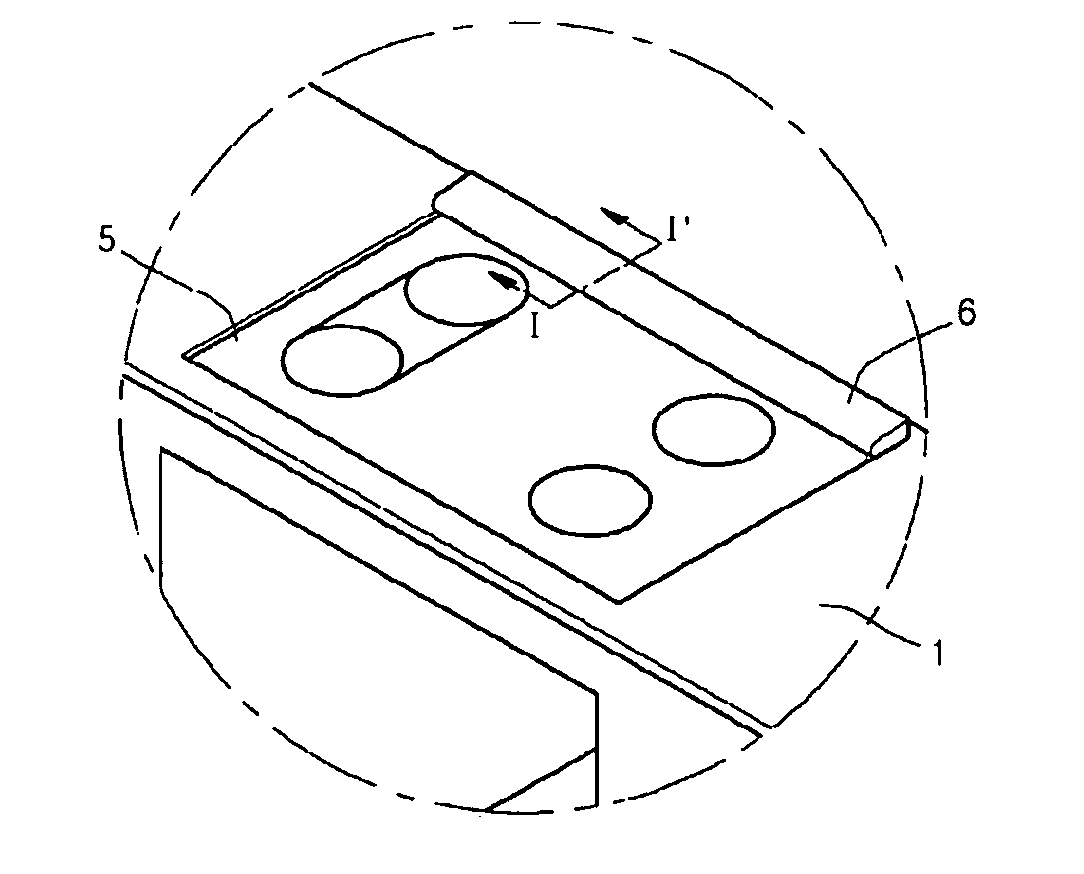

Disk-shaped substrate manufacturing method and washing apparatus

ActiveCN101266803AEasy to removeStable cleaningSemiconductor/solid-state device manufacturingFlexible article cleaningEngineeringMechanical engineering

Owner:RESONAC CORPORATION

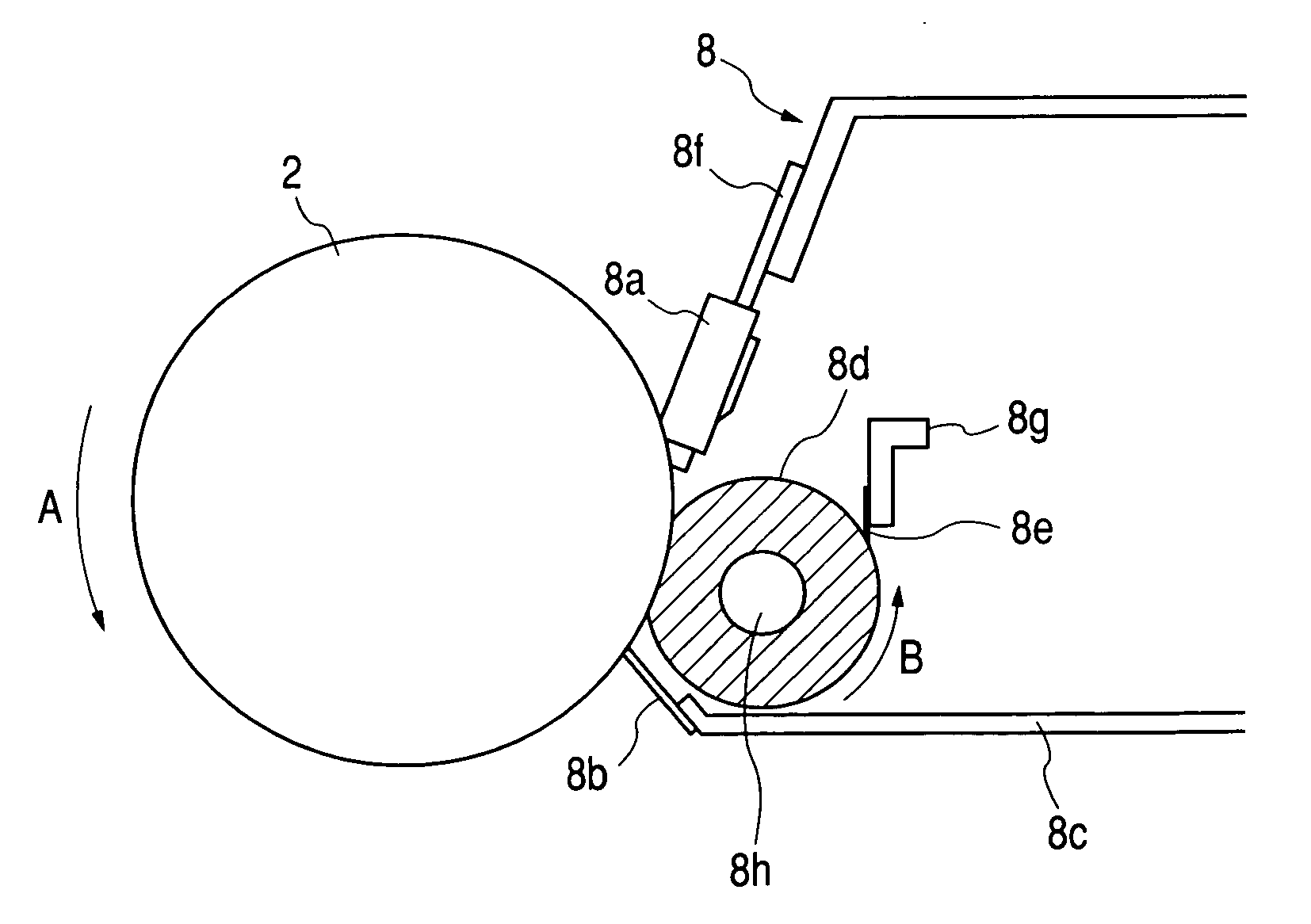

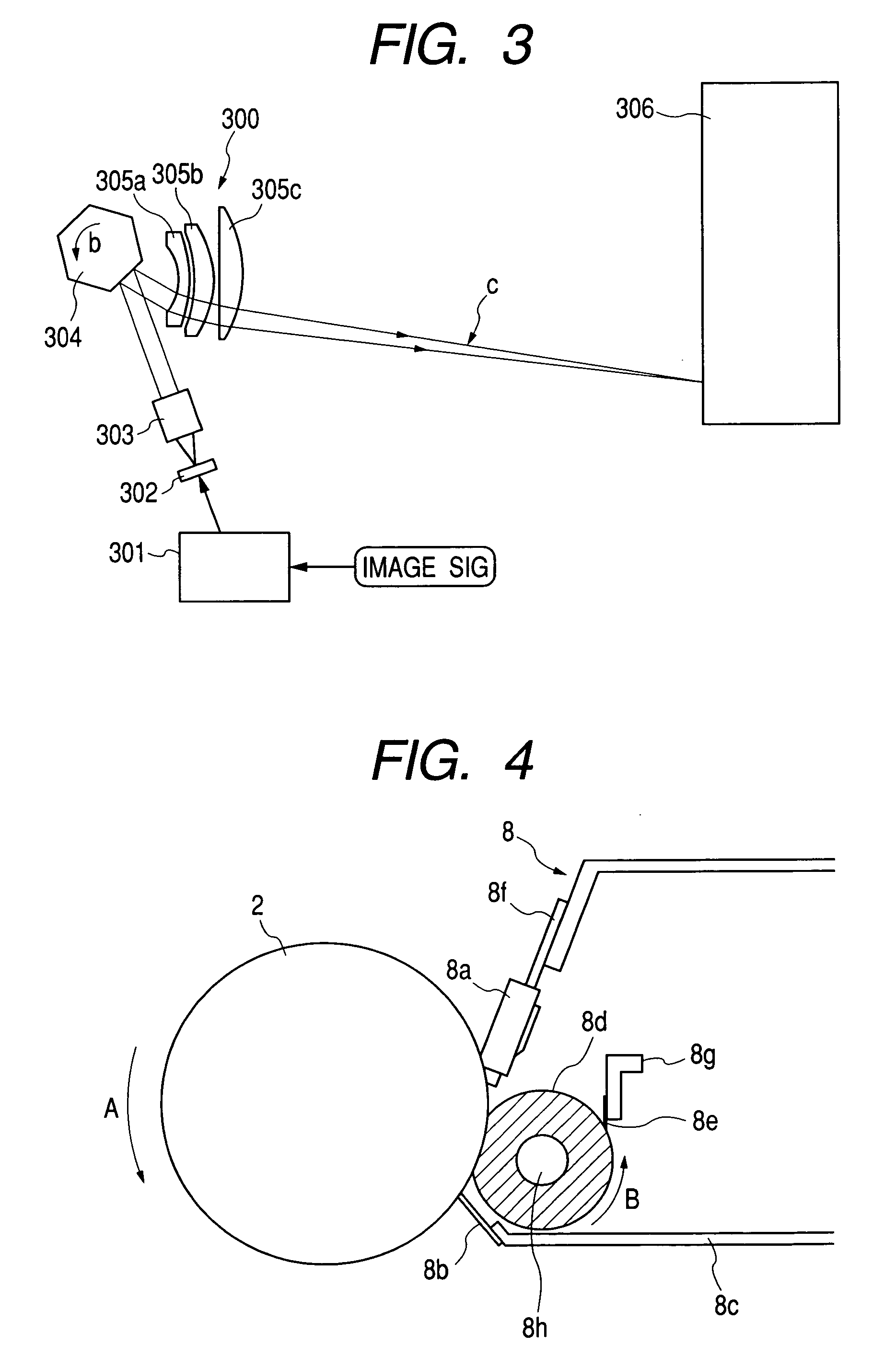

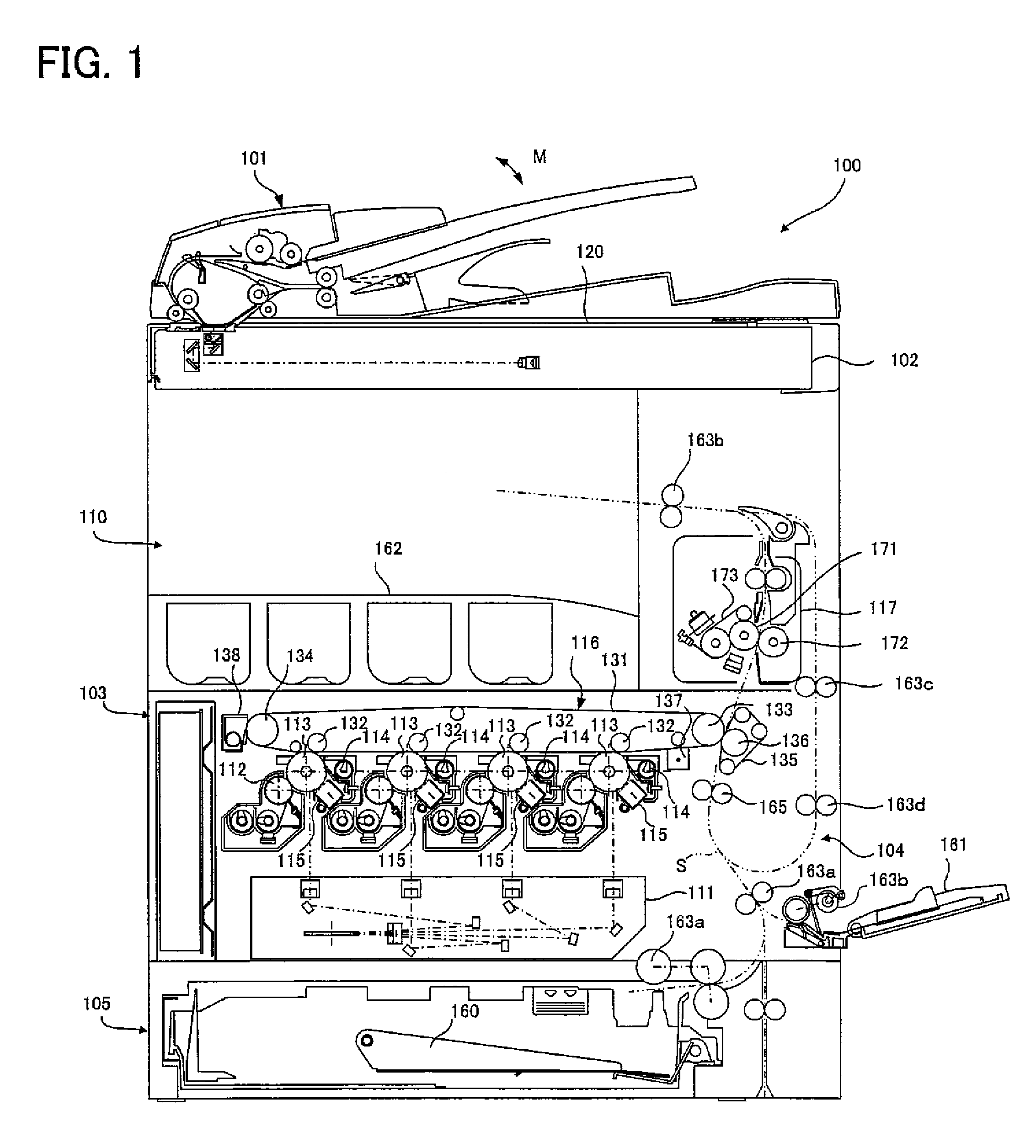

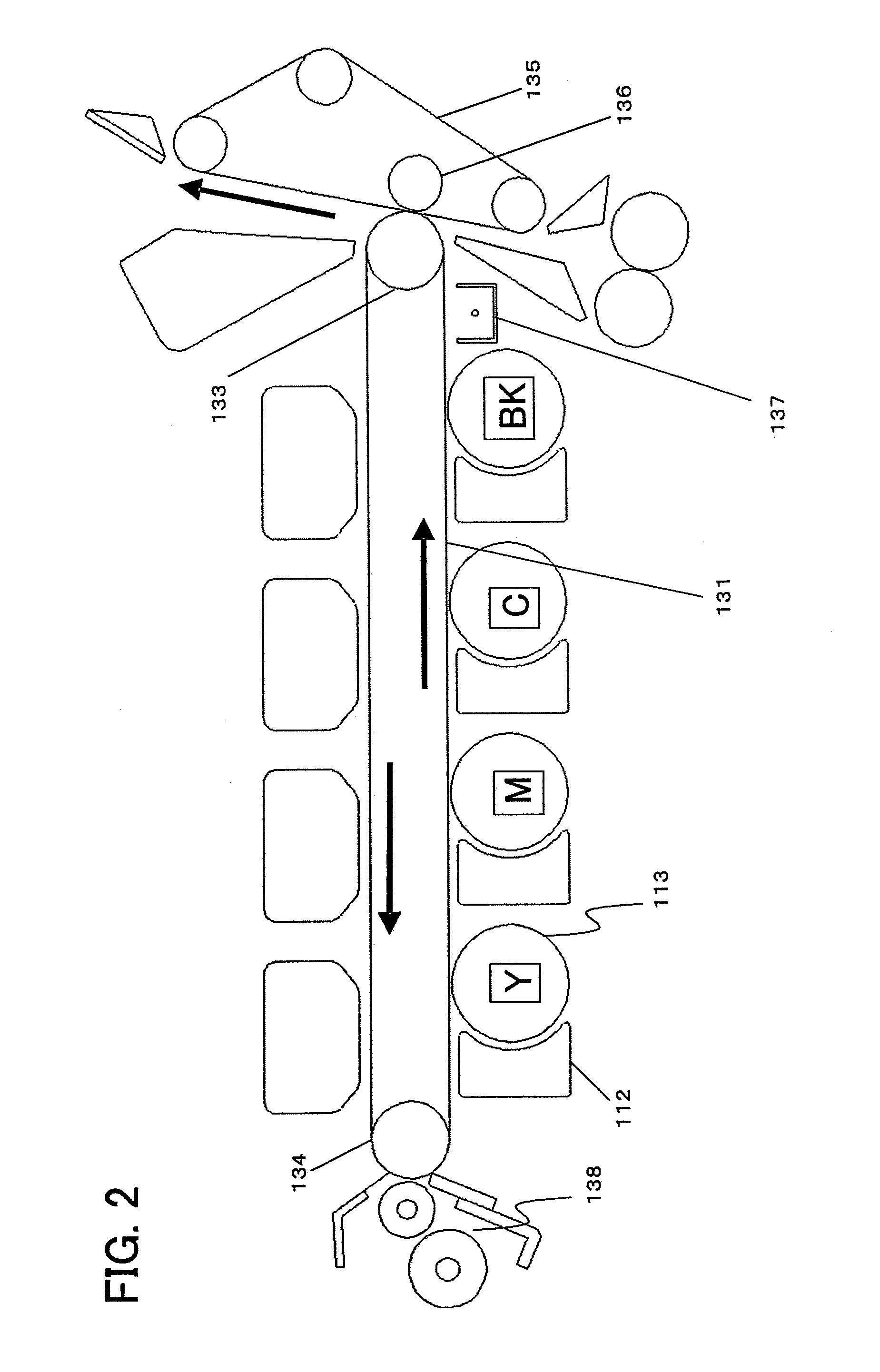

Electrophotographic apparatus

InactiveUS20040057761A1Stable cleaningElectrographic processDevelopersEngineeringElectrical and Electronics engineering

An electrophotographic apparatus comprises a photosensitive member, exposing means, and cleaning means for cleaning a residual developer from the photosensitive member, which comprises a cleaning brush brought into contact with the photosensitive member. In this case, if a brush density of the cleaning brush is D (number / mm<2>), and an area of a pixel of an electrostatic image is S (mm<2> / dot), DxS>=0.06 and D<=200 are satisfied. Thus, an image forming apparatus is provided, in which cleaning stability is improved by uniformly scraping off and dispersing the transfer residual developer from the photosensitive member.

