Continuous excavation device and full-face heading machine

A full-face tunnel boring machine and continuous technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of poor tunnel section forming quality, low excavation efficiency, and inability to excavate and support the entire section at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

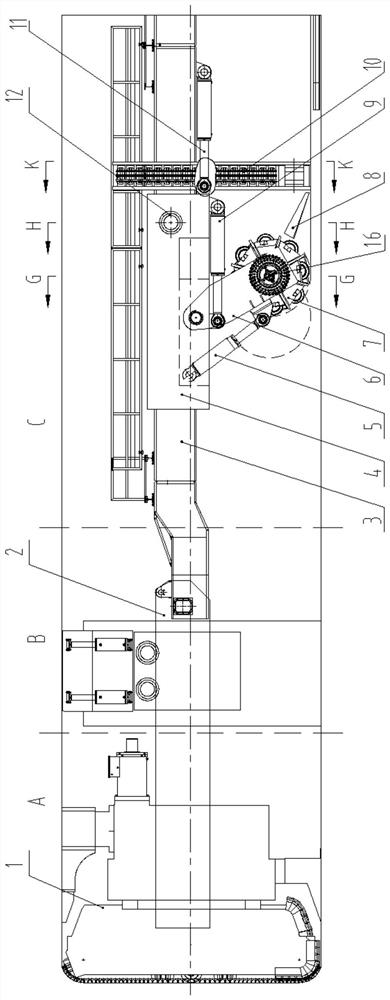

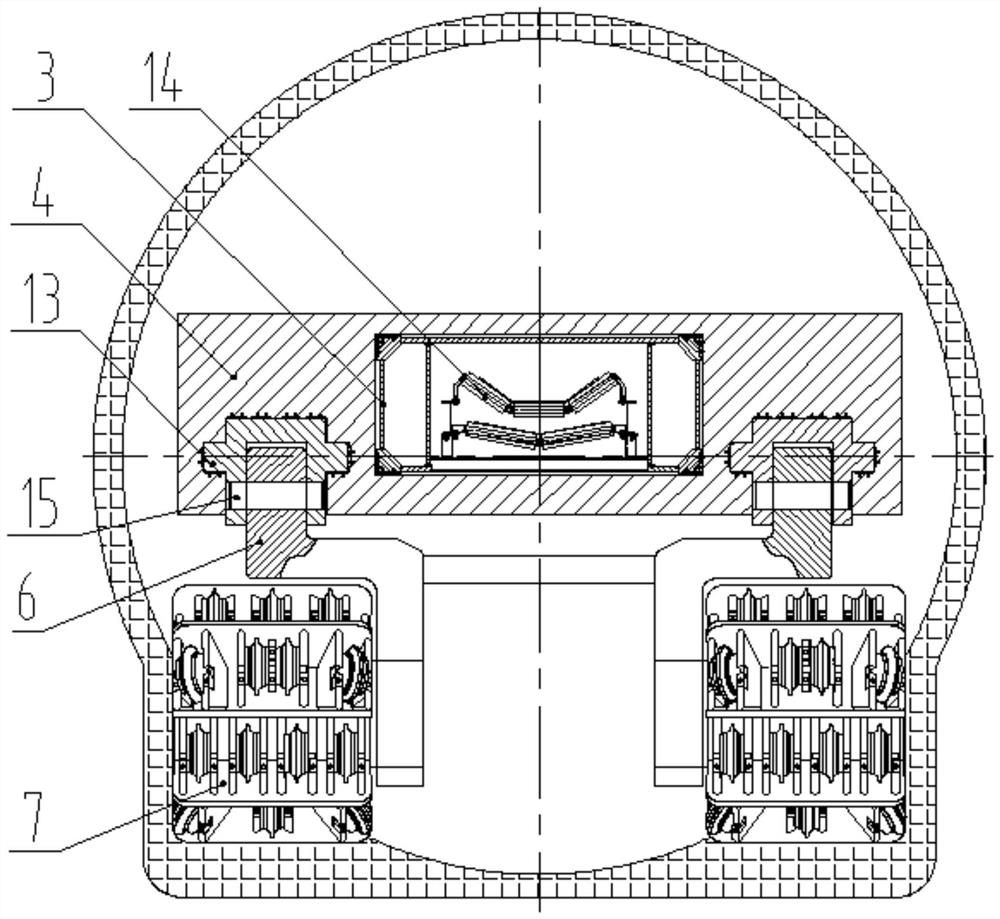

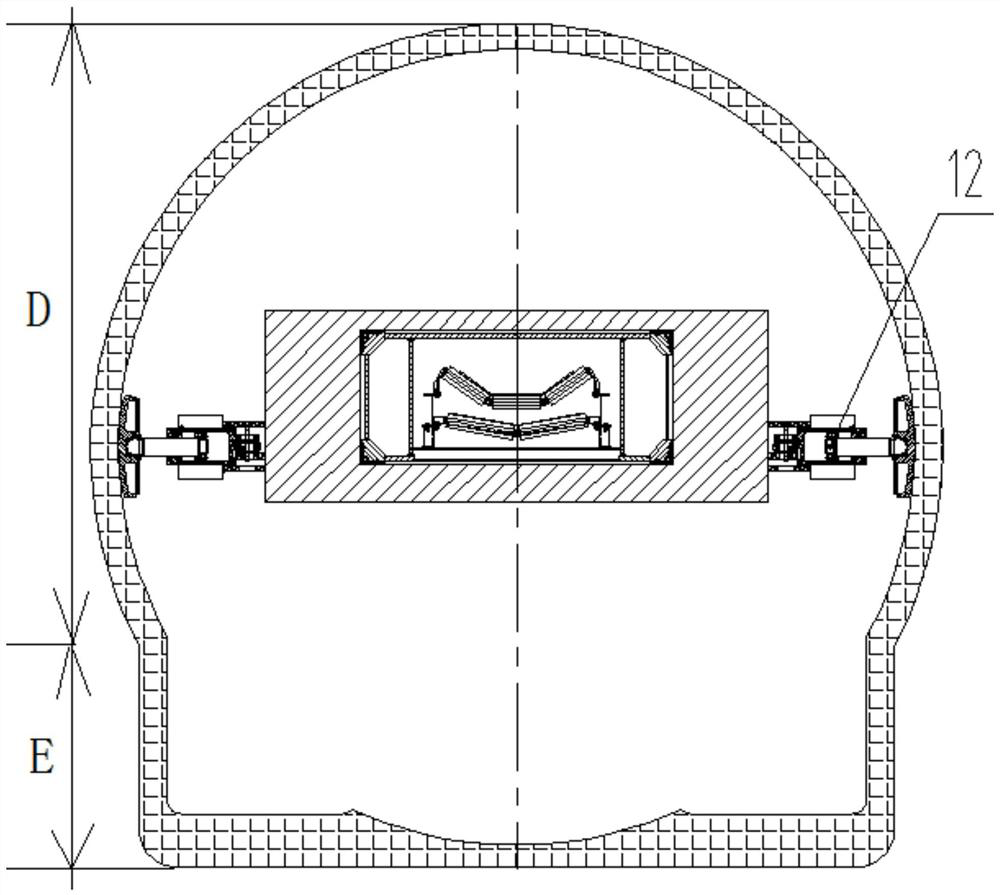

[0021] A continuous excavation device, comprising a rear main beam 3 and a slide box 4 installed inside and outside, the rear main beam 3 extends along the front-to-back direction, the slide box 4 can move in the front-to-back direction relative to the rear main beam 3, and the left and right sides of the slide box 4 Both sides are all provided with excavation mechanism, and described excavation mechanism contains support arm 6 and wheeled cutterhead 7 that are arranged up and down, and wheeled cutterhead 7 is connected with support arm 6 by cutterhead shaft 16, and wheeled cutterhead 7 can Rotate around the cutter head shaft 16, the axis of the cutter head shaft 16 is set along the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com