Non-isothermal glass mold pressing method

A non-isothermal, glass-based technology, applied in glass pressing, glass forming, glass reshaping, etc., can solve the problems of mold loss, silicon deformation, increased time cost and consumable cost, etc., to prolong service life and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will now be described in conjunction with the corresponding drawings. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. These embodiments are provided only so that the present invention will be thorough and complete so that those skilled in the art can fully describe the scope of the present invention. Wording used in the detailed description of the embodiments illustrated in the drawings should not limit the invention.

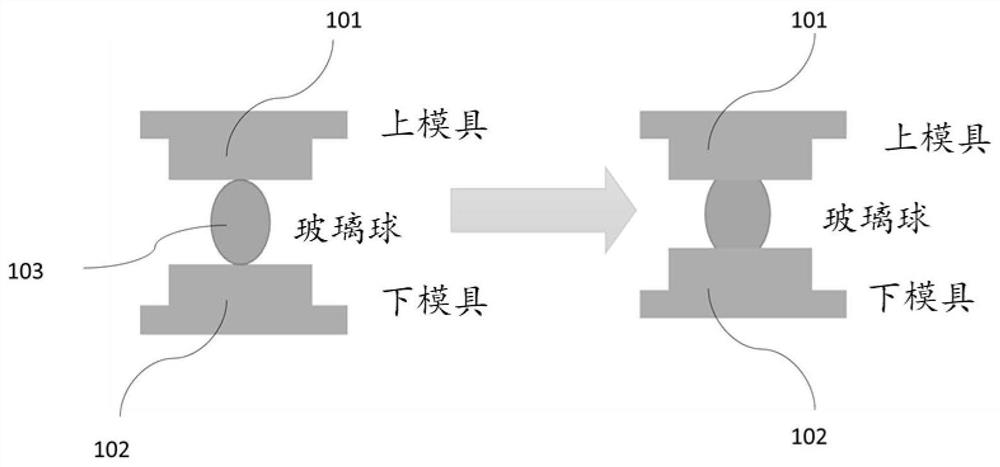

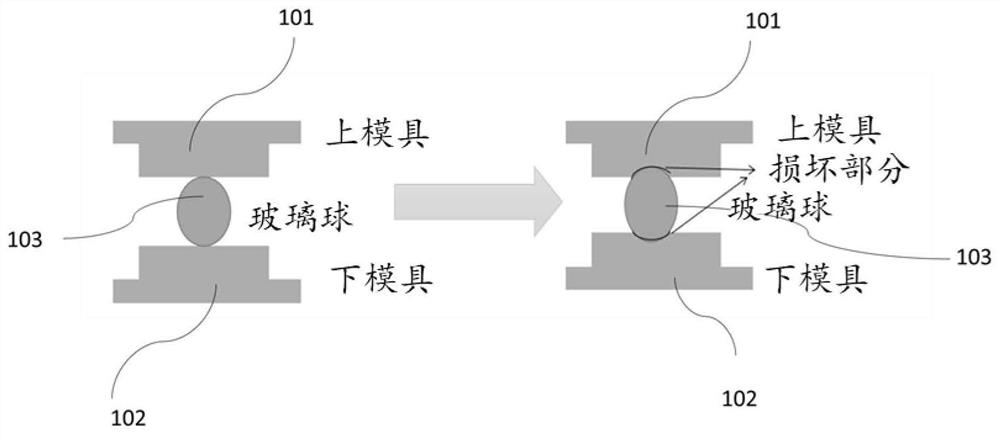

[0033] figure 1 It is a schematic diagram of the pressing steps in the compression molding method of the present invention. In the heating step, glass products to be pressed, such as glass balls 103, are placed on the lower mold 102. The type of glass that can be used is not particularly limited, and known glass can be selected according to the application. For example, optical glasses such as borosilicate glass, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com