Owner:CANON KK

Cleaning and drying device for gauze production

ActiveCN109023772AClean upStable cleaningLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater pipeEngineering

The invention provides a cleaning and drying device for gauze production and relates to the technical field of gauze cleaning and drying. The cleaning and drying device for gauze production includes acleaning tank. A water pipe box is arranged at the bottom of the cleaning box. A drying box is arranged on the left side of the cleaning box. A square rotary roller is fixedly mounted inside the cleaning box. A water injecting and pushing device is arranged at the bottom of the inner wall of the cleaning box. The top of the cleaning box is provided with a water diverting device. A water filteringdevice is arranged at the rear side of the cleaning box. The water filtering device comprises a water filtering box. A pressure roller and a conveying roller are arranged inside the drying box. A swinging water pressing device is arranged at the bottom of the pressure roller, and a ventilation and condensation device is arranged at the top of the drying box. The cleaning and drying device for gauze production has the advantages of high automation, good cleaning and drying effect, certain improvement of gauze production quality and efficiency, convenient cleaning, and reduction of labor intensity and labor cost.

Owner:陈剑璋

Medical test tube scrubbing device

InactiveCN106623309AAchieve the effect of multiple brushingReduce physical exertionHollow article cleaningMotor driveBristle

The invention discloses a medical test tube scrubbing device. The medical test tube scrubbing device comprises a base. The upper surface of the base is fixedly connected with a U-shaped plate. A motor is arranged at the bottom of the inner wall of the U-shaped plate. The output end of the motor penetrates through a first support plate and is fixedly connected with the axis position of the bottom of a driving gear, and the two ends of the first support plate are fixedly connected with the inner walls of the two sides of the U-shaped plate separately. The two sides of the driving gear are engaged with two driven gears correspondingly. Two bearings are inlaid at the two sides of the upper surface of the first support plate. According to the medical test tube scrubbing device, by improving soft bristle sleeves, when the motor drives brush rods to rotate through the driving gear, the soft bristle sleeves can be driven to rotate, cylinders are started to drive corresponding lifting plates to move up and down in sliding rails, and thus the effect of repeatedly scrubbing the inside of a test tube is achieved; and moreover, under the matching action of the two soft bristle sleeves, the experiment progress is accelerated, and the steady cleaning effect is further achieved by improving clamping devices.

Owner:苏州欣祥本机械科技有限公司

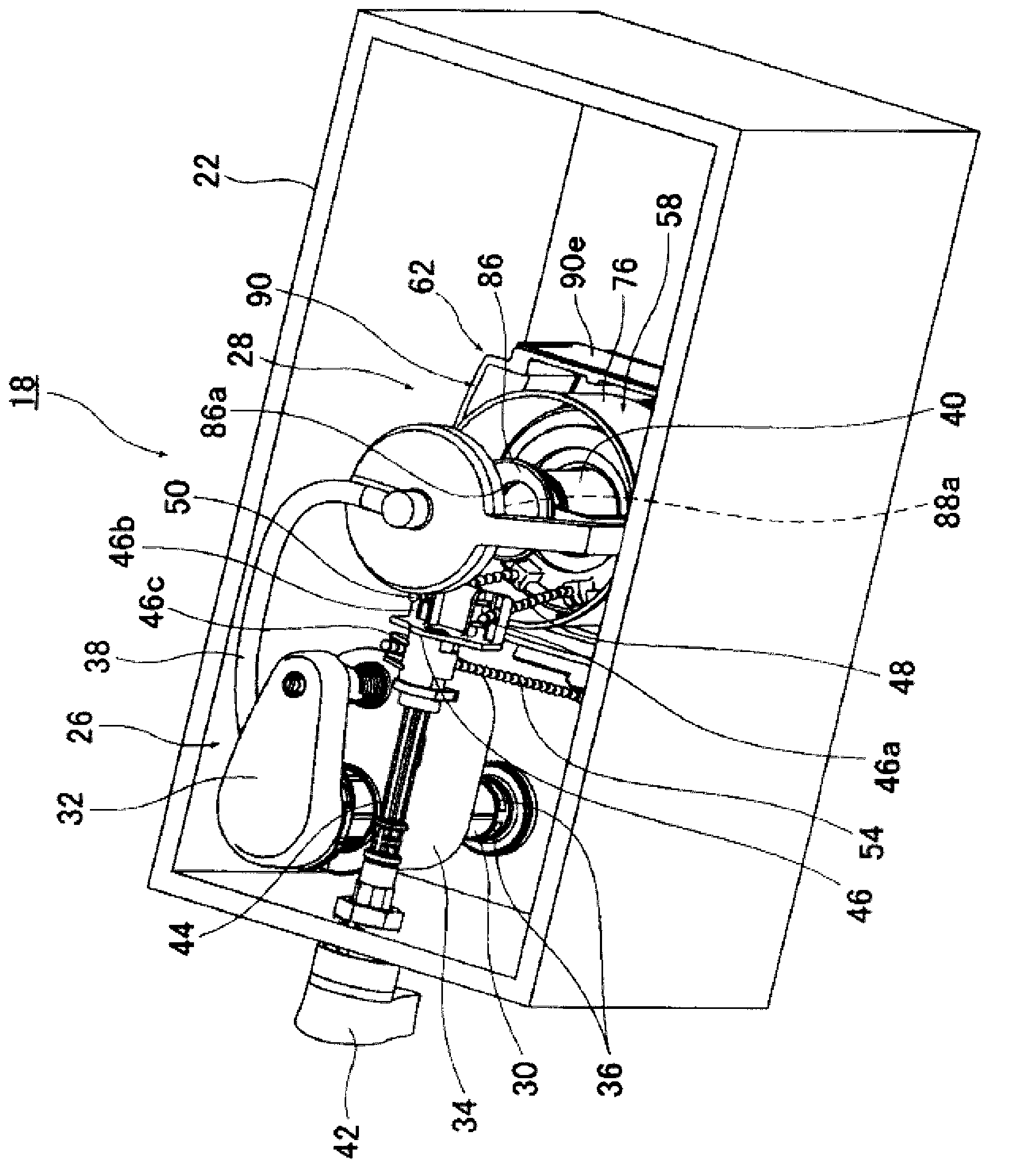

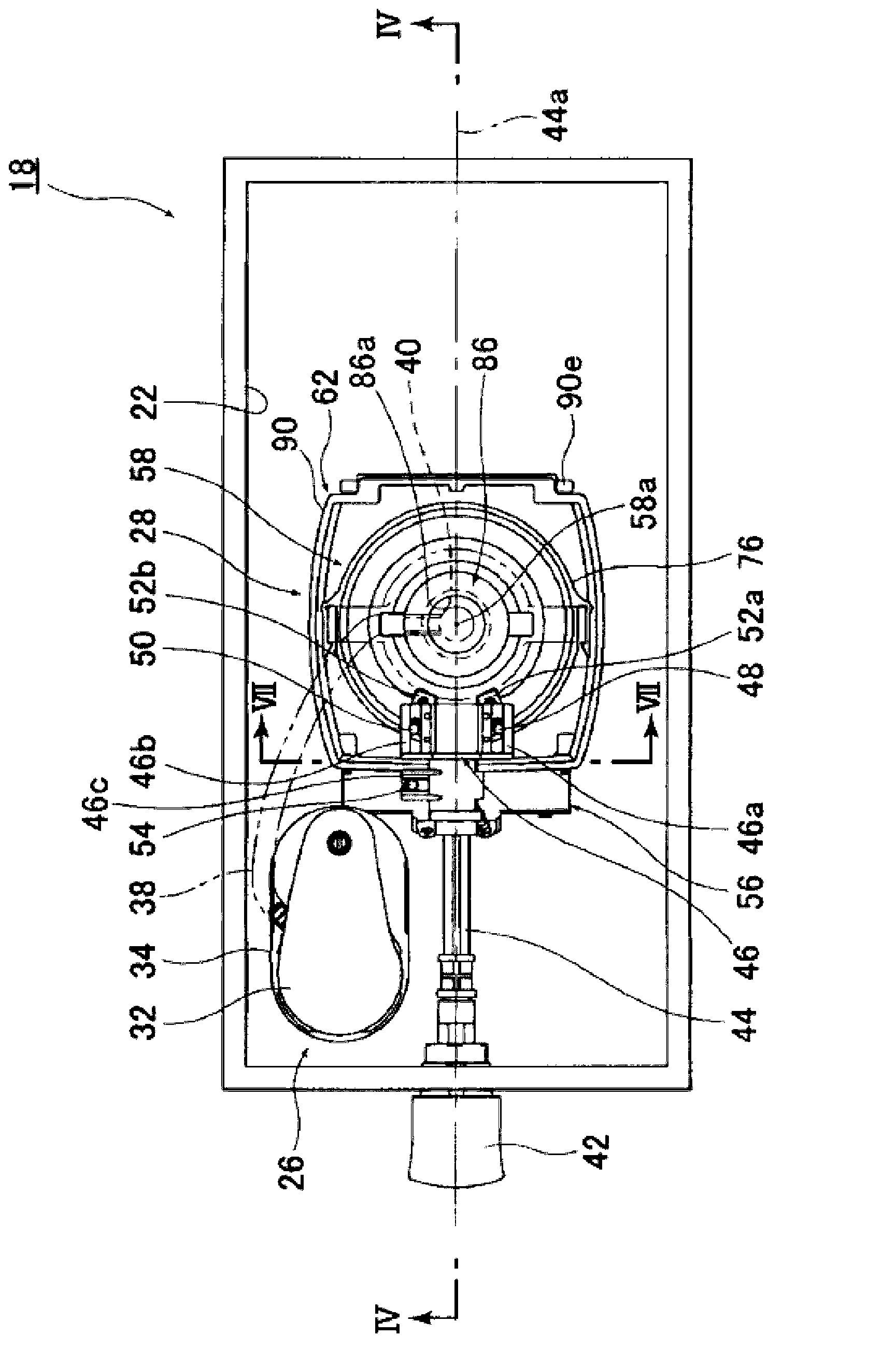

Water discharge valve device and flush water tank device with same

InactiveCN103140636AImprove supply capacityImprove reliabilityFlushing devicesWater storage tankWater tanks

The present water discharge valve device (28) is provided with: a water discharge valve unit (58) provided with a valve element (84) for opening and closing a water discharge opening (22a) and also with a control tube (76) for controlling the ascending and descending motions of the valve element; and a tube body (62) provided with a side wall (90b), an opening section (90c), and a switching valve (56), the side wall (90b) extending upward from the bottom surface of a water storage tank (22) so as to surround both the water discharge opening and the control tube of the water discharge valve unit and having an open upper end, the opening section (90c) being formed so as to penetrate through the side wall, and the switching valve (56) being attached to the side wall so that the switching valve (56) can open and close the opening section. A communication opening (82) for connecting the tube body and the water discharge opening is formed in a side surface which extends from the control tube of the water discharge valve unit to the water discharge opening. The opening section of the tube body is disposed at the same height as or below the upper end of the communication opening.

Owner:TOTO LTD

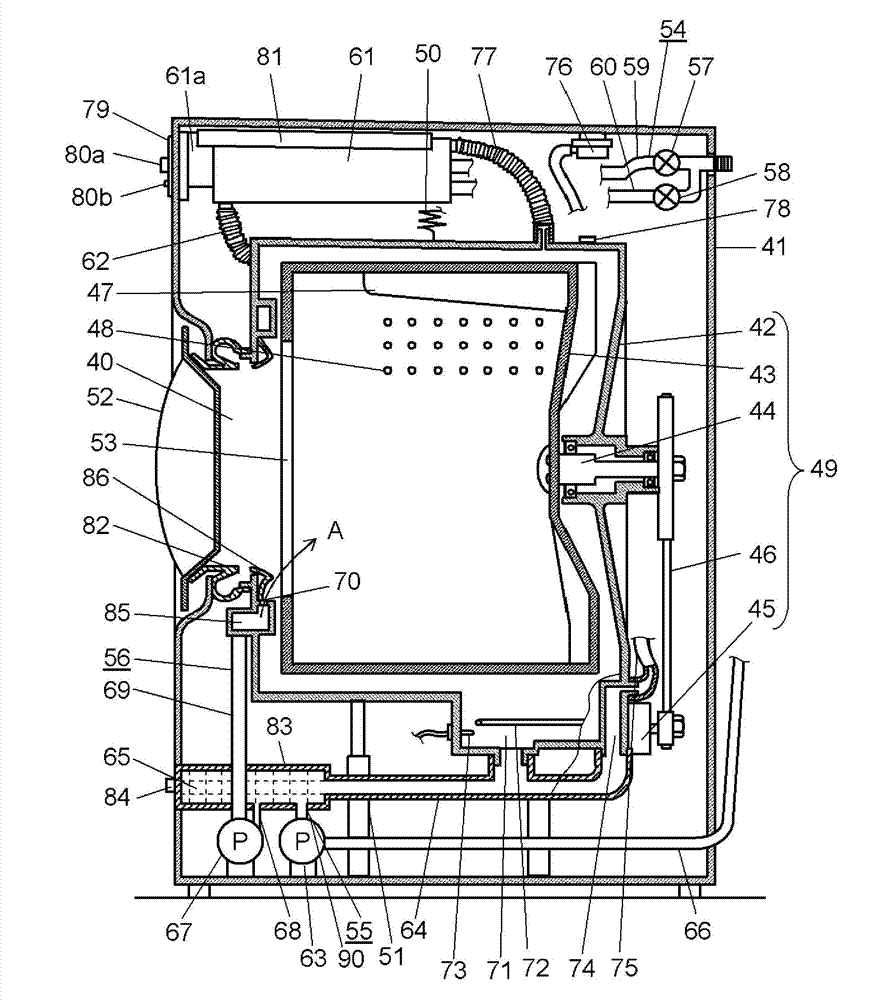

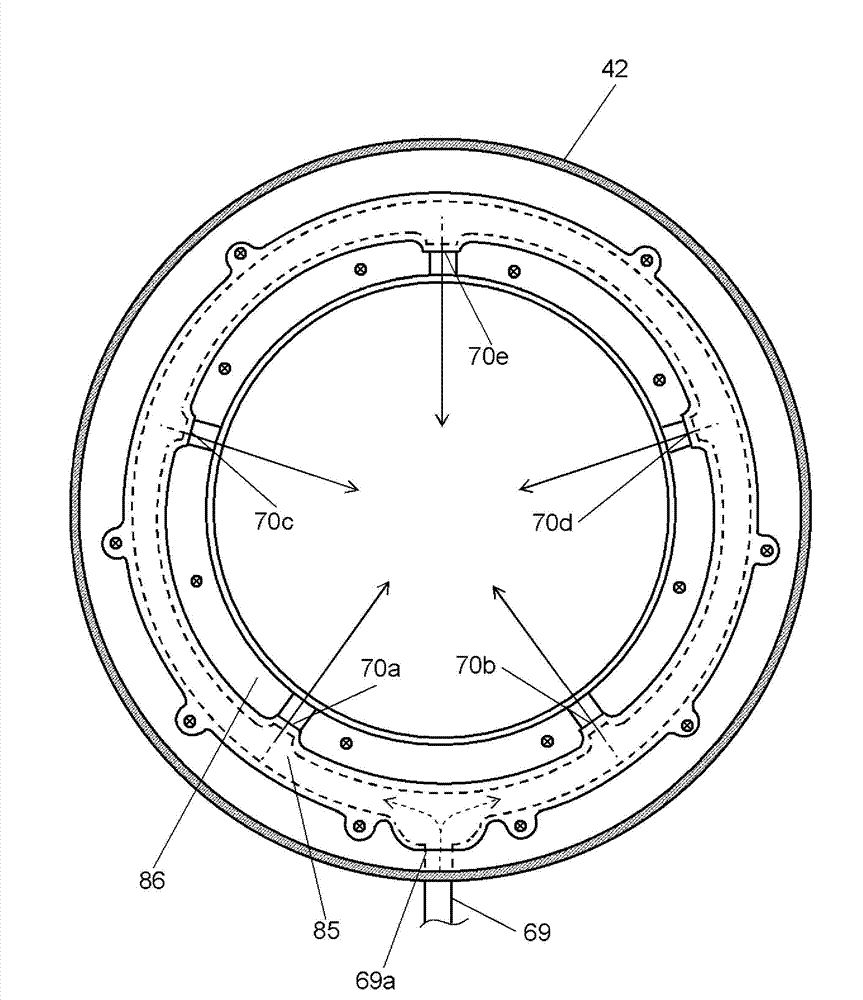

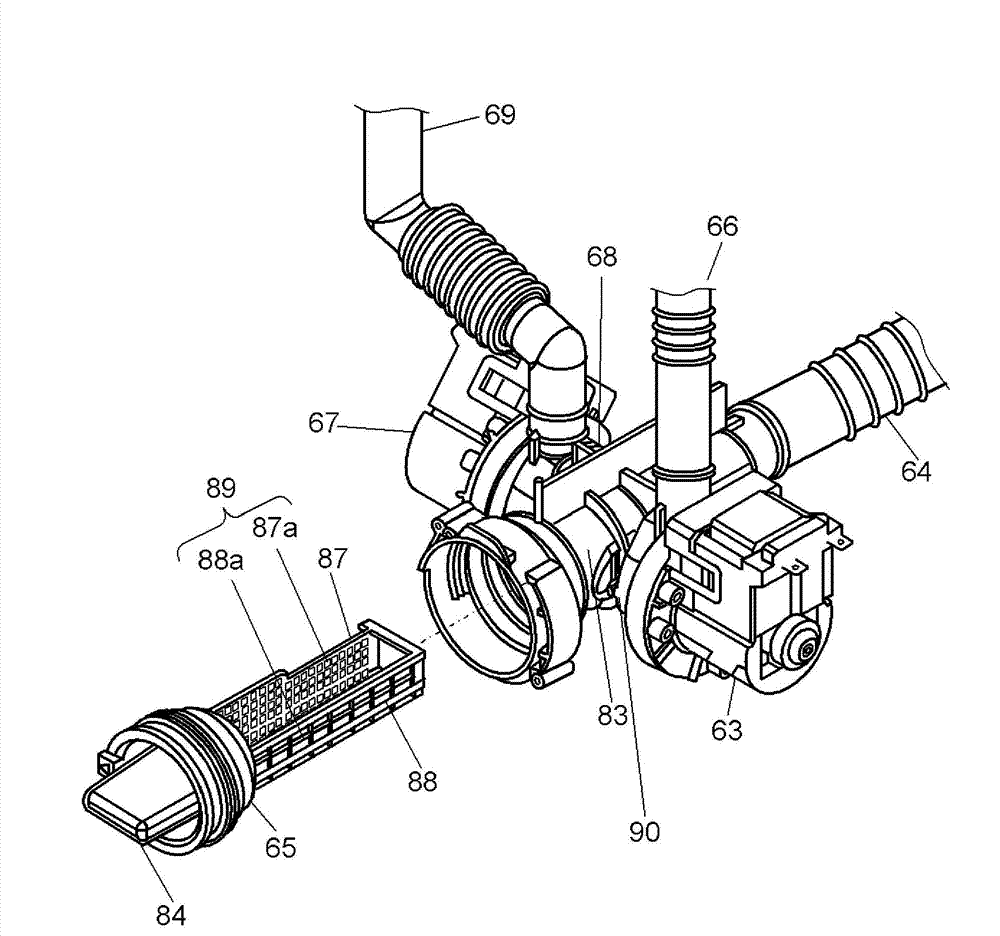

Drum-type washing machine

ActiveCN103052744AStable cleaningOther washing machinesTextiles and paperWater dischargeCirculating pump

