Component mounting device

A technology for installing devices and components, applied in the direction of measuring devices, electrical components, electrical components, etc., can solve the problems of low productivity and achieve the effect of preventing damage and high position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

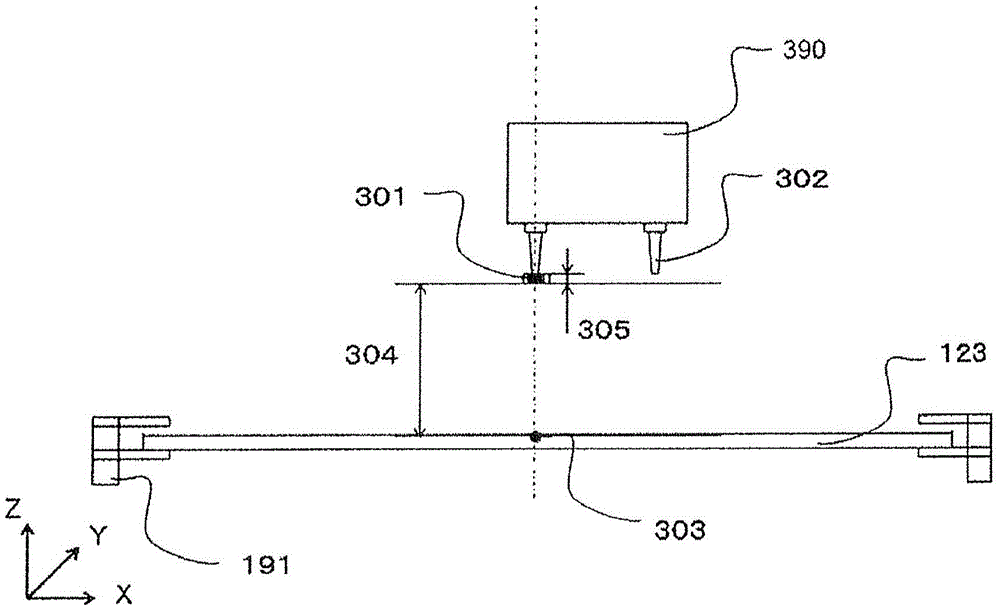

[0029] use Figure 1 to Figure 14 To illustrate Example 1. figure 1 It is a plan view of the entire component mounting device according to Example 1.

[0030] The substrate 123 is conveyed to the electronic component mounting position by the substrate guide 191 from the left side of the drawing sheet.

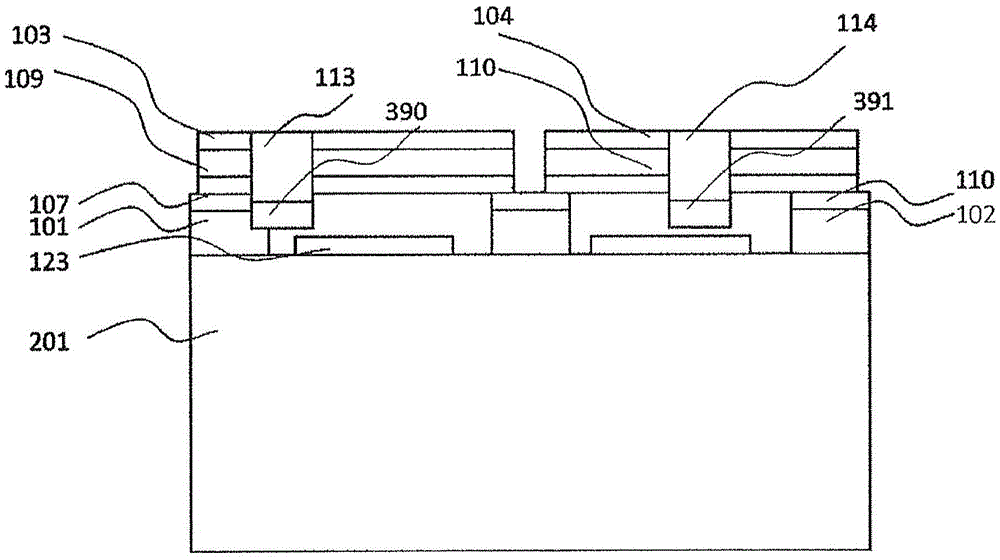

[0031] A first Y beam 101, a second Y beam 102, and a Y beam guide 180 are provided in a direction orthogonal to the conveying direction of the substrate.

[0032] X beams 103, 104, 105, 106 are provided on the first Y beam 101, the second Y beam 102, and the Y beam guide 180, respectively.

[0033] The X beams 103, 104, 105, 106 are based on actuators 107 such as linear motors installed on the Y beams 101, 102 and Y beam guide 180, respectively, along the guide rails 181, 182 in a direction orthogonal to the conveying direction of the substrate. Move up.

[0034] The X beams 103, 104, 105, and 106 are respectively provided with actuators 109, 110, 111, and 112 such as linear motors.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com