Method, mold and system for forging-adsorption composite molding of surface textures of glass

A composite molding and glass surface technology, applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problem of poor three-dimensional effect of texture, collapse of ridge line of three-dimensional texture, increase of R angle of ridge line, etc. Problems, to achieve the effect of enhancing expressiveness, protecting straightness and three-dimensionality, and clear edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

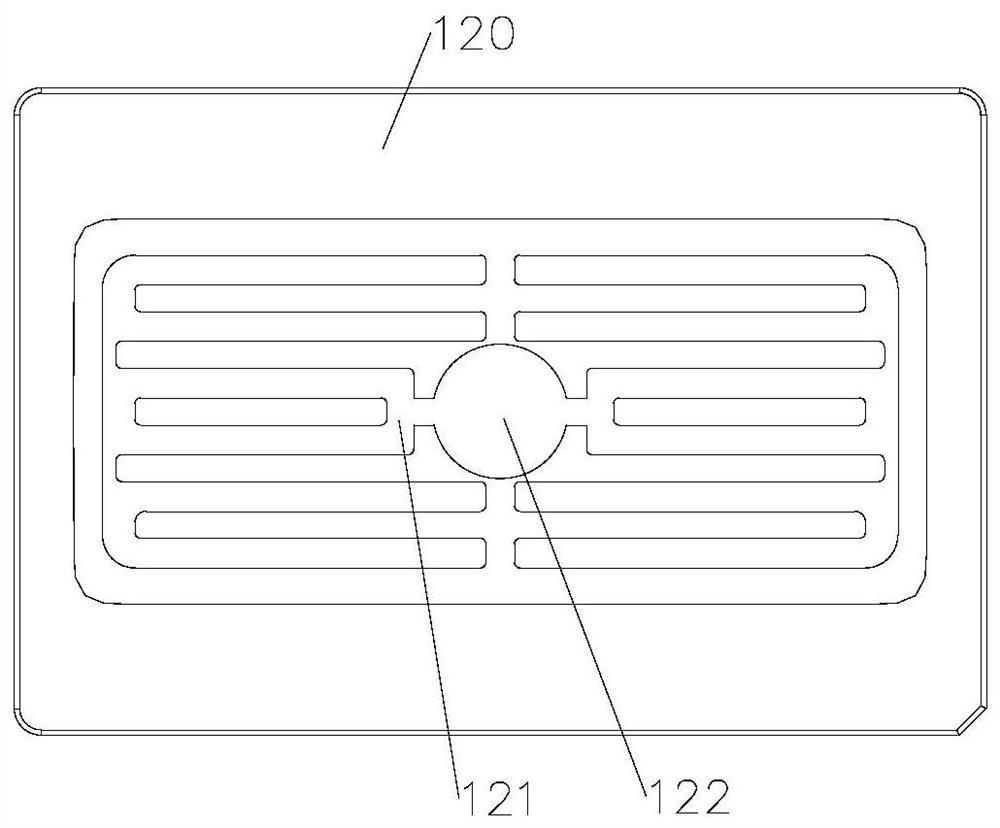

[0056] see figure 1 , the present embodiment provides a mold 100 for forging and absorbing compositely shaped glass surface textures, which is used to shape the three-dimensional textures of glass. The mold 100 for forming glass surface texture by forging and absorbing compositely includes an upper mold 110 and a lower mold 120, wherein the upper mold 110 is a concave mold, and the lower mold 120 is a convex mold. see figure 2 , the lower mold 120 is made of graphite, the upper surface of the lower mold 120 is a molding surface, and the molding surface is provided with diamond or wavy textures, and the raised ridgeline design and processing edge R angle of the surface texture of the lower mold 120 are less than or Equal to 0.1mm. The lower mold 120 has air holes, and the gas above the lower mold 120 can reach the bottom of the lower mold 120 through the air holes. In this way, after the upper mold 110 and the lower mold 120 are pressed together, air holes on the lower mold...

no. 2 example

[0069] see Figure 4 , this embodiment provides a method for forging and absorbing compound glass surface texture, which is mainly realized by using the mold 100 for forging and absorbing compound forming glass surface texture provided in the first embodiment and the system for forging and absorbing compound forming glass surface texture, specifically including The following steps:

[0070] S1: Pre-press the glass into a bent shape.

[0071] Pre-pressing into a bent shape means that the glass is processed by a hot-bending process. First, the glass is heated to about 700°C, and then the glass is hot-pressed through the upper mold 110 and the lower mold 120 to form a glass with curved surface characteristics.

[0072] S2: Perform forging-suction composite molding on the pre-pressed glass, wherein the upper mold 110 performs forging and pressing on the glass, and the lower mold 120 and the glass perform vacuum adsorption.

[0073] Both the upper mold 110 and the lower mold 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com