This drum-type washing machine comprises: a rotating drum (43); a water tank (42); a motor (45); a filter case (83) having a built-in filter (65), the filter case communicating with the water tank (42) via a water drainage pipe (64) connected to a bottom part of the water tank (42); a circulation pump communicating with the filter case (83) via a circulating water intake pipe (68) connected to the filter case (83); a flow path (85) formed inward in a front part of the water tank (42), the flow path communicating with the circulation pump (67) via a circulating water discharge pipe (69) connected to the circulation pump (67); a plurality of jet ports (70) for discharging washing water into the water tank (42), the jet ports being provided to the inner peripheral side of the flow path (85); and a controller (81). The opening area of a jet port (70e) provided to the position farthest from a connecting part (69a) between the circulating water discharge pipe (69) and the flow path (85) is greater than the opening area of jet ports (70a, 70b) provided to the positions nearest the connecting part (69a).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

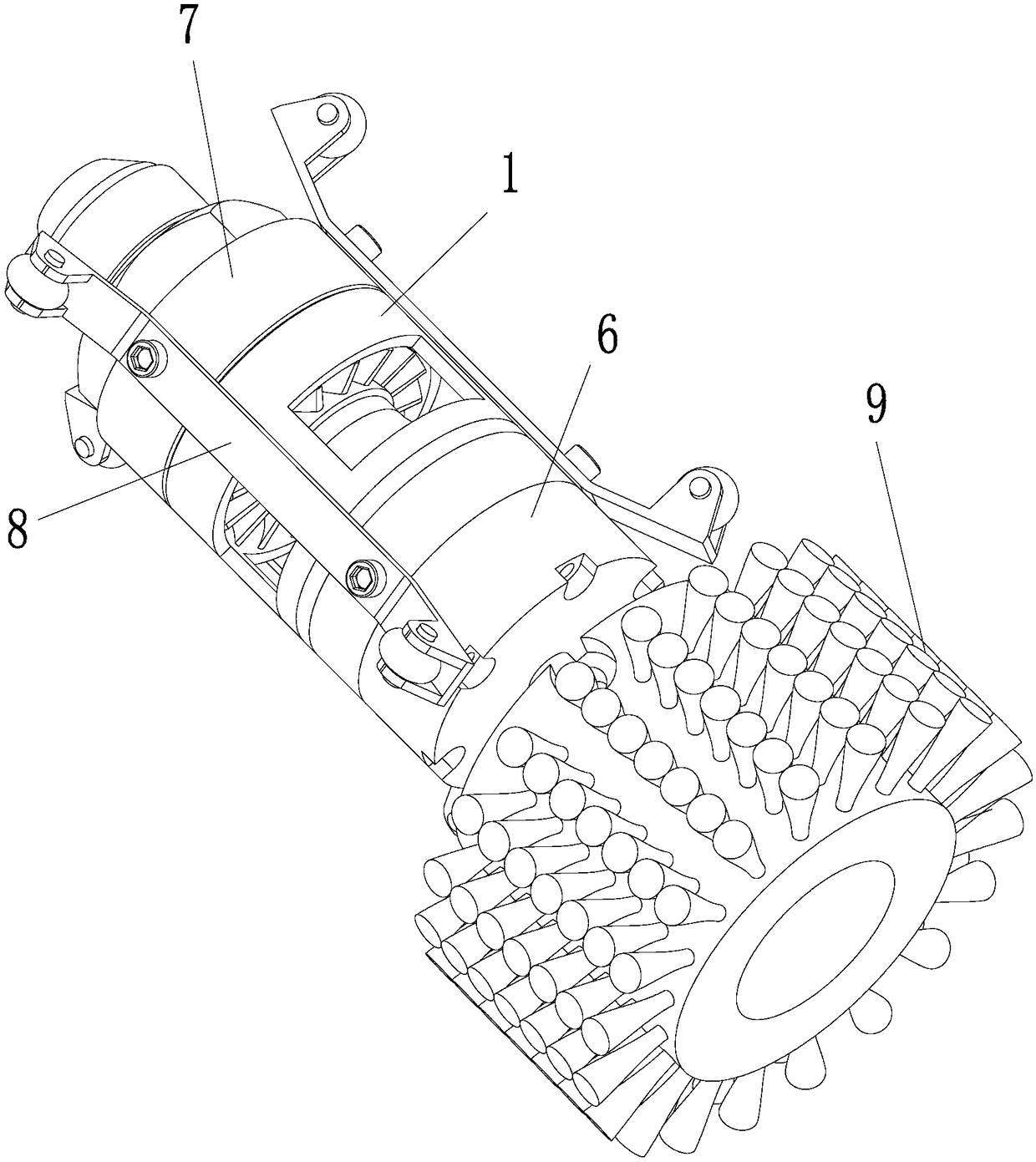

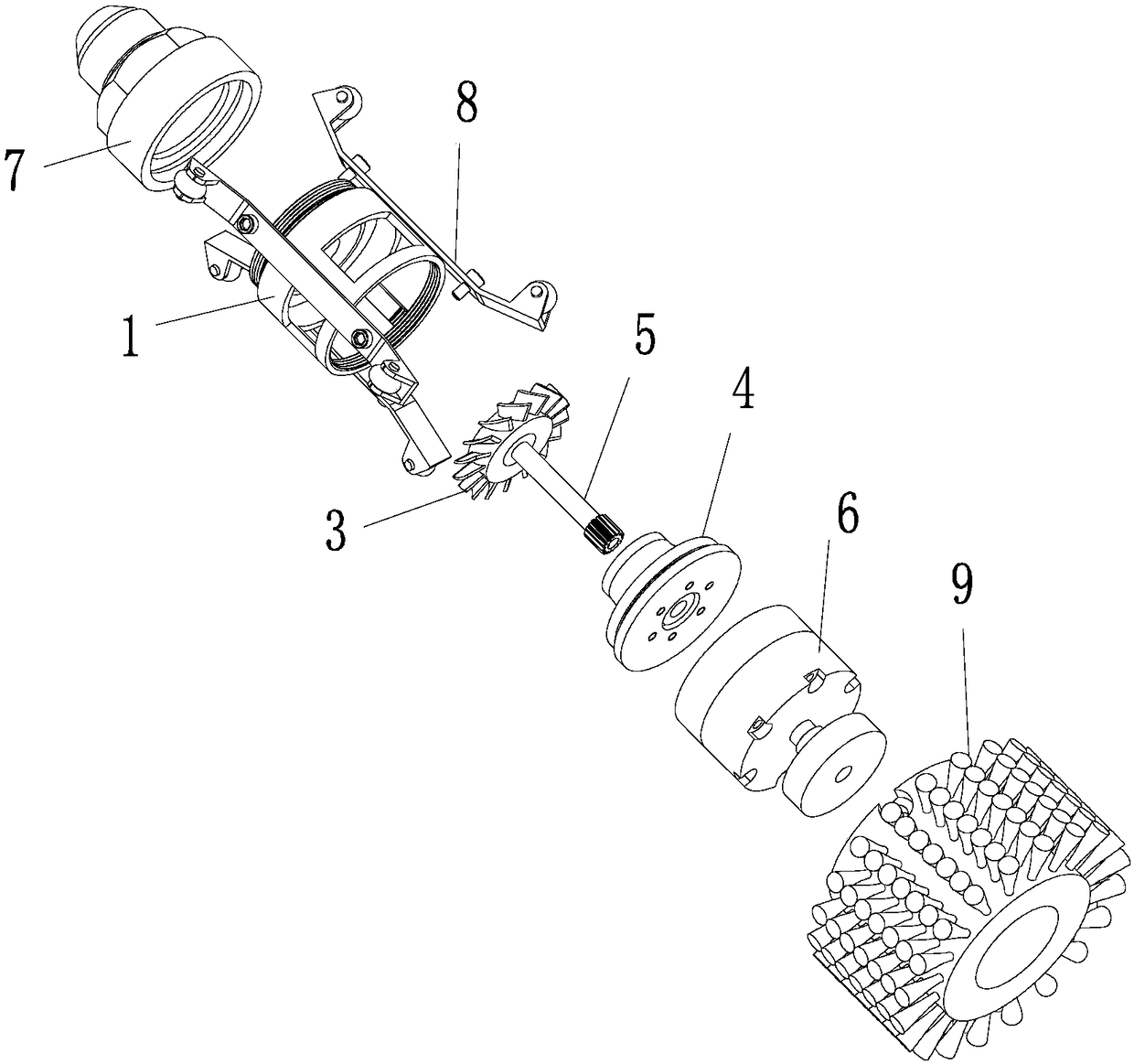

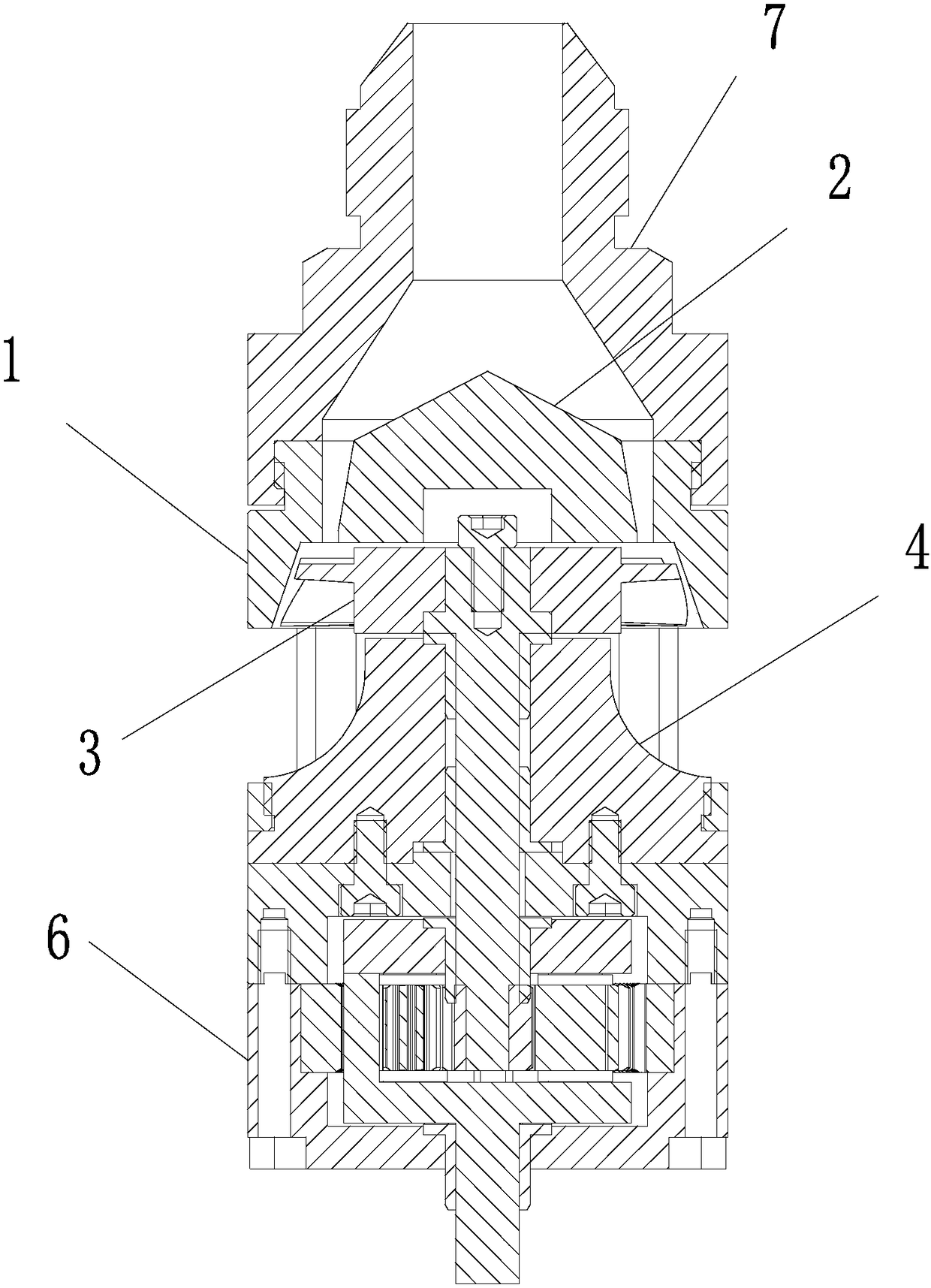

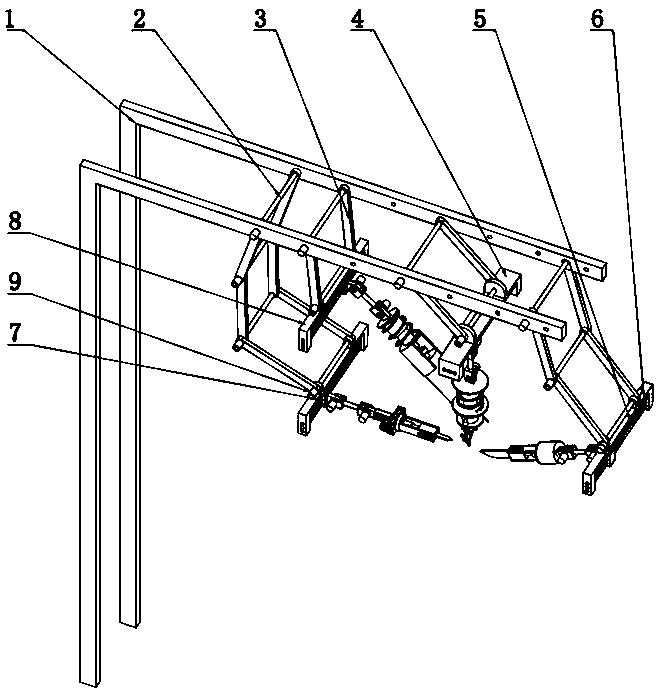

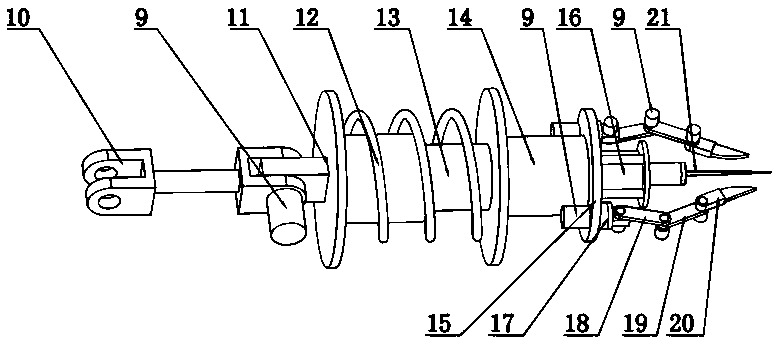

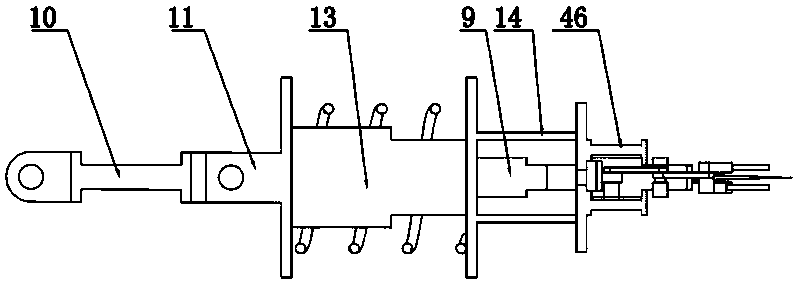

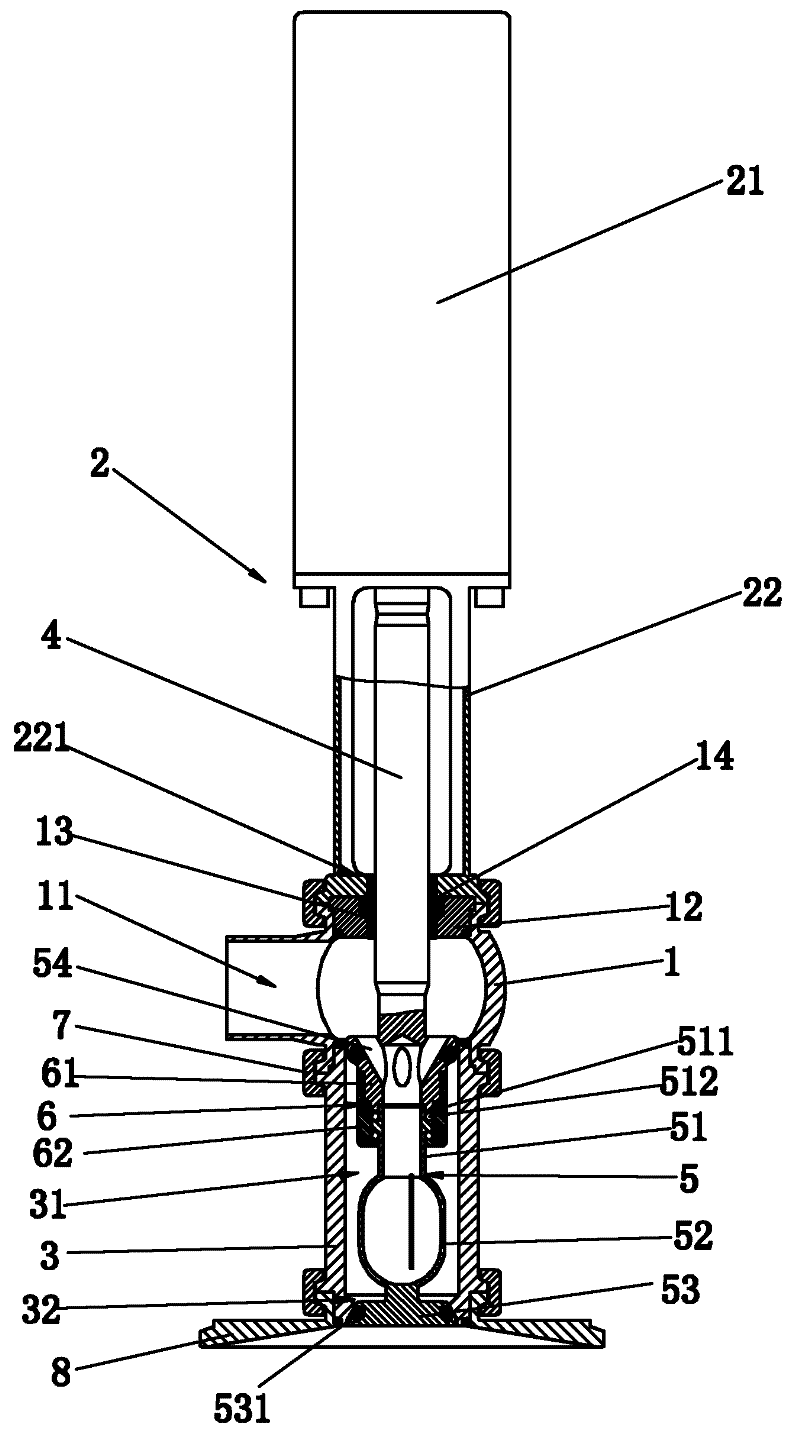

Lipomyoma excision robot

ActiveCN108714049AIncrease freedomWide range of cuttingExcision instrumentsSurgical manipulatorsMoving frameInjector

