Disk-shaped substrate manufacturing method and washing apparatus

A manufacturing method and cleaning device technology, applied in the direction of cleaning methods using liquids, cleaning methods using tools, disc carrier manufacturing, etc., can solve problems such as difficult and uniform cleaning, differences in cleaning capabilities, and different contact states, and achieve stable cleaning , Good effect of removing particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

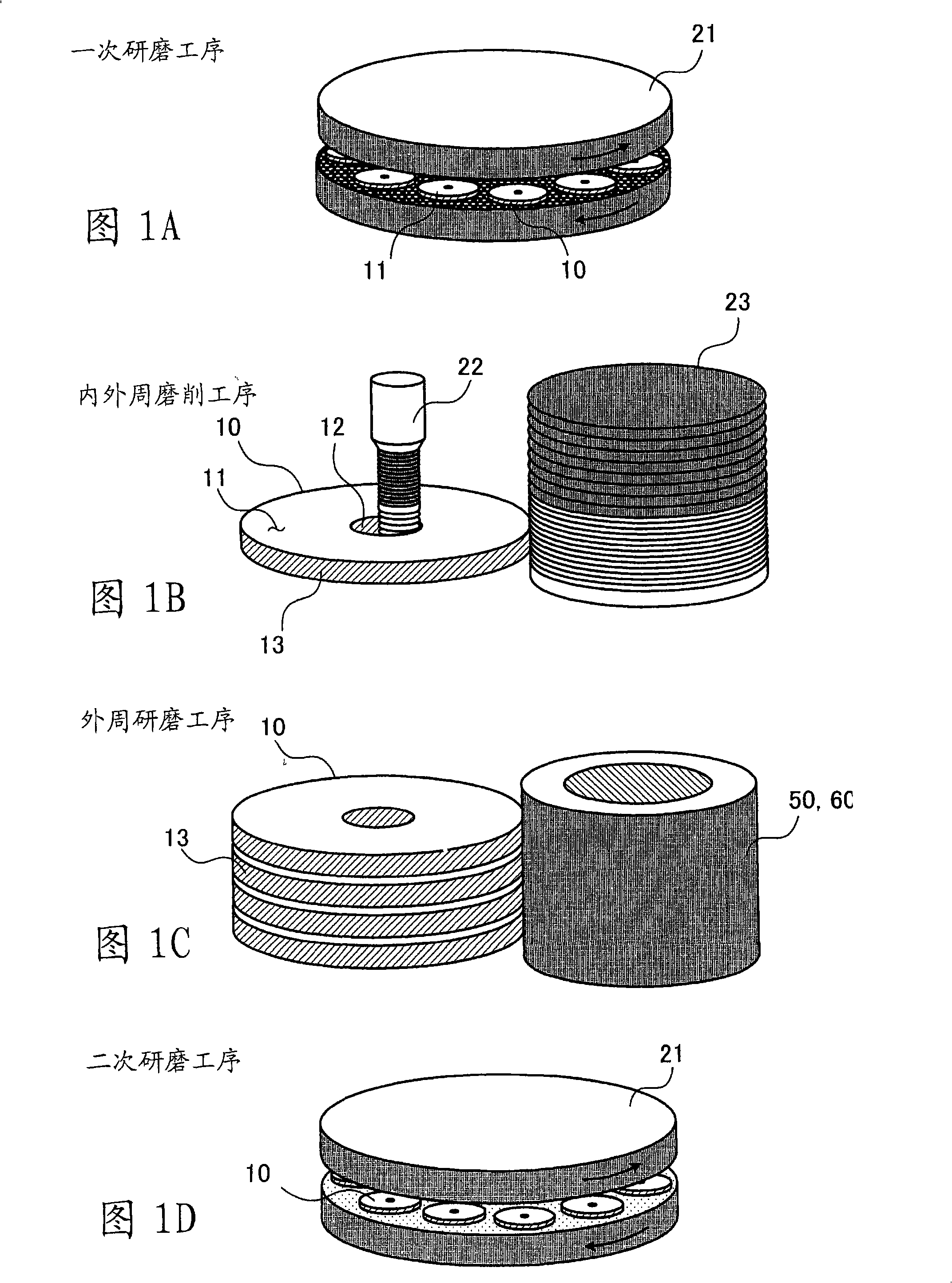

