Pressed glass lamp cup and its preparation method and lamp

A technology for pressing glass and lamp cups, applied in lighting and heating equipment, coatings, point light sources, etc., can solve the problems of low entry probability of material molecules, inability to complete crystallization and film formation, and high product prices, achieving simple equipment and solutions. Internal conduction problem, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

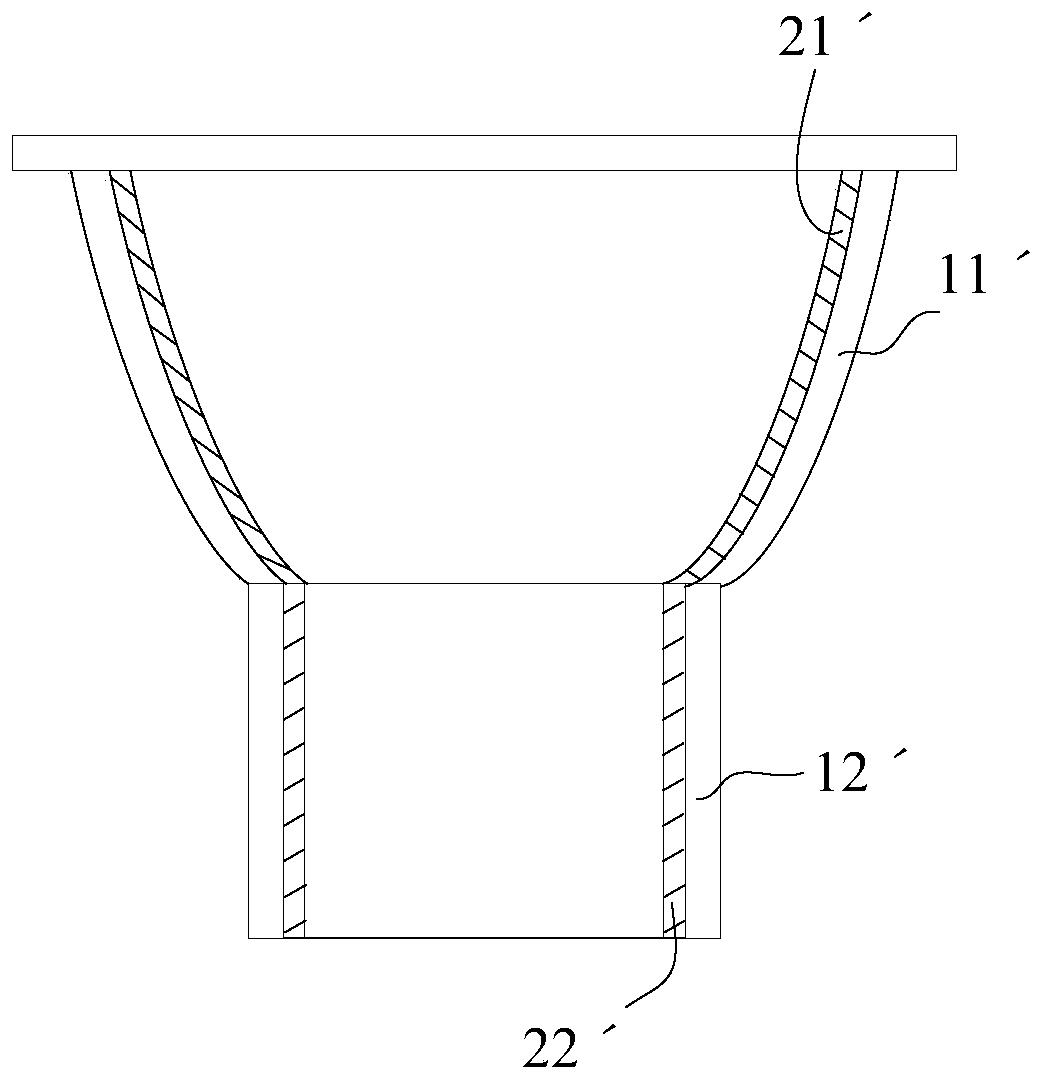

Image

Examples

preparation example Construction

[0052] Correspondingly, the present invention also provides a method for preparing a pressed glass lamp cup, comprising:

[0053] (1) Mix component A, component B and thinner to obtain an insulating coating. After mixing component A, component B and diluent, it is also necessary to perform bubble removal treatment on the insulating coating to avoid bubbles during film formation.

[0054] (2) Dip or spray the insulating paint on the inner surface of the pressed glass lamp cup body, and then perform leveling treatment.

[0055] Dip coating and spray coating adopt different methods for different product specifications and comprehensive output efficiency. For example, when it is applied to PAR lamps, the spray coating process is used; when it is applied to MR16, GU10 and other spotlights, the dip coating process is used.

[0056] (3) drying the glass;

[0057] Specifically, step (3) includes:

[0058] First dry in the low temperature zone of 50-70 degrees for 2-7 minutes; then ...

Embodiment 1

[0065] (1) Production component A: 5% pyromellitic dianhydride, 35% diaminodiphenyl ether, 40% organosilane, 5% 3-aminopropyltrimethoxysilane, β-(3,4- Epoxycyclohexyl) ethyltrimethoxysilane 5%, ethyl orthosilicate 5%, ethyl acetate 5% are mixed according to the proportion;

[0066] (2) Making component B: mixing 60% of siloxane oligomer, 20% of metal oxide catalyst, and 20% of structure control agent according to the proportion;

[0067] (3) Mix component A and component B at a ratio of 100:5 to obtain an insulating coating;

[0068] (4) Dip-coat the insulating paint on the inner surface of the pressed glass lamp cup body, and then perform leveling treatment;

[0069] (5) Dry the glass in a low temperature zone of 50 degrees for 5 minutes; then dry it in a medium temperature zone of 90 degrees for 6 minutes; finally dry it in a high temperature zone of 140 degrees for 10 minutes;

[0070] (6) The glass is forcedly air-cooled until it reaches normal temperature.

Embodiment 2

[0072] (1) Production component A: 10% pyromellitic dianhydride, 25% diaminodiphenyl ether, 30% organosilane, 5% 3-aminopropyltrimethoxysilane, β-(3,4- Epoxycyclohexyl) ethyl trimethoxysilane 10%, ethyl orthosilicate 10%, ethyl acetate 10% mixed according to the proportion;

[0073] (2) Preparation of component B: mix 70% of siloxane oligomer, 15% of metal oxide catalyst, and 15% of structure control agent according to the proportion;

[0074] (3) Mix component A and component B at a ratio of 100:7 to obtain an insulating coating;

[0075] (4) Dip-coat the insulating paint on the inner surface of the pressed glass lamp cup body, and then perform leveling treatment;

[0076] (5) Dry the glass in a low temperature zone of 60 degrees for 4 minutes; then dry it in a medium temperature zone of 100 degrees for 5 minutes; finally dry it in a high temperature zone of 150 degrees for 8 minutes;

[0077] (6) The glass is forcedly air-cooled until it reaches normal temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com