The invention provides a lipomyoma excision robot. The lipomyoma excision robot comprises a main body frame, a take-out part, an injection part, a cross-cutting part, an incision part and the like; the take-out part comprises a take-out part connecting rod, an electric cylinder base, a claw head, a needle seat and the like; the injection part comprises an injector, an injector holder, an injectionpart connecting rod and the like; the cross-cutting part comprises a cross-cutting part connecting rod, a telescopic electric cylinder seat, a lateral translation block, a cross-cutting cutter head and the like; the incision part comprises an incision cutter head, an incision cutter holder, an incision part connecting rod and the like; a main body of the robot is composed of the main body frame,a rotating rod, a sliding block moving frame and the like; the sliding block moving frame is provided with four mechanical arms of the take-out part, injection part, cross-cutting part and incision part; the injection part performs local anesthesia on the skin, the incision part cuts a part of the skin, a needle of the take-out part is inserted into a tumor body, and the claw head of the take-outpart and the cross-cutting part cut the periphery of the tumor body, so that the tumor body is separated, and the lipomyoma is removed.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

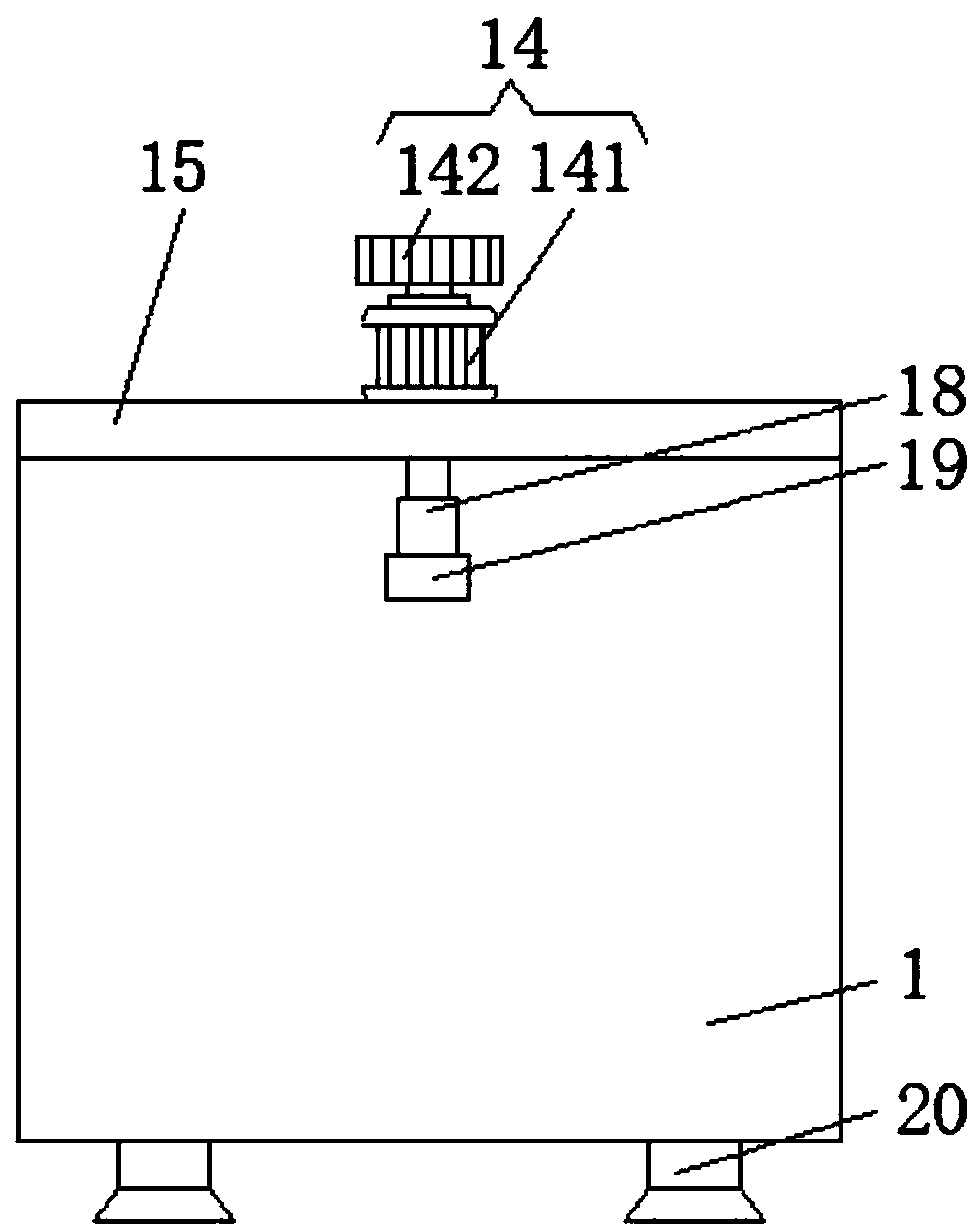

Filter screen cleaning device of air conditioning refrigeration equipment

InactiveCN107497184AEasy to clean upClean upLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir conditioning

The invention relates to a cleaning device, in particular to a filter screen cleaning device of air conditioning refrigeration equipment. The invention aims to solve the technical problem that the filter screen cleaning device, which can simultaneously carry out double-face cleaning on the filter screen and can move, of the air conditioning refrigeration equipment is provided. In order to solve the technical problem, the invention provides the filter screen cleaning device of the air conditioning refrigeration equipment. The filter screen cleaning device comprises a cleaning box and the like, wherein a clamping mechanism is connected in the cleaning box, and a cleaning mechanism is connected in the cleaning box. According to the filter screen cleaning device of the air conditioning refrigeration equipment, an arranged clamping block can tightly clamp the filter screen so as to be favorable for users to carry out cleaning work on the filter screen, a movement rod is manually pulled, a lifting rod is vertically moved to clean the clamped filter screen, and a effects that the filter screen can be simultaneously subjected to double-face cleaning and the filter screen can be stably clamped for cleaning is achieved.

