Bar surface cleaning device

A surface cleaning device and technology of cleaning device, applied in the field of cleaning, can solve the problems of insufficient attention to bar cleaning, low cleaning efficiency, time-consuming and labor-intensive, etc., and achieve better cleaning effect and stable cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

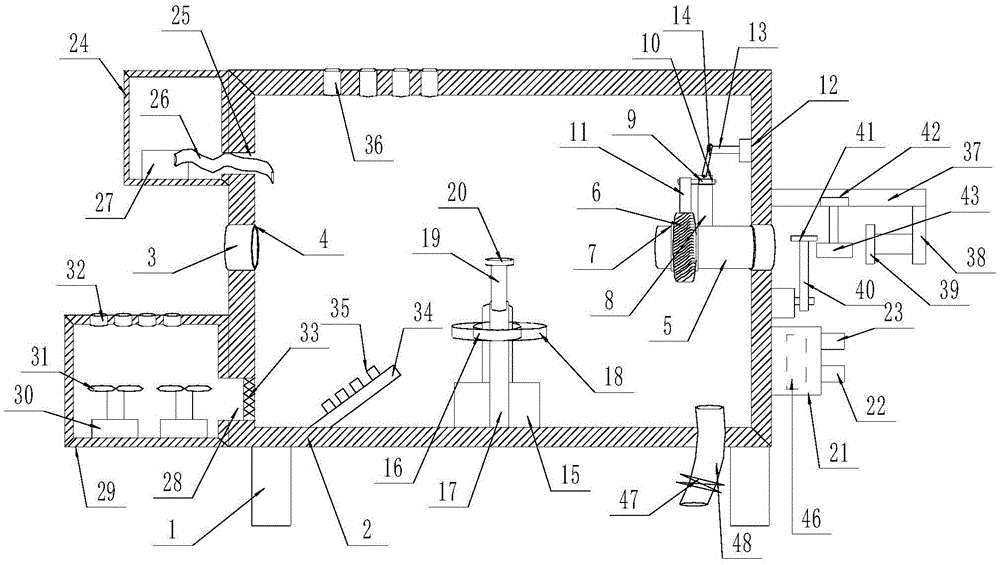

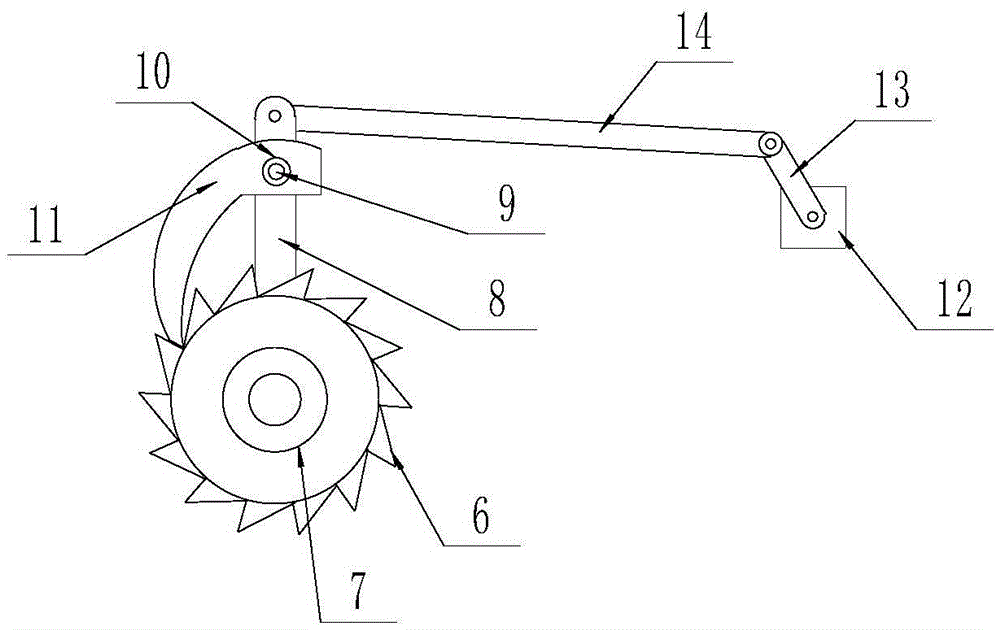

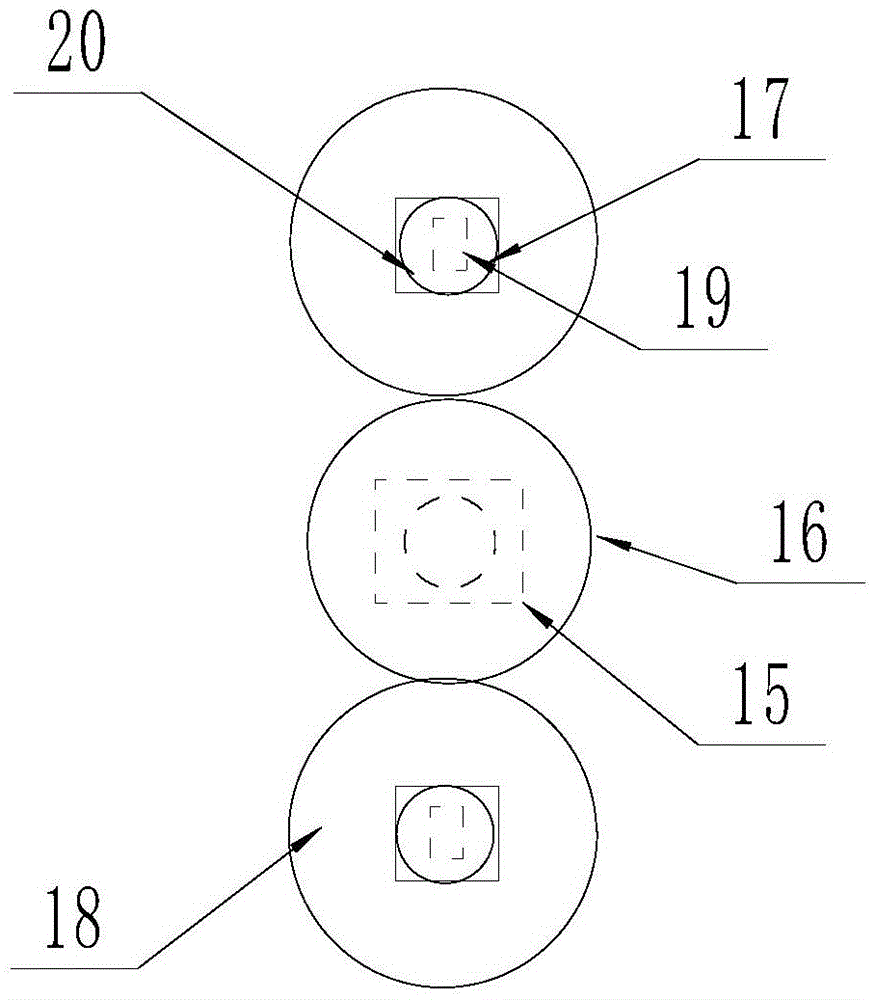

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a bar surface cleaning device includes a frame (1), a cleaning box (2) is arranged on the frame (1), and a rotating cleaning device, spray cleaning device, brushing device and drying device, the cleaning box (2) is equipped with an automatic cut-off mechanism, and the rotary cleaning device is composed of two through holes (3) opened on the opposite sides of the cleaning box (2), plugged in The bearing (4) in one of the through holes (3), the drum (5) that is partly inserted in the other through hole (3), the ratchet (6) that is sleeved on one end of the drum (5), is sleeved on Rotary cylinder (5) and bearing A (7) close to the ratchet (6), the swing rod (8) set on the bearing A (7), the pin hole (9) opened on the swing rod (8), part of the The rotating shaft (10) in the pin hole (9), the movable block (11) that is sleeved on one end of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com