Method and device for mould pressing glass products

A technology for glass products and compression molding, used in the field of direct extrusion systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

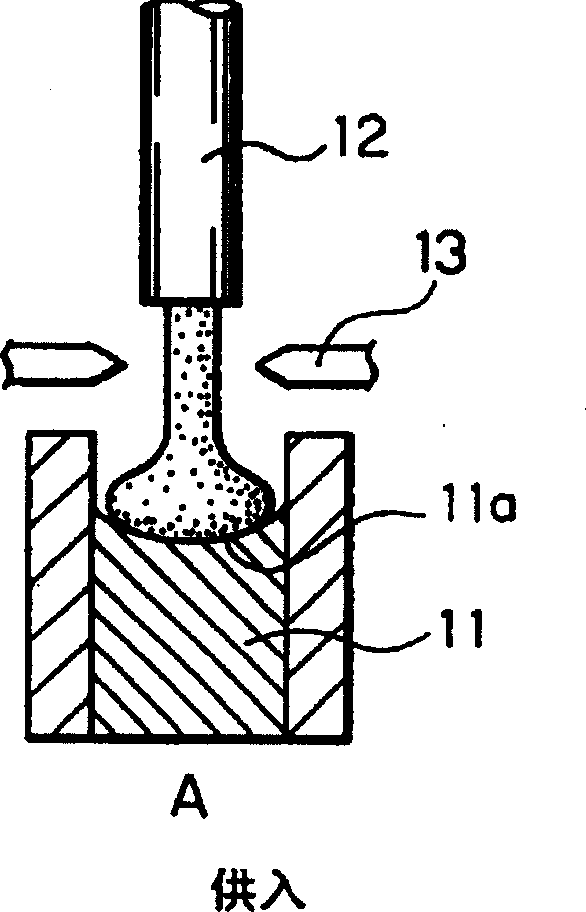

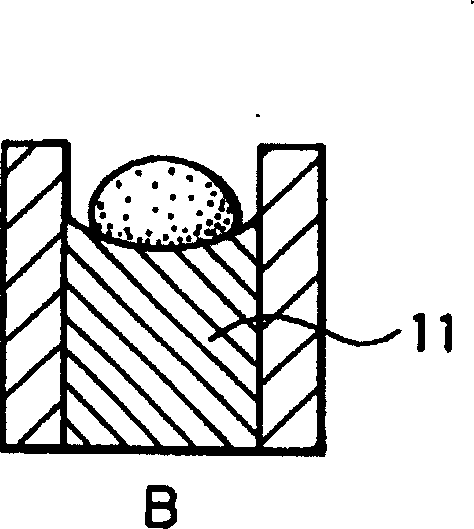

[0033] An embodiment of the present invention will now be described with reference to the accompanying drawings. In the following, a method of molding an optical lens using an extrusion molding apparatus including a turntable as a conveying means and 16 lower dies circumferentially arranged on the turntable will be described directly. When the temperature of the glass is involved, the area in contact with the molding surface of the lower die and its vicinity is referred to as the lower part of the glass, while the area exposed to the outside air and not in contact with the molding surface of the lower die is referred to as the lower part of the glass. called the upper part of the glass.

[0034] refer to figure 1 , a plurality of operating positions A to P for the individual steps of the extrusion molding method of the present invention are defined on the turntable 10 . As shown in the figure, a plurality of lower dies 11 (16 in number) are arranged on the turntable 10 in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com