Owner:周亮

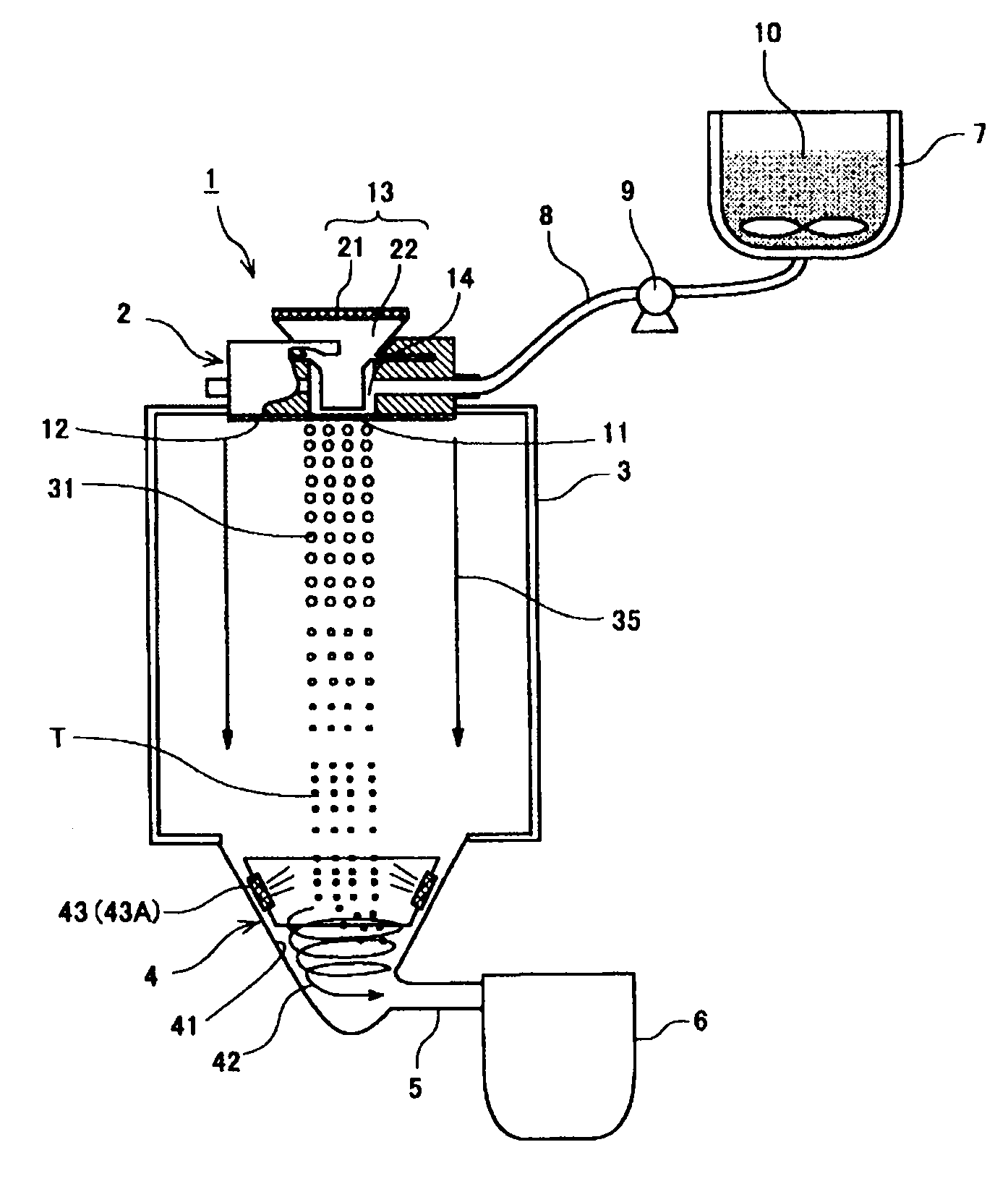

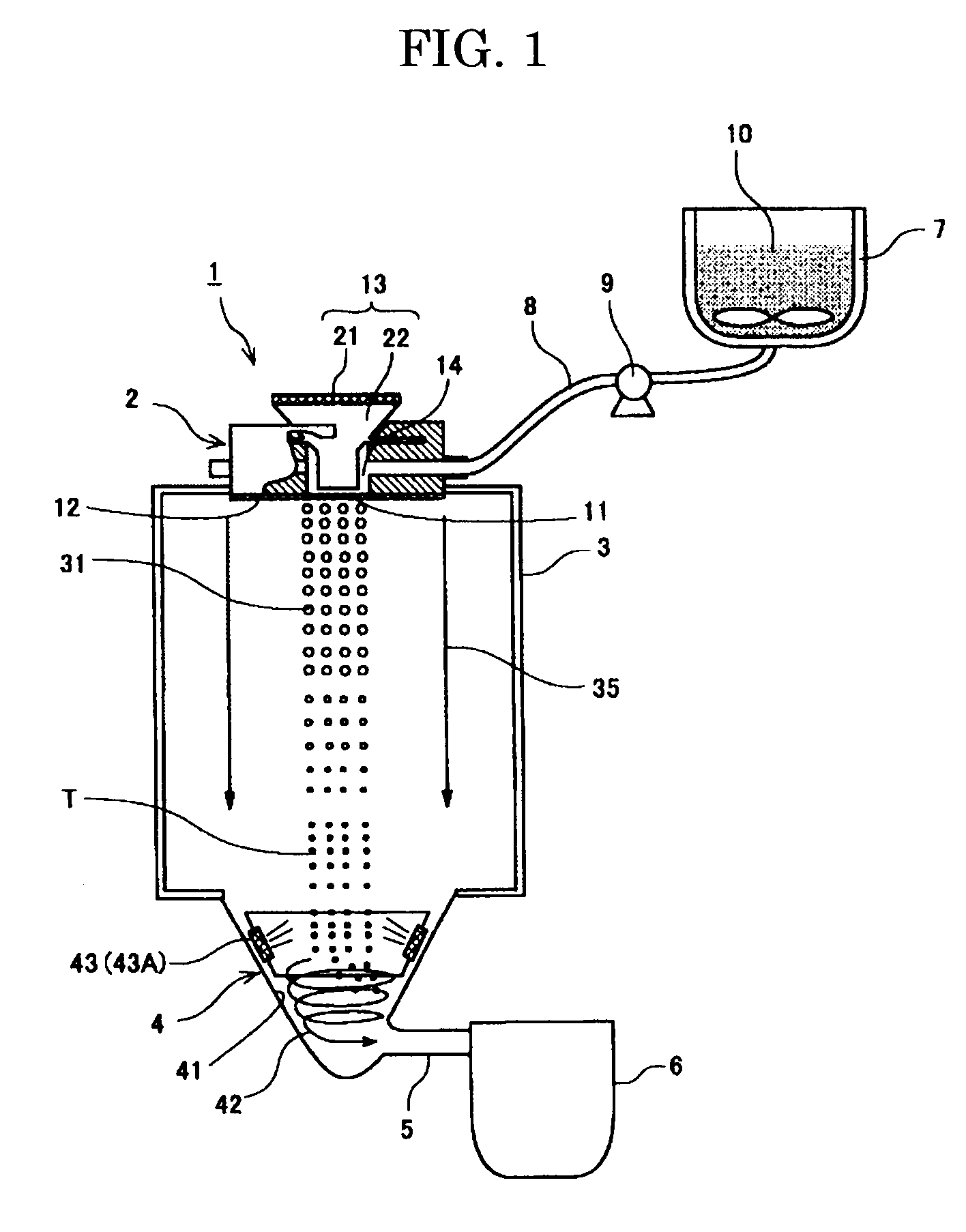

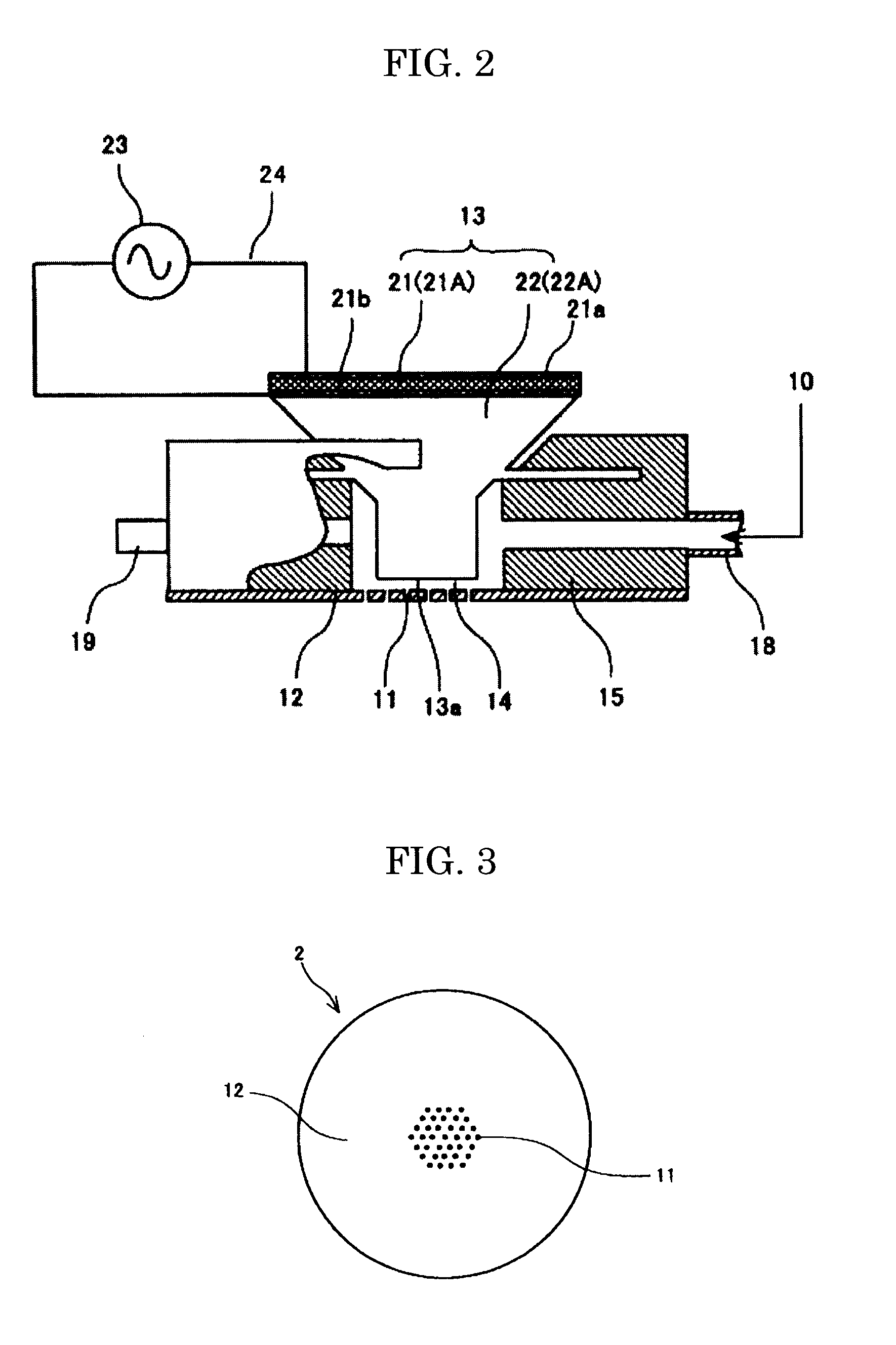

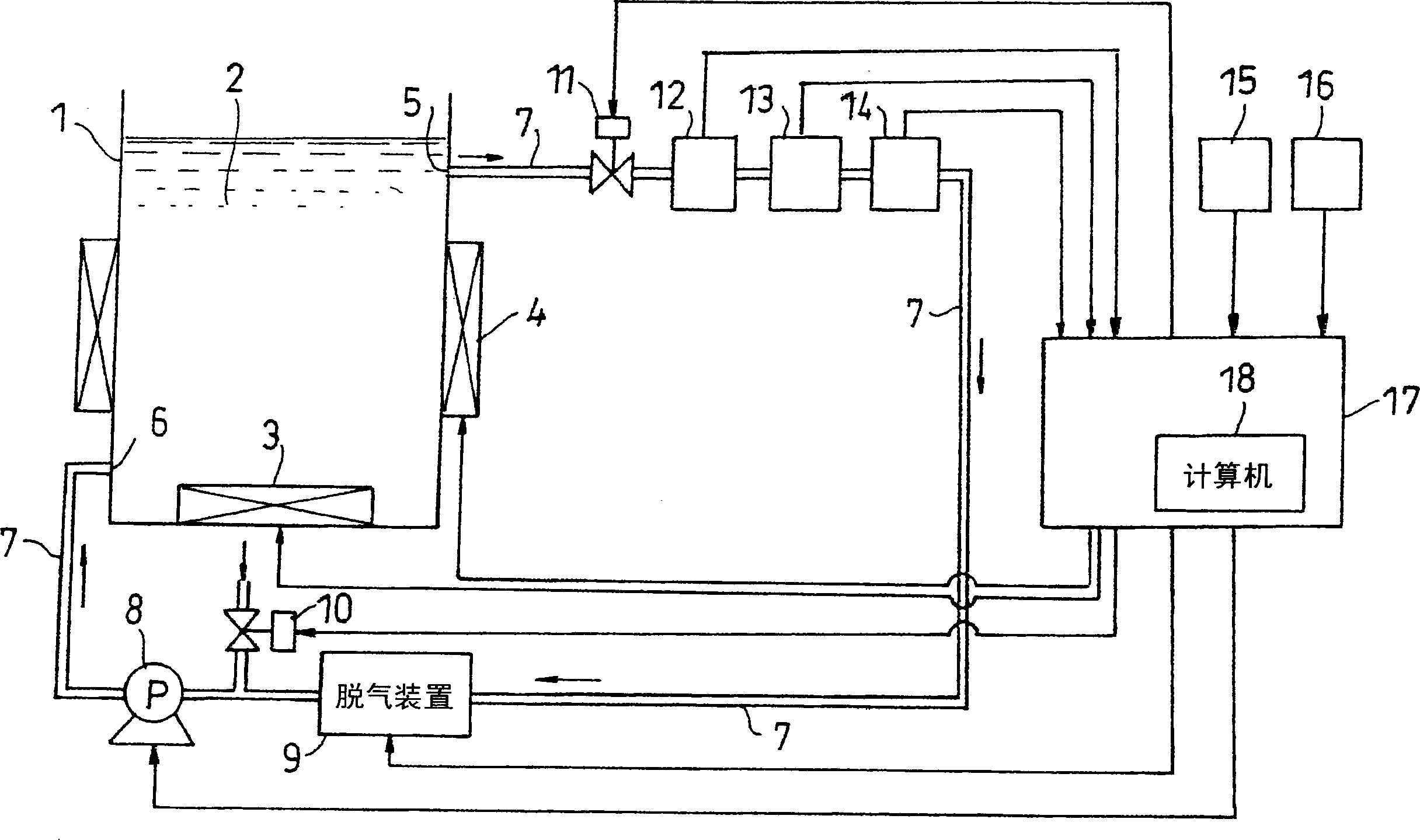

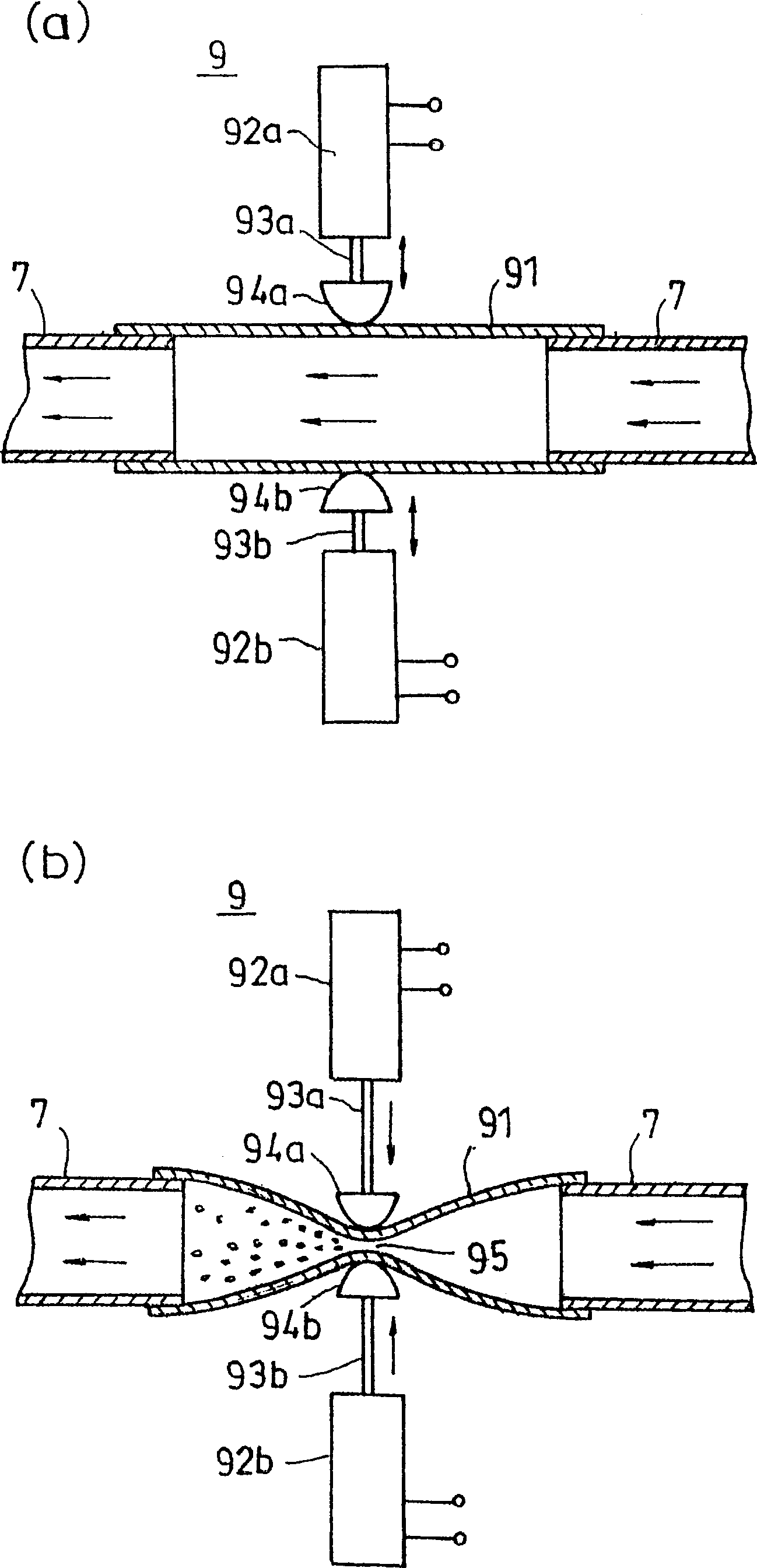

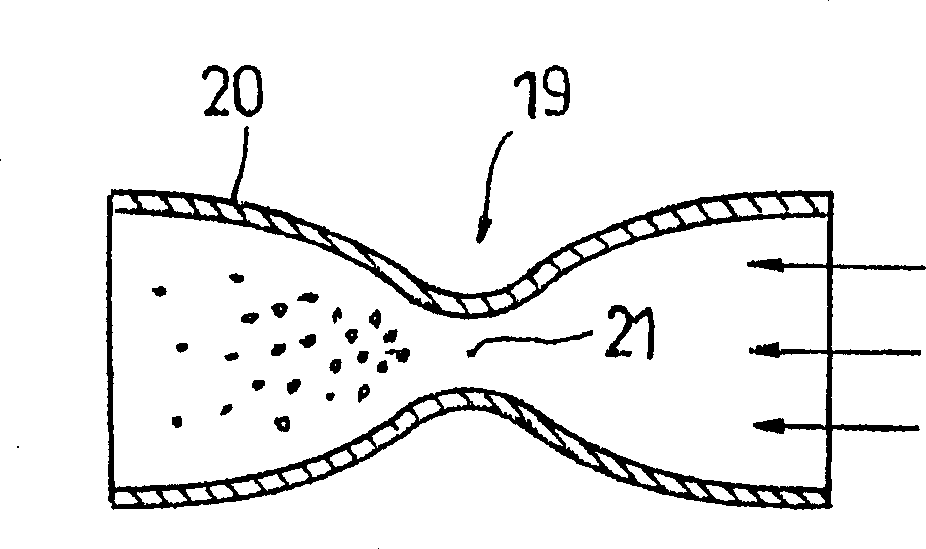

Degassing apparatus and ultrasonic wave washing apparatus using the same

ActiveCN1895719ASimple and reliable removalSimple structureLiquid degasificationCleaning using liquidsCavitationMegasonic cleaning

A cleaning-liquid circulation path (7) is formed so that cleaning liquid in a cleaning tank (1) is suctioned by a circulating pump (8) and circulated through a predetermined path and then, returned to the cleaning tank again. A deaeration device (9) for bubbling dissolved air in the cleaning liquid by cavitation is connected on the way of the cleaning-liquid circulation path so as to bubble the dissolved air in the cleaning liquid flowing through the cleaning-liquid circulation path by the deaeration device, and the bubbled dissolved air flows back to the cleaning tank together with the cleaning liquid so that the bubbled dissolved air is ejected from the liquid surface of the cleaning tank to the outside of the tank. Moreover, a propeller-type pump is used as the circulating pump, and the dissolved air concentration of the cleaning liquid is controlled within a range of 2.5 to 3.5 mg / l.

Owner:KAIJOO KK

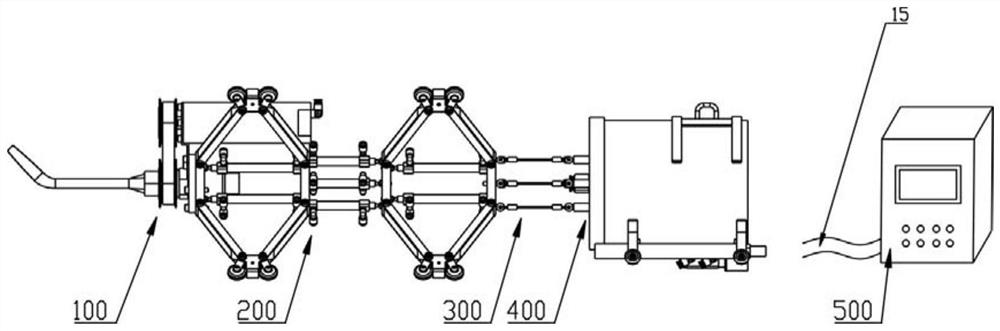

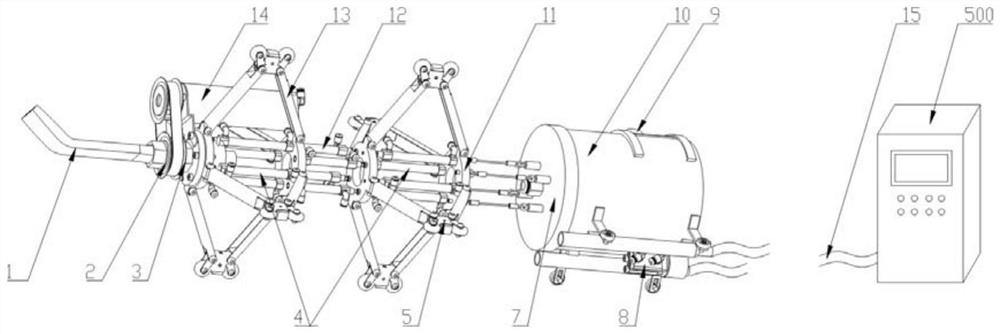

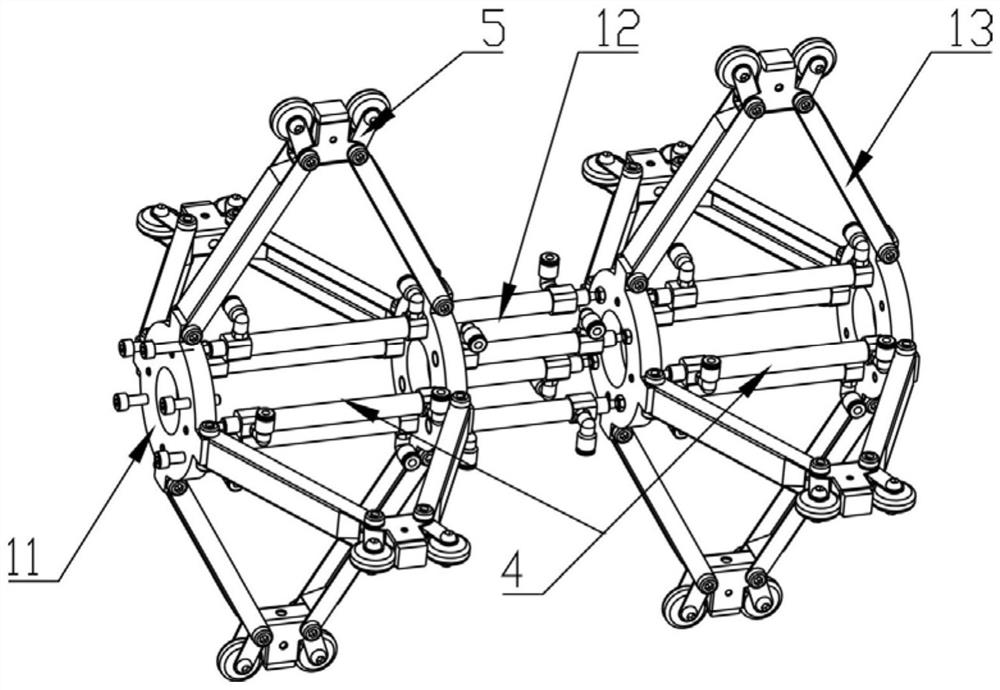

Peristaltic dry ice cleaner in pipeline

The invention provides a peristaltic dry ice cleaner in a pipeline. The peristaltic dry ice cleaner comprises a peristaltic crawling mechanism used for achieving peristaltic movement in the pipeline,a nozzle mounted on the peristaltic crawling mechanism and used for spraying out dry ice and gas and a dry ice bearing and crushing mechanism. The dry ice bearing and crushing mechanism is connected with the peristaltic crawling mechanism so as to move along with the peristaltic crawling mechanism, and the dry ice bearing and crushing mechanism is provided with a storage cavity used for bearing dry ice, a crushing cavity used for crushing the dry ice and a dry ice particle conveying pipe used for communicating the crushing cavity with the nozzle. In the peristaltic dry ice cleaner, the peristaltic crawling mechanism can stably move in the pipeline, the dry ice bearing and crushing mechanism can carry dry ice, and gas with dry ice particles is sprayed out through the nozzle; and due to thefact that the dry ice cleaner does not need to move by carrying a water pipe filled with liquid, the whole dry ice cleaner can conveniently move in the pipeline by means of the peristaltic crawling mechanism, and the inner wall of the pipeline can be stably cleaned.

Owner:XIAMEN UNIV OF TECH

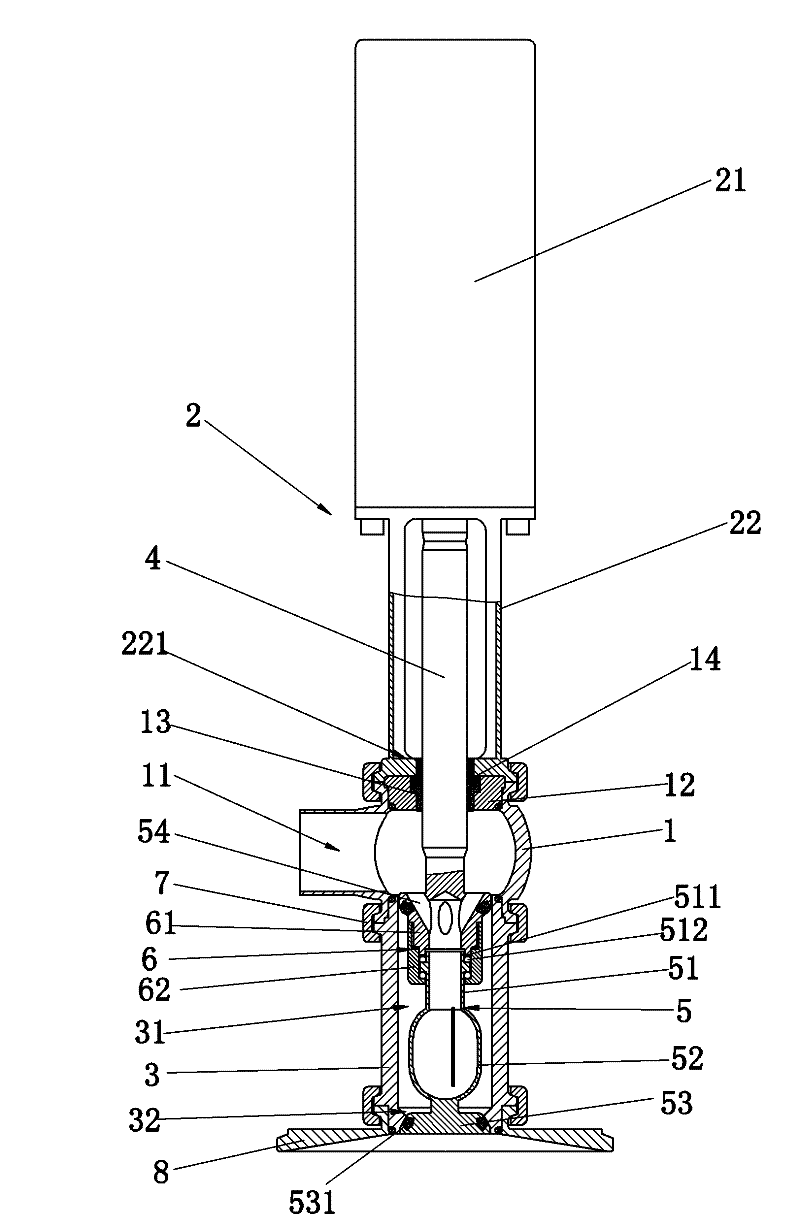

Telescopic cleaning valve

The invention discloses a telescopic cleaning valve. The valve comprises a valve body and a cleaning ball in the valve body, wherein a cleaning solution inlet is arranged on one side of the valve body; an actuator is arranged above the valve body, and comprises an actuation system and a bracket; the bracket is matched with the valve body, and the matching position is sealed; a valve rod is arranged above the cleaning ball; the cleaning ball is fixed at one end of the valve rod, and can rotate relative to the valve rod; the other end of the valve rod extends and passes through the bracket, and is fixed on the actuator; the valve rod can make telescopic motion under driving of the actuator; and a cavity is arranged under the valve body for placement of the cleaning ball. The telescopic cleaning valve can be flexed freely, the cleaning ball is retracted into the cavity under the action of the valve rod after cleaning is completed, and the cleaning ball is protected from damage or pollution; furthermore, the cleaning ball can be pushed out by the valve rod under driving the actuator in cleaning, and rotates under the action of pressure of the cleaning solution to steadily clean cleaned equipment, so that no sanitary blind angle exists.

