Dynamic viscosity testing device and testing method thereof

A testing device and dynamic viscosity technology, which is applied in the direction of DC flow characteristics measurement, etc., can solve the problems of unable to measure the viscosity of flowing liquid, easy to block in capillary, and large ratio difference, etc., to achieve short test time, expand test range and stabilize temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

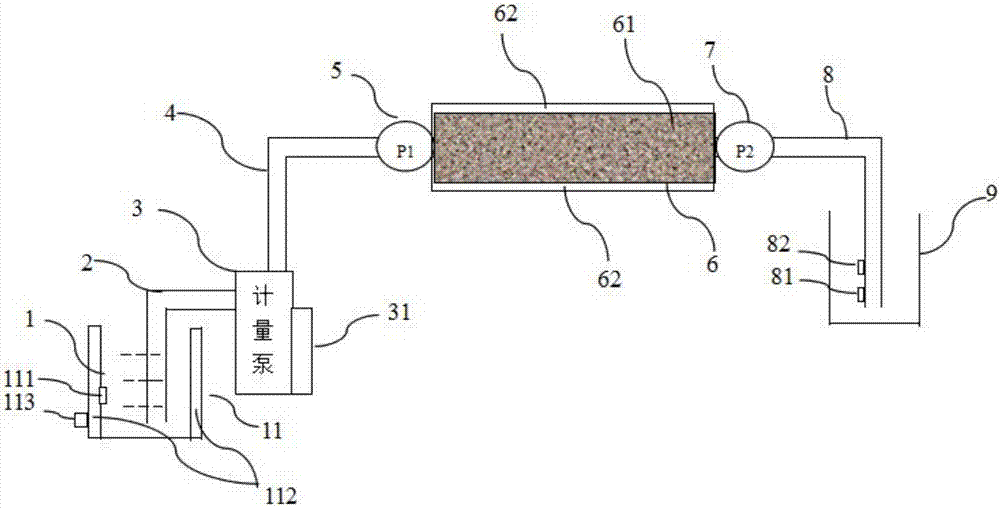

[0028] Such as figure 1 Shown, a kind of dynamic viscosity testing device comprises: the first pressure sensor 5, the second pressure sensor 7, measurer 6, metering pump 3, sample tank 1 and recovery tank 9; ΔP, what the first pressure sensor measures is the pressure P1 at the front end of the measuring device, and what the second pressure sensor measures is the pressure P2 at the end of the measuring device, ΔP=P1-P2; Viscosity μ=k·A·ΔP / ( L·Q), where let K=k·A / (L·Q), then μ=K·ΔP, where μ is the viscosity, ΔP is the pressure difference, k is the permeability of the porous medium, and A is the seepage cross section of the porous medium Area, L is the distance between two cross-sections of the porous medium, Q is the flow rate through the porous medium, k, A, and L are fixed val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com