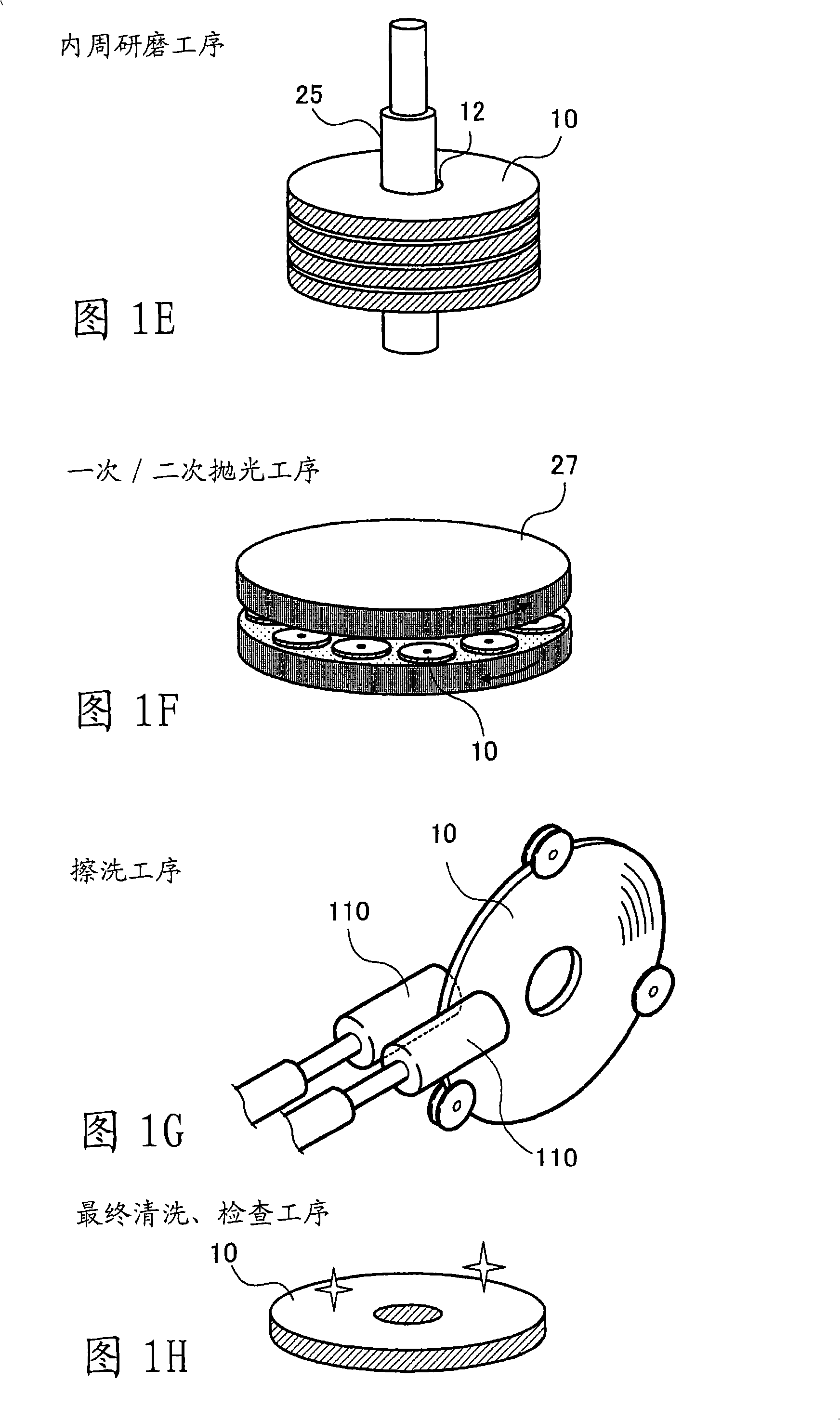

[0029] 1A-H are diagrams showing manufacturing steps of a disk-shaped substrate (disk substrate) to which this embodiment is applied. In this manufacturing process, first, in a primary grinding process as shown in FIG. 1A , the raw material of the disc-shaped substrate (work) 10 is placed on the stage 21, and the flat surface 11 of the disc-shaped substrate 10 is ground. . At this time, on the surface of the table 21 on which the disc-shaped substrate 10 is placed, abrasive grains such as diamond are dispersedly embedded.