Owner:浙江奥米科技有限公司

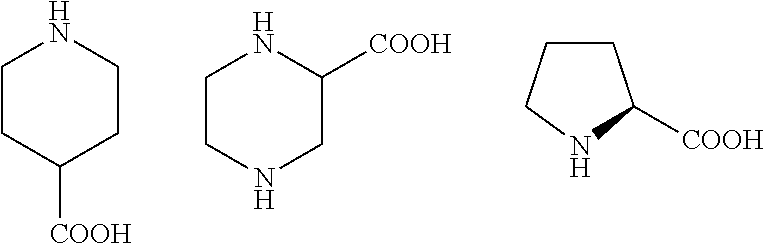

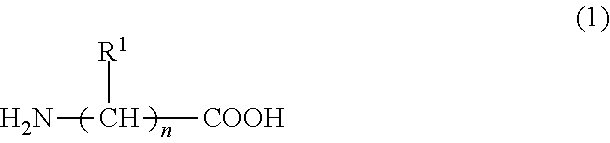

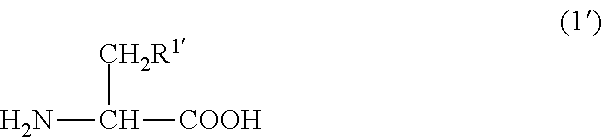

Cleaning agent for metal wiring substrate, and method for cleaning semiconductor substrate

InactiveUS20160060584A1Without impairing flatnessLong maintenance periodNon-surface-active detergent compositionsDetergent mixture composition preparationTectorial membraneCleaning methods

It is a subject of the present invention to provide a cleaning agent for a substrate having a metal wiring, and a cleaning method for a semiconductor substrate comprising that the cleaning agent is used, by which following effects (1) to (5) are obtained, in a cleaning process after chemical mechanical polishing (CMP) in a manufacturing process of a semiconductor device. (1) Residues of fine particles (polishing agents) used in the CMP process, fine particles (metal particles) derived from a polished metal, an anticorrosive, and the like, can be removed sufficiently. (2) A coating film (protective film: oxidation resistant film) on a surface of the metal wiring, containing a complex between an anticorrosive, such as benzotriazole or quinaldic acid, and a surface metal of the metal wiring, formed in the CMP process, can be removed (stripped) sufficiently. (3) An oxide film containing a metal oxide can be formed after removal (stripping) of the coating film. (4) A semiconductor substrate can be obtained stably for a long period of time, without impairing flatness of the surface of the metal wiring (the surface of the oxide film containing the metal oxide), even leaving a substrate after the cleaning process after the CMP. (5) It is hard to deteriorate even after using the cleaning agent for a long period of time.The present invention relates to a cleaning agent for a substrate having a metal wiring, comprising an aqueous solution containing (A) carboxylic acid having a nitrogen-containing heterocyclic ring and (B) alkylhydroxylamine, and having a pH of 10 or higher, as well as a cleaning method for a semiconductor substrate, comprising that the cleaning agent is used.

Owner:WAKO PURE CHEMICAL INDUSTRIES

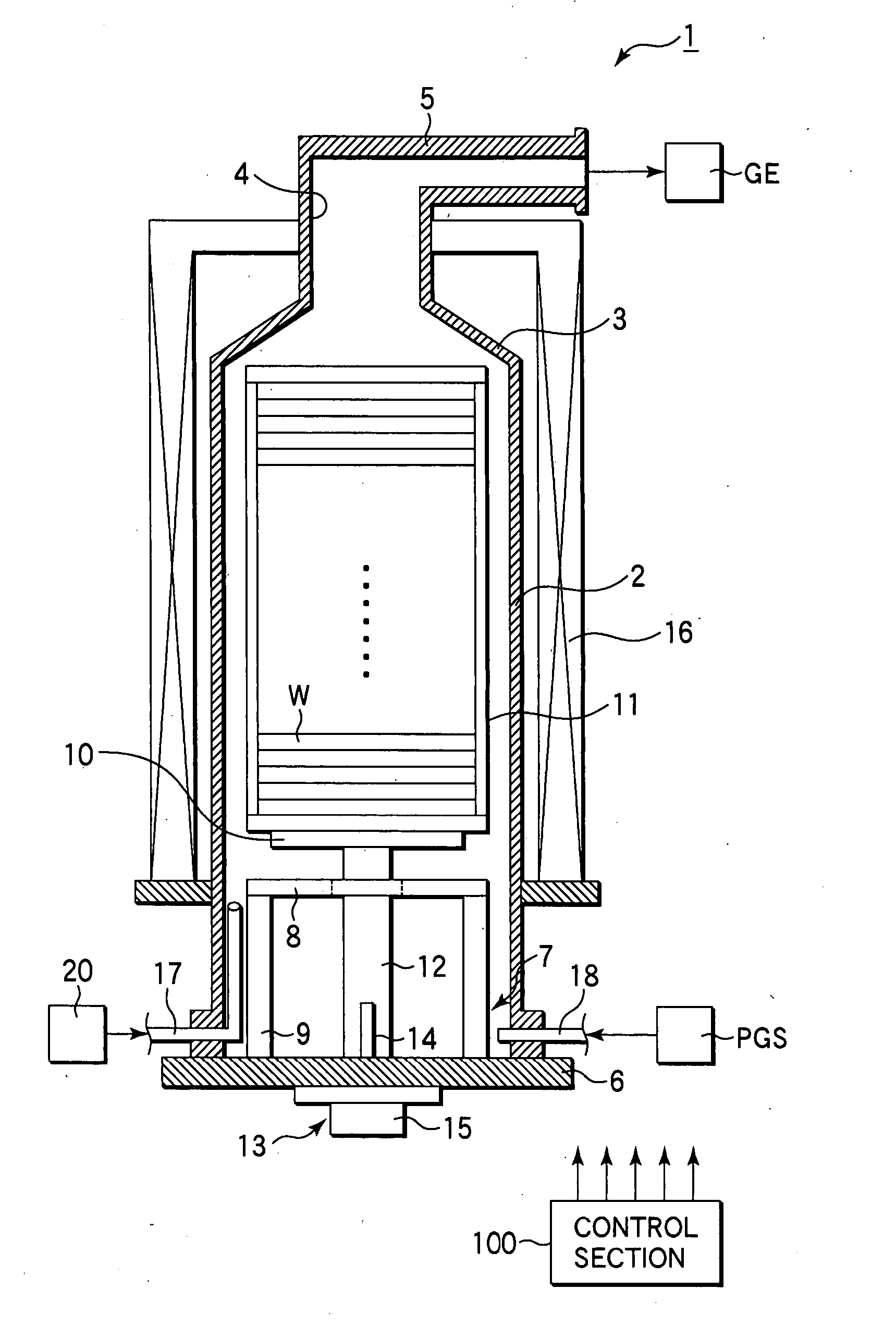

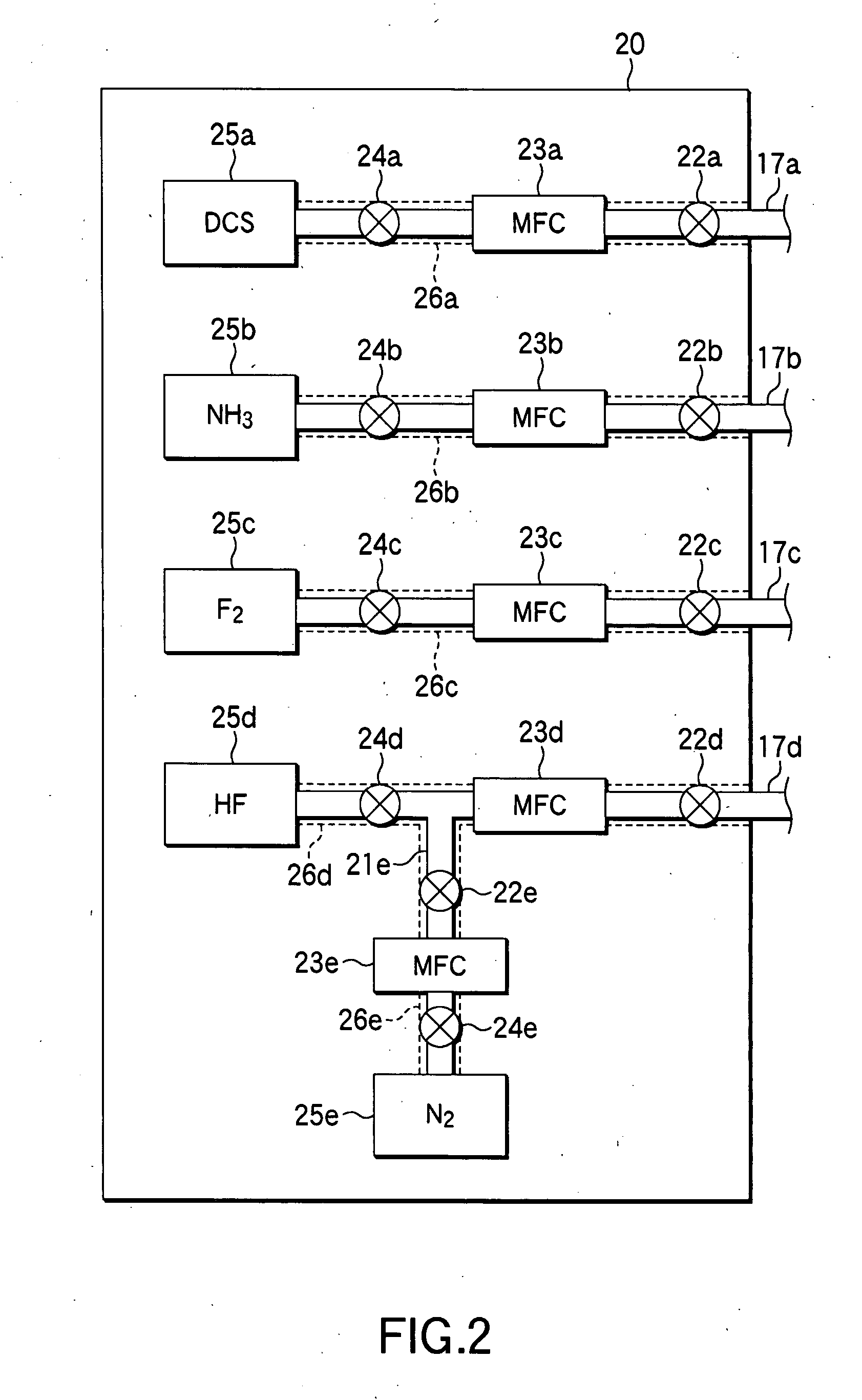

Film formation apparatus for semiconductor process and method for using the same

ActiveUS20080076264A1Stable cleaningDecrease in of of componentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProcess engineering

A method for using a film formation apparatus for a semiconductor process forms a first atmosphere inside an upstream gas passage between a gas supply source of a halogen acidic gas and a flow rate controller. The first atmosphere is set for the halogen acidic gas to have an average molecular weight of 20 or more and 23 or less. Further, the using method supplies the halogen acidic gas from the gas supply source through the upstream gas passage having the first atmosphere thus formed and the flow rate controller, thereby supplying a cleaning gas containing the halogen acidic gas into a reaction chamber of the film formation apparatus. A by-product film deposited on an inner surface of the reaction chamber is etched and removed by use of the cleaning gas thus supplied.

Owner:TOKYO ELECTRON LTD

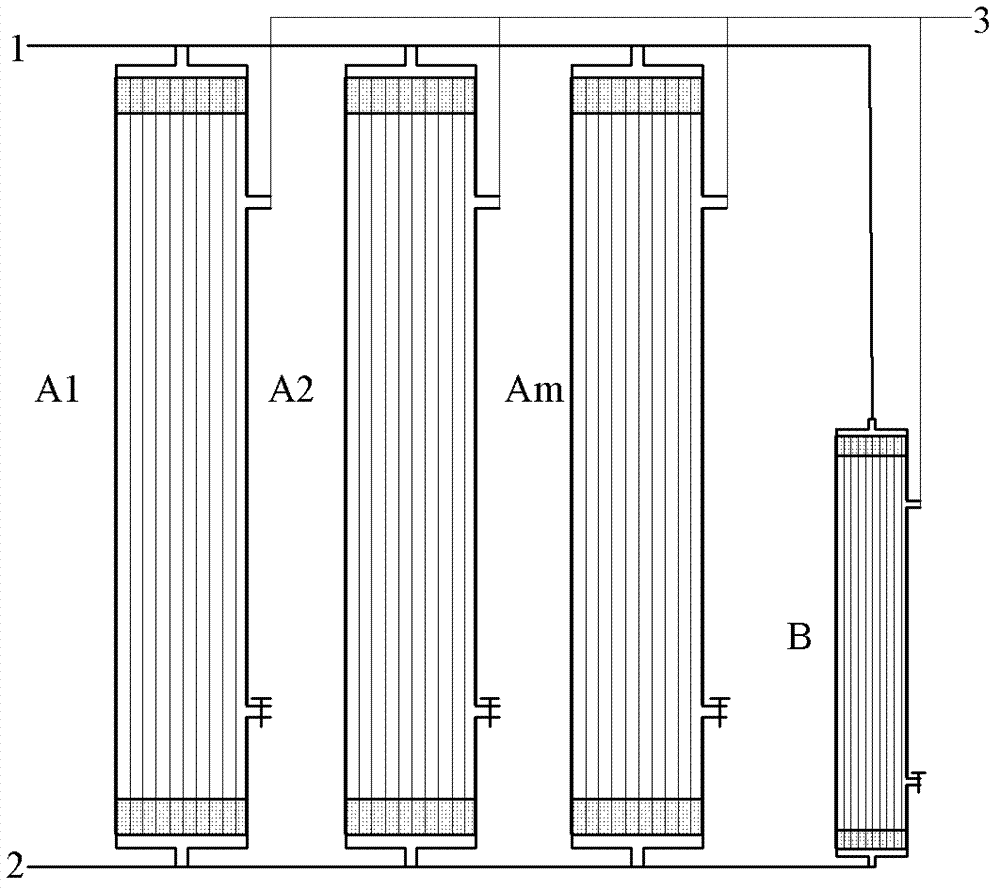

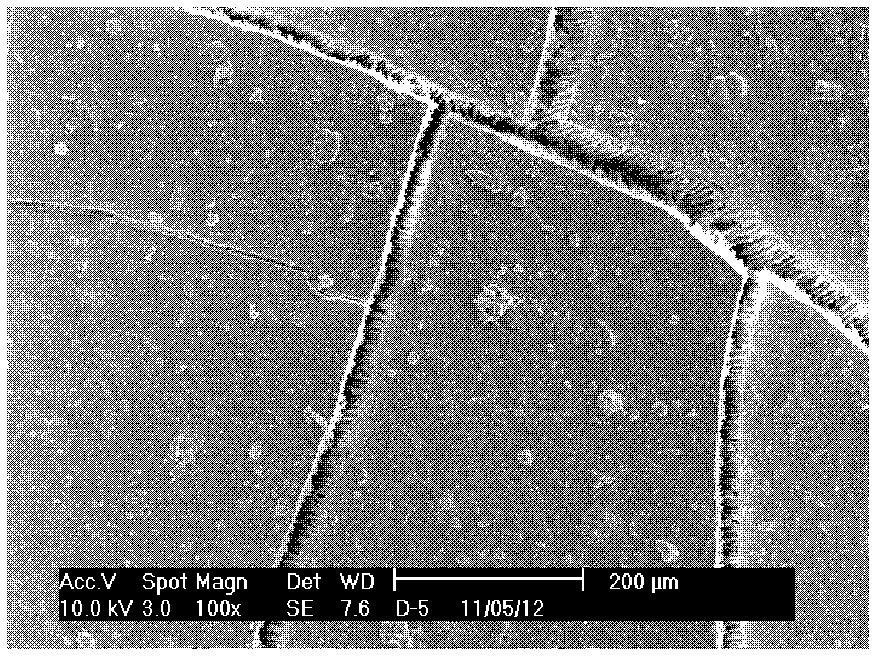

Industrial ultrafiltration membrane device pollutant online extraction and analysis method

ActiveCN103086475ALong runGuaranteed uptimeWater/sewage treatment bu osmosis/dialysisWater productionEnvironmental engineering

The invention relates to an industrial ultrafiltration membrane device pollutant online extraction and analysis method. The invention belongs to the field of membrane-method sewage deep processing and recycling method. The method comprises the steps that: (1) an ultrafiltration membrane with a relatively compact skin structure is used for manufacturing a lateral line membrane assembly; (2) the lateral line membrane assembly is connected in parallel into an industrial ultrafiltration membrane device; and inlet water membrane-surface flow velocity at the lateral line assembly is controlled at 0-8m / s; (3) during an operation process, lateral line membrane assembly water production variation is recorded with timed frequency; when water production is reduced by 50-95% relative to an initial water production, the polluted lateral line membrane assembly is fetched; part of polluted ultrafiltration membrane is fetched and is subjected to low-temperature bake-drying; and membrane-surface pollutant observation and analysis are carried out; and (5) acid and alkali are respectively used for soaking and washing the polluted ultrafiltration membrane, and contents of specific pollutants in the washing liquid are detected. When the method provided by the invention is used in washing the polluted ultrafiltration membrane, water production of the washed polluted ultrafiltration membrane can be restored to higher than 95% of that of the initial water production.

