Glass lid

a technology of glass lids and threaded posts, applied in the field of threaded assembly systems, can solve the problems of difficult cleaning, low construction efficiency, and lids that are not suitable for entry-level products, and achieve the effect of saving construction costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Reference will now be made in detail to presently preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0023]FIG. 1 shows a prior art lid 1 made of sag glass that has an opening 6 cut into it for attaching a knob 8. A stainless steel screw 2, a stainless steel washer 4 and a rubber washer 5 are placed through the opening 6 from the underside of the lid 1.

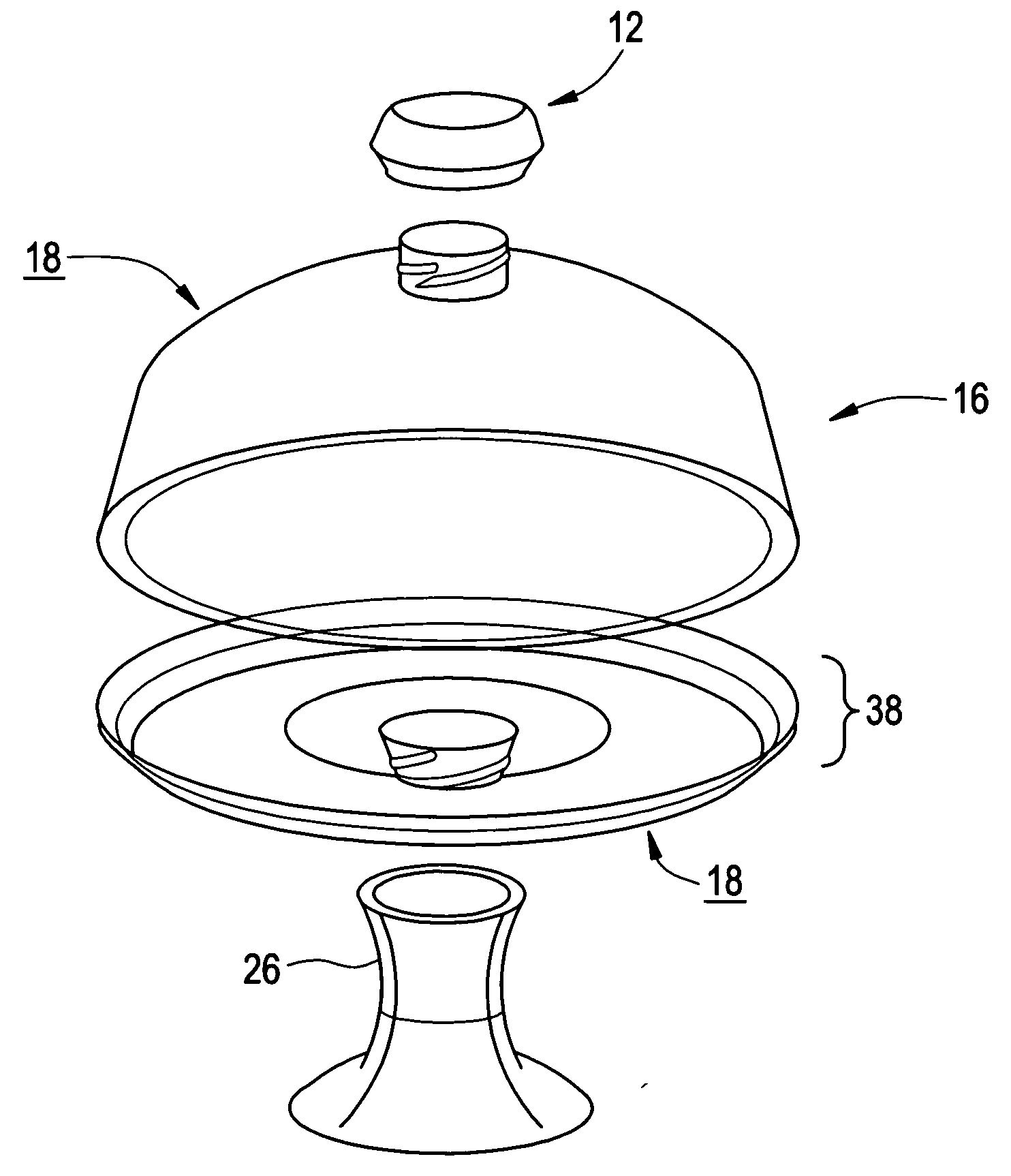

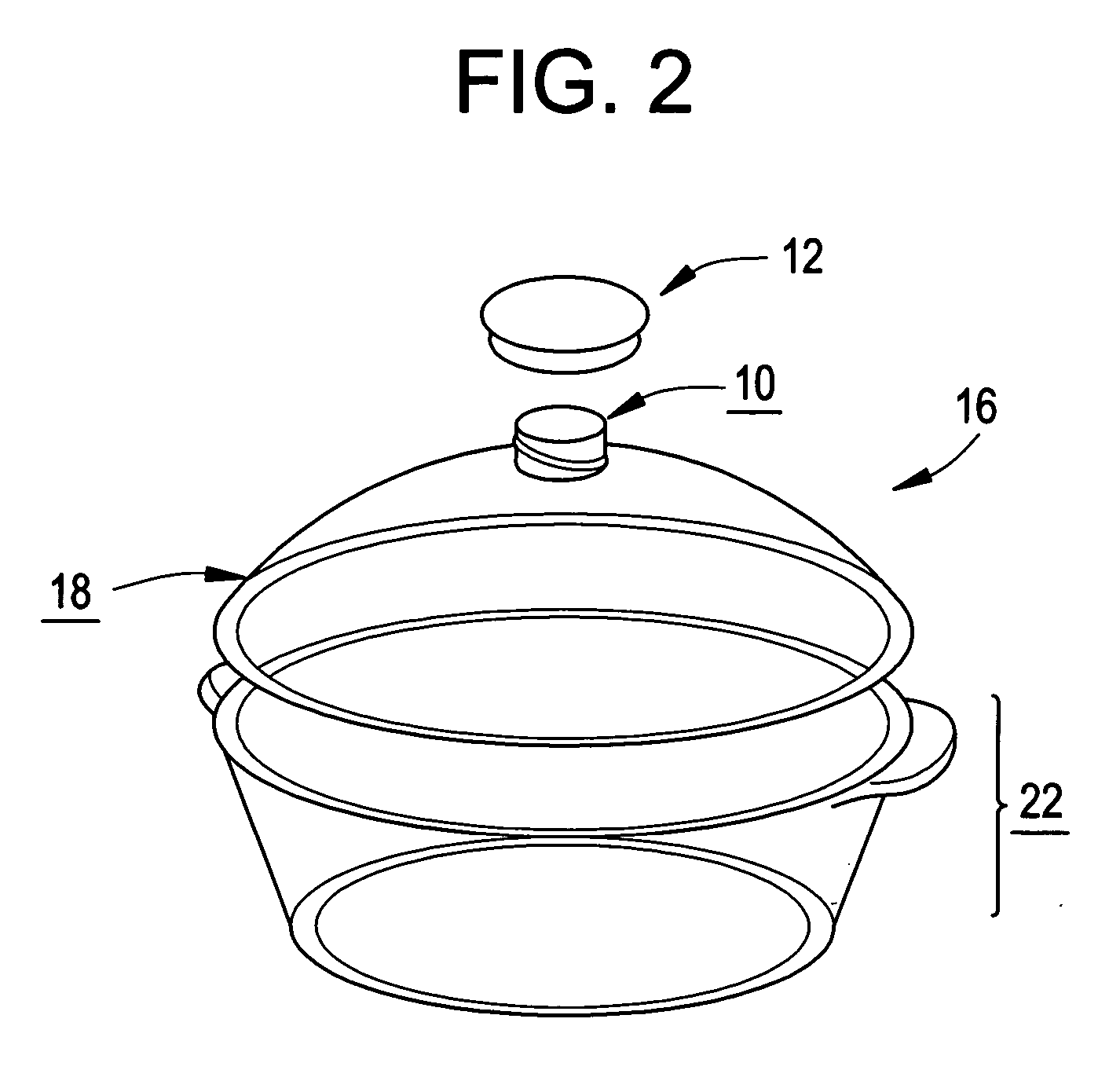

[0024] FIGS. 2 to 5 show a first preferred embodiment of a molded glass lid 16 according to the present invention. In this embodiment, the molded glass lid 16 has an exterior surface portion 18 and an externally threaded post 10 disposed on said surface portion 18, threaded post 10 being formed integrally with surface portion 18. It is also preferred that the externally threaded post 10 is disposed on a center position of the exterior surface portion 18.

[0025] The molded glass lid 16 preferably further comprises an internally threaded knob 12 having an internal diameter tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com