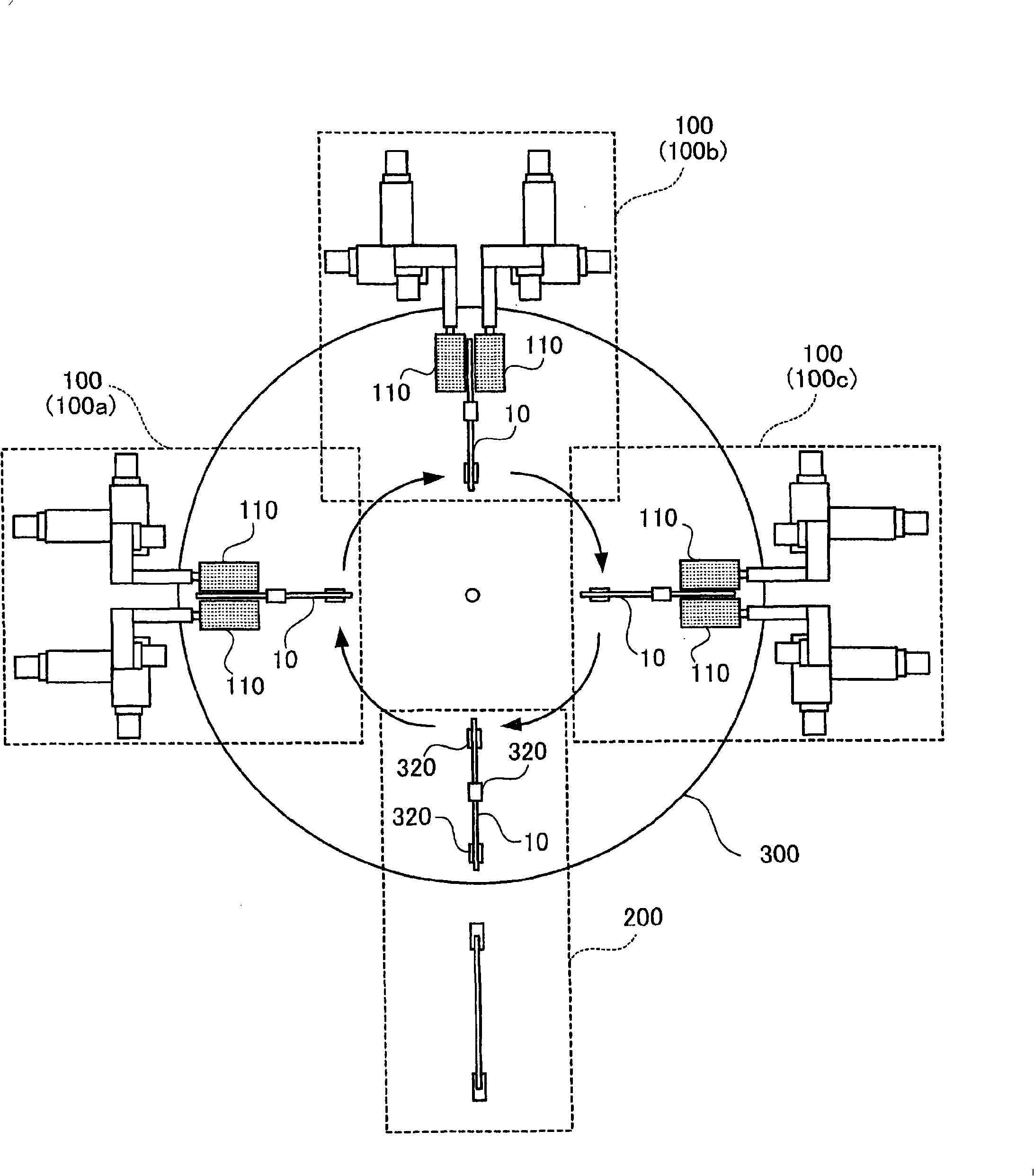

[0030] Next, in the inner and outer circumference grinding process shown in FIG. 1B, the inner circumference 12 of the hole (hole) opened in the center of the disc-shaped substrate 10 is ground with the inner circumference grindstone 22, and the outer circumference grindstone is used to grind the inner circumference 12 of the hole (hole). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com