Owner:CHINA PETROLEUM & CHEM CORP +1

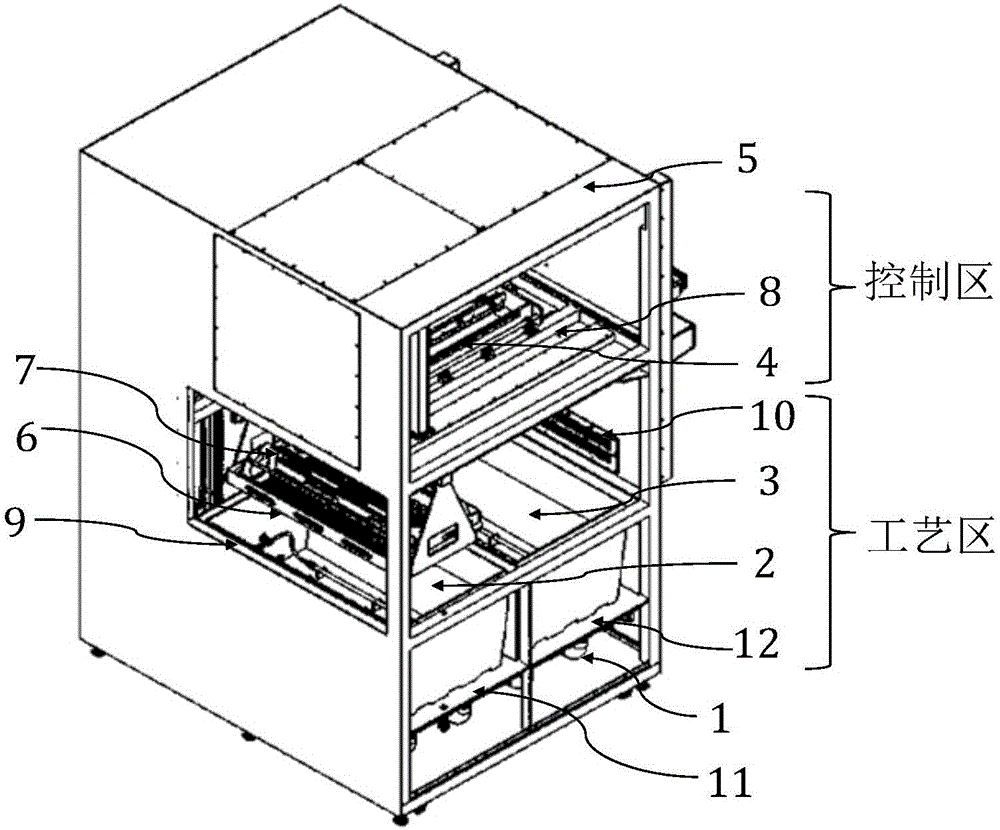

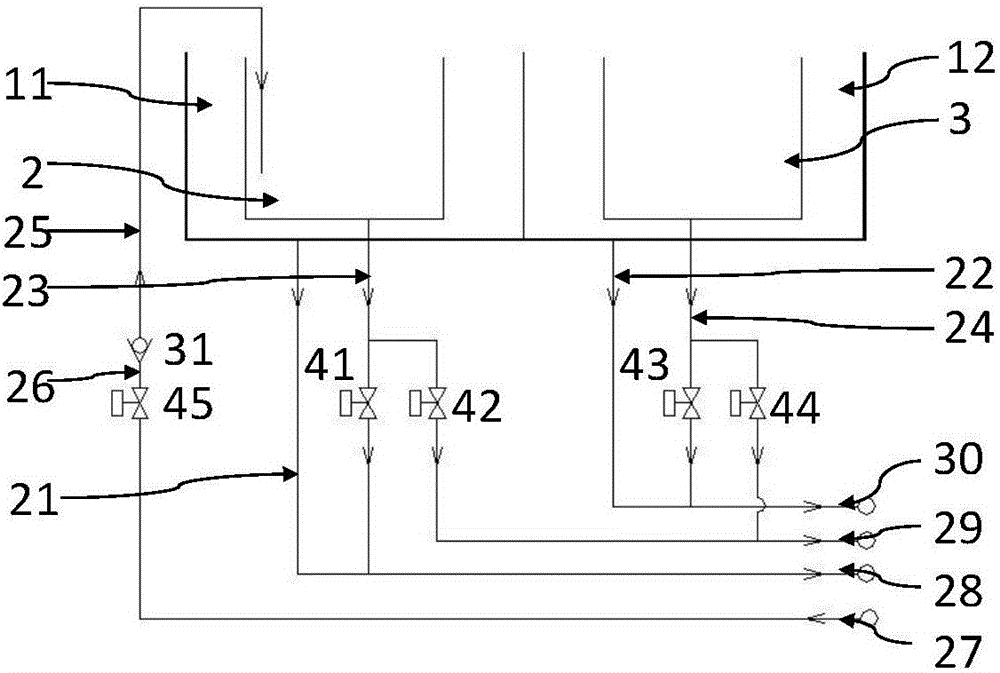

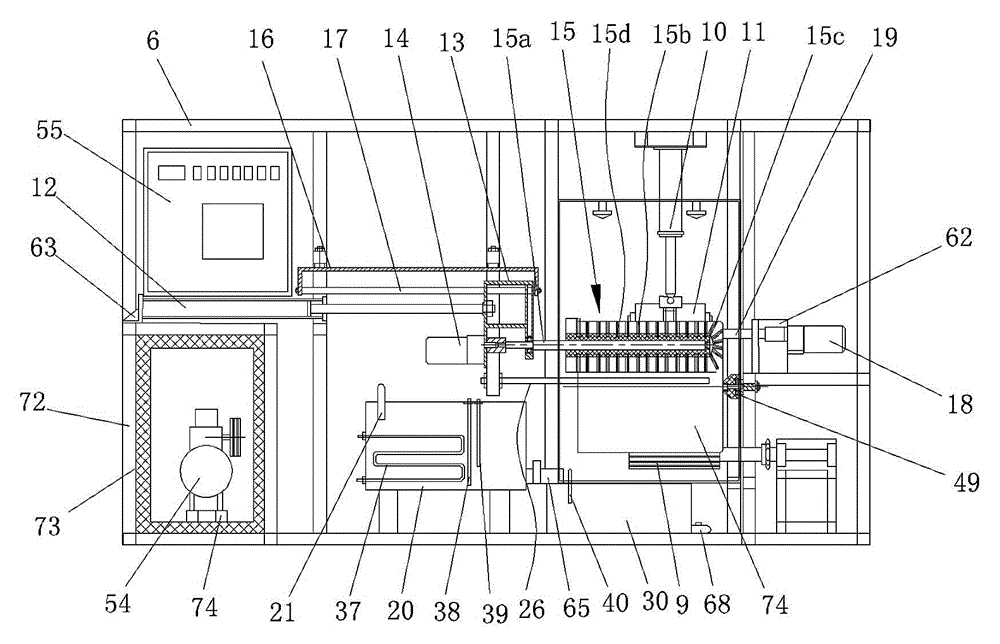

Horizontal quartz boat cleaning machine and cleaning method

InactiveCN106824901AAutomated cleaningComprehensive cleaningCleaning using liquidsCleaning methodsProcess engineering

The invention discloses a horizontal quartz boat cleaning machine and a cleaning method. A quartz boat is carried by a flower basket, repeated lifting or / and horizontal motion are performed under the drive of a manipulator to stir a cleaning liquid in an ultrapure water process tank and a chemical process tank, so that effective vibration cleaning can be performed on the quartz boat and can be accompanied with overflow and air-blowing cleaning processes, and automatic, comprehensive and stable cleaning of the quartz boat is realized; meanwhile, an outer ultrapure water process tank is arranged on the periphery of the ultrapure water process tank, an outer chemical process tank is arranged on the periphery of the chemical process tank, waste liquids in the ultrapure water process tank, the outer ultrapure water process tank, the chemical process tank and the outer chemical process tank can be discharged and recovered in a classified manner by use of a pipeline system, thus, a large quantity of the waste liquids during waste liquid treatment are reduced, and the recovery cost is saved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Surgical test tube cleaning device

The invention discloses a surgical test tube cleaning device. The surgical test tube cleaning device comprises a cleaning frame and a cleaning assembly. The cleaning frame comprises a bottom plate, driving mechanisms, two top plates, two clamping plates, a slide plate, a vertical plate and an oil cylinder; the bottom plate is horizontally arranged; the two top plates are symmetrically arranged above the bottom plate, and the top plates and the bottom plate are connected through the driving mechanisms; the two clamping plates are longitudinally arranged; the vertical plate is longitudinally arranged between the two clamping plates, and the two ends of the vertical plate are fixedly connected with the two ends of the two clamping plates; and the oil cylinder is fixed to the top face of the slide plate, and the output end of the oil cylinder is connected with the vertical plate. The cleaning assembly comprises a box body, a sealed box, a motor, a plurality of rotary rods and a plurality of rotary shafts; the top of the box body is open, and the box body is installed on the bottom plate; the sealed box is arranged on the bottom face of the box body; the top ends of the rotary shafts penetrate through the top face of the sealed box; and the bottom ends of the rotary rods are connected with the top ends of the rotary shafts. The surgical test tube cleaning device can clean the innerwalls of test tubes completely and is good in cleaning effect.

Owner:邹城市邹旺食用菌有限公司

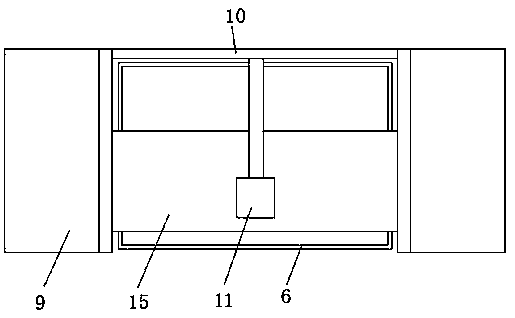

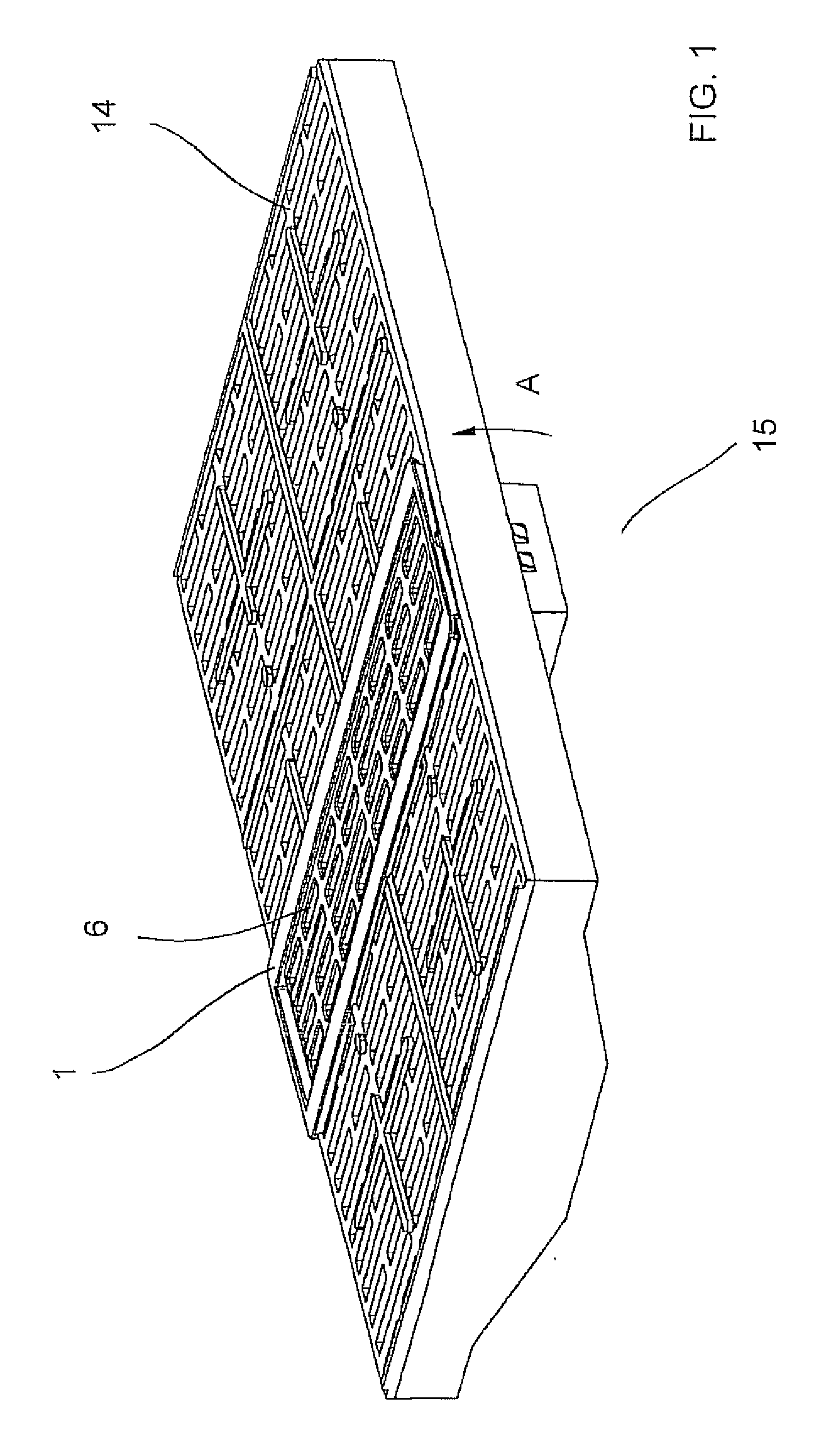

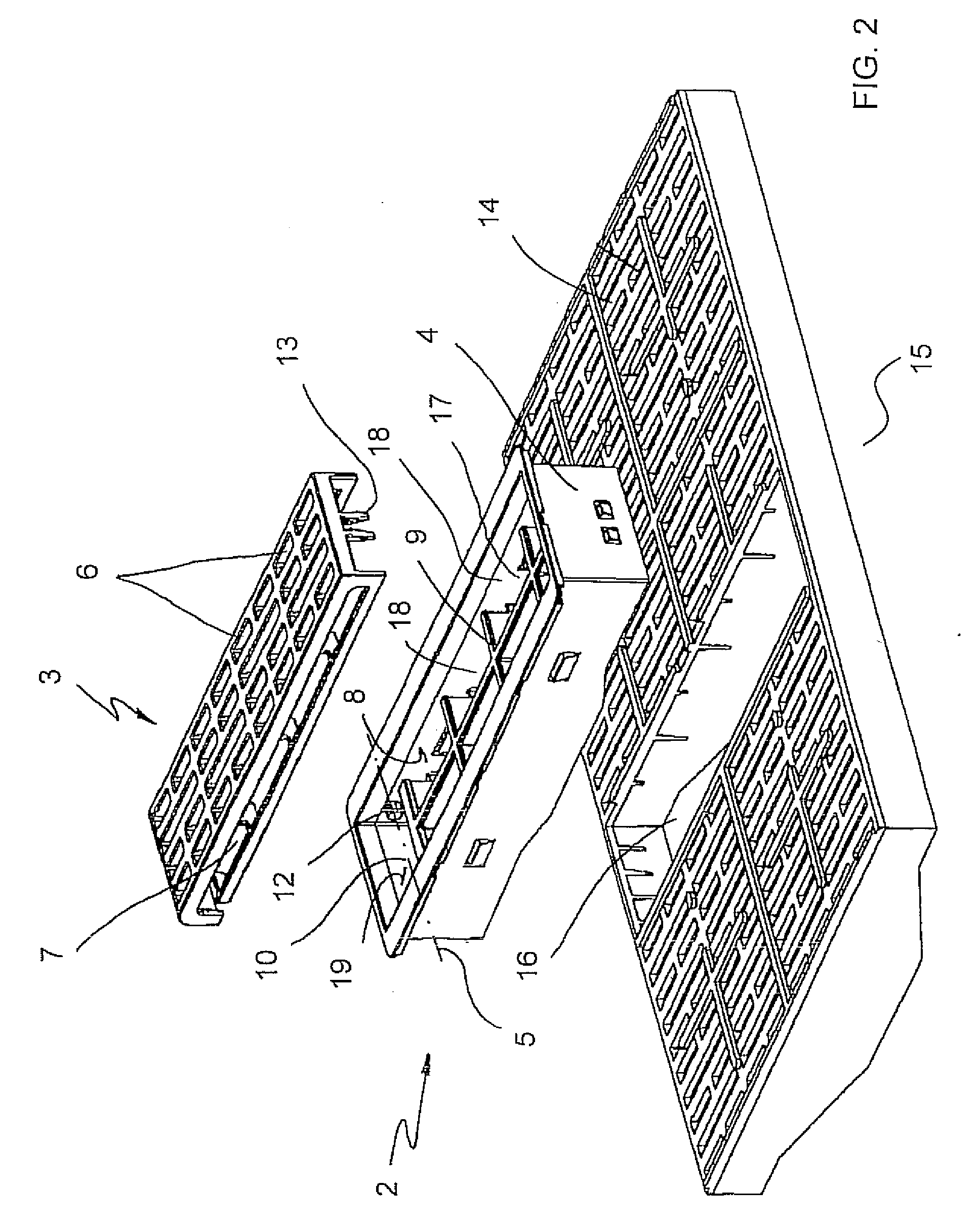

Slatted device for stable floors

Slatted device for stable floors. The device is suitable for being installed as a separation between a waste pit and stable compartment of stabled animals. The device comprises a chassis and a movable trap door having a plurality of openings. The trap door rests on the chassis. A sliding hinge means is provided between the chassis and trap door and the trap door can be moved to a position in which the trap door extends below the chassis.

Owner:ROTECNA

Automatic cleaning equipment for glassware

The invention relates to the technical field of automatic equipment, in particular to automatic cleaning equipment for glassware. The automatic cleaning equipment comprises a base, support plates arefixedly connected with the tops of the left and right ends of the base, a cleaning frame is arranged between the support plates on the two sides, a cleaning mechanism is arranged on the inner side ofthe cleaning frame, a recycling box in bolted connection with the base is arranged on lower side of cleaning frame, and the output end of the recycling box is connected with a cleaning mechanism through a water guide mechanism. According to the automatic cleaning equipment for the glassware, the inner side of glassware can be cleaned by arranging a scrubbing mechanism, the cleaning device can clean the glassware of different sizes by arranging a second telescopic rod, the glassware can be fixed by arranging a clamping block, a suction cup and an air pump, the outer surface of the glassware canbe washed by arranging a spraying pipe, a cleaning frame can be rotated through a first motor by arranging a connecting rod, and therefore the glassware can be dried conveniently.

Owner:SUZHOU WABOTE INTELLIGENT TECH CO LTD

Efficient cleaning device for spring machining and producing

PendingCN108722980AGuaranteed cleaning qualityReduce wasteCleaning using liquidsGear wheelWater resources

The invention discloses an efficient cleaning device for spring machining and producing. The efficient cleaning device comprises a box, a sliding groove is formed in the inner wall of the box, two sliding wheels are in sliding connection to the interior of the sliding groove, the opposite faces of the two sliding wheels are fixedly connected with the left and right side faces of a containing box,a plurality of sleeve columns are arranged on the lower surface of the inner wall of the containing box, the lower surface of the containing box is fixedly connected with the top end of a first rotating shaft, and the surface of the first rotating shaft is sleeved with a first bearing. According to the efficient cleaning device for spring machining and producing, a motor, a driving gear, a drivengear, a second rotating shaft, a second bearing, the containing box and a first cover plate are matched to enable the first cover plate and the containing box to rotate, springs on the sleeve columnscan do relative motion with water, the springs can be in sufficient contact with the water, the spring washing quality is guaranteed, meanwhile, waste of water resources can be reduced, and next-stepmachining or molding of the springs cannot be influenced.

