Energy-saving precise press with multiple connecting rods

A technology of presses and multi-links, applied to presses, stamping machines, manufacturing tools, etc., can solve problems such as increasing the nominal force stroke and prolonging the residence time of the slider

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

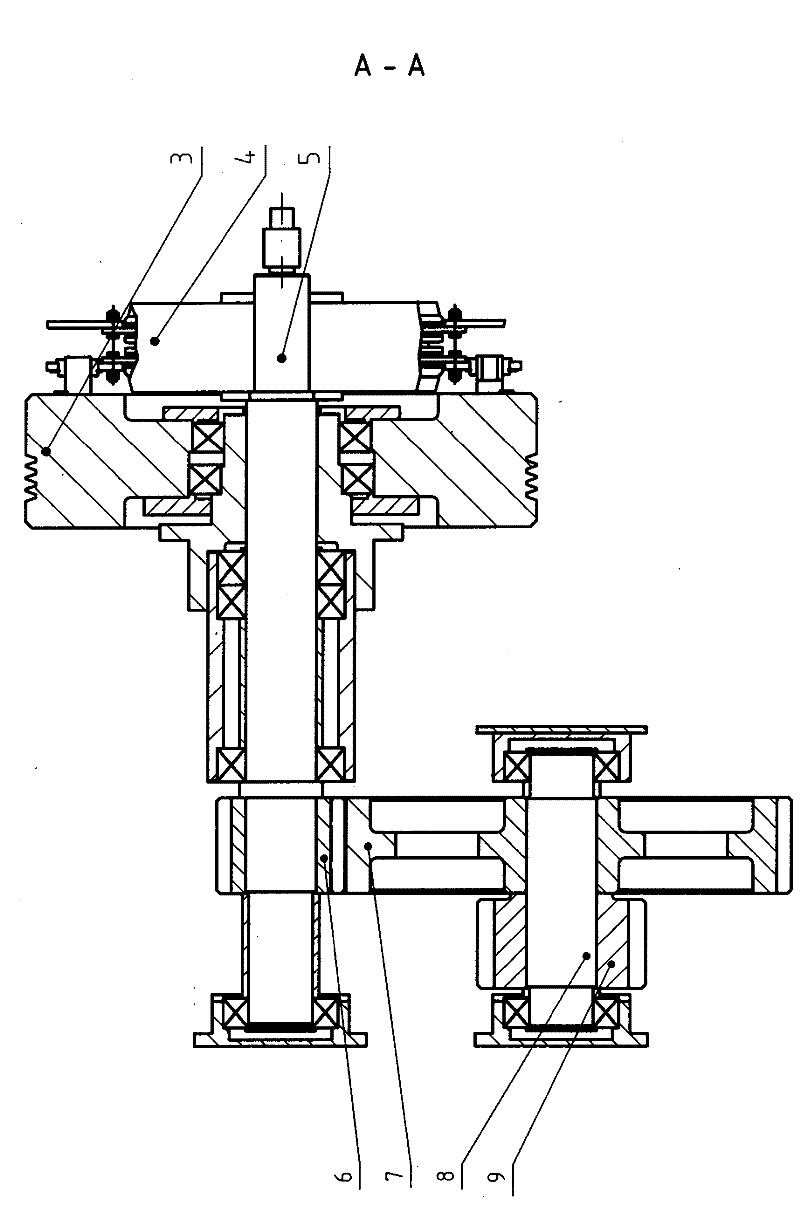

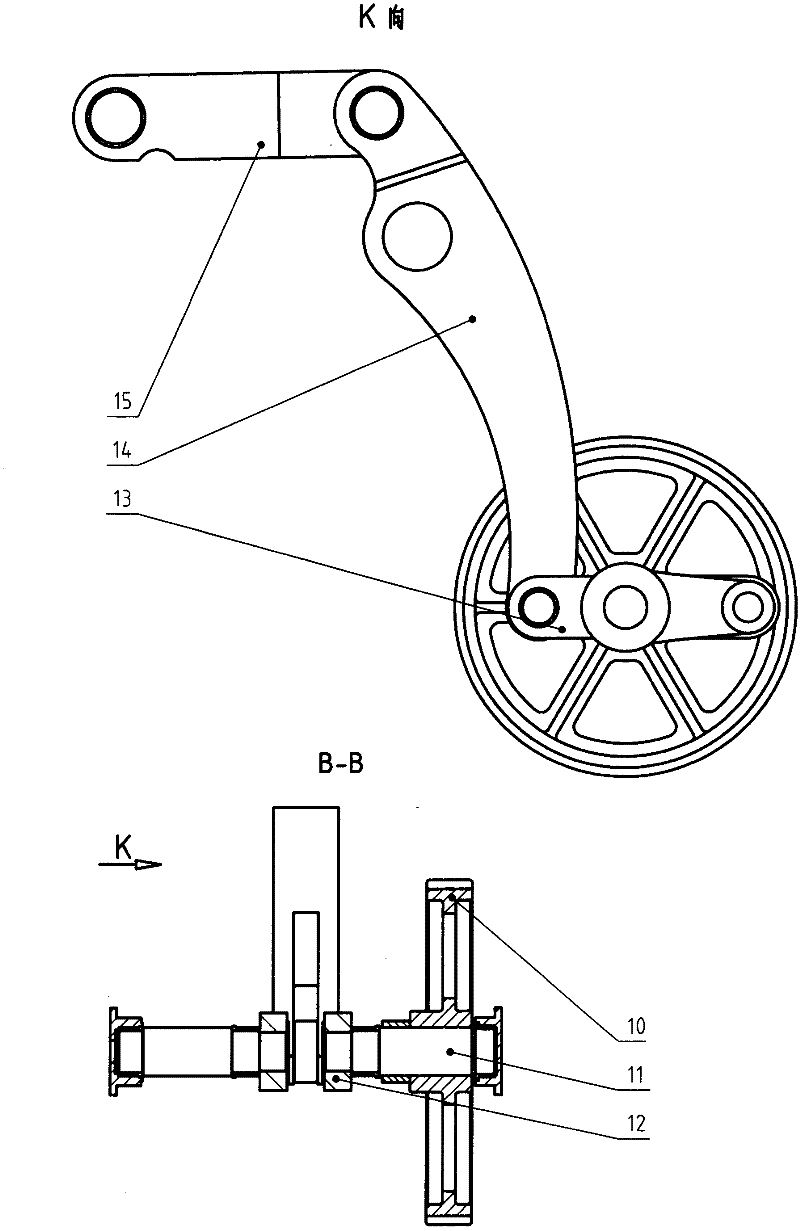

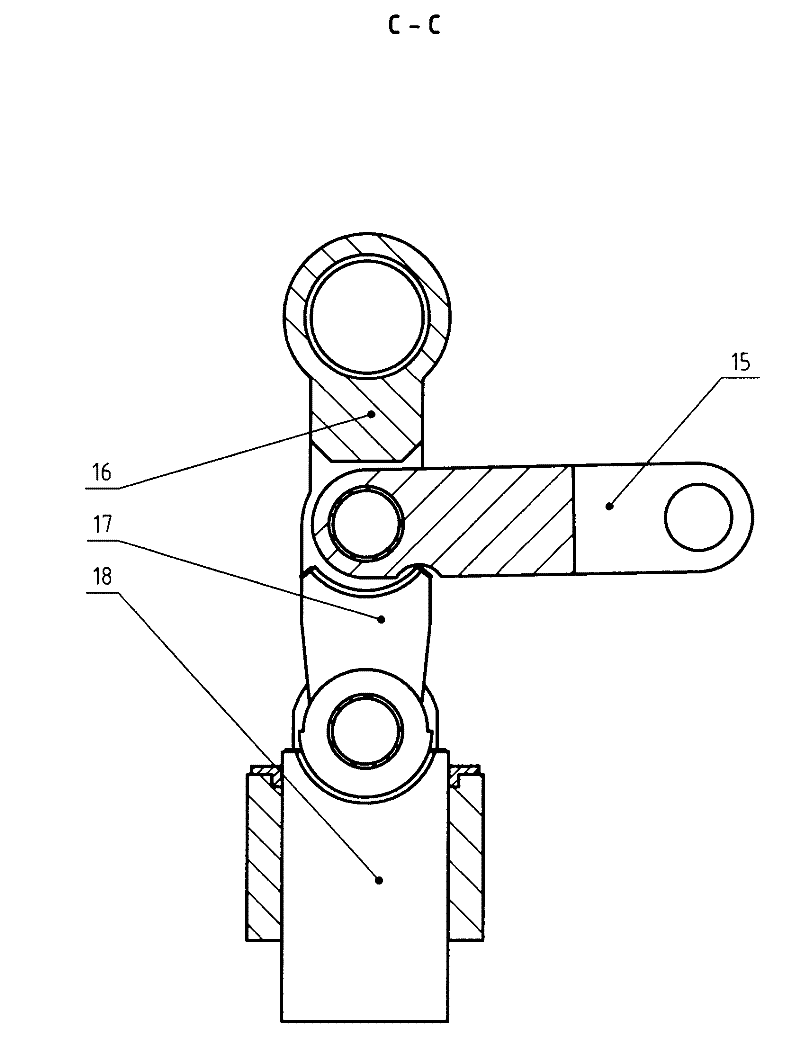

[0014] In the figure: 1. Main motor 2. Small pulley 3. Flywheel 4. Clutch 5. Shaft 6. Pinion 7. Big gear 8. Shaft 9. Pinion 10. Big gear 11. Crankshaft 12. Crank 13. Small connection Rod 14. Reducing rod 15. Large connecting rod 16. Upper connecting rod 17. Lower connecting rod 18. Slider

[0015] The specific working conditions of the press are as follows:

[0016] figure 1 The main motor (1) in the middle drives the small pulley (2) to drive through the V-belt image 3 The flywheel (3) in it rotates. Under the action of the clutch (4), the shaft (5) rotates, the small gear (6) on the shaft (5) and the large gear (7) form a transmission pair, which drives the shaft (8) to rotate, and the small gear (6) on the shaft (8) Gear (9) and bull gear (10) form transmission pair. Drive the crank shaft (11) to rotate, the crank shaft (11) drives the crank (12) to rotate, the crank (12), the small connecting rod (13), and the damping rod (14) form a four-bar mechanism, and the dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com