Owner:江苏省溧水弹簧厂(普通合伙)

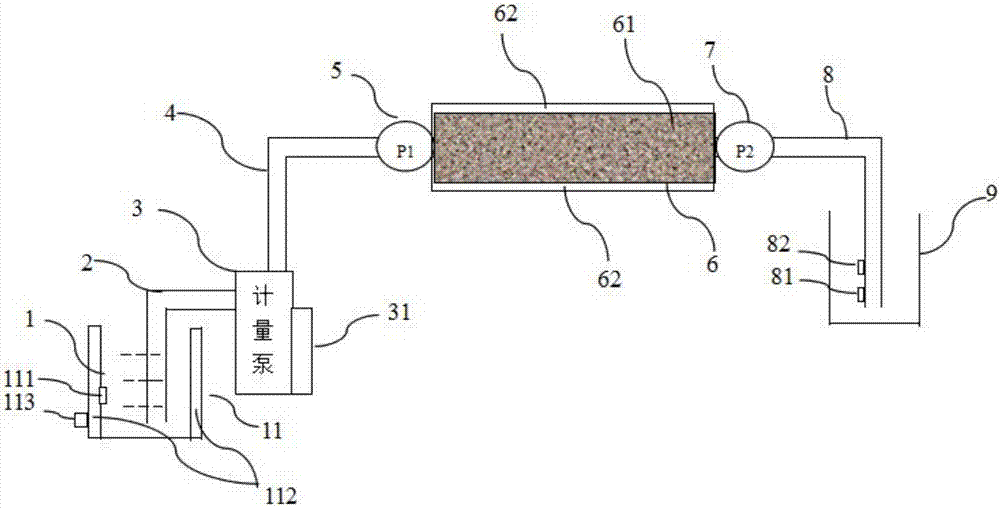

Dynamic viscosity testing device and testing method thereof

InactiveCN106932307AMany poresExpand the scope of testingDirect flow property measurementPorous mediumEngineering

The invention discloses a dynamic viscosity testing device and a testing method thereof. The dynamic viscosity testing device comprises a first pressure sensor, a second pressure sensor, a measurer, a metering pump, a sample pool and a recycling pool, wherein a porous medium is arranged in the measurer, and the measurer is full of the porous medium; the measurer is a cylinder, the porous medium therein is an integrally molded cylinder and completely fits to the inner wall of the measurer, and the porous medium is detachable. The dynamic viscosity testing device is simple, high in sensitivity and simple and easy in operation, the device disclosed by the invention can measure viscosities in various ranges by replacing the porous mediums with different pore sizes in the measurer, and the device disclosed by the invention is easy to clean due to many pores and high measurement accuracy.

Owner:QINZHOU UNIV

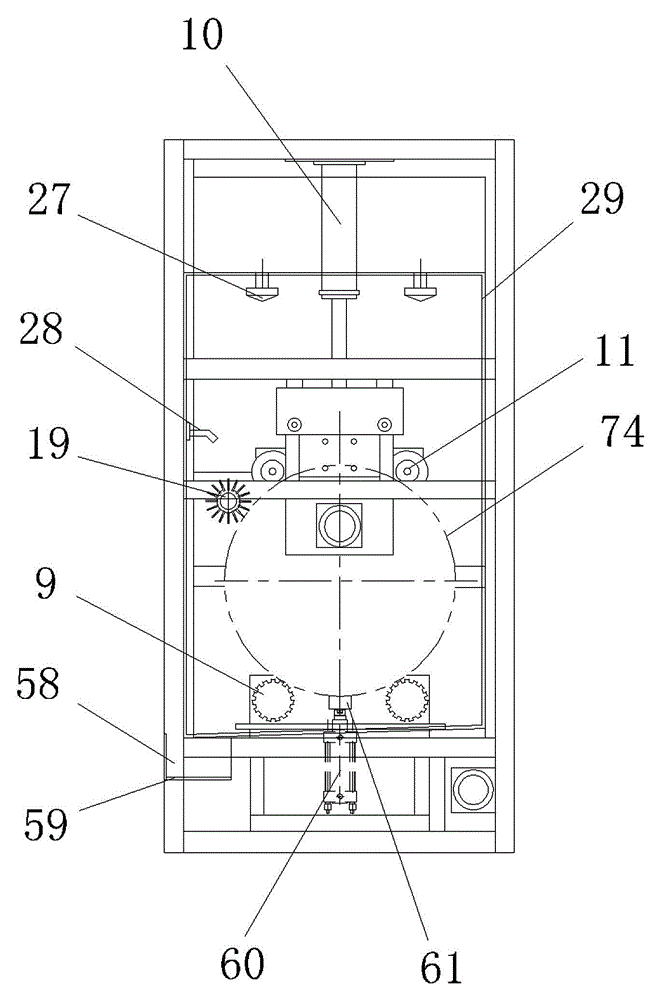

Full-automatic barrel washer

InactiveCN105170590ALarge clamping forcePrevent slippingHollow article cleaningSpool valveAutomatic control

The invention relates to a full-automatic barrel washer. The barrel washer comprises a conveying frame (1) with a conveying belt (2), and the tail end of the conveying frame is correspondingly matched with a cleaning device (4); the rear side of the cleaning device is correspondingly matched with a discharging frame (5), and a first water tank (20) is arranged on a rack (6) and is connected with a first water pipe (21); a pressurizing pump (22) and a first electromagnetic control sliding valve (23) are sequentially arranged on the first water pipe, and the first electromagnetic control sliding valve is connected with a self-cleaning pipe (24), an outer-wall cleaning pipe (25) and an inner wall pipe (26); and the self-cleaning pipe is connected with a self-cleaning spraying head (27), and the outer-wall cleaning pipe is connected with an outer-wall cleaning spraying head (28). The full-automatic barrel washer has the beneficial effects that transmission, clamping and cleaning of a stainless steel barrel are all automatically controlled, clamping is stable, the stainless steel barrel can be effectively prevented from slipping, no oil marks or dirt exists on the inner surface and the outer surface of the cleaned stainless steel barrel, cleaning is rapid, the efficiency is high, and the labor is small.

Owner:陈霁恒

Central air conditioner capable of conveniently cleaning dust at air outlet

InactiveCN112050303AEfficient dust removalStable cleaningLighting and heating apparatusCleaning using toolsCentral air conditioningElectric machinery

Owner:陕西钧诚建鑫机电工程有限公司

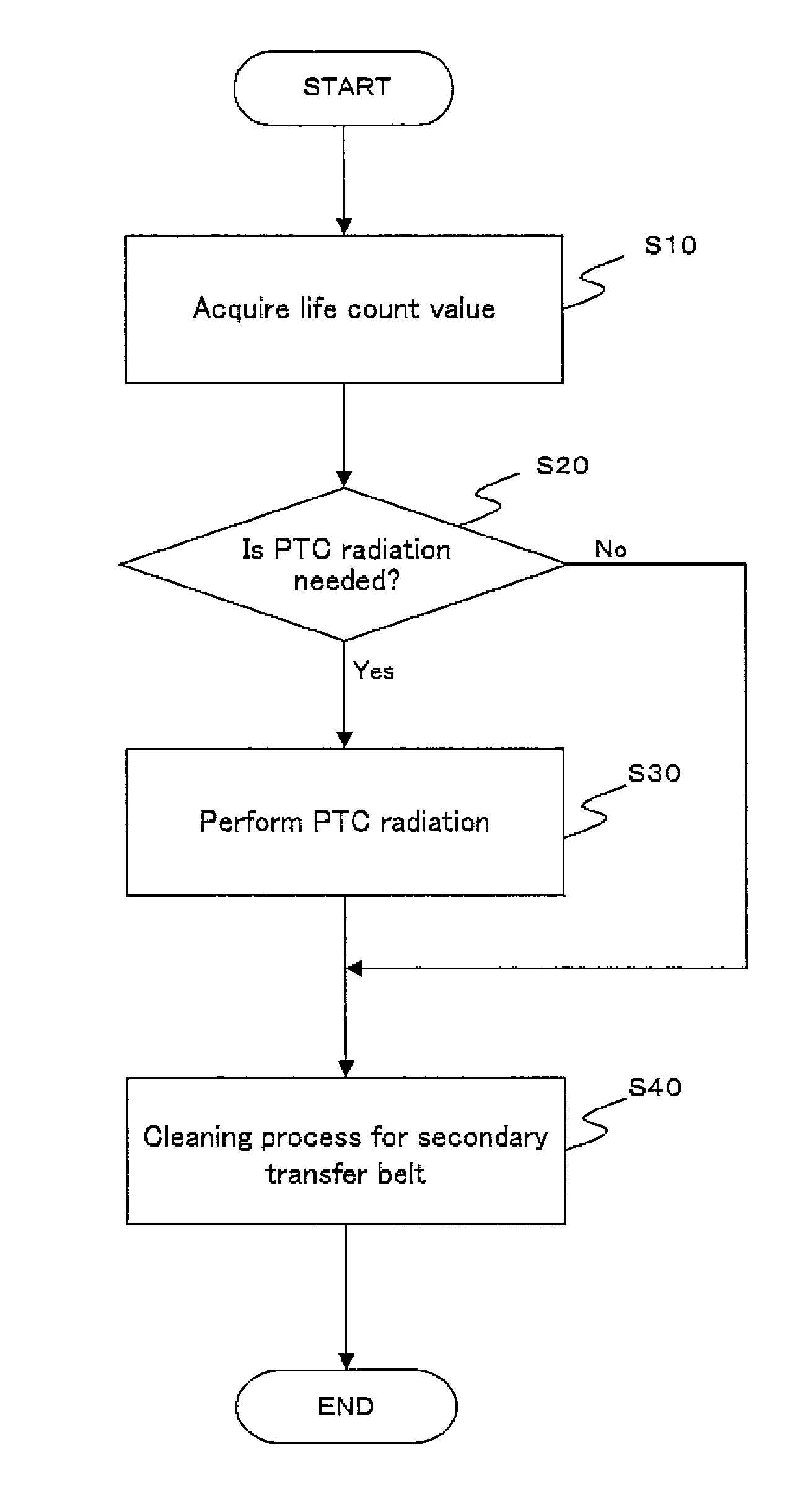

Transfer device and image forming apparatus using the same

InactiveUS7929874B2Stable cleaningLess cleaningElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:SHARP KK

Environment-friendly construction waste treatment equipment for civil engineering

InactiveCN112892701ACleaning upAchieve cleanupGrain treatmentsConstruction engineeringWaste material

The invention discloses environment-friendly construction waste treatment equipment for civil engineering, and relates to the technical field of civil engineering. The environment-friendly construction waste treatment equipment for the civil engineering comprises a machine body, wherein a feeding hopper is arranged at the top end of the machine body, a crushing mechanism is arranged above the interior of the machine body, a vibration screening mechanism is arranged in the middle of the interior of the machine body, a collecting mechanism is arranged at the bottom of the interior of the machine body, one side of the machine body is connected with a first discharging pipe corresponding to the vibration screening mechanism, and one side of the bottom of the machine body is connected with a second discharging pipe communicating with the collecting mechanism. According to the environment-friendly construction waste treatment equipment, through the arrangement of a cleaning brushing mechanism, the crushing mechanism can be cleaned and brushed, so that the crushing mechanism is cleaned, crushed materials are effectively prevented from remaining on the crushing mechanism, rapid crushing of waste materials is facilitated, the crushing efficiency of the crushing mechanism is greatly improved, and the working efficiency of the equipment is improved favorably.

Owner:CHENGDU NORMAL UNIV

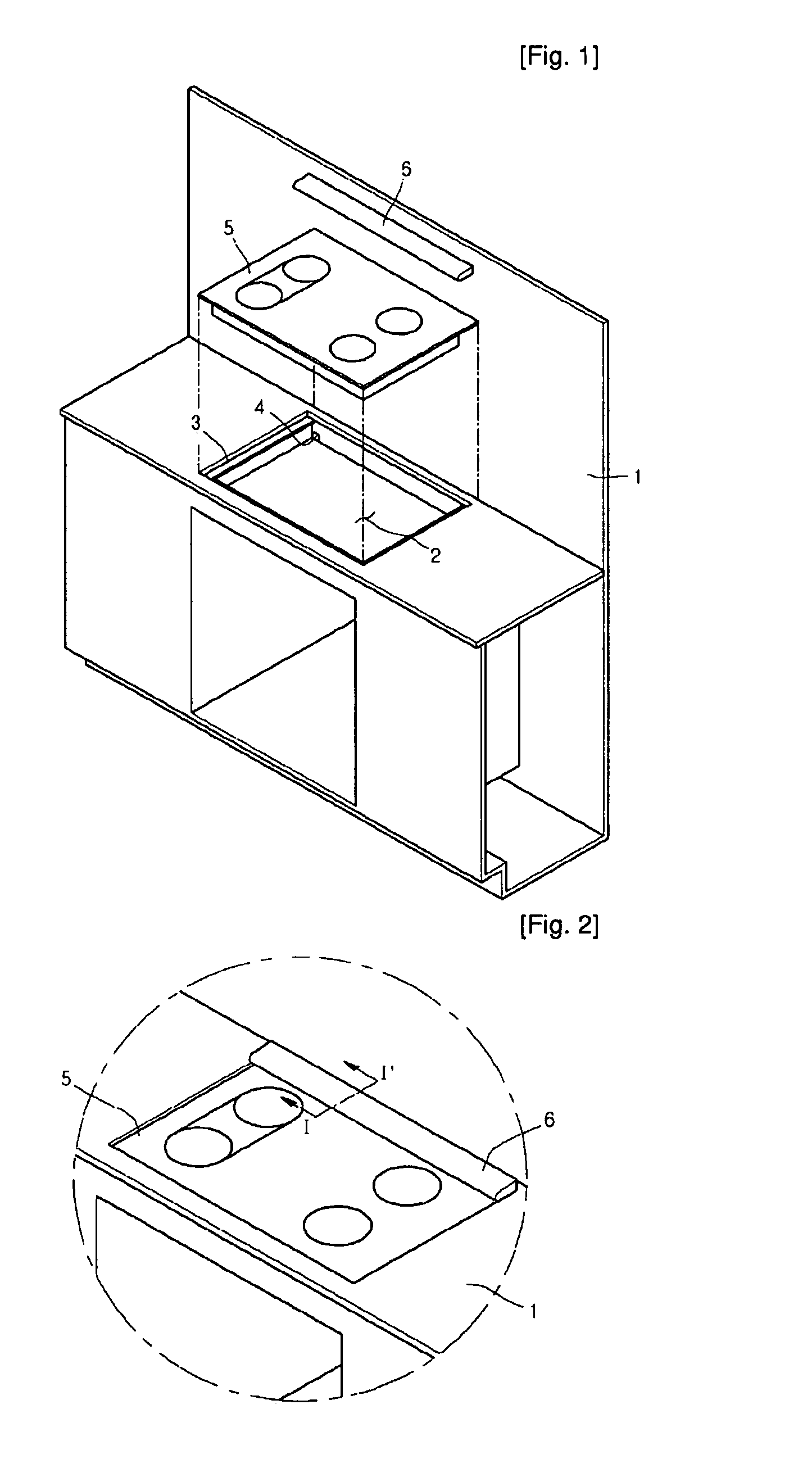

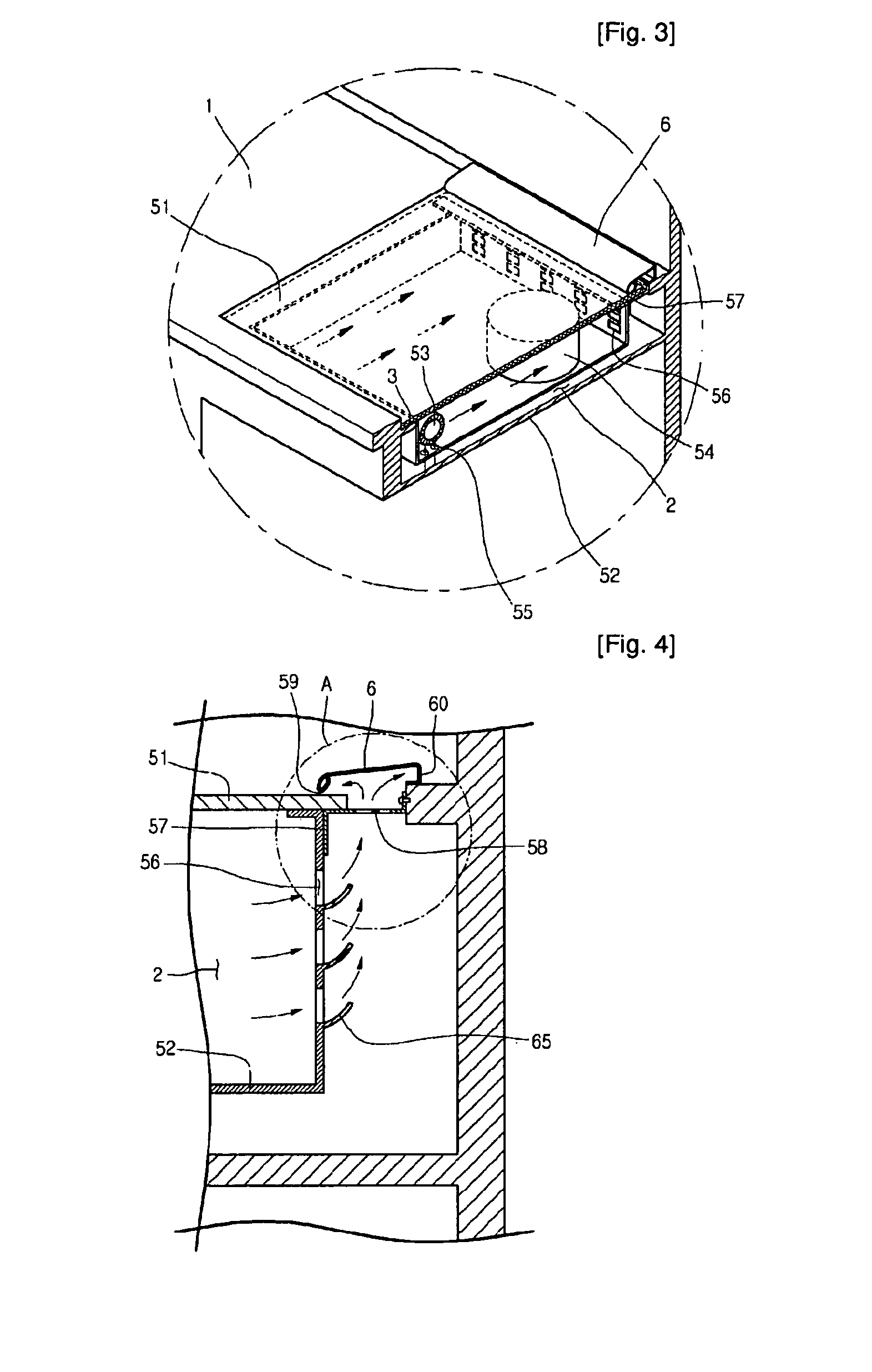

Built-in cooking appliance and installation apparatus for the same

ActiveUS20100108660A1Improve cooling effectStable cleaningDomestic stoves or rangesCooking fumes removalEngineeringCooling channel

Provided is a built-in cooking appliance. According to the built-in cooking appliance, the inside of the cooking appliance is effectively cooled and the inside can be waterproofed without protruding the top plate above the cabinet. Therefore, cooling efficiency, stability in using, convenience in cleaning, esthetic feeling, and reliability of a product can be improved. The built-in cooking appliance includes a top plate, a main body below the top plate, a fan, a cabinet, a gap portion, and a top frame. At least a heating unit is disposed inside the main body. The fan forms a cooling passage inside the main body. The plate is installed on the cabinet. The gap portion defines at least a portion of the cooling passage, and is formed by at least an edge on one side of the top plate and the cabinet separated from each other. The top frame covers the gap portion.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com